Gravel bed foundation deep-cement-mixing pile impervious wall construction method

A technology of cement-soil mixing pile and construction method, which is applied in sheet pile wall, foundation structure engineering, soil protection and other directions, can solve the problem of difficult filling with cement slurry, affecting the quality of cement-soil mixing pile anti-seepage wall, difficult soil drilling In order to reduce the workload of subsequent drilling and grouting, ensure the compactness and integrity, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

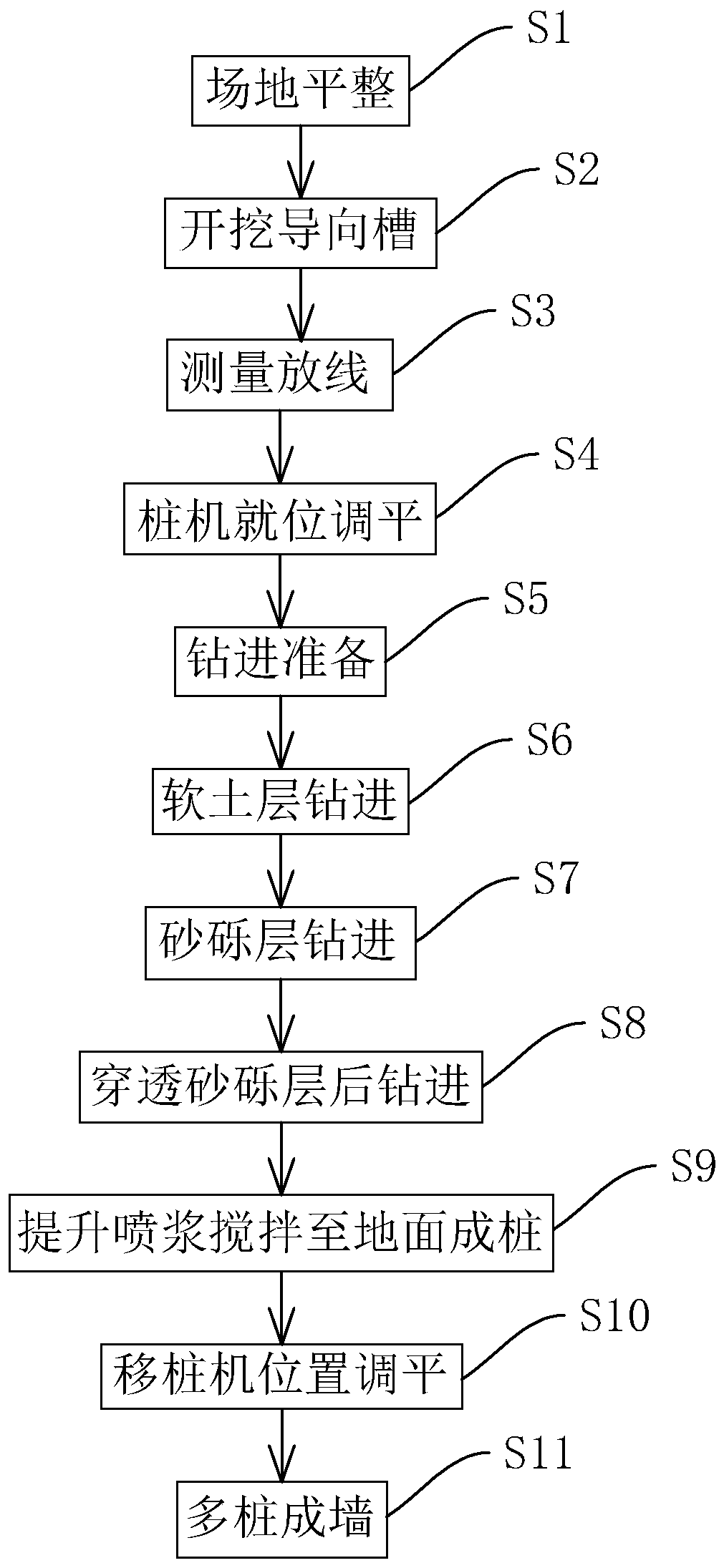

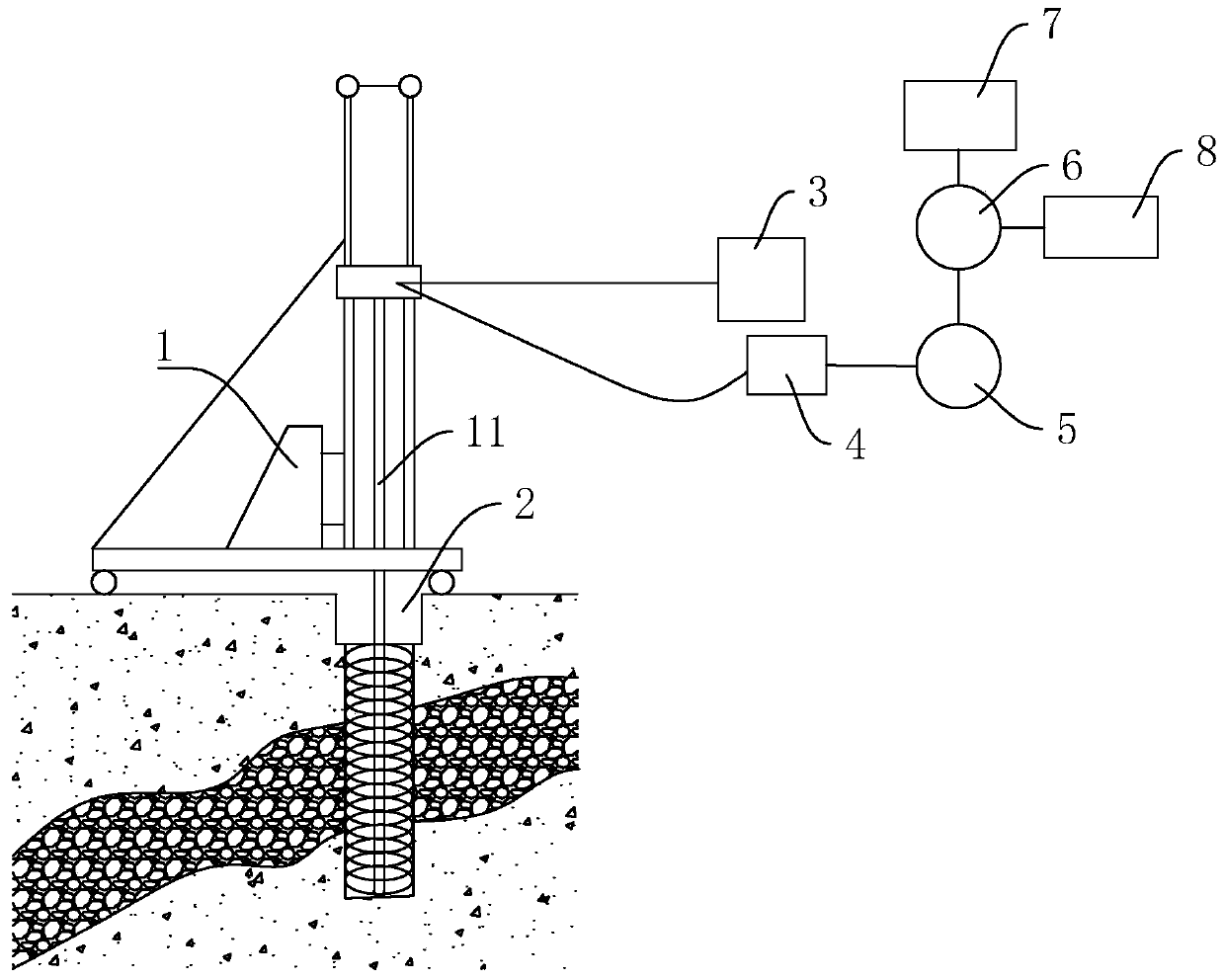

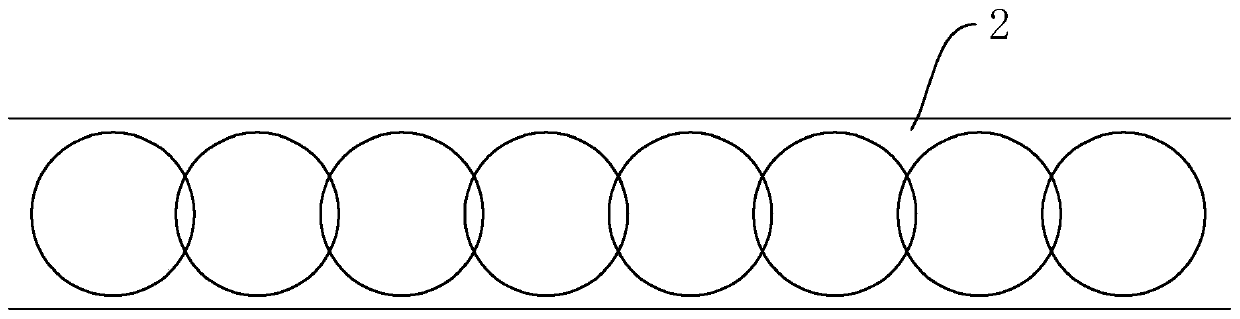

[0045] refer to figure 1 and figure 2 , is a method for constructing an anti-seepage wall of deep cement-soil mixing piles on a gravel layer foundation disclosed by the present invention, comprising the following steps: leveling the ground S1 → excavating guide grooves S2 → measuring and setting out lines S3 → leveling pile drivers in place S4 → drilling Advance preparation S5→drilling in soft soil layer S6→drilling in gravel layer S7→drilling through the gravel layer S8→lifting and mixing the sprayed grout until the piles are formed on the ground S9→leveling the position of the pile mover S10→multiple piles into the wall S11.

[0046] Site leveling S1: Clear the dregs on the foundation surface to ensure the levelness of the work site. Step S1 can ensure that there is no excessive garbage and sundries on the surface of the foundation, effectively ensuring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com