Method for extracting refined ursolic acid from loquat leaves

An extraction method and loquat leaf technology are applied in the field of natural plant extract preparation, can solve problems such as unfavorable industrial application, increase production equipment, increase production cost, etc., and achieve the effects of being beneficial to industrial application, reducing production process and facilitating filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the method for extracting ursolic acid from loquat leaf described in the present invention, comprises the following steps:

[0014] (1) Take 2Kg of fresh or sun-dried loquat leaves, crush them, and pass through a 10-12 mesh sieve; then mix the crushed loquat leaves with ethanol and Span-85 for ultrasonic extraction, and Span-85 The addition amount is 0.1% of the total weight of the pulverized loquat leaves and ethanol. When extracting, use 8-10 times of 95% ethanol solution to extract twice, and the extraction temperature is 70-80°C; after filtering off the medicinal residue, combine the filtrate, pass through a microporous filter membrane with a pore size of 0.7 μm, and use a filter with a molecular weight cut-off of 4000Da for the filtrate. Ultrafiltration membrane is used for ultrafiltration to obtain ultrafiltrate;

[0015] (2) Concentrate the ultrafiltrate until the relative density of the solution is 1.1-1.2g / ml, carry out vacuum drying, control the...

Embodiment 2~7

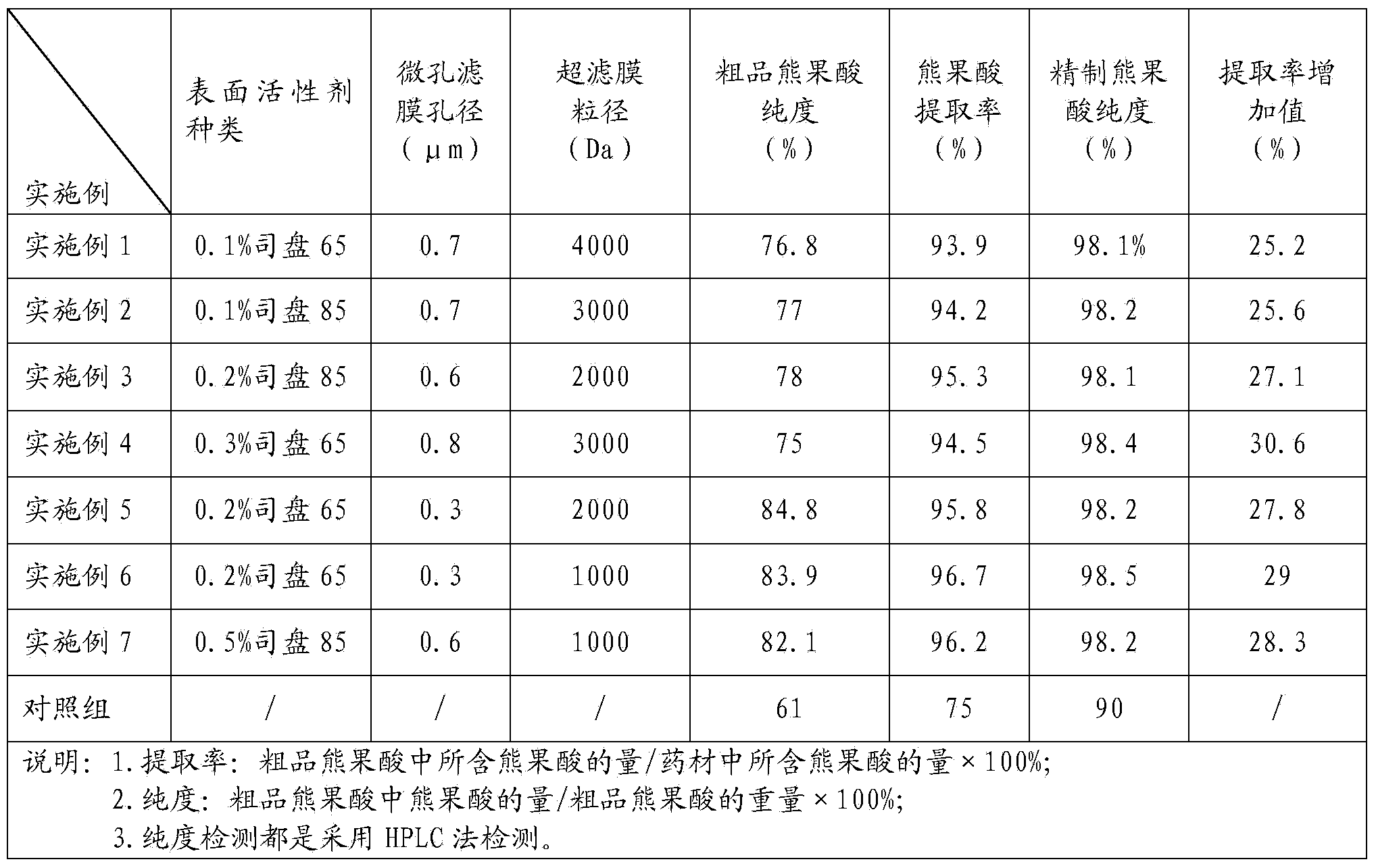

[0017] Examples 2-7: The difference from Example 1 is that the amount of Span-85 or Span-65 is different, the settings of the microporous membrane pore size and ultrafiltration membrane particle size are different, and the product purity and extraction rate are different. See the table below for details. The rest are the same and will not be repeated here.

[0018] Content detection result table of each embodiment

[0019]

[0020] The production method of the control group:

[0021] (1) Take 2Kg of fresh or sun-dried loquat leaves, crush them, and pass through a 10-12 mesh sieve; then carry out reflux extraction of the crushed loquat leaves, and extract twice with 8-10 times 95% ethanol solution during extraction , the extraction temperature is 70-80°C; after the medicinal residues are filtered out, the filtrate is combined, and the filtrate is vacuum-concentrated to a solid-liquid ratio of 1︰0.7-1.2, the vacuum degree is controlled to be ≥0.07Mpa, the temperature is 50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com