A wire take-up device for stone grinding

A wire take-up and stone technology, which is applied to machine tools suitable for grinding workpiece planes, parts of grinding machine tools, grinding machines, etc. It can solve the problem that the process of grinding stone cannot be continued continuously, the power supply is entangled, etc. problem, achieve the effect of reducing the number of times of turning back and running, avoiding signal transmission distortion, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

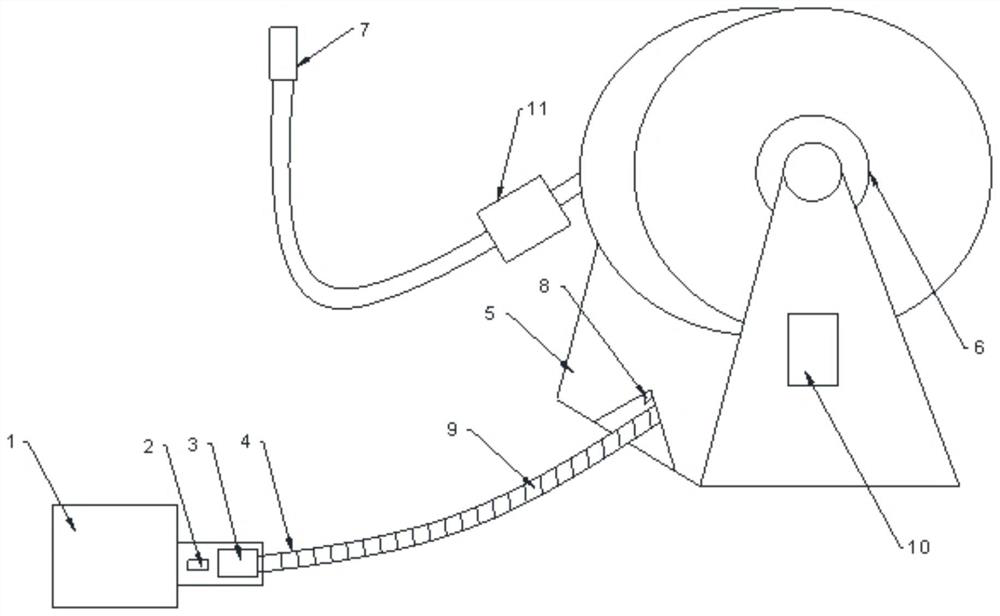

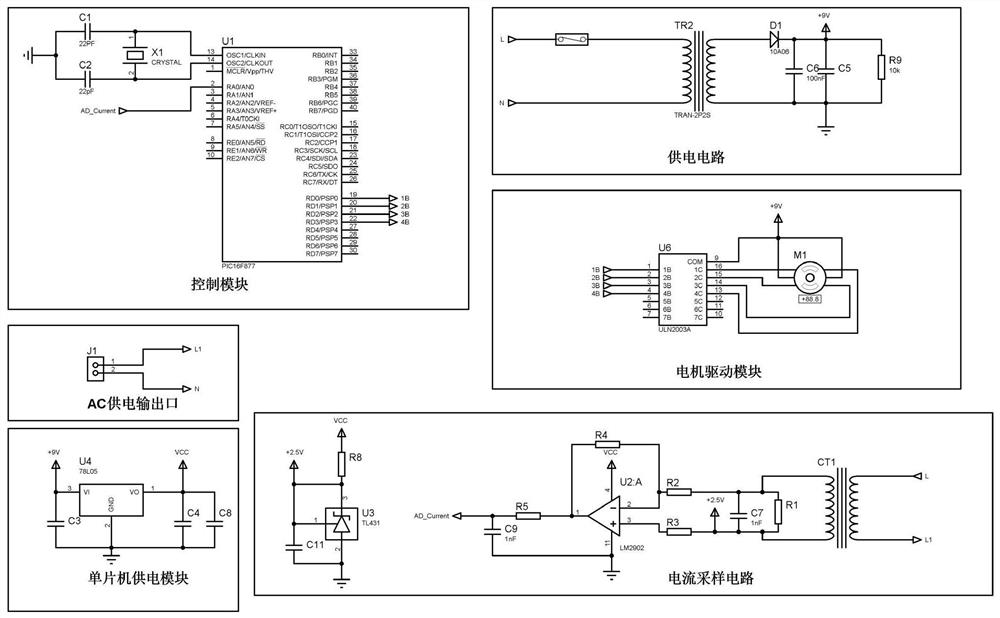

[0049] Such as Figure 1-8 As shown, a wire take-up for stone grinding includes a grinding head 1, a first plug head 3, an electric wire 4, a wire take-up body 5, a power plug 7, a sensor 8, a reflective tape 9 and a controller 10;

[0050] A storage battery 2 is installed inside the grinding head 1. The first plugging head 3 is inserted inside the grinding head 1. The first plugging head 3 is electrically connected to one end of the electric wire 4, and the power plug 7 is electrically connected to the other end of the electric wire 4 to reflect light. The belt 9 is connected to the outer end of the wire 4, the sensor 8 is installed at the wire outlet of the wire take-up body 5, and the controller 10 is installed on the wire take-up body 5;

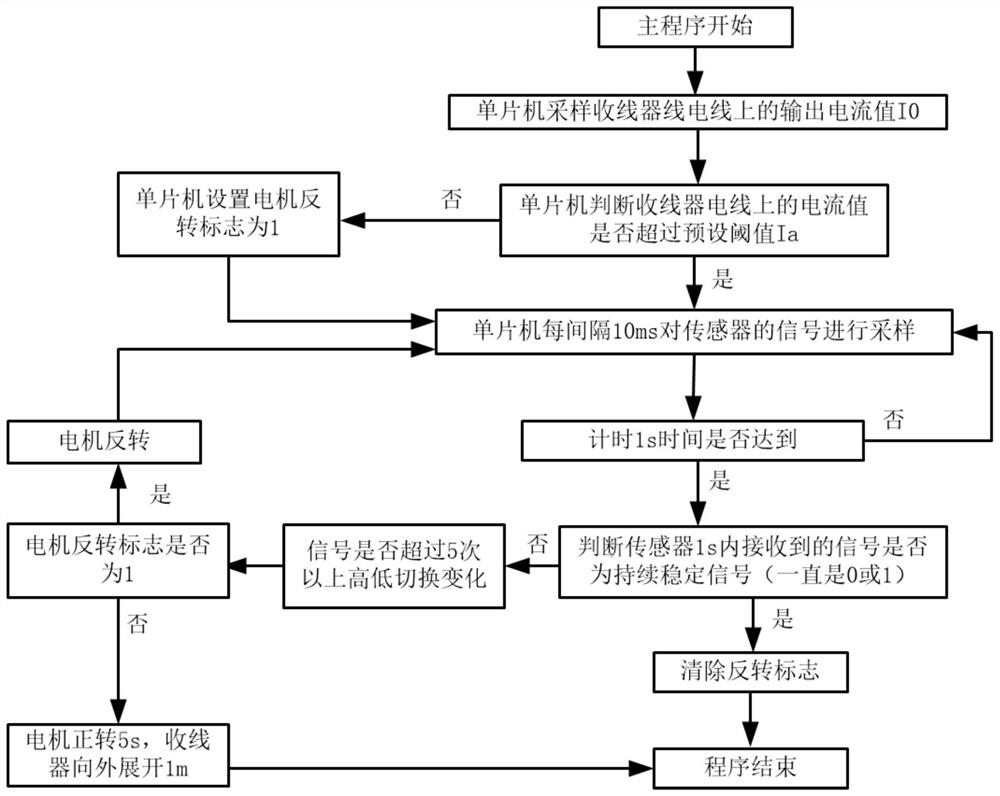

[0051] A motor 6 is installed on the take-up body 5, and there is an electrical connection between the motor 6 and the controller 10. The controller 10 can control the forward and reverse rotation of the motor 6, and the forward rotation...

Embodiment 2

[0075] Embodiment 2: Different from Embodiment 1:

[0076] Reflective tape 9 can be pasted on the outer end of the outer insulating layer of electric wire 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com