An integrated single trailing arm gear reduction wheel side electric drive system

A gear reduction, single trailing arm technology, applied in the direction of electric power unit, power unit, control device, etc., can solve the problem of unfavorable car ride and wheel grounding, large unsprung mass, and complicated wheel side mechanism structure of electric wheel. and other problems, to achieve the effect of reducing unsprung mass, improving wheel grounding, and simple wheel side deceleration mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

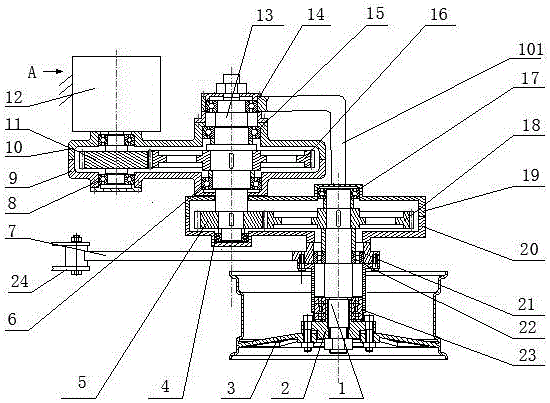

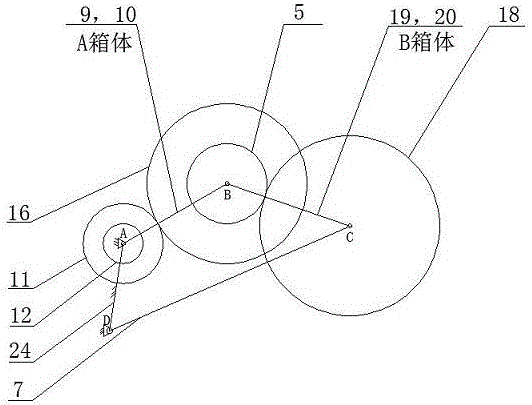

[0018] The present invention mainly includes wheel rim 3, semi-shaft casing 22, wheel hub bearing 23, wheel hub 2, drive shaft 1, rotating shaft 13, driving wheel 11, planetary wheel 16, planetary wheel 5, planetary wheel 18, single longitudinal arm 7, A box Body (9,10), B casing (19,20), motor 12, bearing 8, bearing 14, bearing 15, bearing 6, bearing 4, bearing 17, bearing 21, vehicle frame 24, L-shaped arm 101.

[0019] Attached below figure 1 , figure 2 , image 3 The present invention is further described.

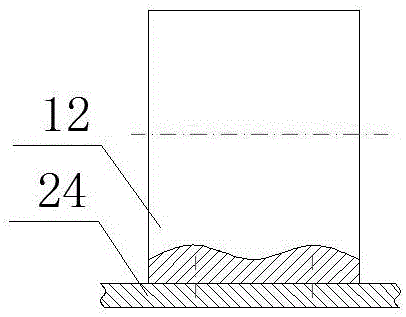

[0020] figure 1 It is a structural schematic diagram of an integrated single trailing arm gear reduction type wheel-side electric drive system. figure 2 for figure 1 Partial side view at A. The motor 12 is bolted to the frame 24 and becomes part of the sprung mass. The driving wheel 11 is installed and supported in the A box body (9, 10) through the bearing 8. A box can rotate around the axis of the motor through the outer ring of the bearing 8 to form a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com