Double clutch structure reducer

A dual-clutch, reducer technology, applied in clutches, mechanically driven clutches, clutches that mesh with each other, etc., can solve problems such as complex structures, and achieve the effects of small size, stable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

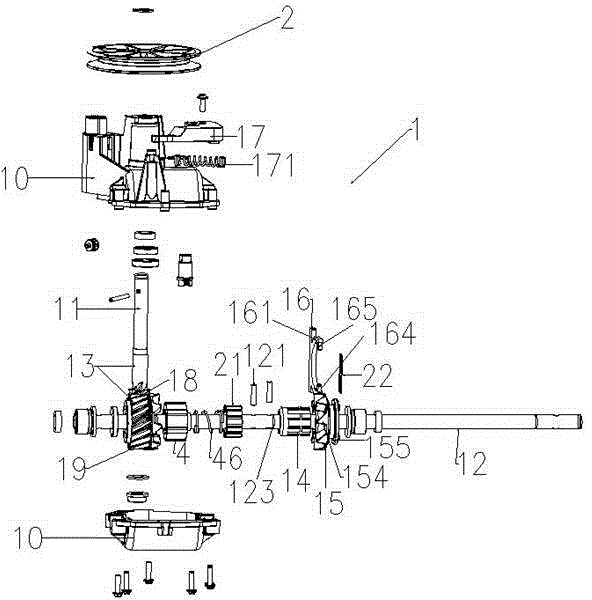

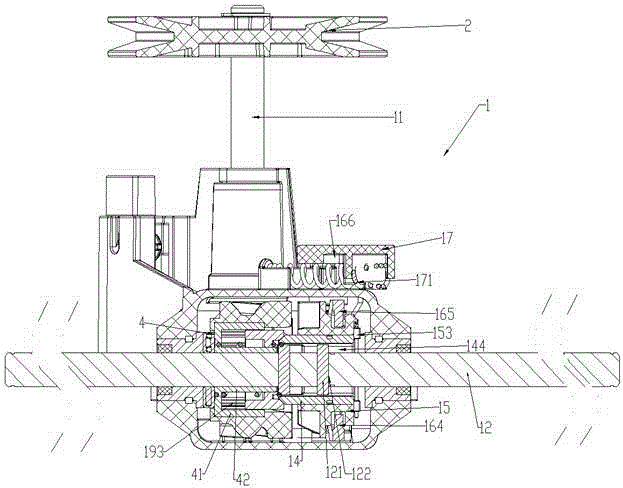

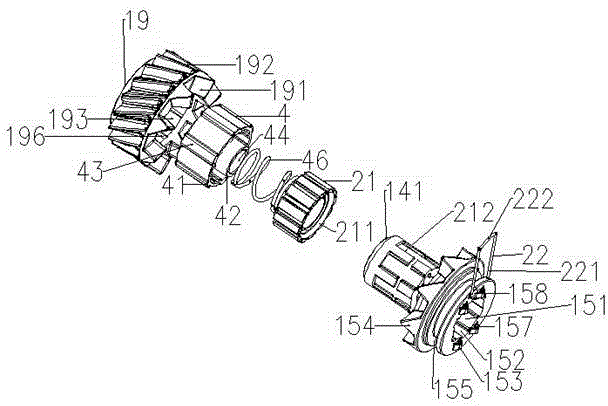

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] refer to figure 1 and figure 2 , the reducer 1 can work between the source power input shaft 11 and the power output shaft 12, which is usually used in self-propelled mechanical equipment. For example, in a self-propelled lawn mower, the power is transmitted to the pulley 2 installed on the input shaft through a transmission belt (not shown in the figure), and the power is output by the power output shaft 12 through the speed reducer. Conventionally, the drive wheels of the self-propelled machine are driven by the power take-off shaft 12 . In order to be suitable for walking, the rotational speed of the output shaft 12 is smaller than that of the input shaft in the application of self-propelled mechanical equipment, and its torque is greater than that of the input shaft 11 .

[0044] The reducer has a housing 10, and the housing is connected toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com