Stable clutch type grass comber

A clutch type, grass brushing technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as loud noise, easy damage to the connection structure of the clutch lever and handle lever, and the inability to accurately position the clutch lever. , to achieve the effect of preventing swing, avoiding damage to the connection structure, and simple and easy clutch structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

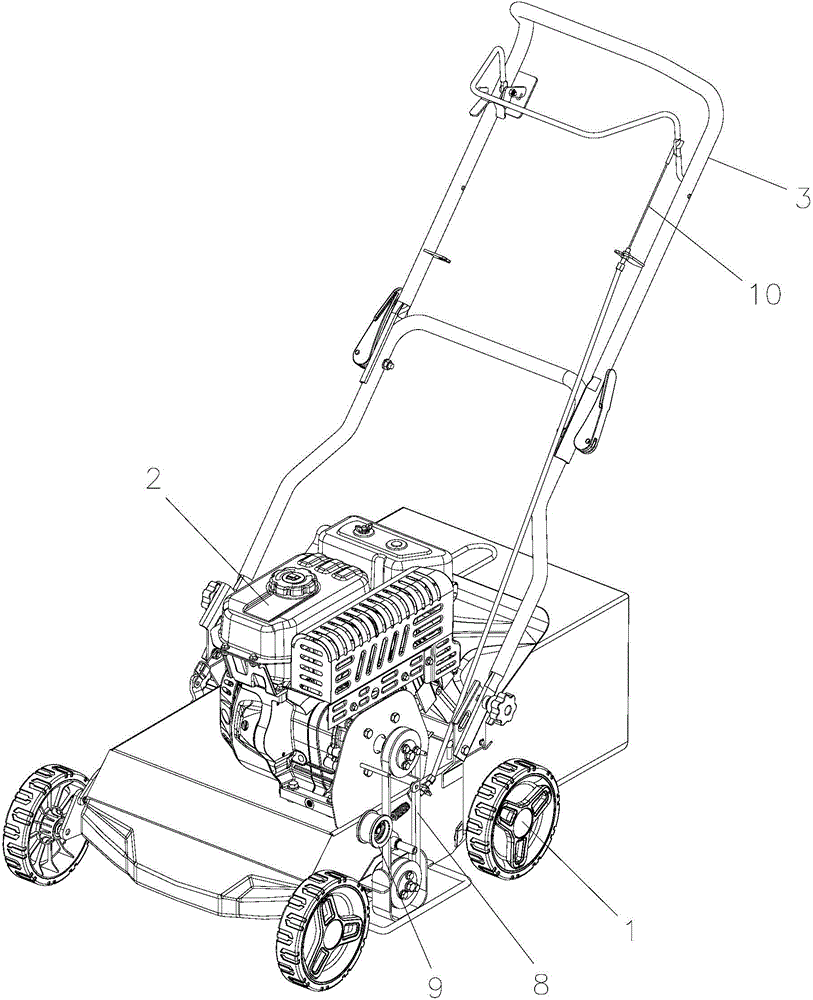

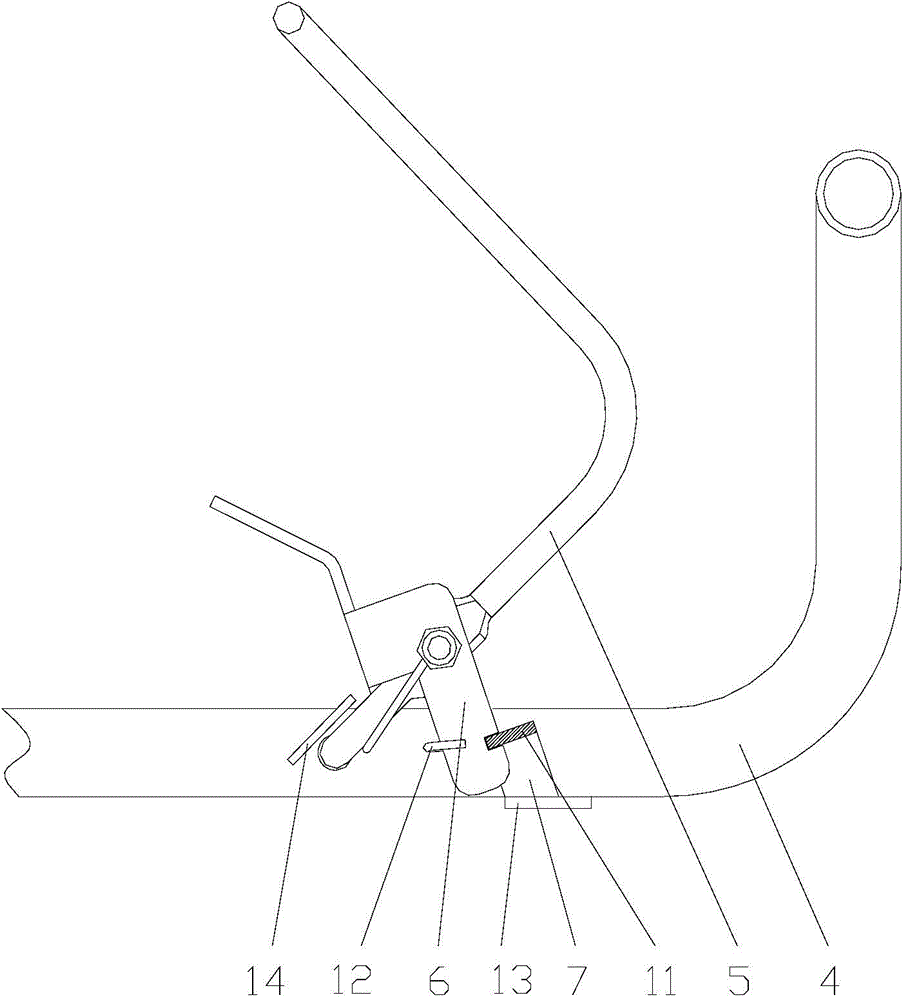

[0013] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the handle structure, as shown in the figure: the stable clutch type grass comber of the present embodiment includes a running mechanism 1, a driving engine 2 and a control handle 3; the bottom of the running mechanism 1 is equipped with a movable blade assembly; The driving engine 2 and the control handle 3 are all fixedly installed on the running mechanism 1; the control handle 3 includes a handle bar 4, a clutch control lever 5 and a safety handle 6; the clutch control lever 5 is hinged to the handle lever 4 for driving the clutch pull The cable 10 moves; the safety handle 6 is hinged to the clutch lever 5 in such a way that it can be closed with the clutch lever 5 and cross the clutch lever 5 at a certain angle and can rotate freely within the angle range. The handle lever 4 The positioning block 7 for positioning the safety handle 6 along the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com