Method for carrying out bench cut method construction in IV-grade surrounding rocks by using three-arm drill jumbo

A technology of rock drilling jumbo and step method, which is applied in the direction of blasting, etc., which can solve the problems of slow drilling speed, high energy consumption, and harsh working environment, etc., achieve fast drilling time, improve the working environment, and reduce drilling and blasting Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

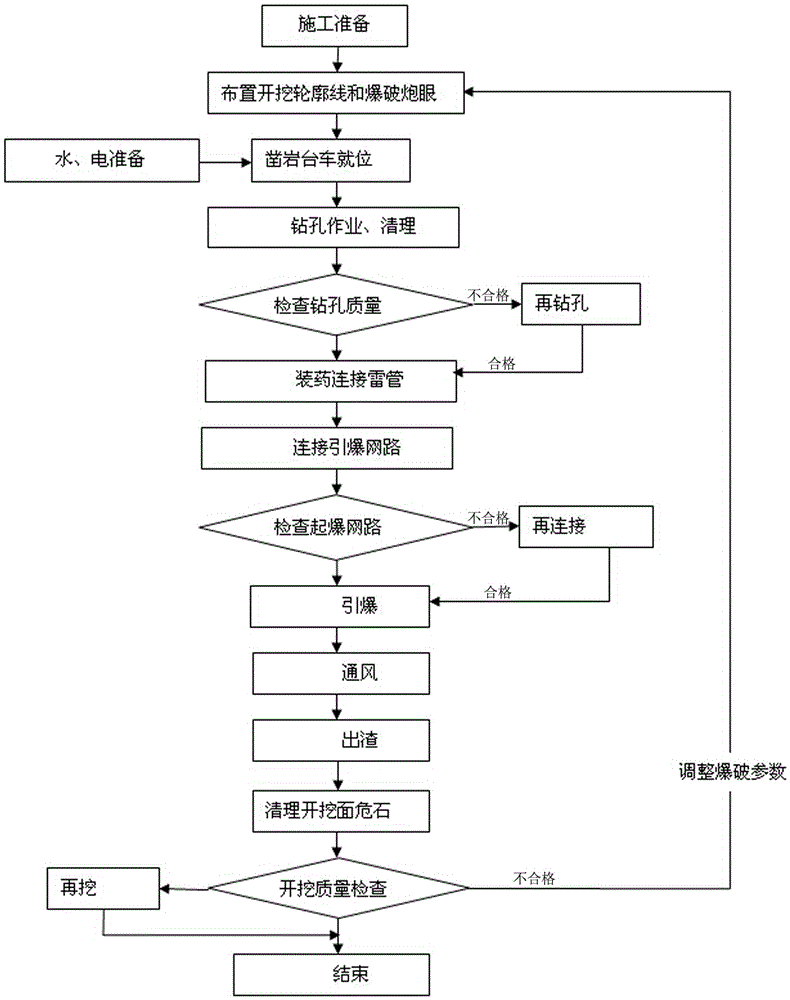

[0018] The method of using the three-arm rock drilling rig in the step method construction in the surrounding rock of grade IV in this embodiment, such as image 3 As shown, follow the steps below:

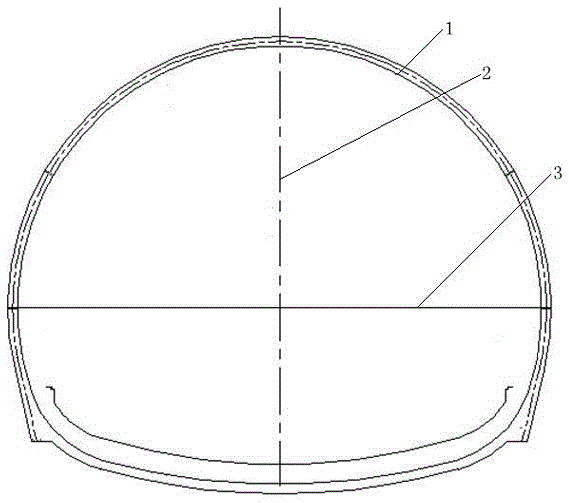

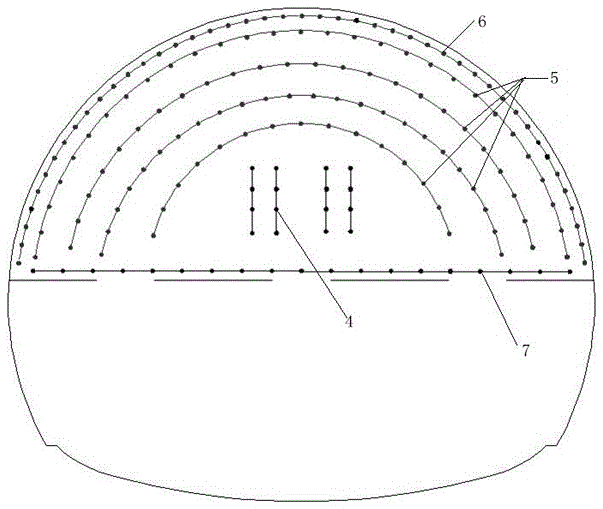

[0019] (1) Construction preparation: Use Komatsu PC220-8 excavator to carry out the risk elimination work, the duration is about 30min, the line is laid out according to the tunnel construction design drawing, the setting out error of the surrounding contour line should not be greater than ±2cm, such as figure 1 As shown, the line setting uses the total station to accurately release the tunnel excavation contour line and the tunnel center line, and use red paint to mark the over-excavation and under-excavation in the previous cycle, and follow the blasthole layout diagram. figure 2 The position of the blastholes of the upper step is marked as shown; the distance between the cut holes 4 of the upper step is 50-80cm, the depth is 2.3m, a total of 16 cut holes 4, the auxiliary holes 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com