Method for efficiently removing phosphorus, arsenic and silicon impurities, extracting tungsten and recovering alkali from crude sodium tungstate solution

A technology of sodium tungstate and sodium polytungstate, which is applied in chemical instruments and methods, tungsten compounds, alkali metal compounds, etc., can solve the problems that tungsten cannot be extracted and purified at the same time, and achieve complete recovery and reuse, thorough recovery, The effect of efficient impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

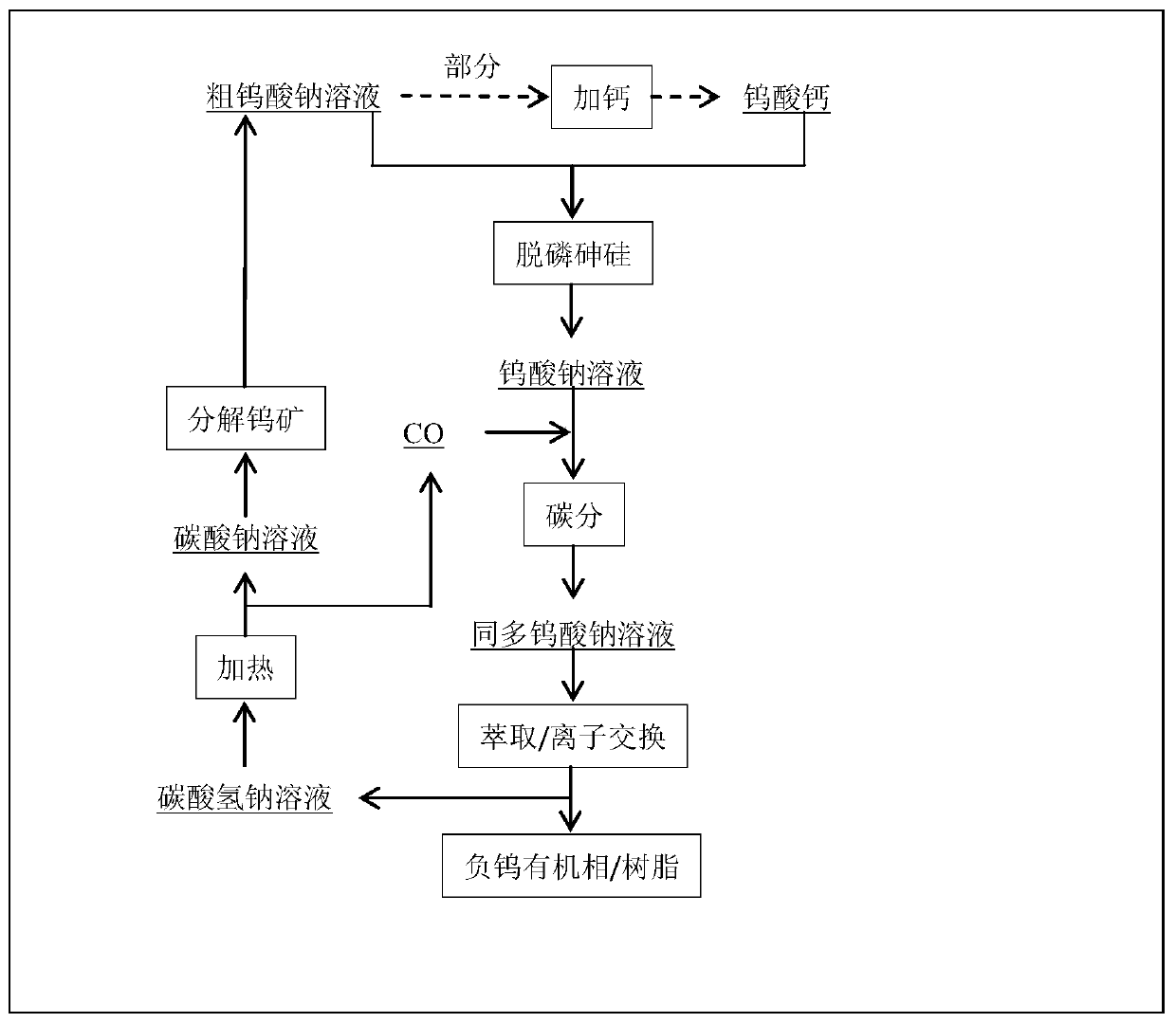

[0024] (1) Divide the crude sodium tungstate solution obtained after decomposing tungsten ore into two parts, and add calcium to one part to form calcium tungstate, wherein the amount of calcium added is the phosphorus, arsenic, silicon 1.2 times the total molar weight, and then mixed with another crude sodium tungstate solution for reaction, the reaction temperature is controlled at 85°C, and the reaction time is 3 hours, so that the phosphorous ions, arsenic ions, and silicon ions in the crude sodium tungstate solution Calcium salt precipitates are formed, and then filtered to obtain sodium tungstate solution;

[0025] (2) Pass carbon dioxide gas into the sodium tungstate solution obtained in step (1) to react, control the carbon dioxide pressure to be 5MPa, the reaction temperature is 50°C, the reaction time is 2 hours, and the pH of the solution is reduced to 4.5, so that the solution Tungsten exists in the form of polymerized ions, that is, isopolytungstate sodium solutio...

Embodiment 2

[0030] (1) Add artificial calcium tungstate to the crude sodium tungstate solution, the amount of artificial calcium tungstate added is 1.2 times the total molar amount of phosphorus, arsenic and silicon in the crude sodium tungstate solution, control the reaction temperature to 140°C, and the reaction time For 1 hour, phosphorus ions, arsenic ions, and silicon ions in the crude sodium tungstate solution all form calcium salt precipitates, and then filter to obtain sodium tungstate solution and calcium salt precipitates;

[0031] (2) Pass carbon dioxide gas into the sodium tungstate solution obtained in step (1) to react, control the carbon dioxide pressure to be 10MPa, the reaction temperature is 70°C, the reaction time is 0.5 hours, and the pH of the solution is reduced to 3, so that the solution Tungsten exists in the form of polymerized ions, that is, isopolytungstate sodium solution is obtained;

[0032] (3) The polytungstate sodium solution obtained in step (2) is then a...

Embodiment 3

[0036] (1) Add artificial calcium tungstate to the crude sodium tungstate solution, the amount of artificial calcium tungstate added is 1.5 times the total molar amount of phosphorus, arsenic and silicon in the crude sodium tungstate solution, control the reaction temperature to 30°C, and the reaction time For 6 hours, phosphorus ions, arsenic ions, and silicon ions in the crude sodium tungstate solution all form calcium salt precipitates, and then filter to obtain sodium tungstate solution and calcium salt precipitates;

[0037] (2) Control the pressure of carbon dioxide to be 0.2MPa, under the condition that the reaction temperature is 25°C, pass carbon dioxide gas into the sodium tungstate solution obtained in step (1) until the pH of the solution is 6, and the reaction time is 4 hours. In the carbon dioxide process, the sodium tungstate solution undergoes a decomposition reaction, so that the tungsten in the solution exists in the form of polymerized ions, that is, the isop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com