Dye-sensitized solar battery with sealing structure and preparation method thereof

A technology for solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of shortening the service life of solar cells, affecting the efficiency of solar cells, corrosion of silver grids by electrolytes, etc., so as to reduce the probability of corrosion of silver grids and packaging materials, avoid The effect of blocking the screen and reducing non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

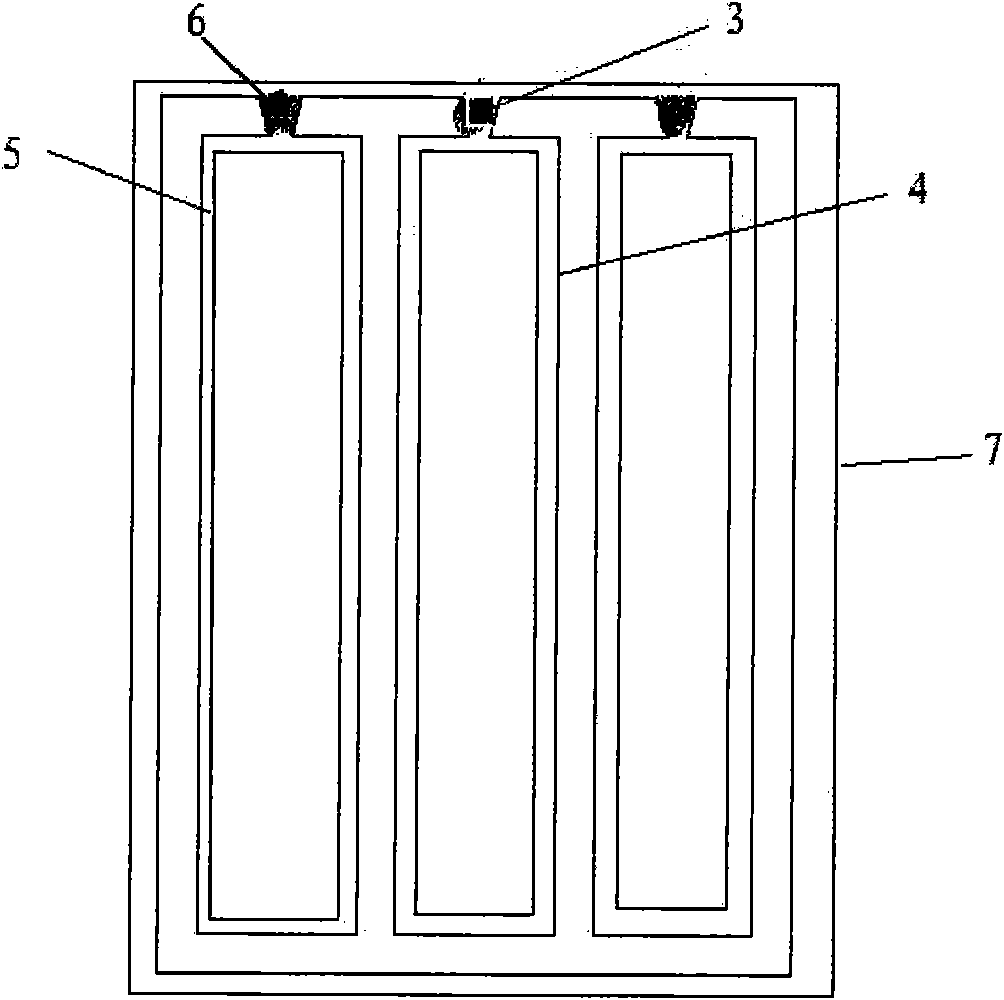

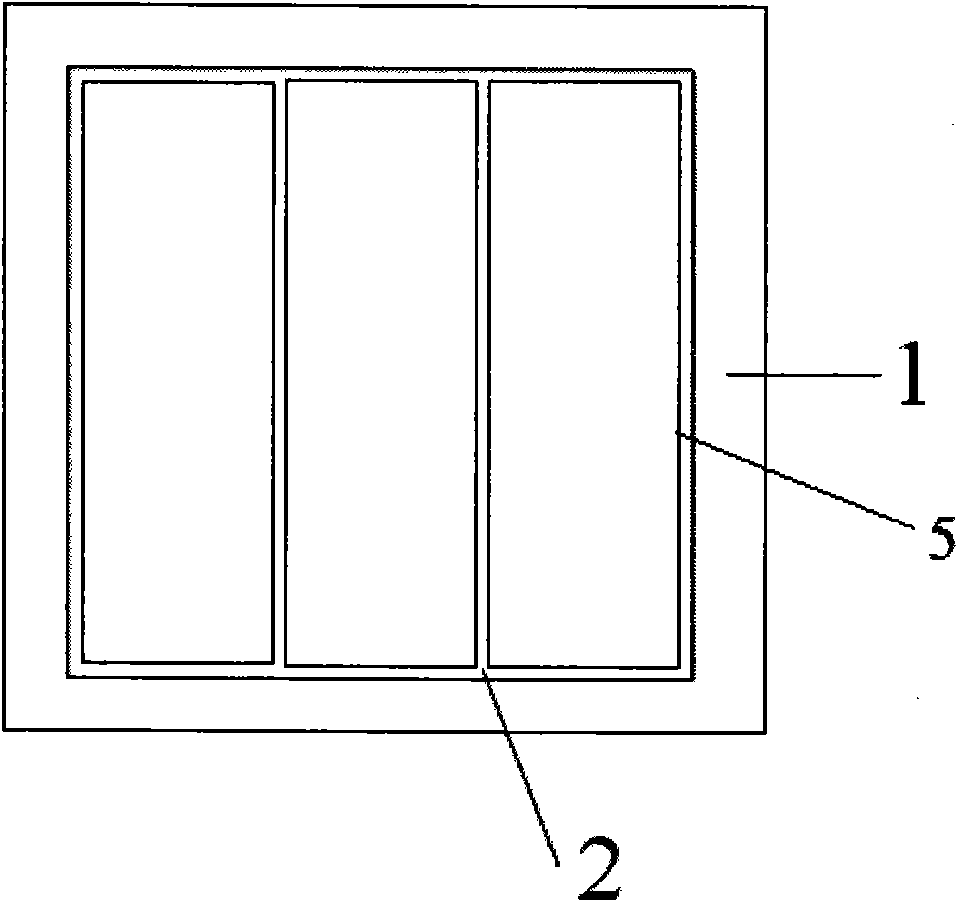

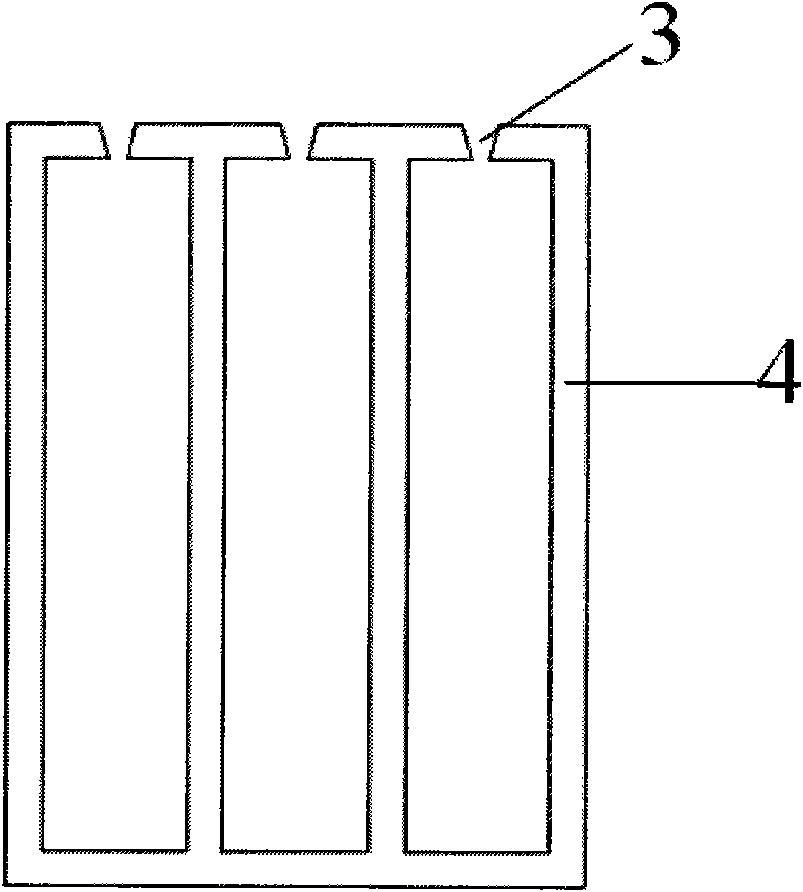

[0028] Attached below figure 1 , 2 and 3 further describe the present invention in detail.

[0029] Such as figure 1 as shown, figure 1 Exemplarily shows the dye-sensitized solar cell with sealing structure described in the present invention, it comprises, conductive glass 1 (not shown) and platinum electrode substrate 7, generally, the size of platinum electrode substrate 7 and conductive glass 1 and the same size, and can be sealed and bonded together; on the conductive glass 1, a plurality of silver grids 2 are printed (not shown, see figure 2 ), the inside of the silver grid 2 is printed with a photoanode 5 smaller than the size of the silver grid 2, and the silver grid 2 is covered with a film 4 with an injection hole 3, the film 4 covers the silver grid 2 and seals the silver grid 2. Generally, the silver grid 2 is mostly in the shape of a square or a round frame, and corresponds to the film 4, and can be combined and sealed together, and the electrolyte material fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com