Coaxial multi-gear front-drive hybrid power system

A hybrid power system, coaxial technology, applied in the field of coaxial multi-speed front-drive hybrid power system, can solve the problems of separate motor shaft setting, large space occupation, large idle space, etc., and achieves the difficulty of manufacturing cost and processing technology Low, convenient for vehicle layout, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

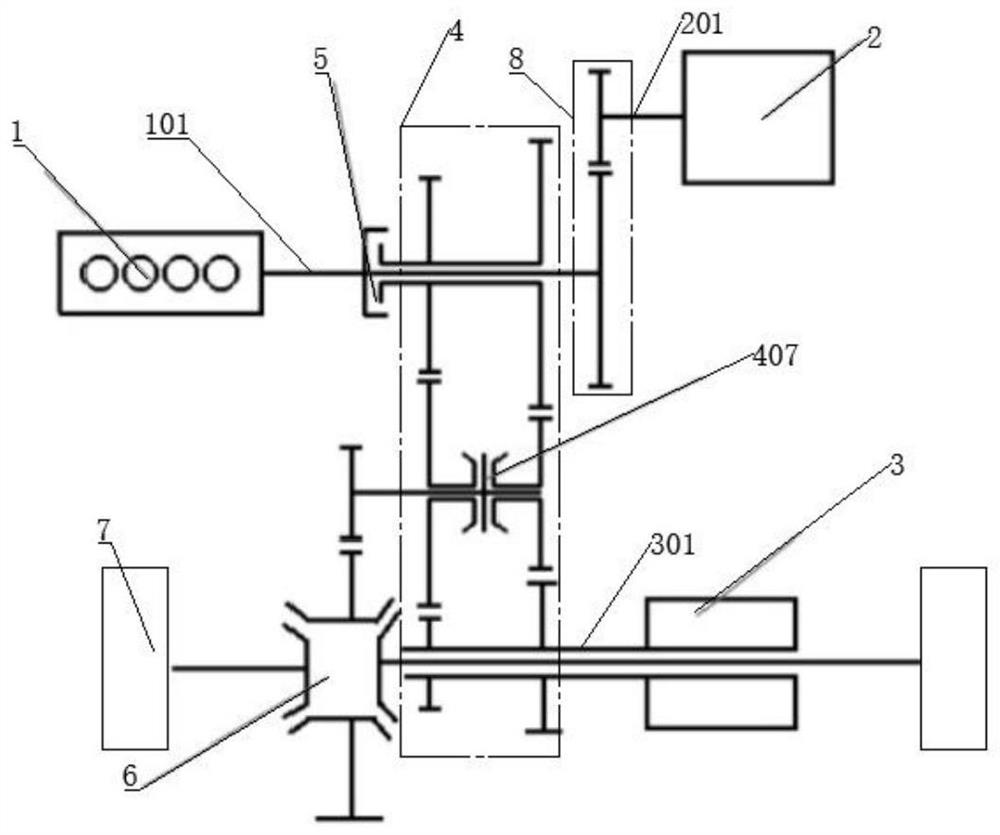

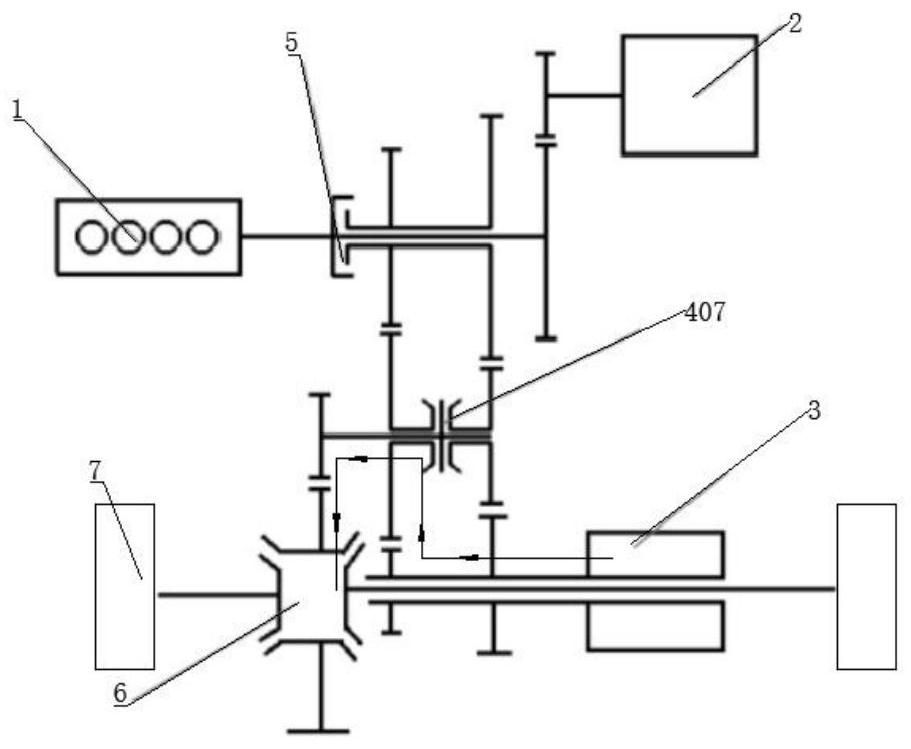

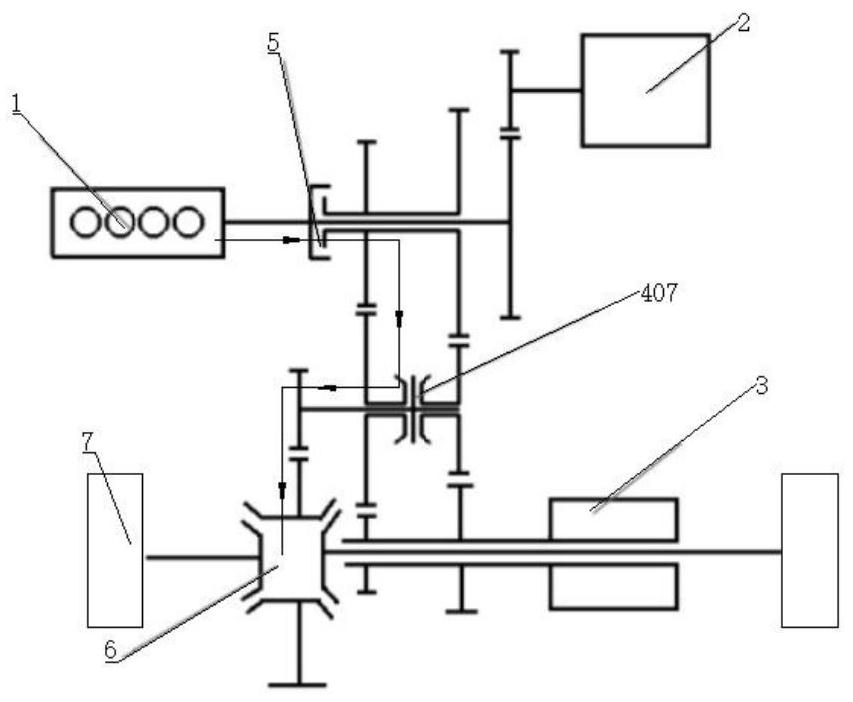

[0033] like figure 1 As shown, a coaxial multi-gear front-drive hybrid power system includes an engine 1, a generator 2, a drive motor 3, a gear transmission mechanism 4, a clutch 5 and a differential 6, and the clutch 5 is arranged on the output shaft of the engine 101 and the gear transmission mechanism 4, the output shaft of the gear transmission mechanism 4 is connected to the differential 6, the generator 2 is electrically connected to the drive motor 3, and the motor output shaft 301 of the drive motor 3 Constructed as a hollow shaft structure, the output shaft of the differential 6 passes through the motor output shaft 301 and is connected to the wheel 7; the motor output shaft 301 is power connected to the gear transmission mechanism 4; it also includes a speed-increasing gear pair 8, the The engine output shaft 101 is connected to the generator input shaft 201 through the speed increasing gear pair 8 .

[0034] This embodiment includes four working modes:

[0035] l...

Embodiment 2

[0040] like figure 1 As shown, a coaxial multi-gear front-drive hybrid power system includes an engine 1, a generator 2, a drive motor 3, a gear transmission mechanism 4, a clutch 5 and a differential 6, and the clutch 5 is arranged on the output shaft of the engine Between 101 and the gear transmission mechanism 4, the layout position of the clutch 5 and the synchronizer 407 are staggered to ensure that the system assembly has a smaller size in the finishing space, which is convenient for the layout of the whole vehicle.

[0041] The output shaft of the gear transmission mechanism 4 is connected to the differential 6;

[0042] The motor output shaft 301 of the drive motor 3 is configured as a hollow shaft structure, and the output shaft of the differential 6 is connected to the wheel 7 after passing through the motor output shaft 301; , the shafting of the driving motor 3 is arranged coaxially with the differential 6, that is, coaxially with the wheel 7, and has a compact st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com