One-time forming blasting method for extra-high voltage electric transmission line pile-well

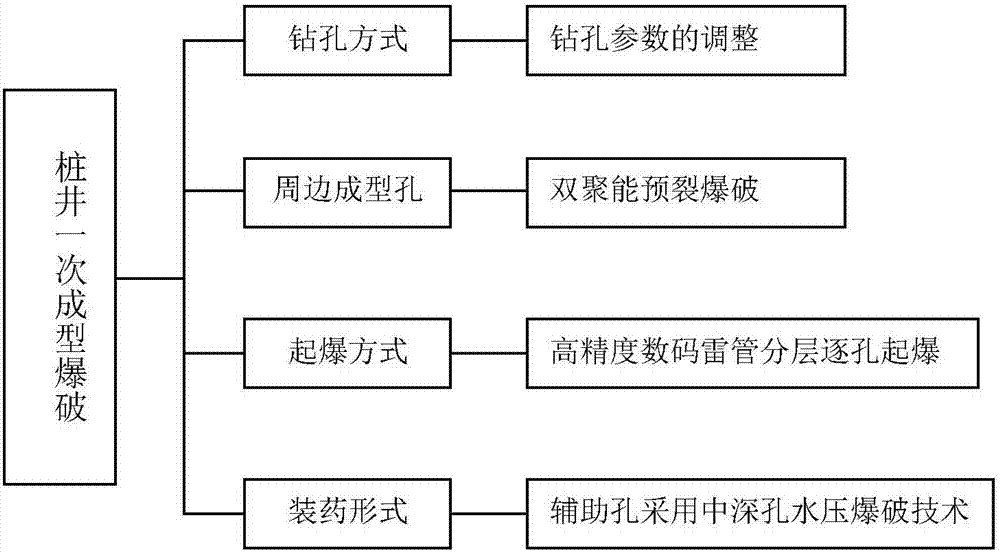

A transmission line and ultra-high voltage technology, which is applied in the field of one-time formation blasting of ultra-high voltage transmission line pile wells, can solve the problems of high explosive consumption, high construction risk, and large number of drilling holes, etc., so as to reduce the number of blasting times, reduce safety risks, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] UHV transmission line pile well with a diameter of 2.5m and a depth of 9m.

[0038] The blasting parameters are designed as follows:

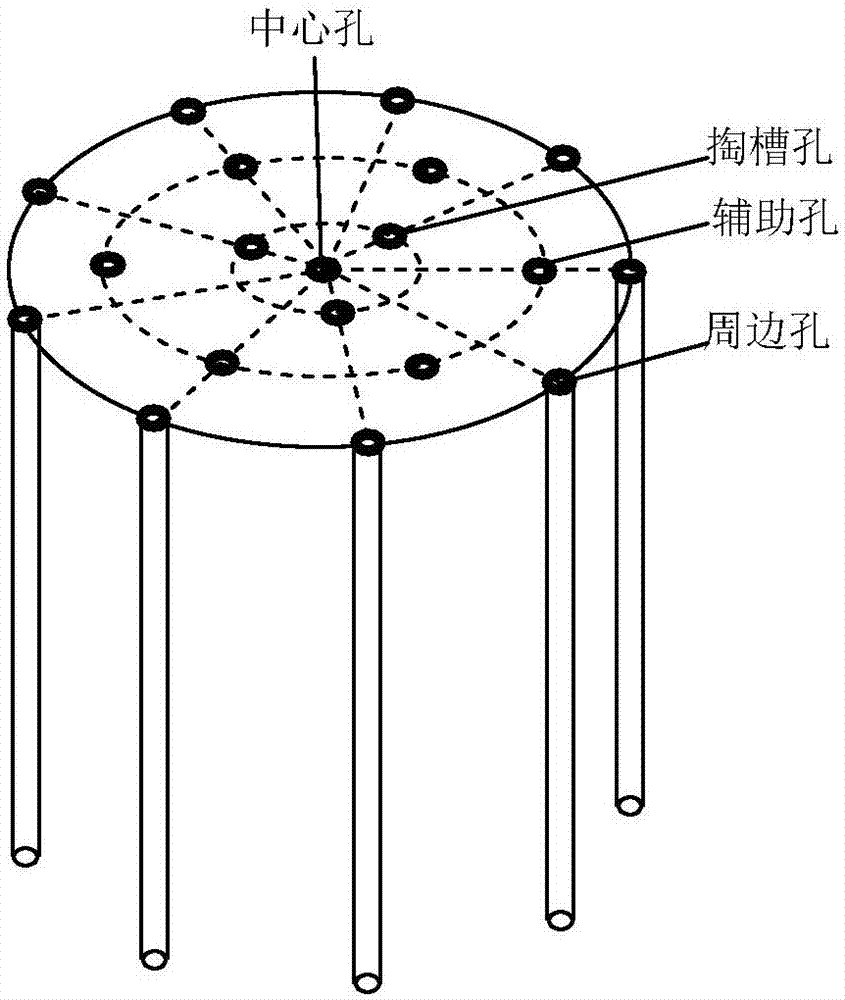

[0039] (1) The diameter of the blast hole. The blast hole diameters of the center hole, cut hole, auxiliary hole and peripheral holes are all taken as 90mm, and the center hole is used as the free surface and compensation space.

[0040] (2) Depth of blast hole. The center hole, cut hole, auxiliary hole and peripheral holes are 9.5m deep.

[0041] (3) Hole layout parameters. The distance between the peripheral holes is 0.87m, and a total of 9 holes are arranged; the distance between the auxiliary holes is 0.63, and a total of 6 holes are arranged; a total of 3 cutting holes are arranged, and one center hole is arranged. The blasthole layout is as figure 2 shown.

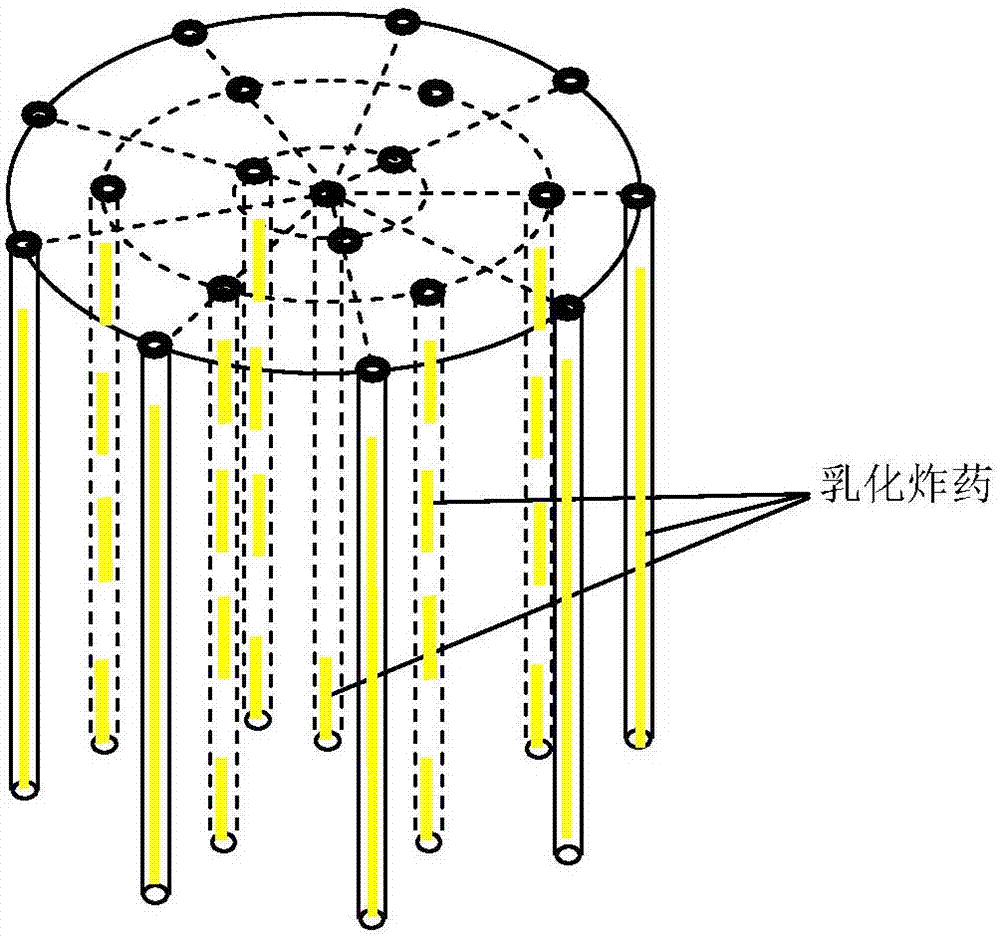

[0042] (4) Form of charge. The peripheral hole adopts the charge form of large-angle double-concentrated pre-splitting blasting, the cutting hole and the auxiliary hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com