Device and method for zero emission preparation of aqueous oxidizer salt solution

A technology of salt water solution and oxidant, which is applied to explosives processing equipment, offensive equipment, explosives, etc., and can solve problems such as no compulsory control, environmental pollution, and waste water generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

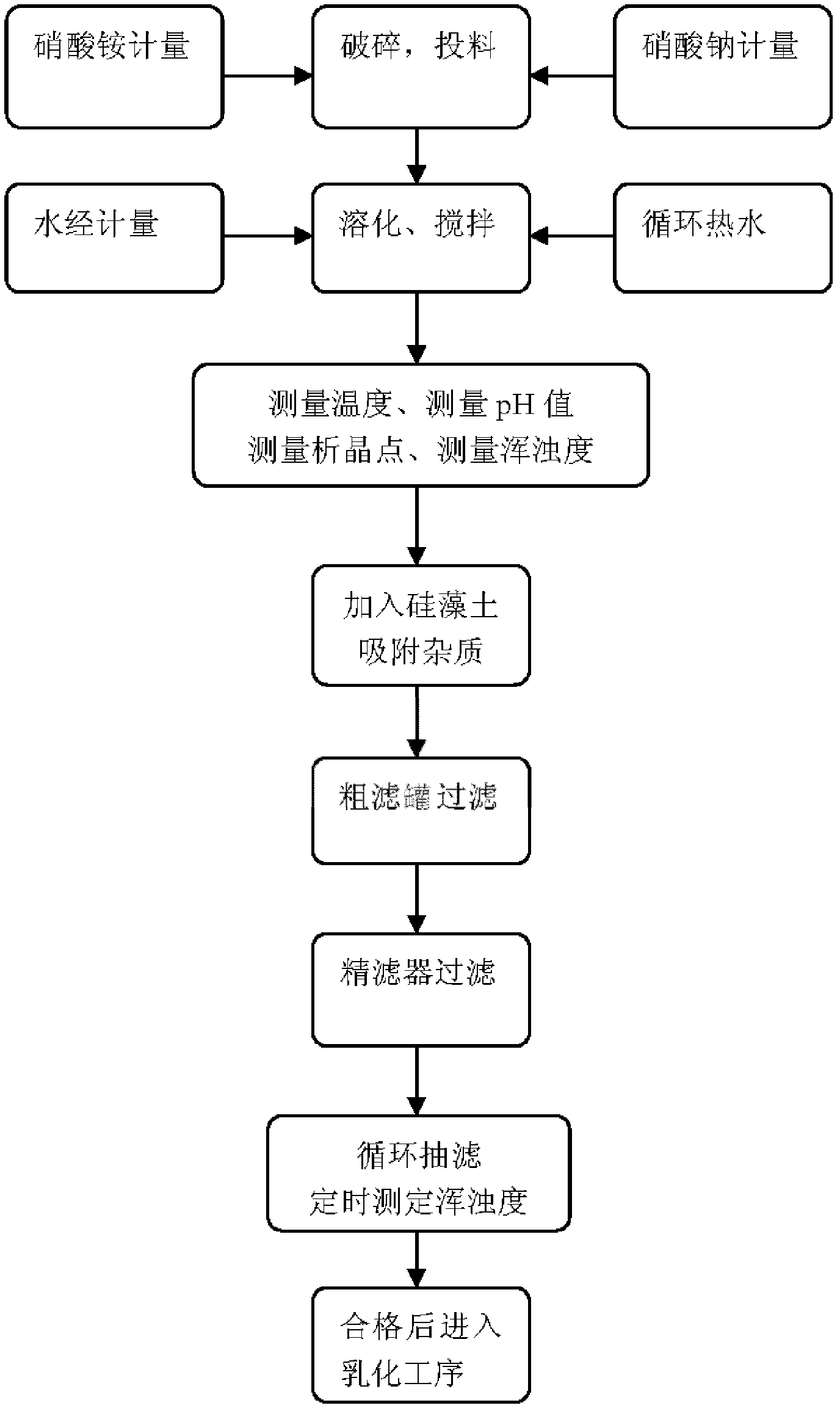

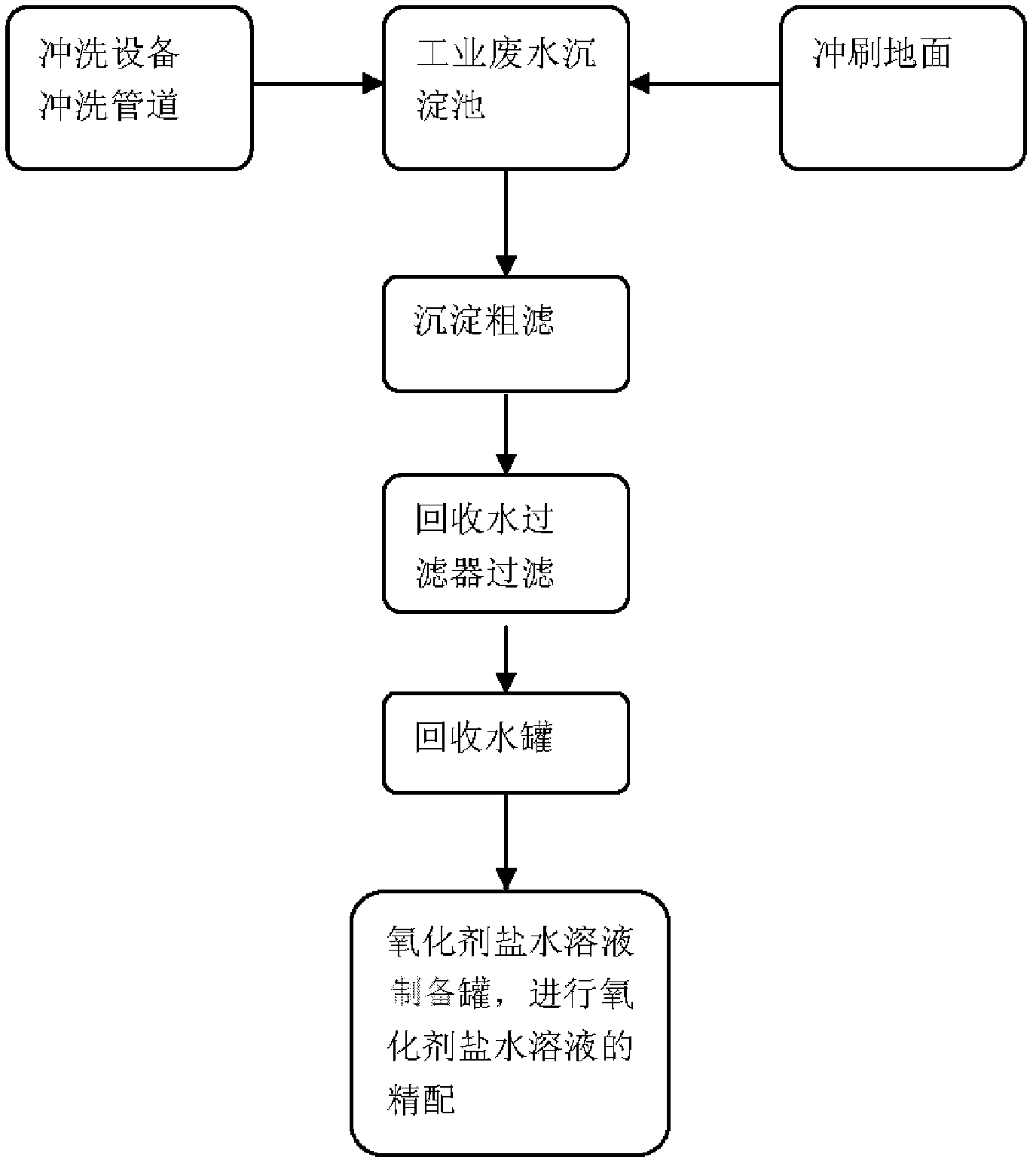

[0046] Various aspects of the present invention will be further described below in conjunction with the accompanying drawings by way of example.

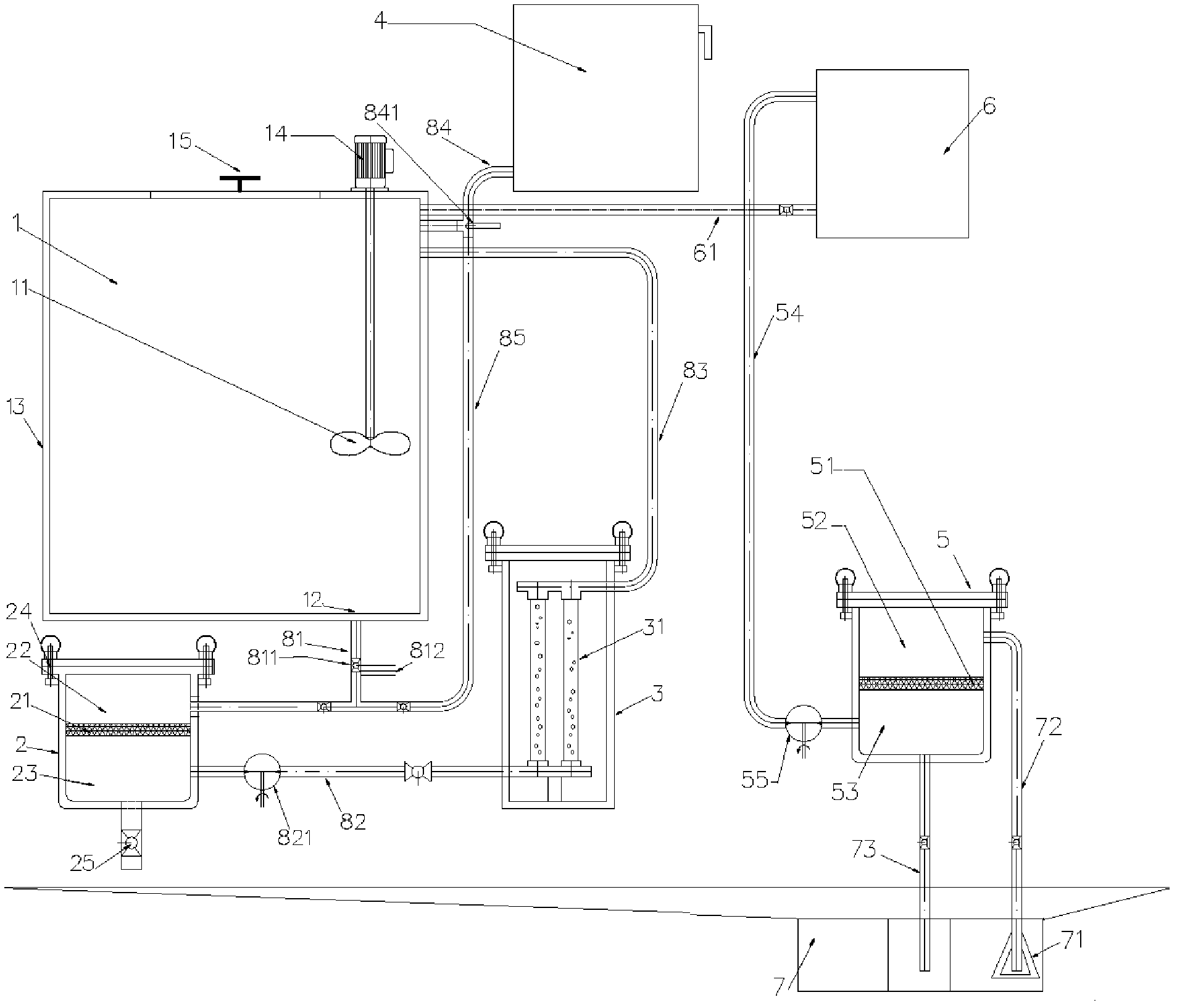

[0047] see figure 1 , which depicts a schematic diagram of one embodiment of an apparatus for preparing an aqueous solution of an oxidizing agent brine according to the first aspect of the invention. The preparation device of oxidant salt solution of the present invention comprises:

[0048] Preparation tank 1, wherein is provided with agitator 11;

[0049] A coarse filter tank 2, wherein a coarse filter screen 21 is arranged, and the upper space 22 of the coarse filter screen is connected to the bottom opening 12 of the preparation tank 1 through a first pipeline 81;

[0050] The fine filter 3 is provided with at least one fine filter body 31 in it, the bottom of the fine filter body is connected to the lower space 23 of the coarse filter screen in the described coarse filter tank by the second pipeline 82, and the top of the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com