Electric cable stripper

A technology of wire strippers and cables, applied in the direction of line/collector components, circuits, electrical components, etc., can solve the problems of crank linkage mechanism exposure, increase device weight, increase battery capacity and volume, etc., to ensure continuous performance and reliability, reduced space requirements, reduced volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

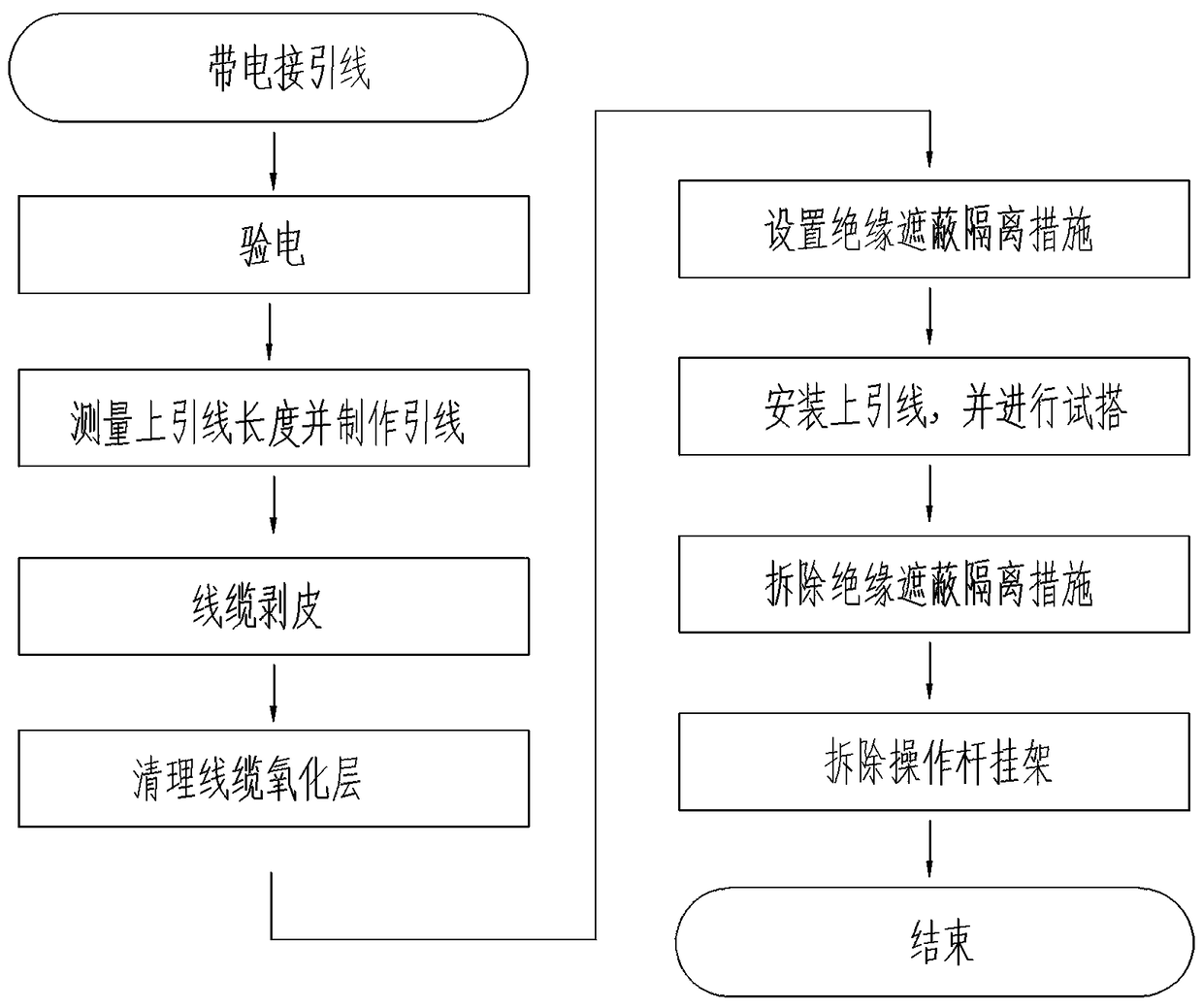

[0027] Such as figure 1 As shown, this preferred embodiment performs the live connection of the power insulated cable through the following steps:

[0028] 1. Enter the live working area and check the electricity. The No. 1 and No. 2 electricians have been approved by the person in charge of the work and wear insulating protective equipment. The No. 1 electrician shall carry the insulation transfer rope, climb the pole to a suitable working position, and hang the insulation transfer rope. No. 2 electrician installs the operating pole hanger; the electrician on the pole uses an electroscope to conduct electrical inspection on the live body and cross arm to confirm that there is no leakage; the requirements during the electrical inspection process: 1) Insulating tools and materials should be transferred up and down. Rope; 2) Correct use of insulated ropes (when transferring tools and instruments, the back of the operator should not be carried, and the insulated tail rope should not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com