Patents

Literature

31results about How to "Efficient desulfurization and denitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grading oxidation and absorption type method for simultaneous desulphurization and denitration of sintering flue gas, and system

InactiveCN103977679ALow costRapid responseDispersed particle separationAir quality improvementNitrogen dioxideFlue gas

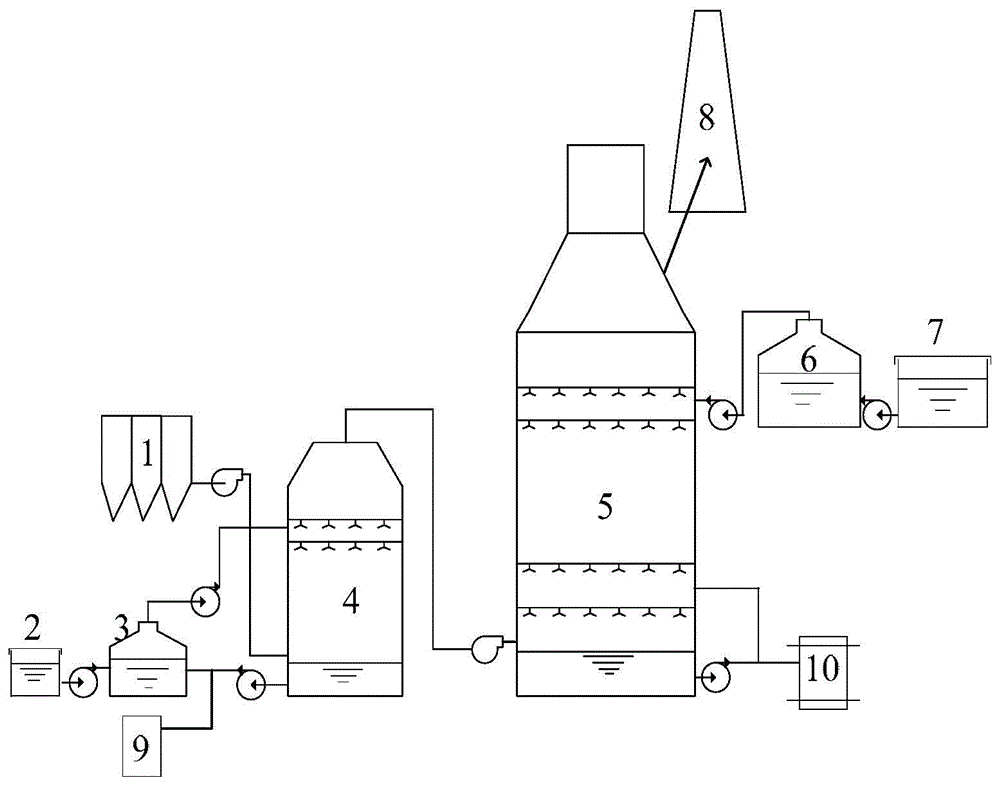

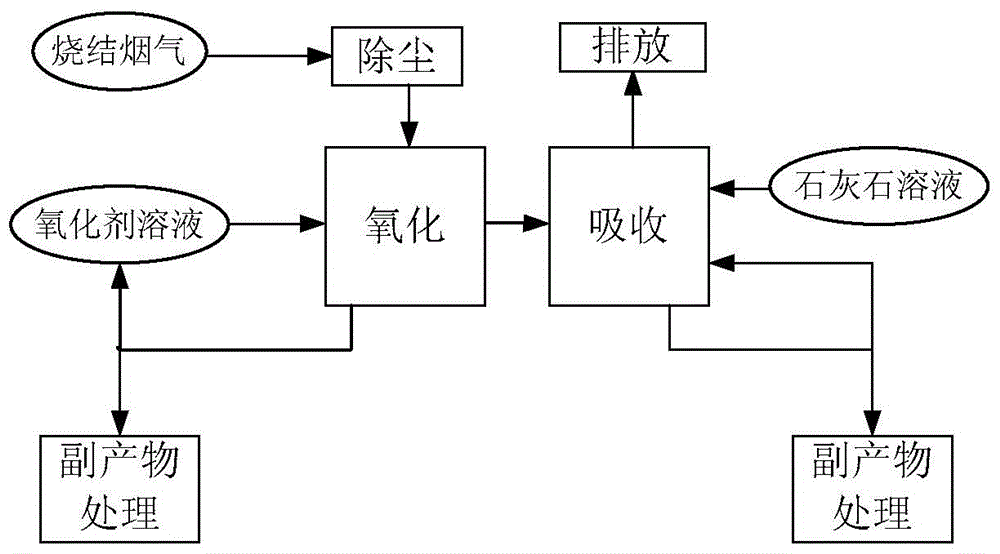

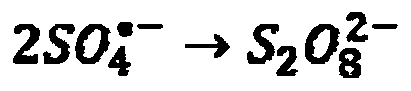

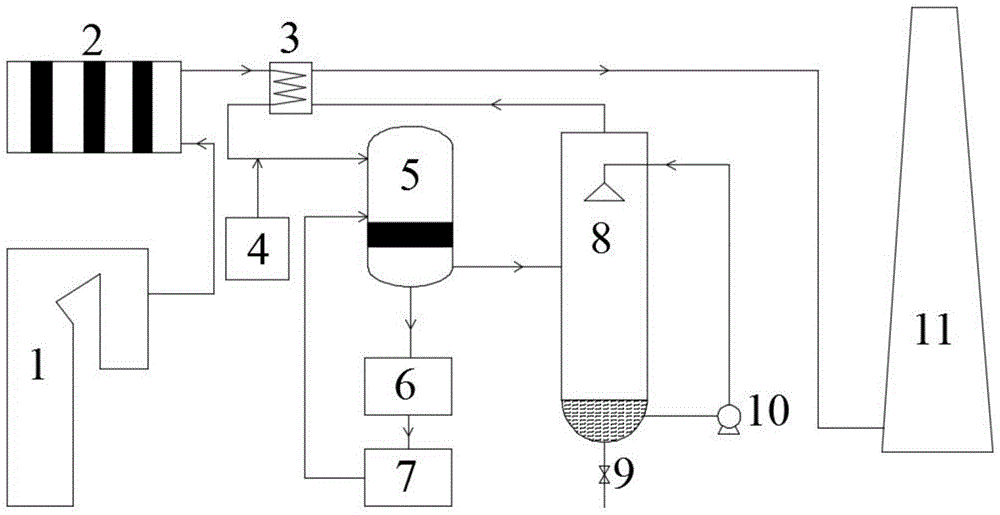

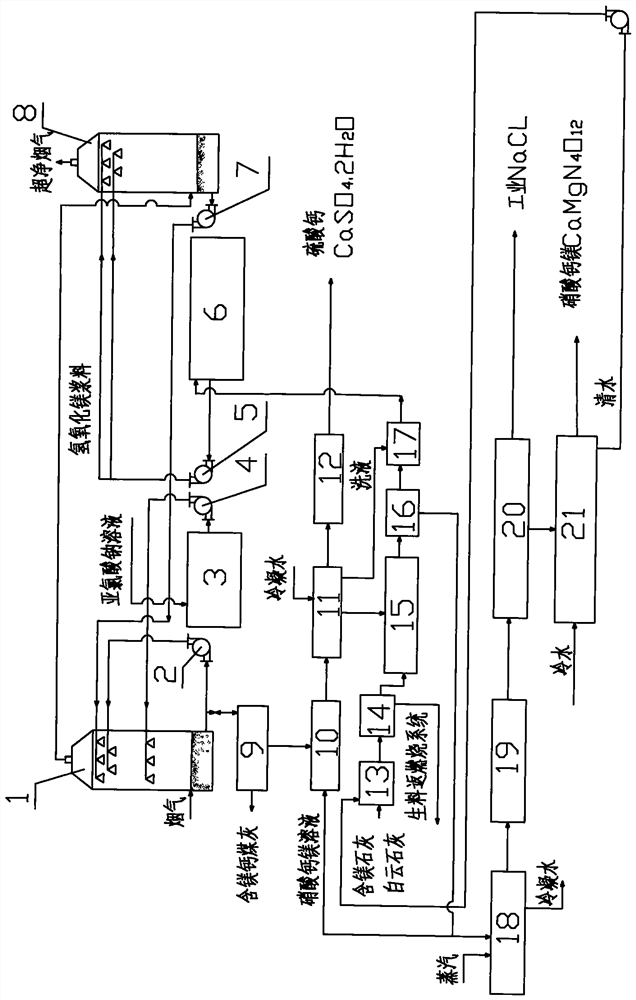

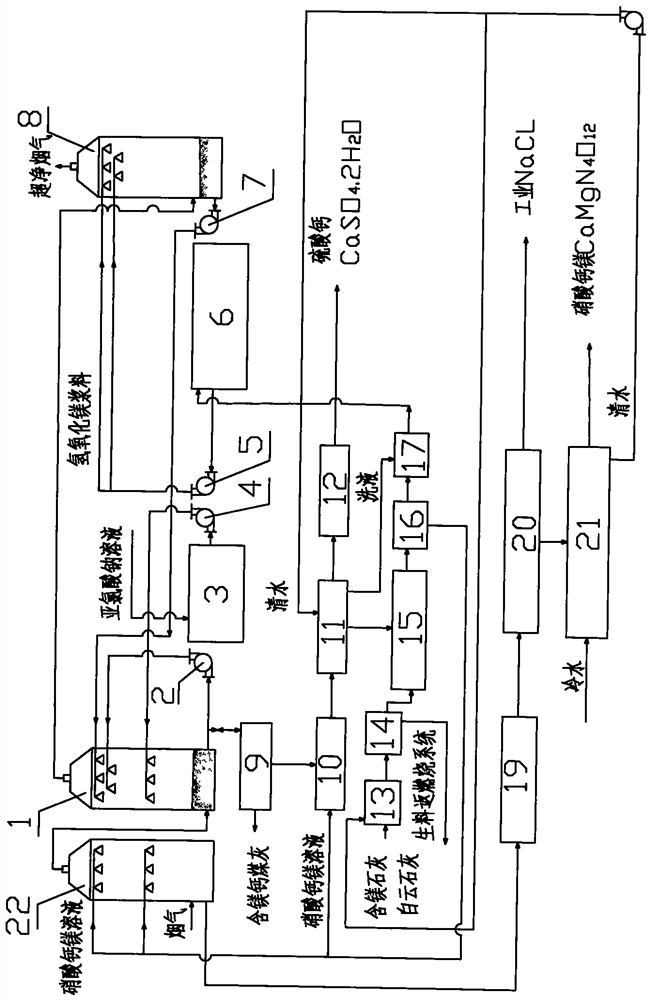

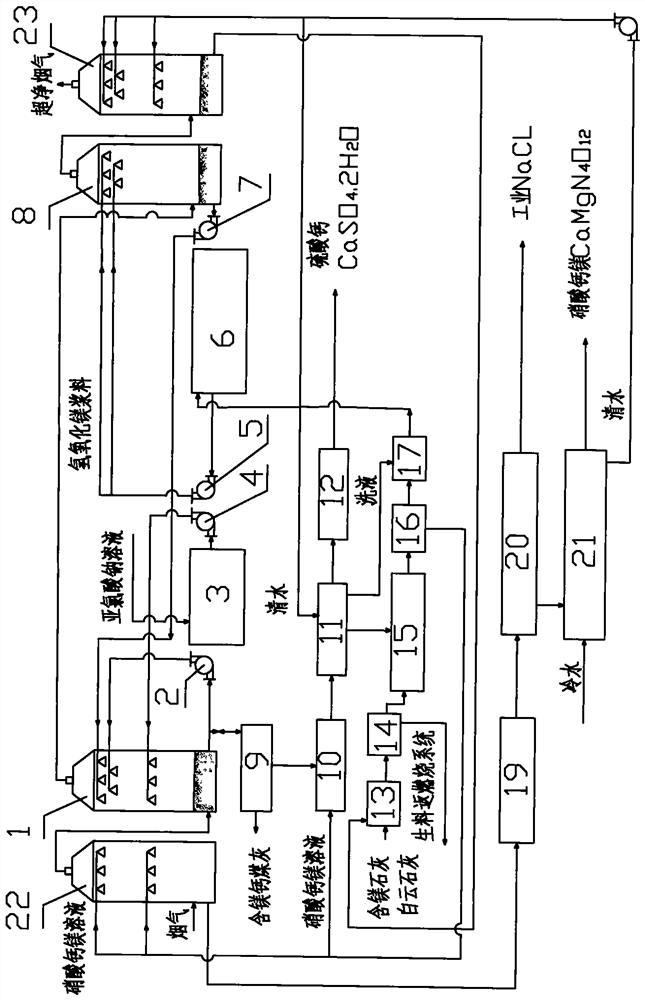

The invention discloses a grading oxidation and absorption type method for simultaneous desulphurization and denitration of sintering flue gas, and a system. An oxidant solution is adopted in a first grade oxidation tower to spray and oxidize the sintering flue gas so that nitrogen oxides are oxidized into nitric oxide and sulfur dioxide is oxidized into sulfur trioxide. An absorbent solution is adopted in a second grade absorption tower to spray and absorb the sintering flue gas being sprayed and oxidized so that the nitric oxide and the sulfur trioxide are absorbed. Finally, the sintering flue gas after spray oxidation and spray absorption is discharged. The method and the system largely reduce the using amount of the oxidant at the same time of achieving the objectives of simultaneous desulphurization and denitration, and are efficient and energy-saving.

Owner:SOUTHEAST UNIV

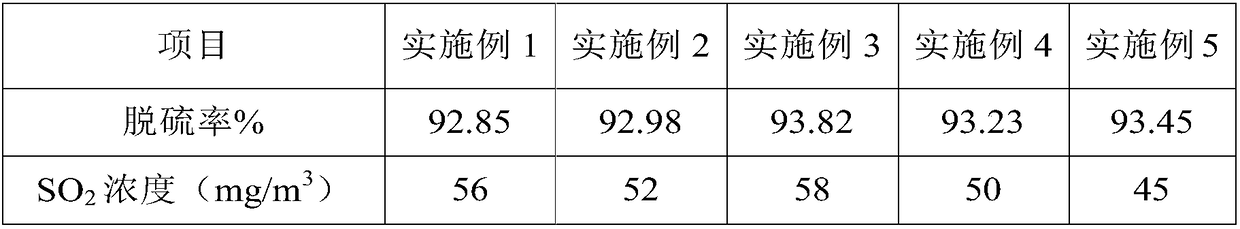

Method for producing cementing material through flue gas desulfurization and denitrification

The invention discloses a method for producing a cementing material through flue gas desulfurization and denitrification. The method comprises the following steps: (1) treating flue gas with ozone anda desulfurization and denitrification agent, thereby forming an absorbing product, and further treating the absorbing product, thereby acquiring a dry desulfurization and denitrification side product; (2) forming the cementing material by mixing the raw materials containing the desulfurization and denitrification side product, solid wastes and magnesium oxide, wherein the desulfurization and denitrification agent contains 30-60 weight parts of magnesium oxide, 20-50 weight parts of red mud and 20-50 weight parts of carbide slag, and the magnesium oxide is selected from at least one of lightlyburned magnesite powder, light burned dolomite powder and analytical pure magnesium oxide. According to the method disclosed by the invention, the atmospheric pollution problem caused by sulfur dioxide and nitrogen oxide, the treatment problem of some wastewater containing acid and alkaline and the recycling problem of solid wastes, such as industrial solid wastes and construction wastes can be solved.

Owner:ZHONGJING ECO IND CO LTD

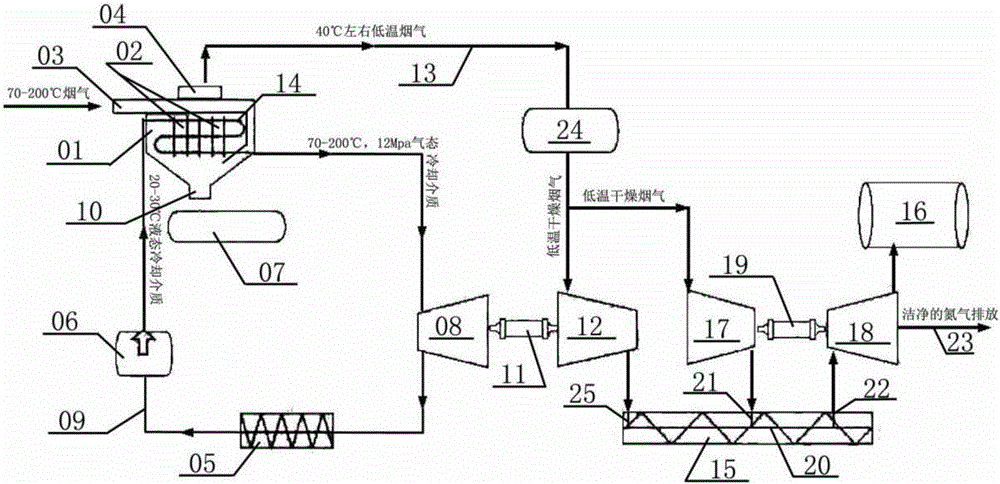

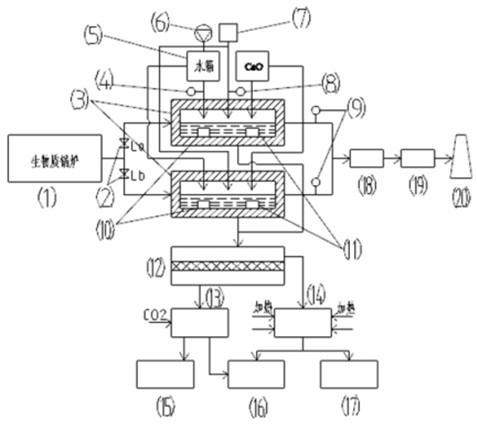

Method and device for desulfurizing and denitrating flue gas based on cryogenic liquefaction and separation

PendingCN106512638ARealize desulfurization and denitrificationReduce energy consumptionGas treatmentDispersed particle separationPollutionZero emission

The invention relates to a method and a device for desulfurizing and denitrating flue gas based on cryogenic liquefaction and separation. According to the method and the device, the flue gas is desulfurized and denitrated at ultralow temperature by mainly depending on a cryogenic air liquefaction technology; the waste heat of the flue gas is recycled simultaneously; CO2 in the flue gas is collected; the purpose of efficiently desulfurizing and denitrating the flue gas by inputting a small amount of high-quality energy is achieved; chemical by-products can also be obtained; the waste heat is recycled; the purposes of changing waste into wealth and treating pollutants by using pollutants are achieved; equipment investment is reduced; the operation cost is reduced; the flue gas pollution is treated while certain economic benefit is brought; a high-cost flue gas treatment manner of only investing and bringing no benefit at present is changed. In addition, no catalyst is used; the waste heat, water, sulfides, nitrides and the CO2 in the flue gas are simultaneously subjected to waste reclamation; zero emission is achieved; the energy consumption is low; the equipment size is small; one set of the equipment is capable of simultaneously desulfurizing and denitrating; the automation degree is high; great help is supplied to haze treatment and air pollution treatment.

Owner:刘民凯

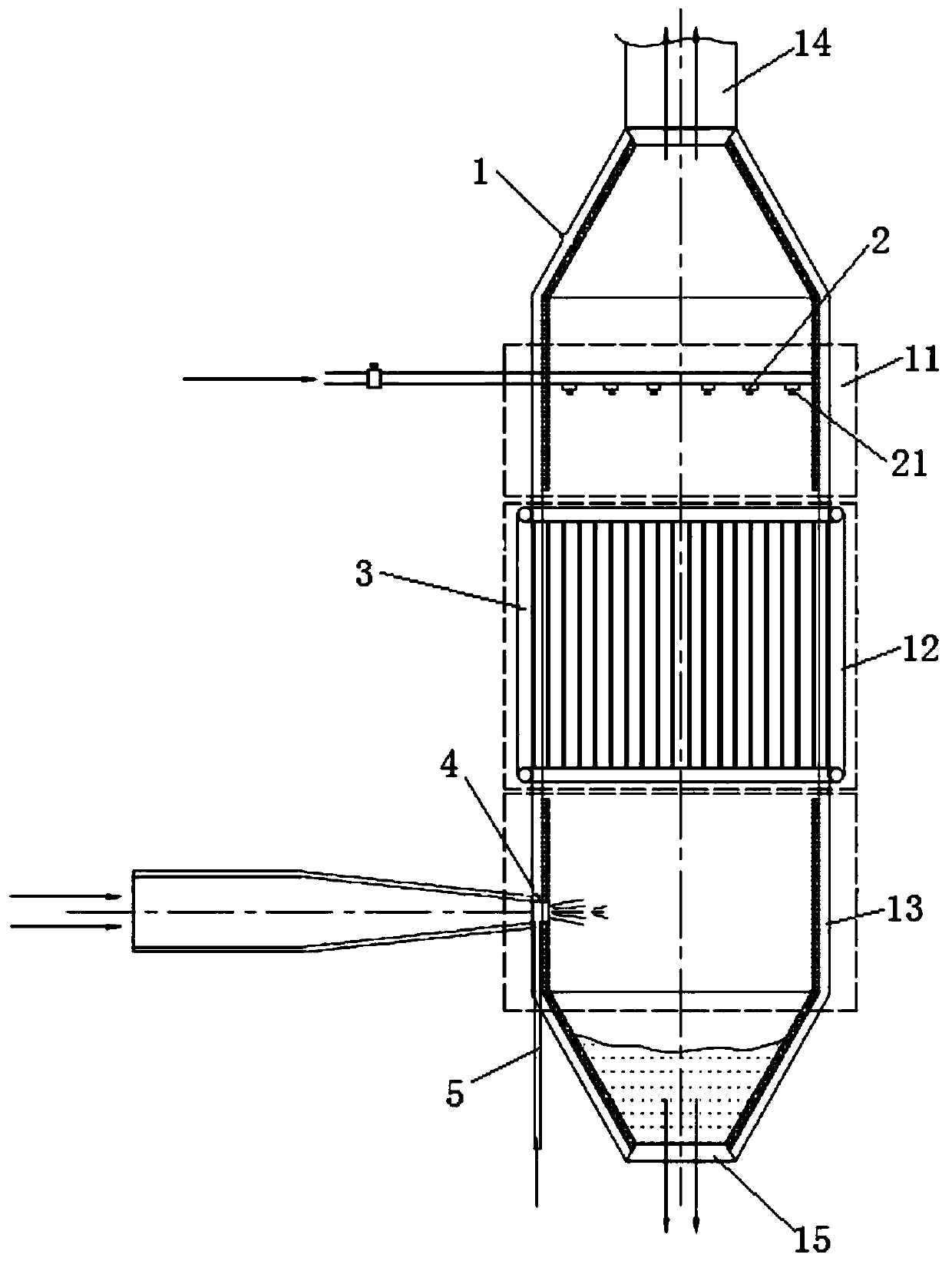

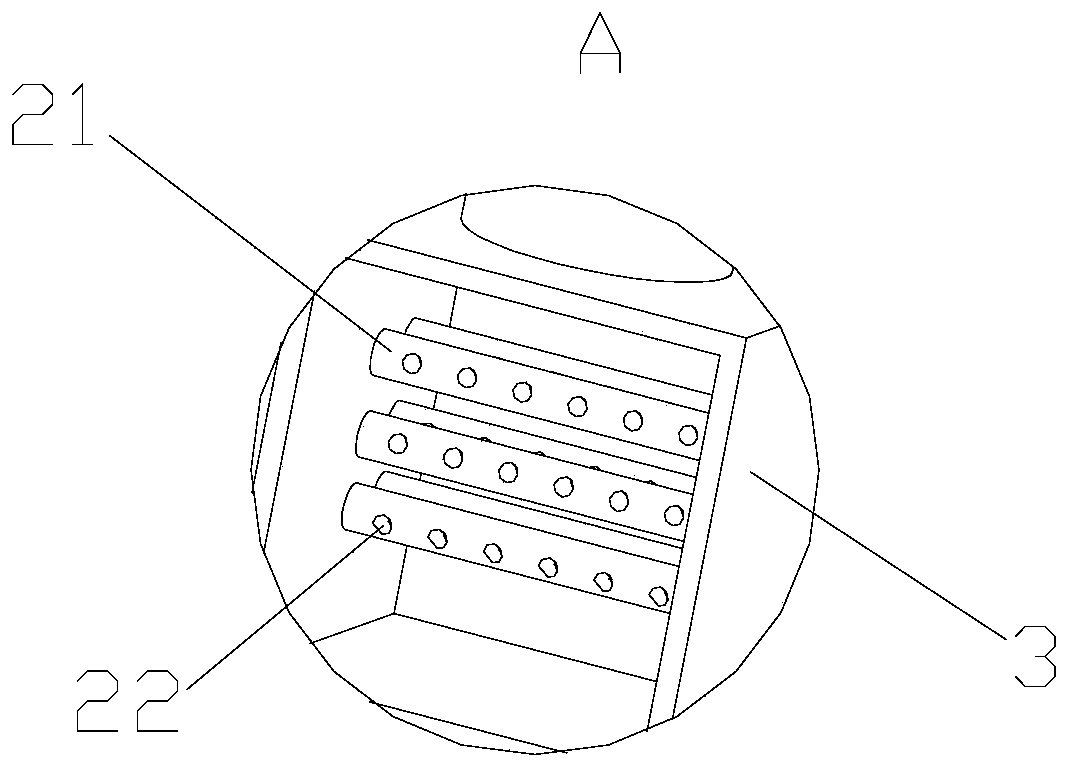

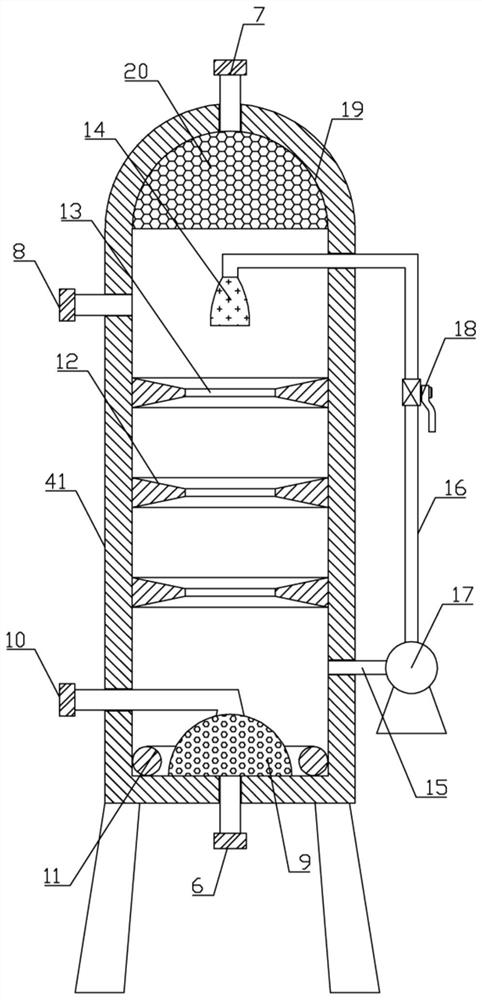

High-efficiency energy-saving environment-friendly quenching column

InactiveCN110433643ATake advantage ofHigh speed useGas treatmentUsing liquid separation agentFlue gasSludge

The invention discloses a high-efficiency energy-saving environment-friendly quenching column, and belongs to the technical field of flue gas treatment. The quenching column includes a quenching column main body which consists of a spraying section, a waste heat recovery section and a high-temperature flue gas inlet section. The top of the quenching column main body is provided with a low-temperature gas outlet, and the bottom end of the main body is provided with a dust sludge discharging port. Spraying heads are arranged at intervals in the spraying section. Waste heat recovery pipes are paved on the external wall of the waste heat recovery section. The surface of the high-temperature flue gas inlet section is communicated with a venturi tube port. A flue gas treatment tube is disposed at the venturi tube port. The quenching and a chemical method are adopted to provide double security; efficient rapid cooling, dust removal, desulfurization and denitrification and dioxin removal are ensured, and heat of flue gas can be fully utilized, thus effectively saving energy, reducing energy consumption and reducing the production cost.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Efficient desulfurization and denitration absorbing agent and preparation method thereof

InactiveCN108654311ANo pollutionEfficient desulfurization and denitrificationDispersed particle separationNitratePotassium alum

The invention discloses an efficient desulfurization and denitration absorbing agent and a preparation method thereof. The efficient desulfurization and denitration absorbing agent comprises, by weight, 5-15 parts of ammonium sulfate, 2-6 parts of urea, 2-10 parts of white alum, 1.2-2.6 parts of magnesium hydroxide, 3.0-4.5 parts of complexing agents, 1.0-2.0 parts of sodium borate and 4.5-6.5 parts of molding solution. According to the efficient desulfurization and denitration absorbing agent and the preparation method thereof, the absorbing agent lower precipitated mixture powder dispersed in the molding solution and the sodium borate, the lower precipitated mixture powder comprises the ammonium sulfate, the urea, the white alum and the magnesium hydroxide, raw materials are complexed through the complexing agents, dried and crushed to prepare the absorbing agent, the absorbing agent is uniform in shape and stable in nature, sulfate and nitrate can be rapidly, efficiently and thoroughly removed, and environments cannot be polluted.

Owner:DSP TECH DEV WENZHOU CO LTD

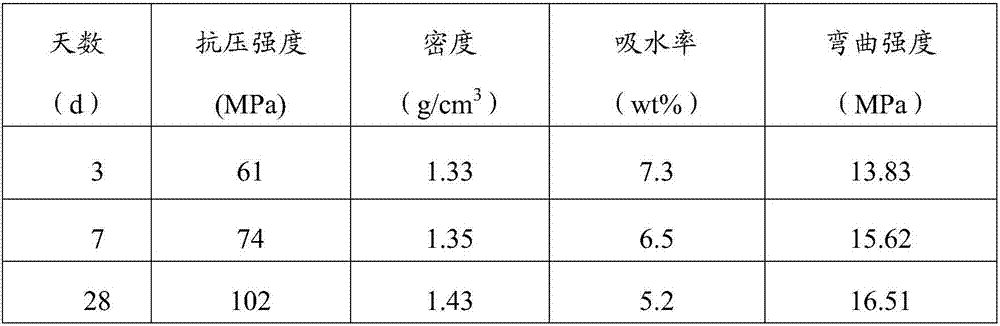

Method for making cementitious material by flue gas desulfurization and denitrification

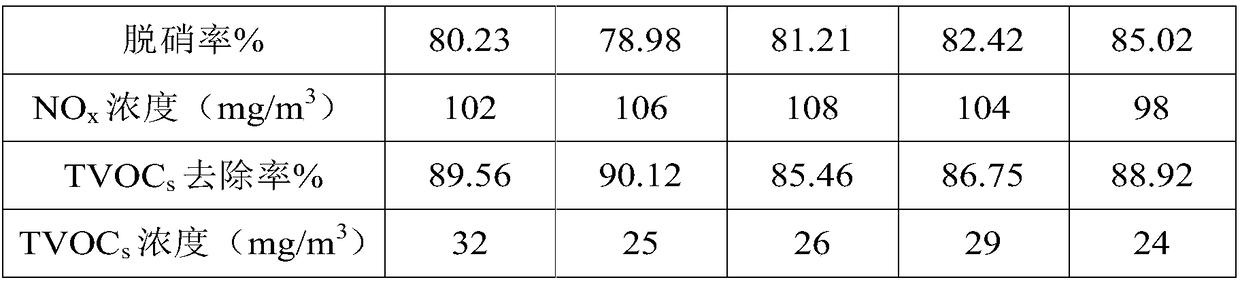

InactiveCN107583419AEfficient desulfurization and denitrificationAchieve recyclingDispersed particle separationSlagRed mud

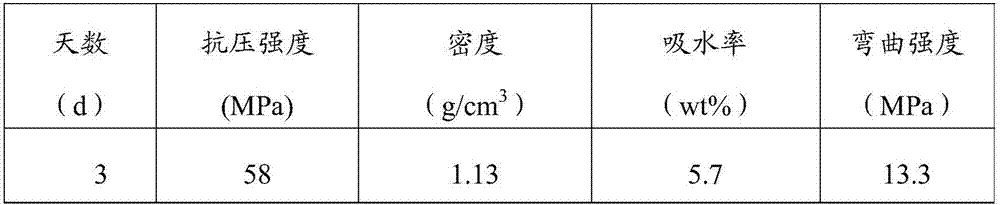

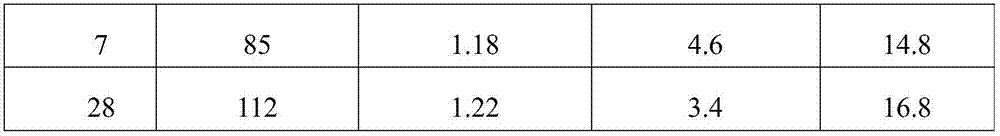

The invention discloses a method for making a cementitious material by flue gas desulfurization and denitrification. The method comprises the following steps: (1) performing desulfurization and denitrification treatment on flue gas with slurry containing a desulfurization and denitrification agent to form an absorption product, and performing evaporation concentration, cooling crystallization, centrifugal separation and drying on the absorption product to obtain a drying product, wherein the desulfurization and denitrification agent is prepared from 35 to 65 parts by weight of magnesium oxide,25 to 55 parts by weight of carbide slag and 25 to 55 parts by weight of red mud; (2) uniformly mixing the drying product, industrial solid waste, the magnesium oxide and an additive to form the cementitious material, wherein every 100 parts by weight of the cementitious material is prepared from 25 to 50 parts by weight of the drying product, 35 to 60 parts by weight of the industrial solid waste, 5 to 20 parts by weight of the magnesium oxide and 0.5 to 5 parts by weight of the magnesium oxide. Through adoption of the method disclosed by the invention, flue gas desulfurization and denitrification can be realized; meanwhile, an obtained by-product and the industrial solid waste are combined to form the cementitious material, thereby realizing cyclic utilization of the industrial solid waste.

Owner:ZHONGJING ECO IND CO LTD

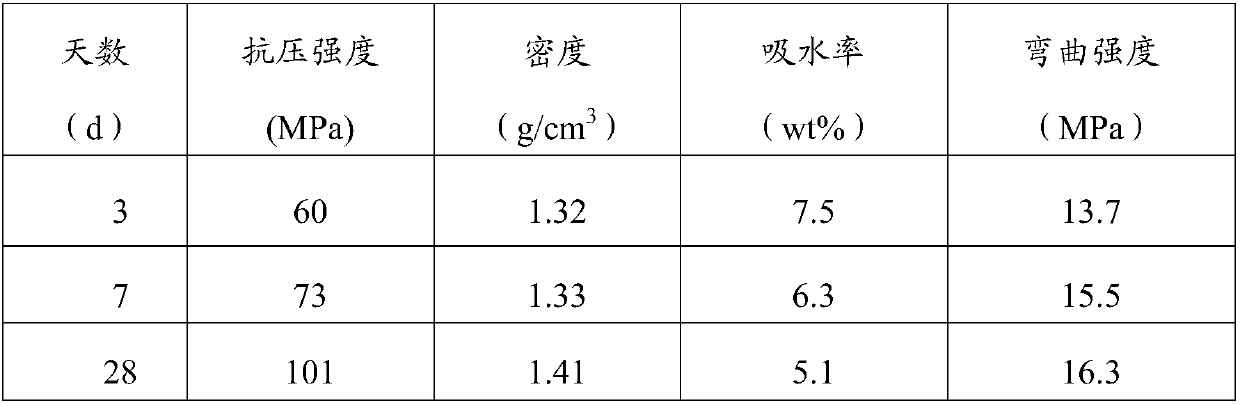

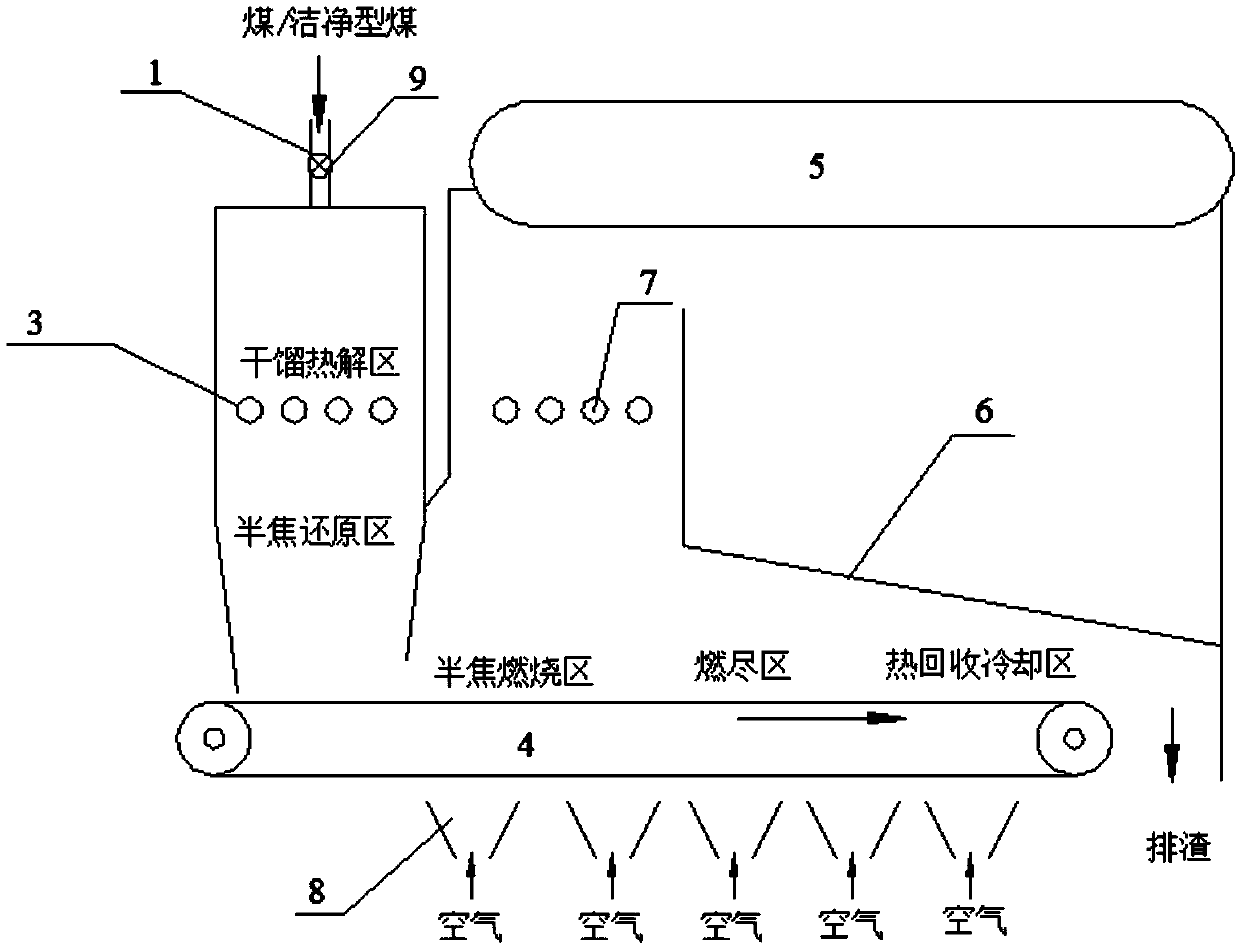

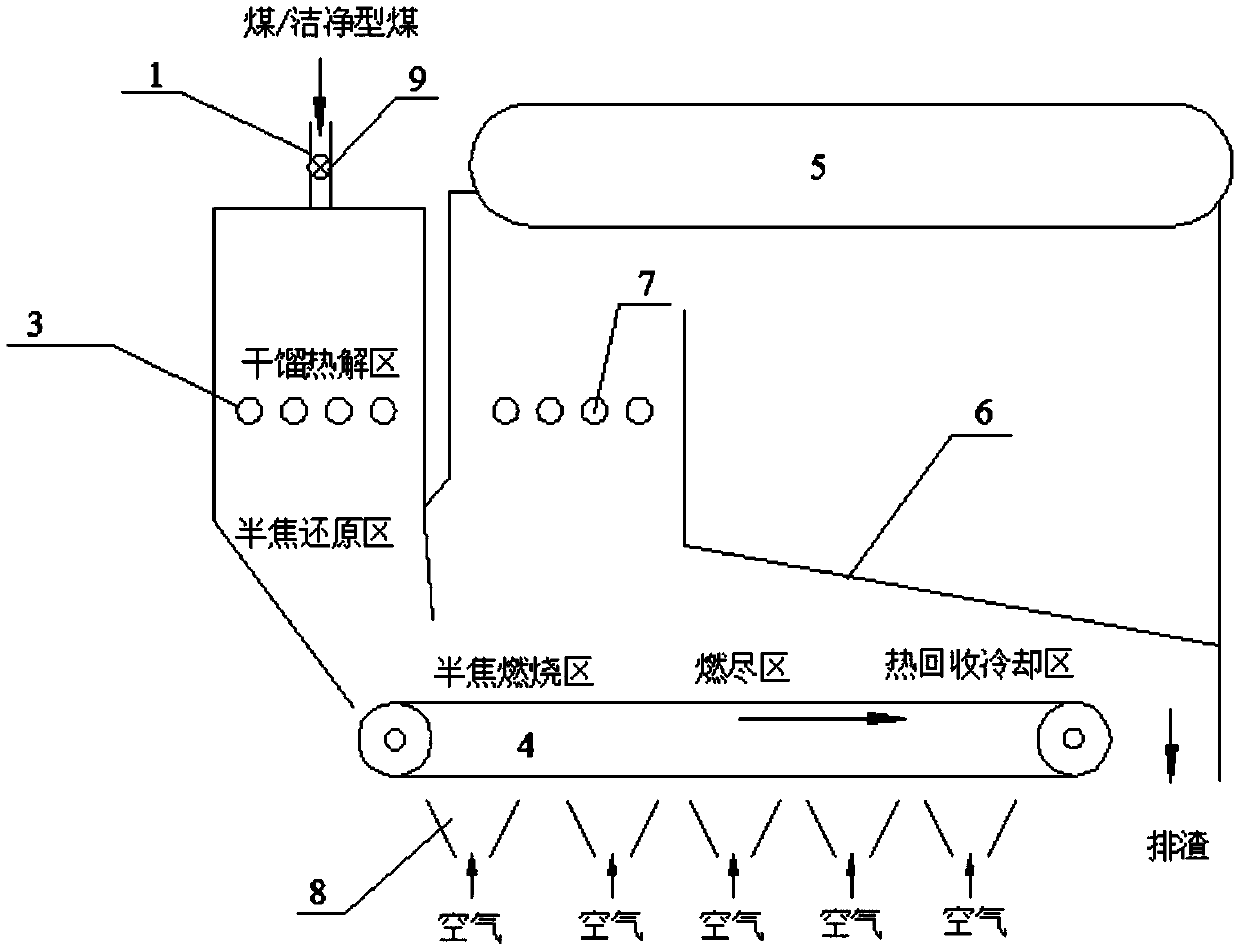

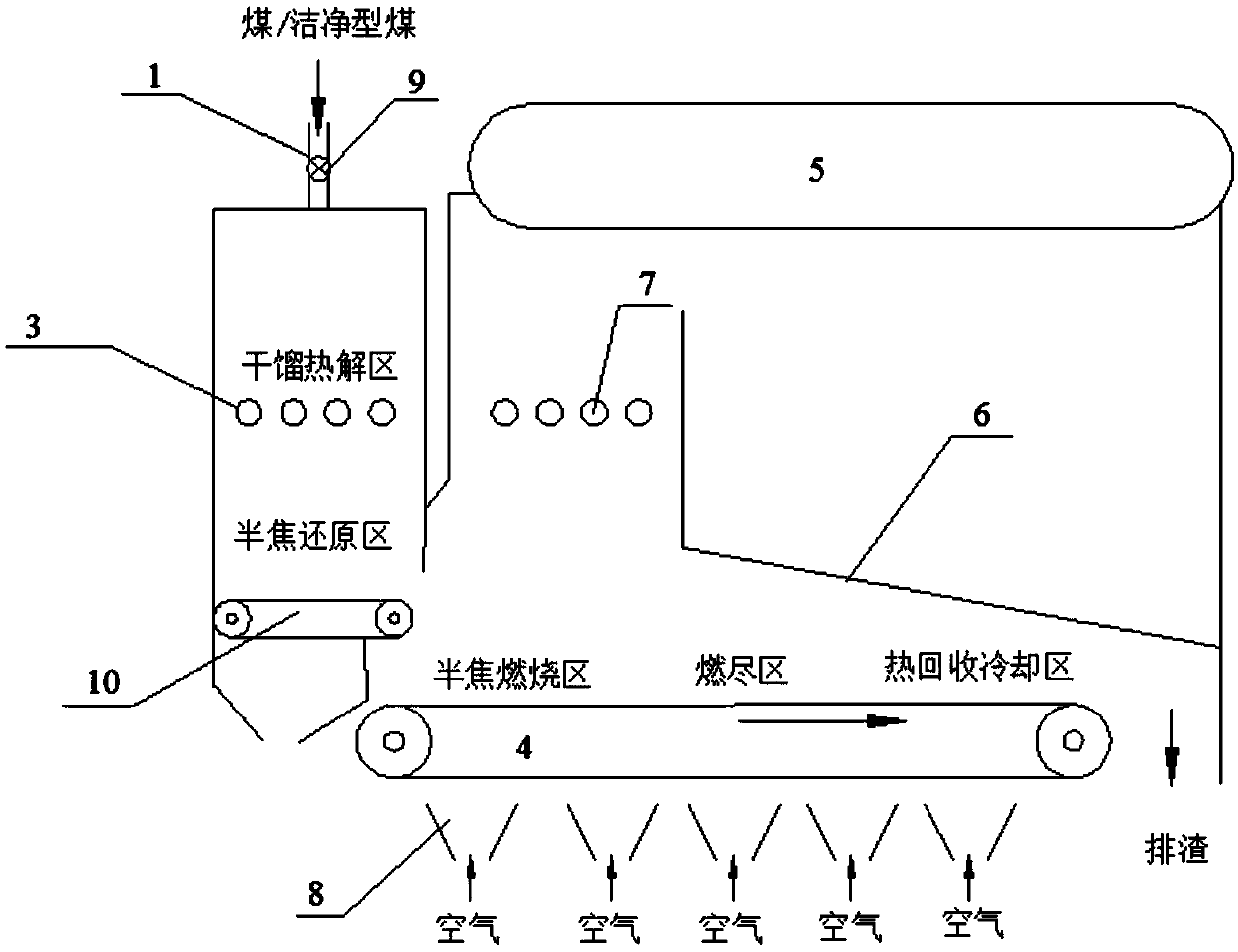

Energy-saving and environmental-friendly layer-burning boiler suitable for solid fuel and processing method of layer-burning boiler

InactiveCN109578976AIncrease disturbanceReduce incomplete combustion heat lossSolid fuel combustionAir/fuel supply for combustionLow nitrogenMulti pollutant

The invention provides an energy-saving and environmental-friendly layer-burning boiler suitable for solid fuel and a processing method of the layer-burning boiler. A boiler body of the layer-burningboiler is internally provided with a first cavity and a second cavity with the bottoms communicating with each other, a pre-burning air opening is formed in the middle boiler wall of the first cavityand / or a pre-burning air pipe is arranged in the middle of the first cavity, the areas / the area, on the upper part of the pre-burning air opening and / or on the upper part of the pre-burning air pipe,inside the first cavity are / is destructive distillation pyrolysis areas / a destructive distillation pyrolysis area, the areas / the area, on the lower part of the pre-burning air opening and / or on the lower part of the pre-burning air pipe, inside the first cavity are / is semi-coke reduction pre-burning areas / a semi-coke reduction pre-burning area, a first chain grate is arranged on the lower partsof the first cavity and the second cavity, a steam drum is arranged at the top of the second cavity, a rear arch is arranged below the steam drum, and at least two air chambers are arranged below thefirst chain grate. According to the energy-saving and environmental-friendly layer-burning boiler suitable for the solid fuel and the processing method of the layer-burning boiler, nitrogen oxides generated by burning are converted into harmless nitrogen through a reaction with reducing pyrolysis gas and semi-coke in a low-nitrogen pre-burning mode, and through methods such as combining pyrolysisdesulfurization and burning desulfurization and pyrolysis products of coal to form reburning denitration, emission of multi-pollutants such as SOx, NOx, and CO is effectively reduced.

Owner:YANKUANG GRP CO LTD +1

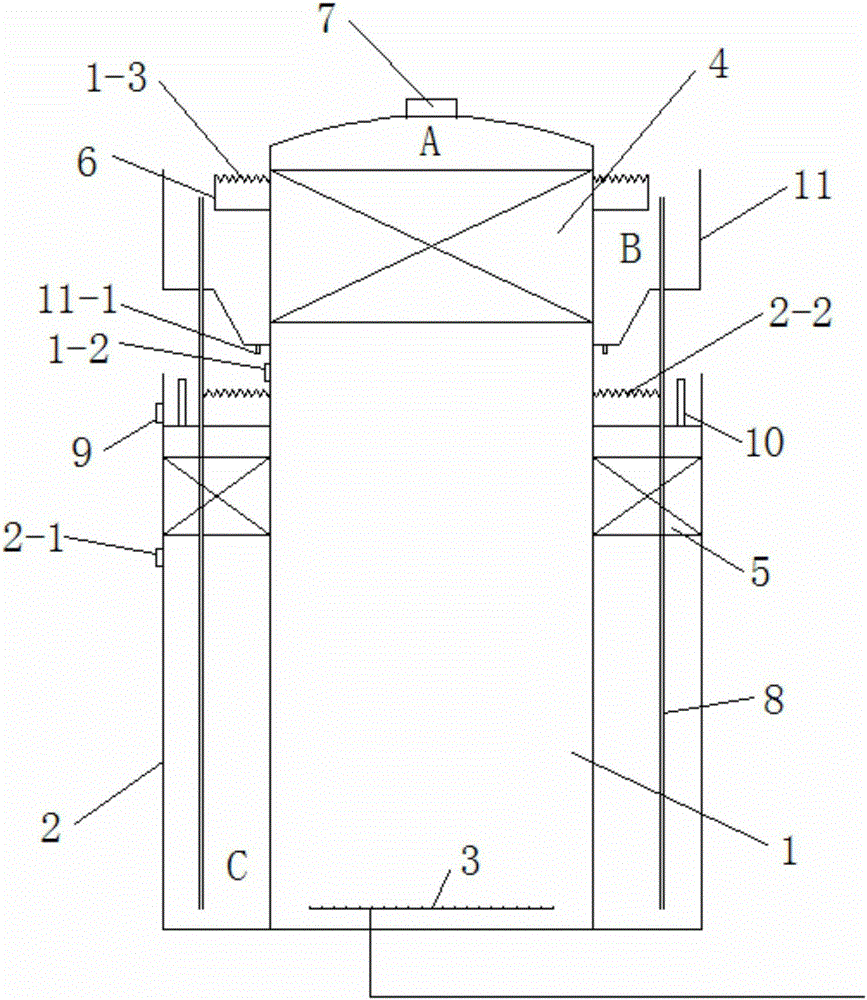

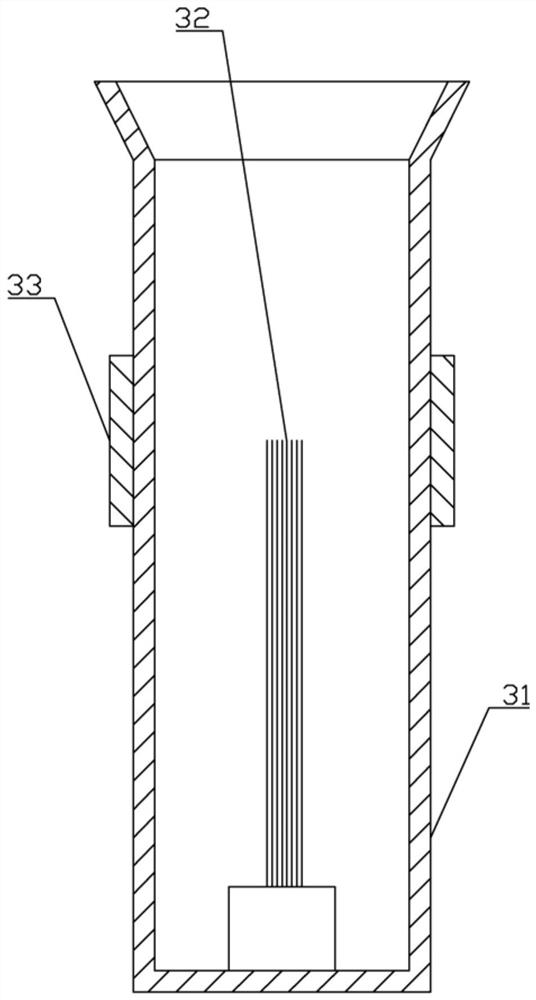

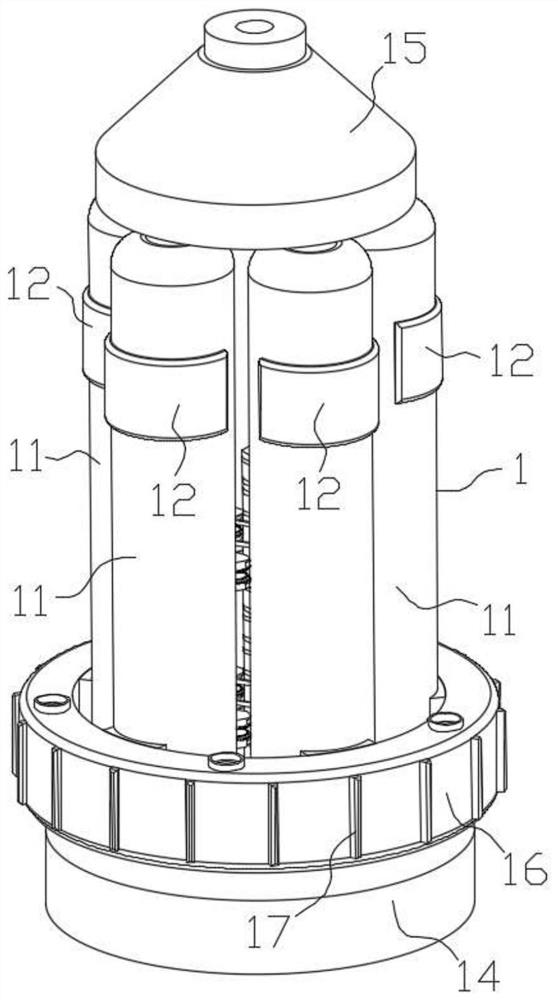

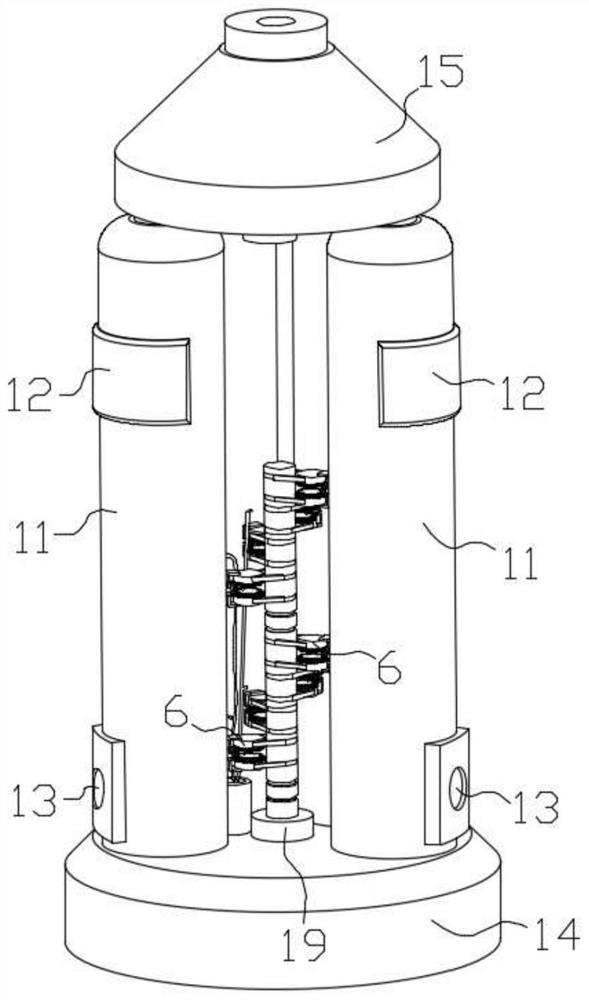

Sleeve type split-phase anaerobic reactor for organic wastewater treatment as well as regulating and controlling method for treating sulfur-containing and nitrogen-containing wastewater by using reactor

ActiveCN105198176APrevent outflowCompact layoutWater contaminantsMultistage water/sewage treatmentWater qualityMethane production

The invention relates to an anaerobic reactor for treating organic wastewater and an application method, particularly to a sleeve type split-phase anaerobic reactor for organic wastewater treatment as well as a regulating and controlling method for treating sulfur-containing and nitrogen-containing wastewater by using the reactor, and aims to solve problems that existing two-stage anaerobic reactor equipment occupies large areas and pipeline connection is complex. The sleeve type split-phase anaerobic reactor comprises an inner barrel, an outer barrel, a water distribution device and two three-phase separation devices, wherein the inner barrel and the outer barrel are arranged coaxially, the water distribution device is mounted at the bottom of the inner barrel, one three-phase separation device is arranged at the upper part of the inner barrel, a water outlet is formed in the wall of the inner barrel, a settling zone is defined by a cofferdam and the outer wall of the inner barrel, and multiple downcomers are fixed on a bottom plate of the cofferdam and extend to the bottom of the outer barrel. The sleeve type two-stage anaerobic reactor is closely arranged, occupies a small area and is simple to manage and control, the two-stage biochemical treatment process of hydrolytic acidification and anaerobic methane production of the wastewater is finished in one reactor, and the quality of effluent is improved.

Owner:HARBIN INST OF TECH +1

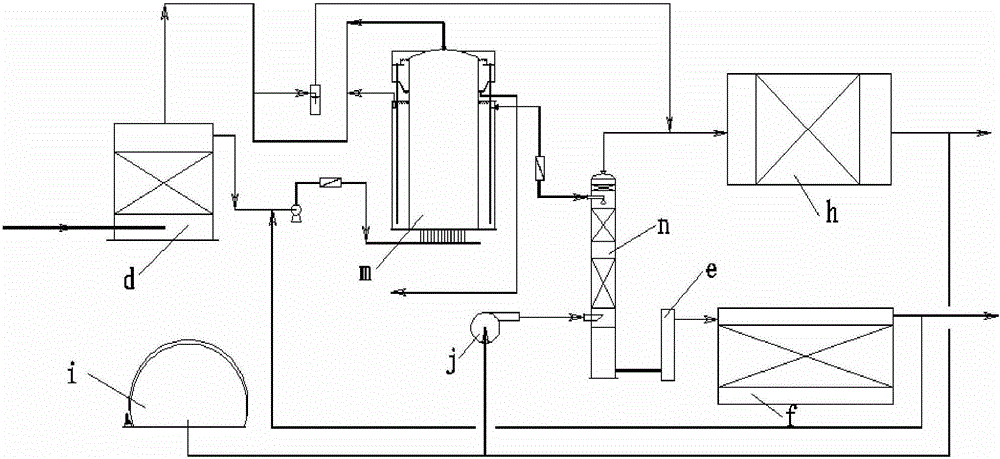

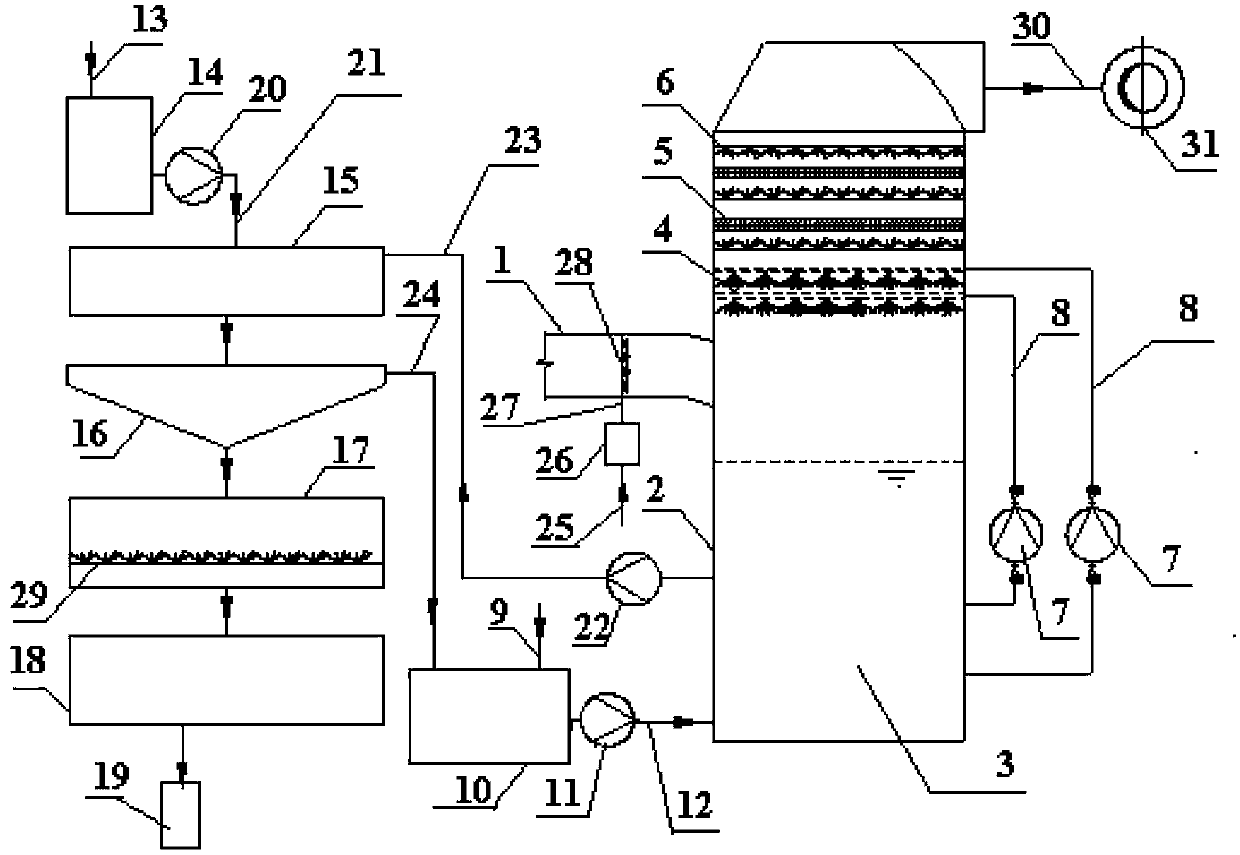

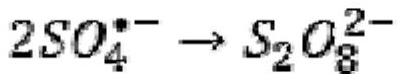

Condensing dioxygen method desulfuration denitration integration device and process thereof

InactiveCN102580489AImprove energy efficiencyRun smoothlyCombination devicesRecycling by productWater tanks

The invention discloses a condensing dioxygen method desulfuration denitration integration device and a process thereof. The integration device comprises a boiler room smoke vent, a first level dry type dust removing device, an induced draft fan, a second level wet type dust removing device, a comprehensive desulfuration denitration tower and a chimney which are sequentially connected through flues. An ozone filling device is disposed on the flue on which the first level dry type dust removing device is connected with the induced draft fan. A liquid inlet of the second level wet type dust removing device and a liquid inlet of the comprehensive desulfuration denitration tower are both connected with a circulating water tank. A liquid outlet of the second level wet type dust removing device is connected with a precipitation water tank. A liquid outlet of the comprehensive desulfuration denitration tower and a liquid outlet of the precipitation water tank are both connected with the circulating water tank. A liquid outlet of the circulating water tank is connected with a crystallization tower, and a liquid outlet of the crystallization tower is connected with the circulating water tank. By means of a set of device, the process adopts the dry and wet method for desulfurating, denitrating and dedusting smoke of coal-fired boilers, and has the advantages of being high in energy efficiency, stable in operation, little in investment, low in operation cost, strong in applicability and free of secondary pollution, treating wastes with processes of wastes, recycling by-products and the like.

Owner:无锡市灵龙机械设备有限公司

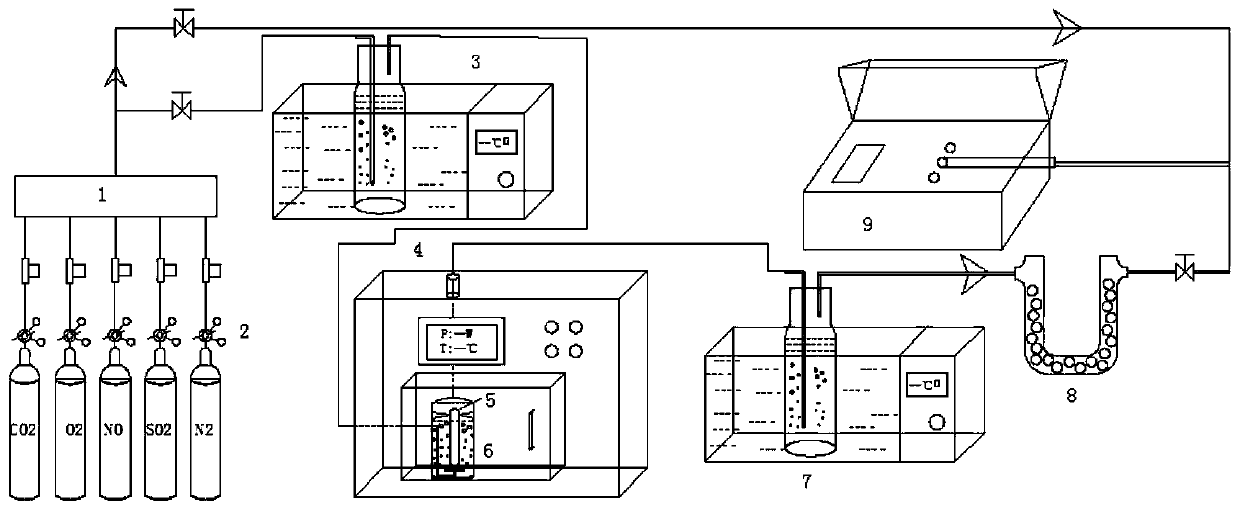

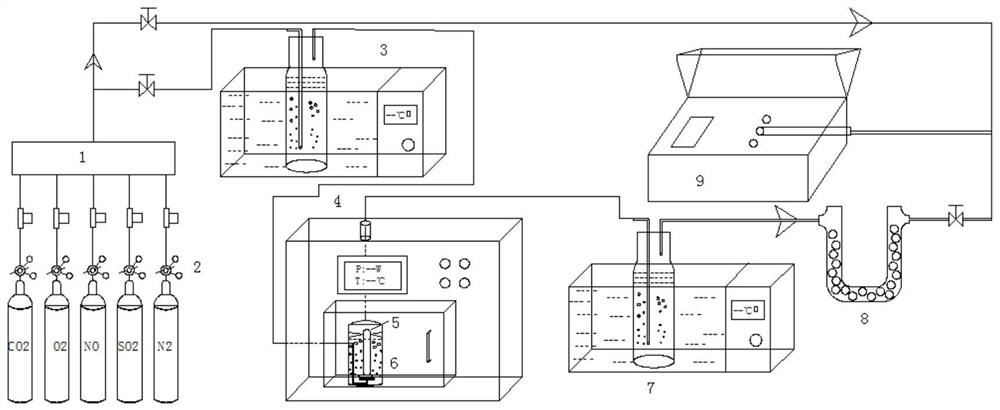

Flue gas purification method combining photocatalytic oxidation with double-cycle absorption

ActiveCN110385038ALow infrastructure and operating costsSmall footprintDispersed particle separationNitrate fertilisersNitrogen gasFlue gas

The invention belongs to the technical field of flue gas purification, and discloses a microwave coupling ultraviolet photocatalytic oxidation desulfurization and denitration method. The method comprises the steps that NO gas and SO2 gas are mixed and diluted by nitrogen and oxygen and enter a SO2 pre-absorption system to remove the SO2 preliminarily, then the gases enter a microwave reactor whichsupplies microwaves and excites an inorganic lamp, and the temperature is raised simultaneously in the process to improve the oxidation efficiency of a liquid phase oxidizing agent; subsequently, a liquid phase composite oxidizing agent is subjected to catalyzed activation in a photocatalytic reactor, a variety of highly active free radicals are produced, and then the highly reactive free radicals oxidize NO; the newly formed nitrogen oxides are absorbed by a subsequent absorption device; and exhaust gas after absorption is finally discharged into the atmosphere. The microwave coupling ultraviolet photocatalytic oxidation desulfurization and denitration method can meet the latest ultra-low emission pollutant standards of thermal power plants. The treatment system is lower in capital construction and operation costs, can simultaneously perform desulfurization and denitrification process, reduces floor space, and is easy to operate, and the desulfurization and denitration effect is morerapid and efficient.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Flue gas low-temperature efficient desulfurization and denitrification device and method

InactiveCN111545026AEfficient desulfurization and denitrificationLow costGas treatmentDispersed particle separationPtru catalystAmmonia production

The invention discloses a flue gas low-temperature efficient desulfurization and denitrification device and method. The flue gas low-temperature efficient desulfurization and denitrification device comprises a flue gas exhaust pipe, a desulfurization system, a mixer, an ammonia production system, a denitrification system, a recovery system and an ammonia production tank; firstly, a fluidized desulfurizing agent is sprayed out through nanopores in a powder spraying pipeline by utilizing a compressed air assembly, is fully mixed and filtered with flue gas introduced by the flue gas exhaust pipein a mixing filter, then is introduced into a mixer, and is fully mixed with heated and dried ammonia gas; the mixed gas passes through an active coke layer to adsorb sulfur dioxide gas, and desulfurization treatment is carried out; and secondly, the mixed gas penetrates through a plurality of catalyst layers to be subjected to denitrification reaction, impurities obtained by filtering the flue gas and the active coke layer are recycled by utilizing a recycling system, and meanwhile, the gas subjected to denitrification reaction is discharged into the atmosphere through the ammonia productiontank, so that efficient desulfurization and denitrification can be realized, and the cost is reduced.

Owner:江苏峰峰鸿运环保科技发展有限公司

High-efficiency flue gas desulfurization and denitrification catalyst and preparation method thereof

ActiveCN107519890AEfficient desulfurization and denitrificationGood effectGas treatmentHeterogenous catalyst chemical elementsAluminium chlorideYttrium

The invention discloses a high-efficiency flue gas desulfurization and denitrification catalyst and a preparation method thereof. The high-efficiency flue gas desulfurization and denitrification catalyst is prepared from 8-12 wt% of active components, 5-8 wt% of cocatalyst and 80-87 wt% of carrier; the active components comprise yttrium oxide, tricobalt tetroxide, manganese dioxide and aluminum chloride; the cocatalyst is ferric oxide or nickel oxide; the carrier is modified activated carbon; the specific surface area of a molecular sieve is 350-500m<2> / g, and the pore diameter is 0.8 to 1.2 mL / g. The catalyst disclosed by the invention takes the yttrium oxide, the tricobalt tetroxide, the manganese dioxide and the aluminum chloride as the active components, the ferric oxide or the nickel oxide as the cocatalyst and the modified activated carbon as the carrier, and has a good effect on desulfurization and denitrification, can remove sulfur and nitrate in flue gas, and can be widely used for desulfurization and denitrification of large-scale flue gas emission enterprises such as iron and steel enterprises, bituminous coal power plants, bituminous coal furnaces and metallurgical industry.

Owner:NANJING WEIHENG EXPERIMENTAL EQUIP CO LTD

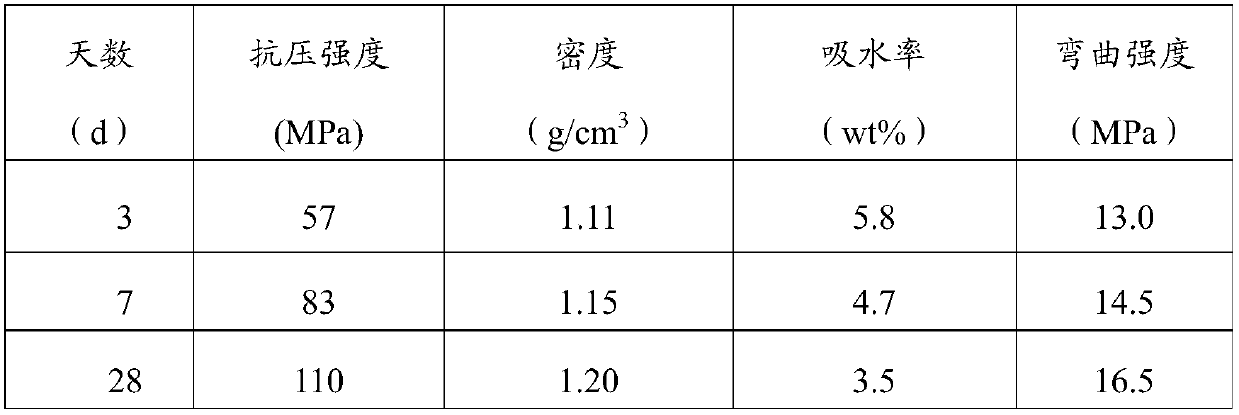

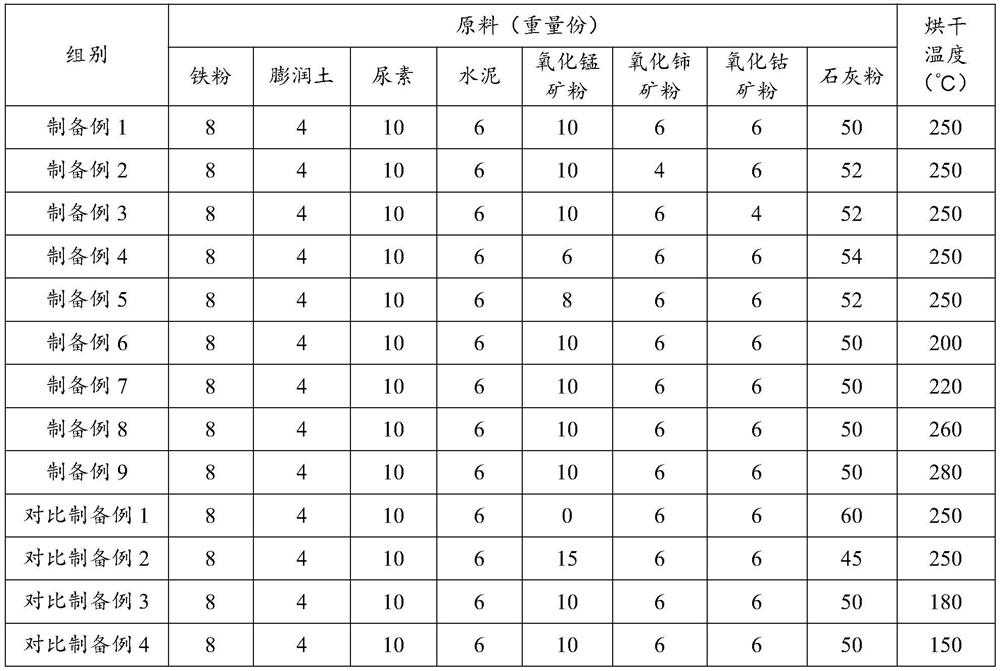

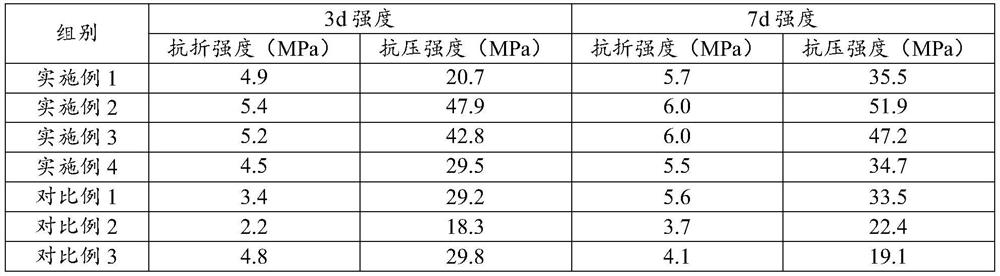

Method for producing building material by utilizing desulfurization and denitrification byproducts

InactiveCN113666679AEfficient desulfurization and denitrificationEasy to prepareSolid waste managementDispersed particle separationIron powderFlue gas

The invention discloses a method for producing a building material by using desulfurization and denitrification byproducts. The method comprises the following steps of: S1, mixing raw materials including 4-16 parts by weight of iron powder, 1-14 parts by weight of bentonite, 2-20 parts by weight of cement, 20-70 parts by weight of lime powder, 2-14 parts by weight of manganese ore, 4-10 parts by weight of cerium ore, 2-15 parts by weight of cobalt ore and 2-15 parts by weight of a pore forming agent, granulating the mixture, and performing drying to obtain a desulfurization and denitrification absorbent; S2, placing the desulfurization and denitrification absorbent in a flue gas environment for desulfurization and denitrification, so as to obtain desulfurization and denitrification byproducts. and S3, producing the building material by using the desulfurization and denitrification byproducts. The method not only can effectively perform desulfurization and denitrification, but also can realize resource reutilization of the desulfurization and denitrification byproducts.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Flue gas desulfurization and denitrification system and use method thereof

PendingCN112717646AOvercome intractable shortcomingsEfficient desulfurization and denitrificationGas treatmentDispersed particle separationPtru catalystFlue gas

The invention discloses a flue gas desulfurization and denitrification system and a use method thereof, and relates to the technical field of air pollution control, the flue gas desulfurization and denitrification system comprises an air inlet pipe, an additive generator, a dielectric barrier coupling positive pulse corona discharge device, an absorption tower, an exhaust pipe and connecting pipes. The air inlet pipe is connected with the additive generator, the additive generator, the dielectric barrier coupling positive pulse corona discharge device and the absorption tower are sequentially connected through connecting pipes, and the exhaust pipe is connected with the absorption tower. The simultaneous desulfurization and denitrification method is efficient, does not need a catalyst, can be carried out under normal pressure, eliminates adverse effects of O2, CO2 and H2O in actual flue gas on NTP method denitrification, is high in desulfurization efficiency, is not easy to cause secondary pollution, and enables NO and SO2 to be efficiently removed at the same time. The invention is accepted by basic scientific research business cost subsidy (project number XDJK2020C077) of central colleges and universities in 2020 and experimental technology research project subsidy (project number SYJ2020025) of southwest universities in 2020.

Owner:SOUTHWEST UNIVERSITY

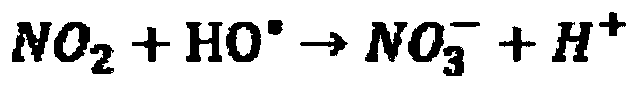

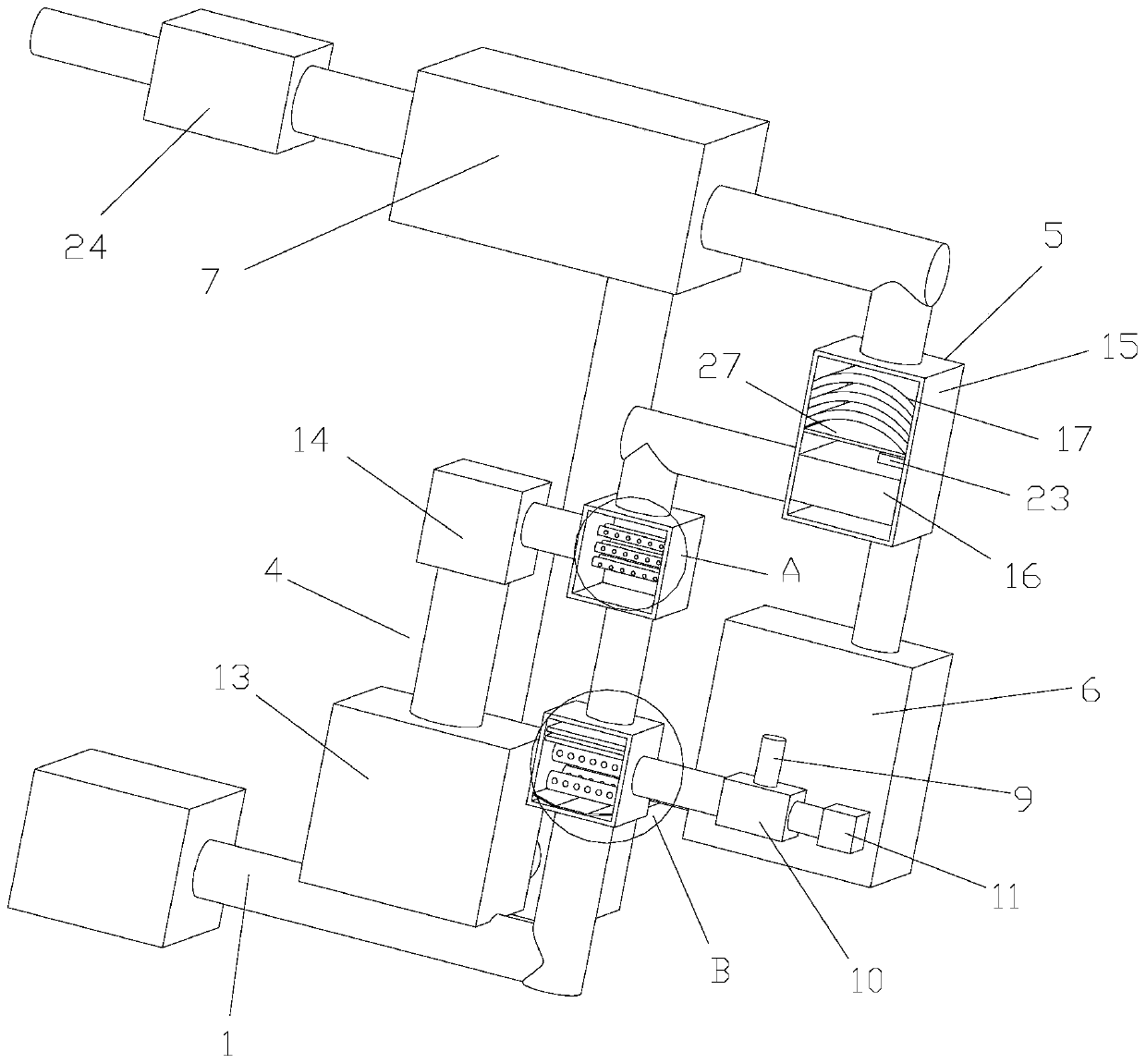

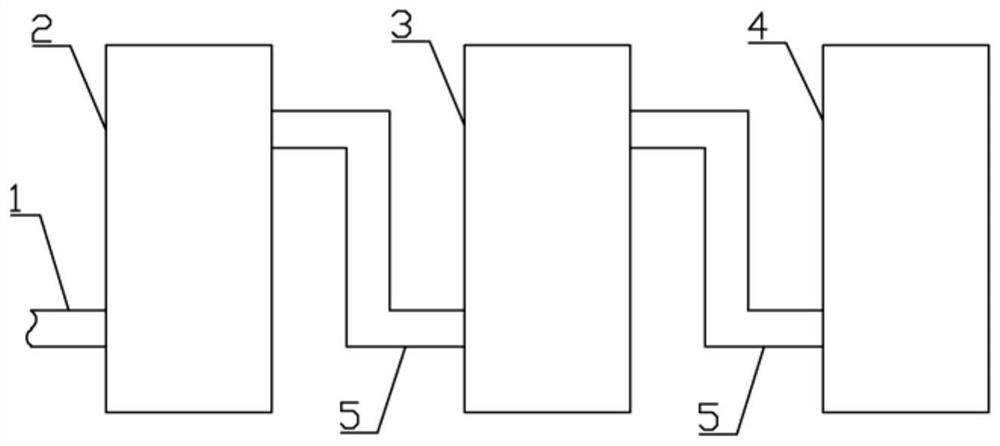

Flue gas desulfurization and denitration device

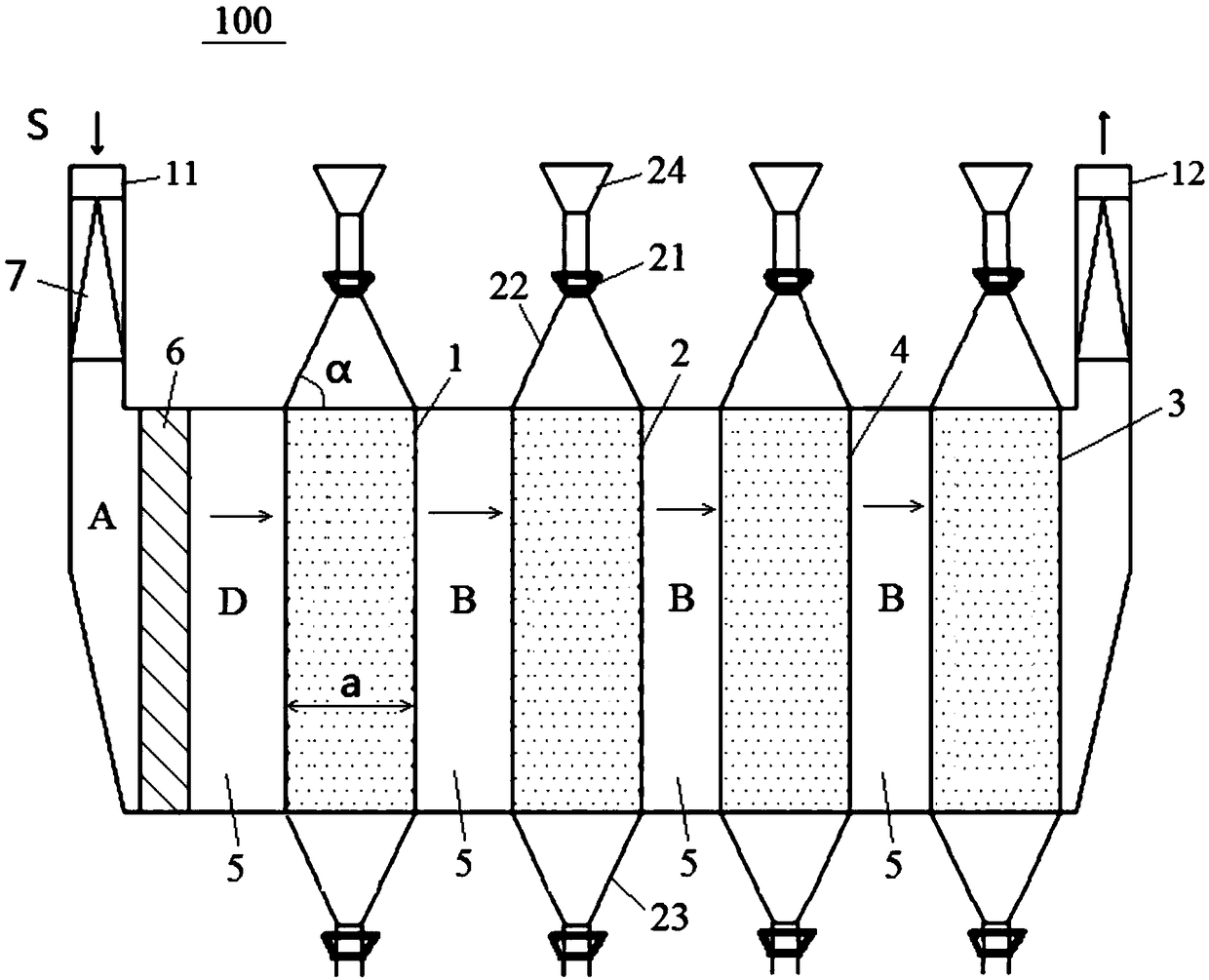

PendingCN108126492AEfficient desulfurization and denitrificationSimple installation structureGas treatmentDispersed particle separationFlue gasFlue-gas desulfurization

The invention relates to the field of environmental protection technical equipment and discloses a flue gas desulfurization and denitration device. The flue gas desulfurization and denitration deviceat least comprises a first reaction bed filled with a desulfurization material, a second reaction bed filled with a denitration material and a vacant third reaction bed, wherein the first reaction bed, the second reaction bed and the vacant third reaction bed are sequentially arranged at intervals along a flue gas flow channel in an initial state. When the desulfurization material in the first reaction bed reacts with flue gas to reach a saturated state, the first reaction bed can form a vacant state, the third reaction bed can be configured to be filled with the denitration material, and thesecond reaction bed can be configured to be filled with the desulfurization material; and when the desulfurization material in the second reaction bed continuously reacts with the flue gas to reach asaturated state, the first reaction bed can be configured to be filled with the desulfurization material, and the second reaction bed at least can form a saturated state. The flue gas desulfurizationand denitration device disclosed by the invention can realize efficient desulfurization and denitration of the flue gas and is more economical for the treatment of the flue gas.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

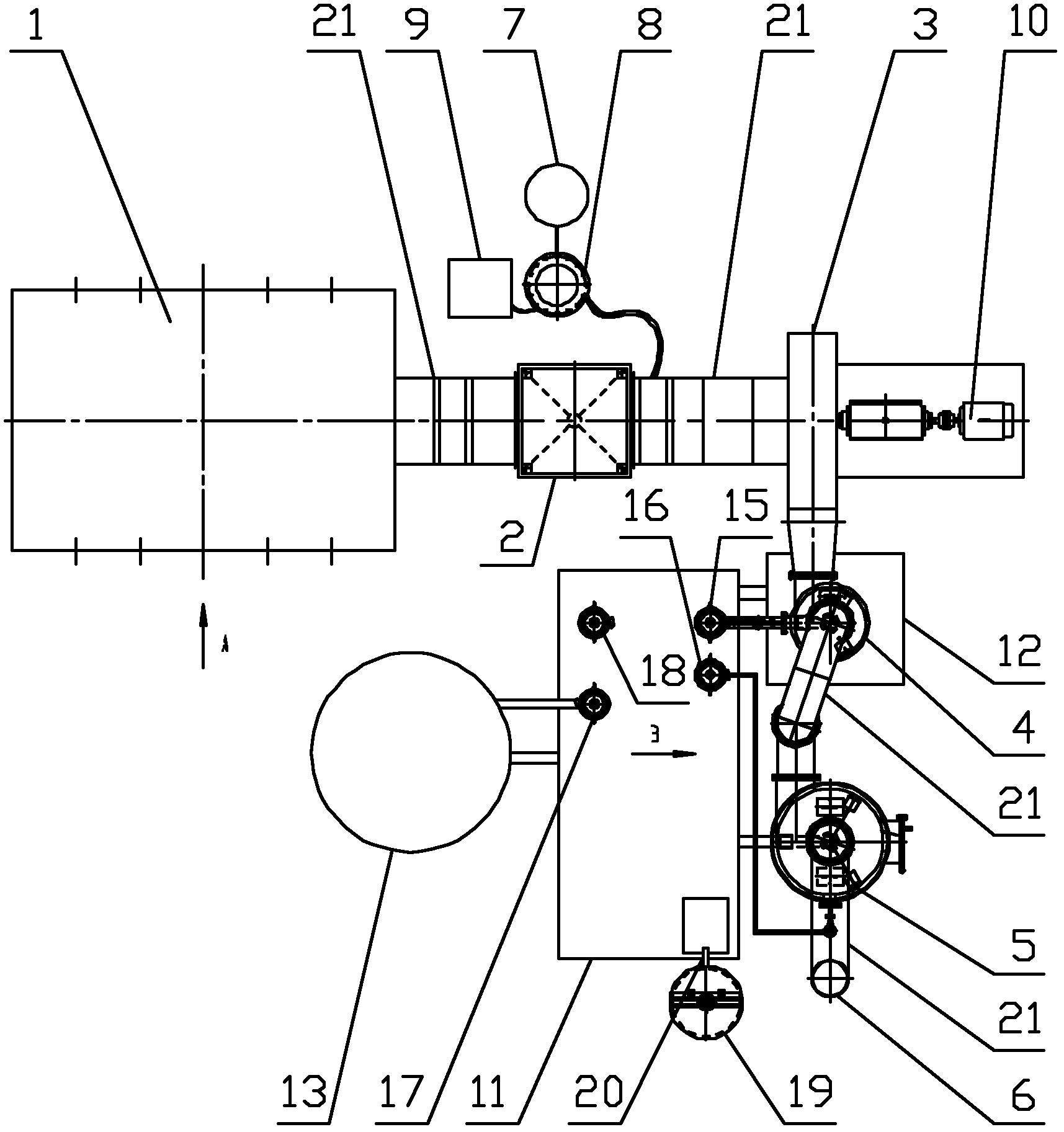

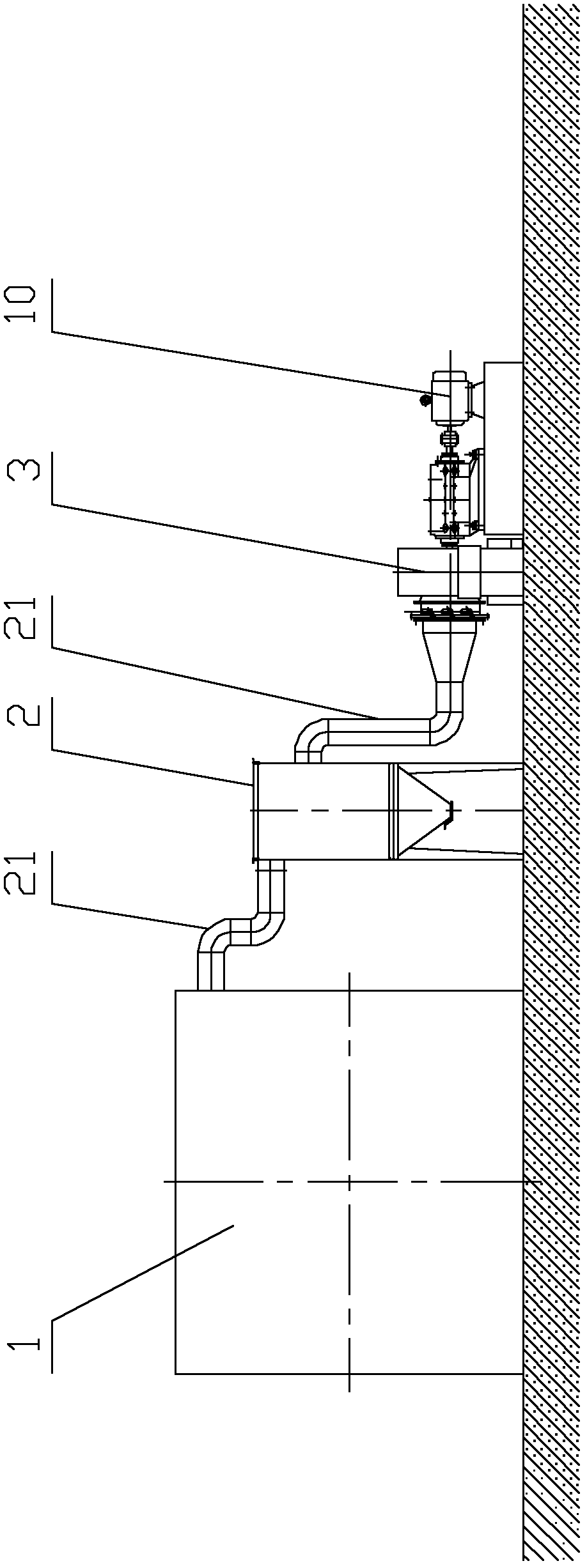

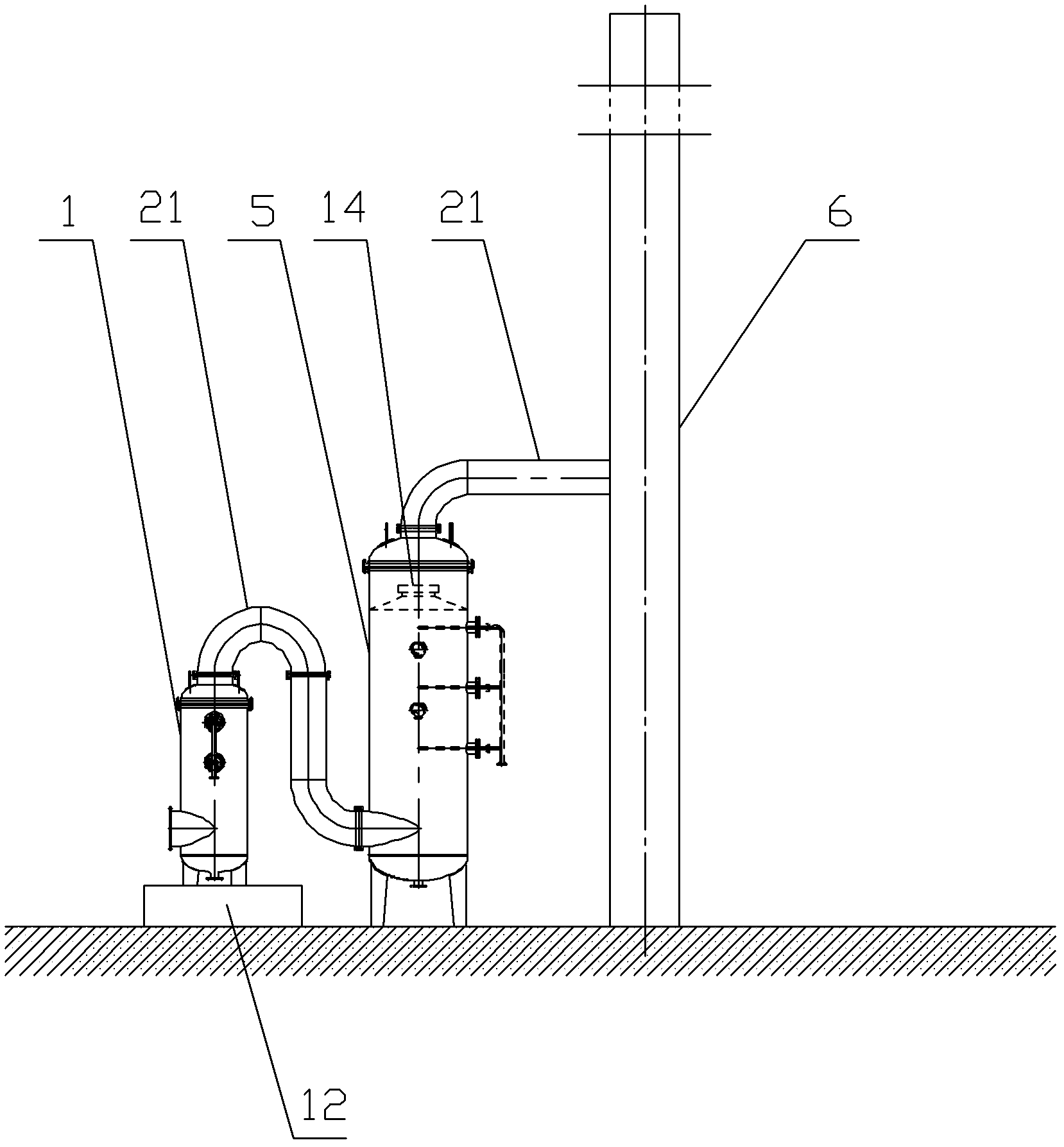

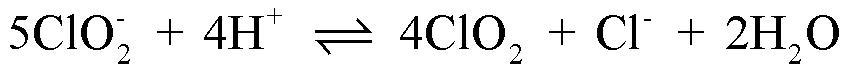

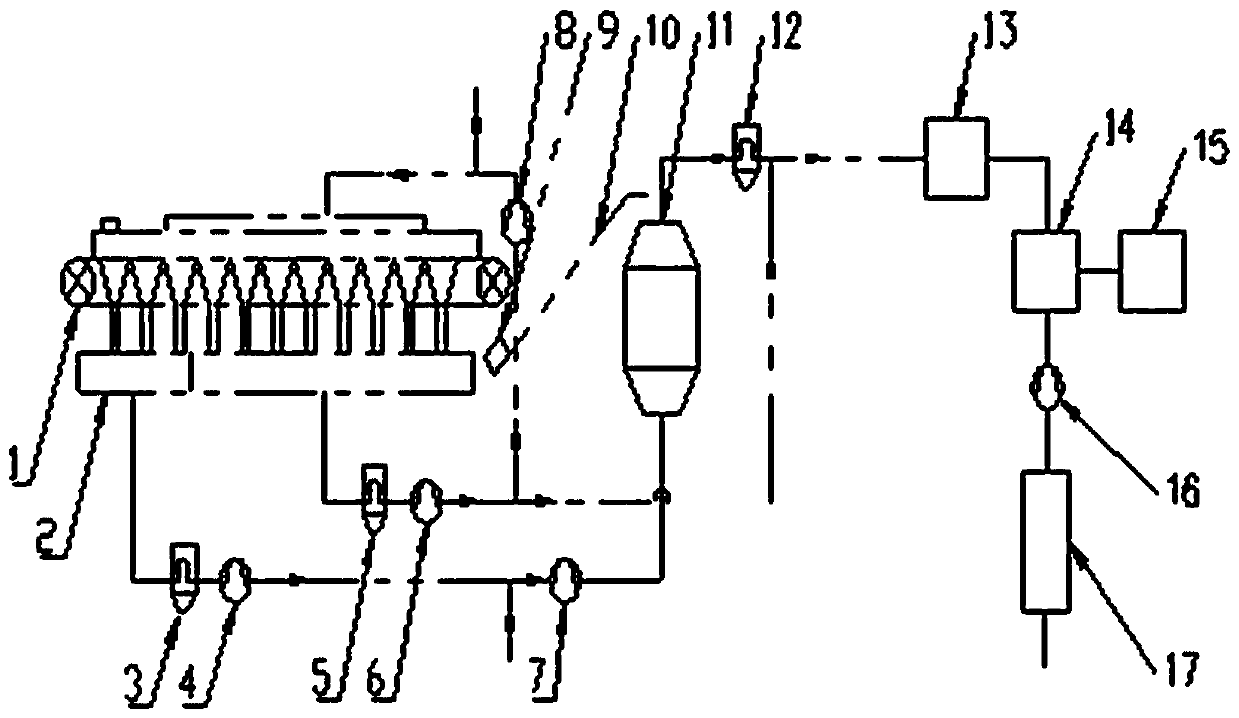

A method and device for ammonia desulfurization, denitrification and dust removal of catalytic cracking regeneration flue gas

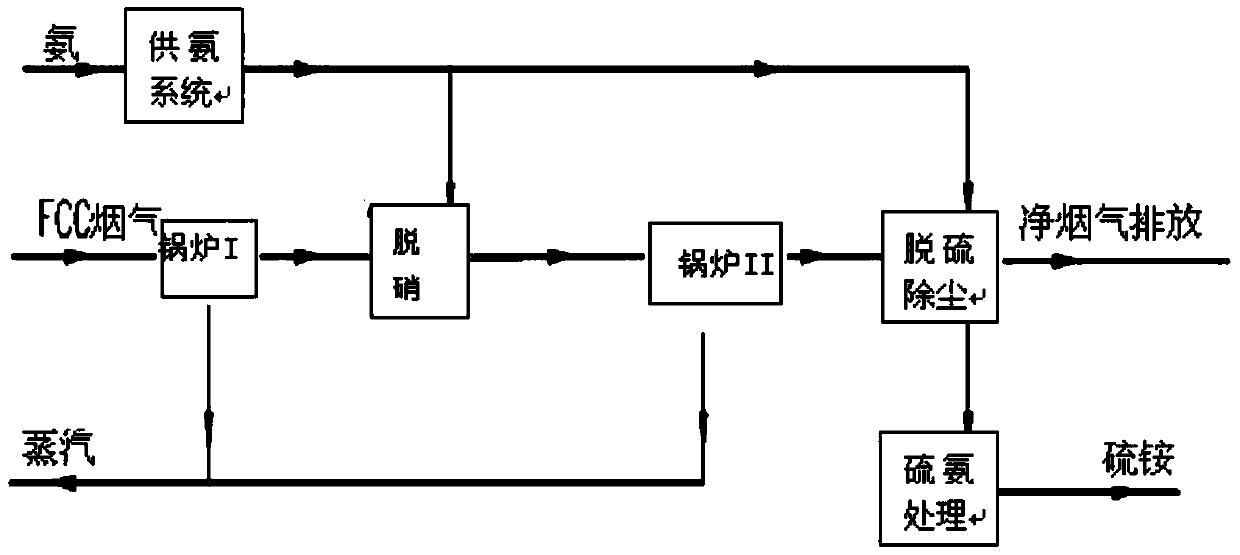

ActiveCN104941423BHigh desulfurization, denitrification and dust removal efficiencyNo waste dischargeUsing liquid separation agentEnergy inputPtru catalystDust control

The invention relates to an ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas, comprising the following steps: enabling high-temperature catalyst regeneration flue gas coming from a catalytic cracking unit and containing catalyst dust to firstly enter a waste heat boiler I, reducing the temperature of the flue gas to 280-430 DEG C, wherein the heat of the flue gas is externally supplied by steam produced by the waste heat boiler I; enabling flue gas at temperature of 280-430 DEG C to enter a denitrification device for denitrification and enter a waste heat boiler II through an outlet flue after sufficiently reacting on the surface of a denitrification catalyst in a denitrification reactor; removing sulfur dioxide, nitric oxide and byproduct ammonium sulfate by taking ammonia as a reactant, and removing catalyst dust in the regeneration flue gas to achieve clean gas up-to-standard release; the three waste free release purifying method can be applied to catalytic cracking catalyst regeneration flue gas treatment in oil refining.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

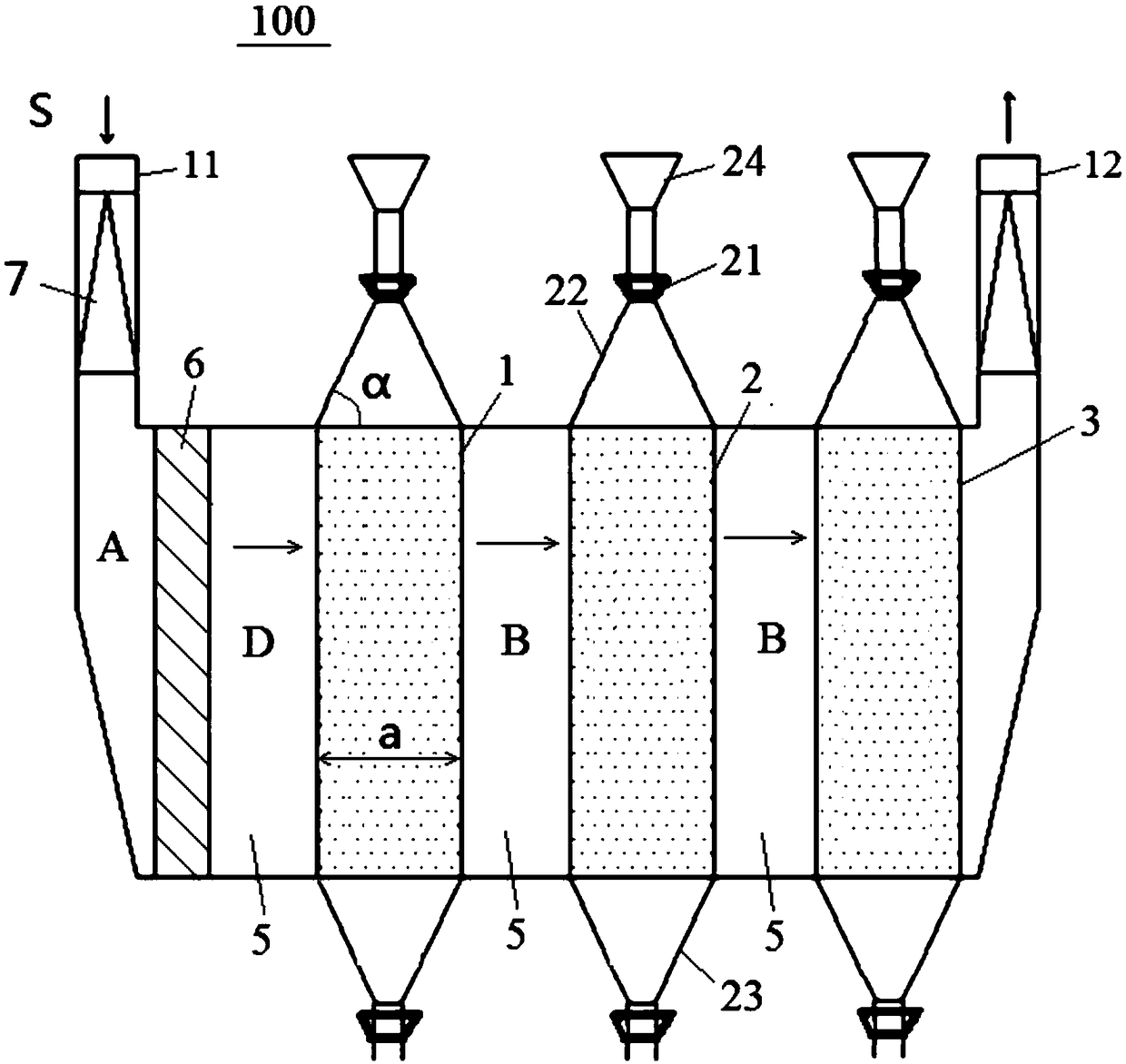

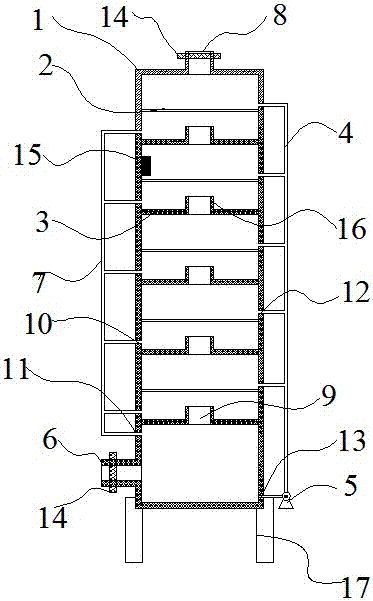

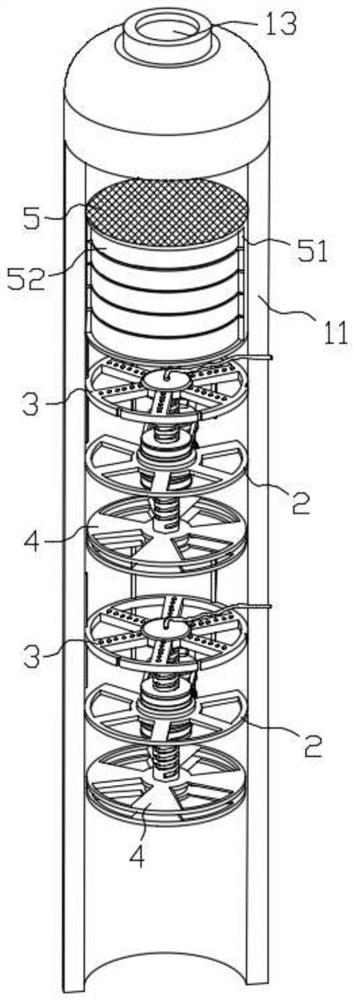

Desulfurization and denitration method by using screened-airflow shock wave suspension

InactiveCN107213768ASlow downIncrease contact timeDispersed particle separationShock waveProcess engineering

The invention discloses a desulfurization and denitration method by using a screened-airflow shock wave suspension. The method comprises the following steps: step 1, gas containing sulfides and / or nitrides are introduced to the bottom of a desulfurization and denitration device; and the interior of the desulfurization and denitration device is divided into at least two desulfurization and denitration units by partition boards in a vertical direction, each desulfurization and denitration unit is provided with an airflow distribution net, and each airflow distribution net is provided with net-shaped through holes; step 2, water or an alkaline solution is introduced to the airflow distribution net, the ratio of the water to the gas is (2-3):1000, the gas is fully absorbed by the water or the alkaline solution for reaction in a gas rising process, and the sulfides and / or the nitrides in the gas are removed; and step 3, the gas purified in the step 2 is exhausted from the top of the desulfurization and denitration device. The desulfurization and denitration method by using the screened-airflow shock wave suspension is safe, energy conservation and environmental protection are achieved, the technological process is short, and production costs are greatly saved.

Owner:郴州万墨环保科技有限公司

A kind of desulfurization and denitrification agent and its preparation method and application

ActiveCN107297144BEfficient desulfurization and denitrificationRealize low temperature desulfurization and denitrificationGas treatmentDispersed particle separationPtru catalystCalcium hypochlorite

The invention discloses a desulfuration and denitration agent which comprises the following ingredients by weight percentage: 1-15% of cyanuric acid, 1-15% of cosolvent, 1-20% of catalyst, 0-10% of chelating agent, 1-20% of stabilizer and 50-95% of water, wherein the catalyst is one or more of sodium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid, sodium dichloroisocyanurate, sodium chlorite, sodium chlorate and dibromohydantoin. The invention further discloses a method of using the desulfuration and denitration agent for desulfuration and denitration. The desulfuration and denitration agent is low in cost, and simple and easy to obtain, can achieve the efficient desulfuration and denitration at a low temperature, avoids the problem of secondary pollution caused by the denitration using gas generated by high temperature pyrolyzing, and is suitable for large-scale application.

Owner:山东大明消毒科技有限公司 +1

ozone coupled mno 2 / al 2 o 3 Catalytic oxidation of so in flue gas 2 Method for preparing sulfuric acid

ActiveCN104492424BEfficient recyclingEfficient desulfurization and denitrificationLighting and heating apparatusDispersed particle separationFlue gasCatalytic oxidation

The invention relates to the ozone low-temperature catalytic oxidation technology, and provides a method for producing sulfuric acid by catalytic oxidation of sulfur dioxide in flue gas via ozone coupling with manganese dioxide / aluminum oxide. The method includes cooling the flue gas passing through a selective catalytic reduction (SCR) reactor, injecting ozone, introducing the flue gas into a reaction tower with a desulfurizer, and performing oxidizing reaction to oxidize sulfur dioxide into sulfur trioxide, allowing the sulfur trioxide to enter into an absorption tower with the flue gas, and spray-washing the sulfur trioxide by 98.3% concentrated sulfuric acid to obtain the sulfuric acid product. The method of the invention performs catalytic oxidation of sulfur dioxide by using ozone coupling with manganese dioxide / aluminum oxide desulfurizers to produce sulfuric acid. The method of the invention has renovating significance in view of existing SCR coupling wet desulphurization devices; existing desulfurization towers can be transformed and integrated with the method, so as to achieve high-efficiency desulfurization denitration and effective sulfur resource recovery, save investment cost, and gain second income. The method of the invention can further treat organic matter and carbon monoxide while desulfurization.

Owner:ZHEJIANG UNIV

Control method for treating sulfur-containing and nitrogen-containing wastewater by using sleeve-type phase-separation anaerobic reactor for organic wastewater treatment

ActiveCN105198176BPrevent outflowCompact layoutWater contaminantsMultistage water/sewage treatmentWater qualitySmall footprint

A sleeve-type phase-separation anaerobic reactor for organic wastewater treatment and a control method for treating sulfur-containing and nitrogen-containing wastewater. The present invention relates to an anaerobic reactor for treating organic wastewater and its application method. The first-stage anaerobic reactor equipment occupies a large area and the pipeline connection is complicated. The sleeve-type phase-splitting anaerobic reactor includes an inner cylinder, an outer cylinder, a water distribution device and two three-phase separation devices. The inner cylinder and the outer cylinder are coaxially arranged, and a water distribution device is installed at the bottom of the inner cylinder. The upper part of the cylinder is equipped with a three-phase separation device, and a water outlet is opened on the wall of the inner cylinder. The coffering weir and the outer wall of the inner cylinder form a sedimentation area, and a plurality of downpipes are fixed on the bottom plate of the cofferdam. Extends to the bottom of the outer cylinder. The sleeve-type two-stage anaerobic reactor of the present invention is closely arranged, occupies a small area, and is simple in management and control, and realizes the two-stage biochemical treatment process of hydrolytic acidification and anaerobic methane production of waste water in one reactor, and improves the water output. water quality.

Owner:HARBIN INST OF TECH +1

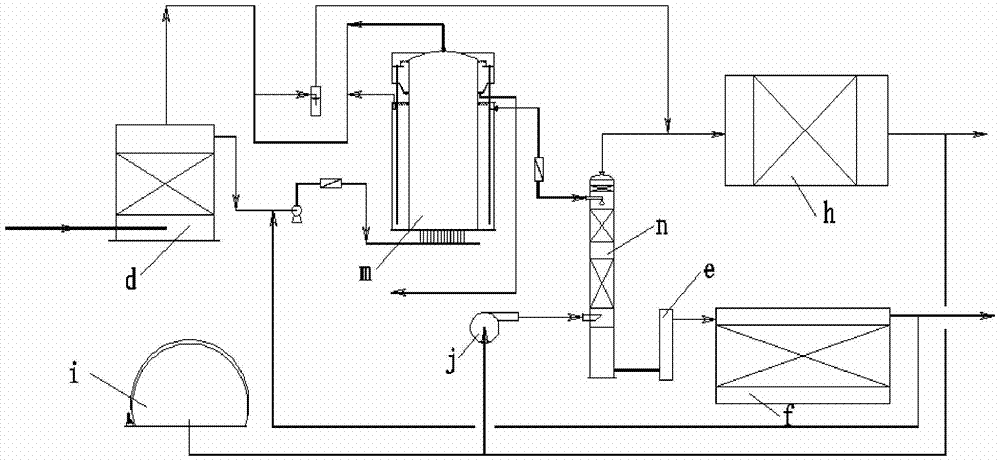

Biomass boiler denitration system

InactiveCN111992016AEfficient desulfurization and denitrificationGas treatmentDispersed particle separationFlue gasAir flow meter

The invention relates to a novel biomass boiler flue gas desulfurization and denitrification integrated system. Specifically, a flue gas desulfurization and denitrification reaction part of the systemcomprises a reactor, an air blower, a water tank, a water feeding pump and a quick lime storage tank which are connected in parallel. The circulating operation of the system depends on monitoring ofa Ca(OH)2 concentration meter, a water flow meter, an air flow meter, a thermometer and a NOx concentration meter in the reactor so as to set a proper alternate operation period, and the solid-liquidseparation device is used for separating and recycling reacted substances of the reactor which finishes the period and suspends operation, so that the economic cost is reduced while the operation lifeof a unit is prolonged. The system is assisted by a waste heat recovery device, so that the heat of the purified low-temperature flue gas is further utilized to improve the economic benefit of the equipment, and a good reference is provided for research and application of environment-friendly and efficient biomass boiler flue gas purification treatment equipment.

Owner:HARBIN UNIV OF SCI & TECH

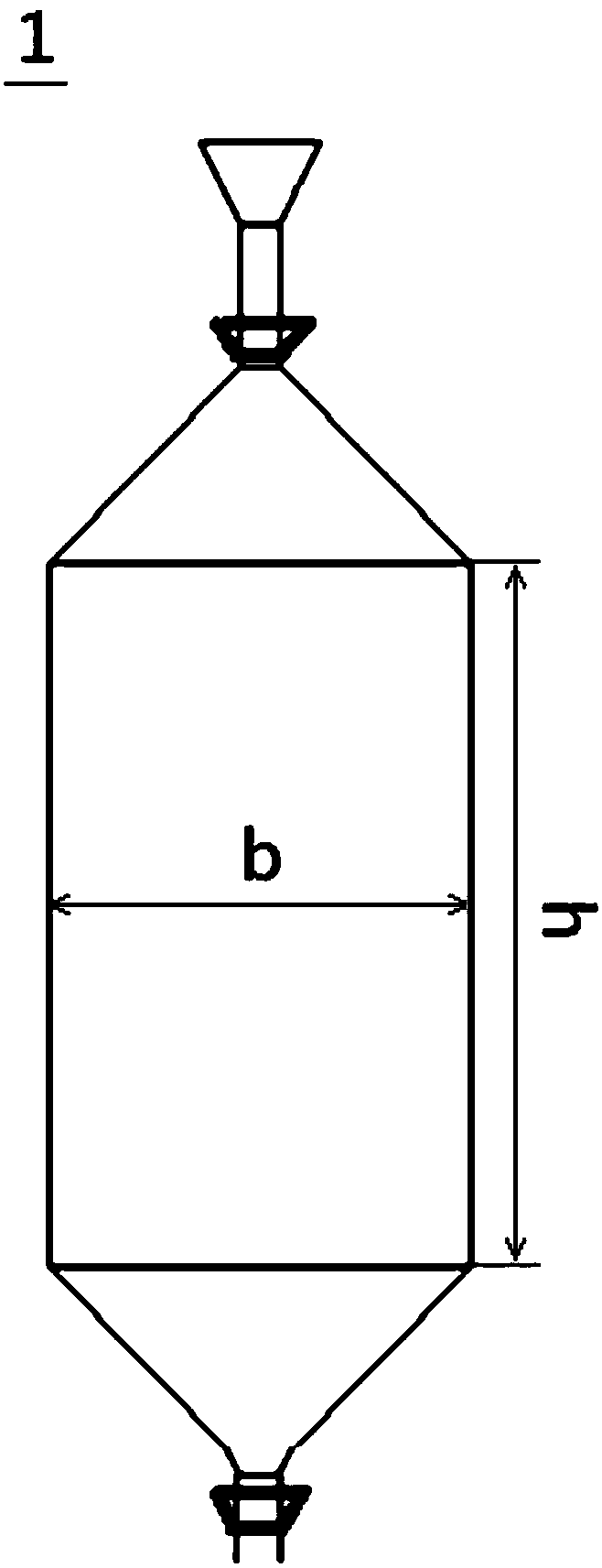

Desulfurization and denitration device by using screened-airflow shock wave suspension

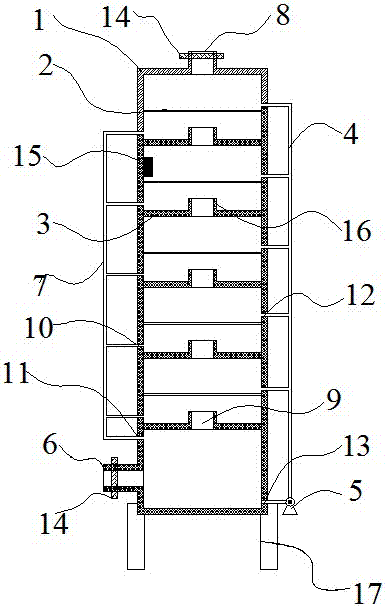

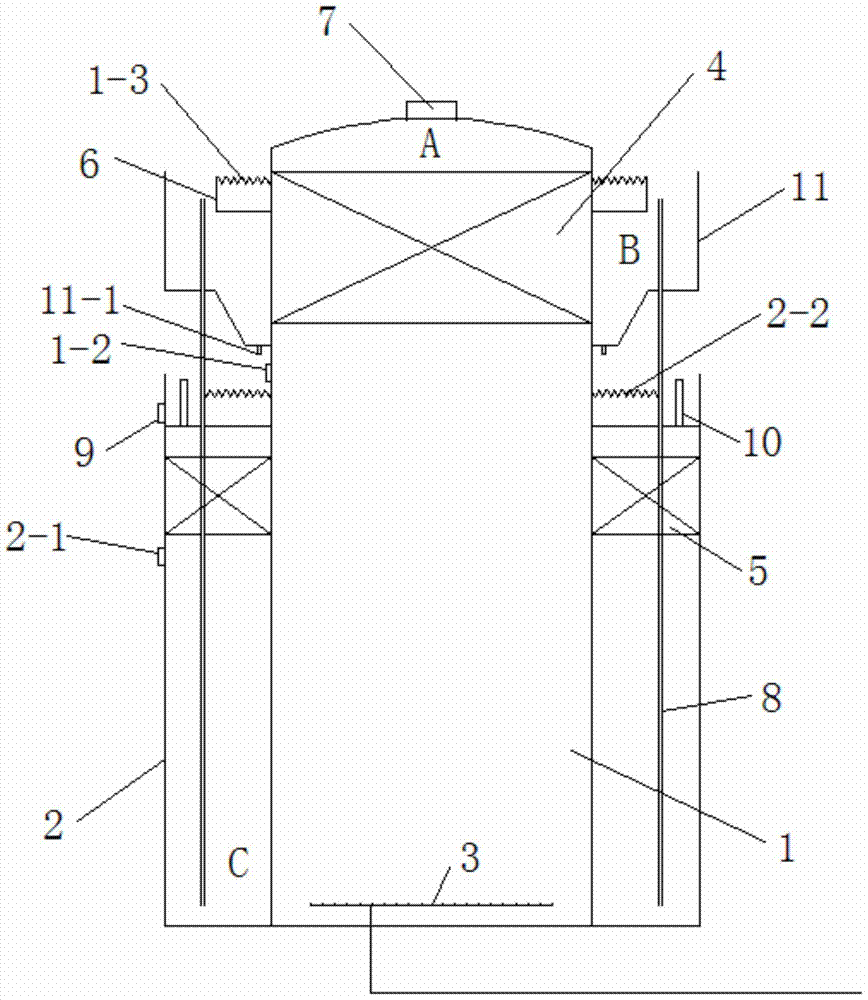

InactiveCN107213767ASlow downIncrease contact timeDispersed particle separationShock waveEngineering

The invention discloses a desulfurization and denitration device by using a screened-airflow shock wave suspension. The device comprises a container body, the upper part of the container body is provided with a gas outlet, and the lower part of the container body is provided with a gas inlet. The device is characterized in that, the interior of the container body is provided with two or more stages of desulfurization and denitration units, the container body is disposed on a support, the desulfurization and the denitration units are successively disposed in the interior of the container body, and each desulfurization and denitration unit comprises a liquid-collecting board and an airflow distribution net. The desulfurization and denitration device by using the screened-airflow shock wave suspension has the advantages of saving energy and protecting environment, the technological process is short, the land occupation area is small, the industrial automation is easy to realize, the production is safe, and production costs are greatly saved.

Owner:郴州万墨环保科技有限公司

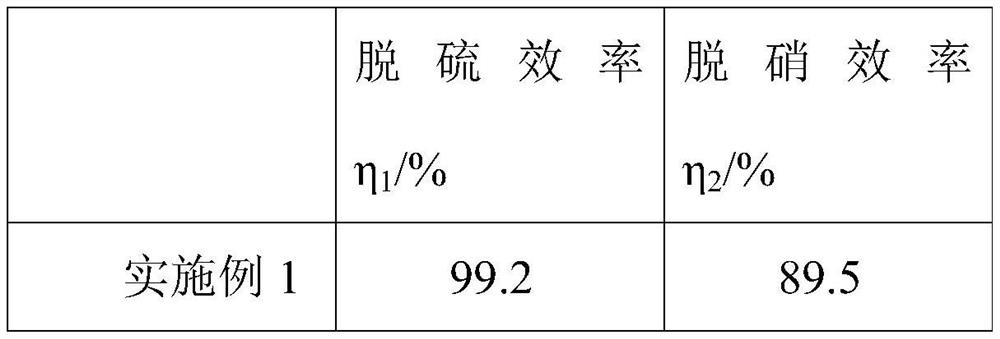

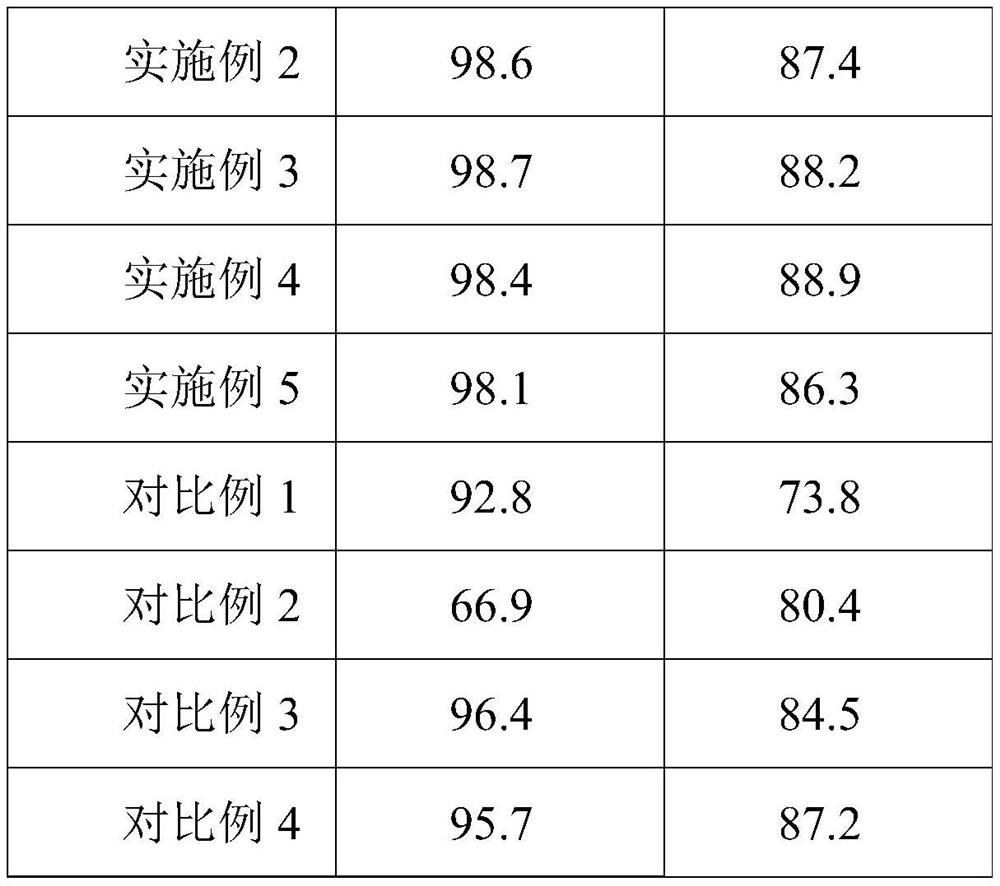

Solid waste incineration flue gas desulfurization and denitrification process

ActiveCN113828100AImprove adsorption capacityInhibition of adsorptionGas treatmentOther chemical processesFlue gasSorbent

The invention relates to the technical field of gas purification, and in particular, relates to a solid waste incineration flue gas desulfurization and denitrification process, wherein the process comprises the steps: cooling high-temperature flue gas generated by solid waste incineration, spraying alkali liquor, introducing the treated flue gas into desulfurization and denitrification equipment, filling desulfurization and denitrification equipment with a pre-activated adsorbent, and demisting the flue gas treated by the adsorbent to obtain purified flue gas. Tests show that the solid waste incineration flue gas desulfurization and denitrification process can greatly reduce sulfur-containing and nitrate-containing gases in the flue gas generated by solid waste incineration, and has excellent purification efficiency, the desulfurization efficiency is greater than or equal to 98%, and the denitrification efficiency is greater than or equal to 86%.

Owner:江苏东本环保工程有限公司

System and technology for cleaning flue gas

ActiveCN102847430BAvoid secondary pollutionInnovative designDispersed particle separationAir quality improvementChemical industryNitrogen oxides

The invention relates to a technology for cleaning flue gas. The system comprises a raw flue gas input pipe, an absorption tower and a clean flue gas discharge device, wherein the raw flue gas input pipe, the absorption tower and the clean flue gas discharge device are connected. The system also comprises an oxidation device connected to the raw flue gas input pipe, an absorbent feeding device and an absorption liquid regenerating and recovery device, wherein the absorbent feeding device and the absorption liquid regenerating are connected to the absorption tower. A slurry tank, an absorbent spraying layer and a demister layer are arranged in the absorption tower from bottom to top. The technology adopts a sodium-based absorbent to realize removal of nitrogen and sulphur pollutants in flue gas at a low temperature or a normal temperature. The system has a novel design and the technology has simple and environmentally friendly processes, realizes recycling integrated purification treatment on flue gas, realizes synchronous efficient desulfuration and denitration by the same process route, avoids secondary pollution on the environment in full recovery and treatment on later-stage products, is conducive to reduction of an economic cost, and is suitable for purification treatment on flue gas or industrial tail gas produced by a metallurgical chemical industry and a coal-fired power generation industry mainly discharging sulfur and nitrogen oxides as pollutants.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

Three-stage flue gas low-temperature combined desulfurization and denitrification system and method thereof

PendingCN112569764AImprove NO adsorption performanceFeatures to improve desulfurization performanceGas treatmentDispersed particle separationFlue gasEnvironmental engineering

The invention relates to a three-stage flue gas low-temperature combined desulfurization and denitrification system and a method thereof, one end of a desulfurization reactor is communicated with a flue gas cooler, and the other end of the desulfurization reactor is sequentially communicated with a demister, a carbon-based adsorbent pretreatment reactor, a flue gas reheater and a denitrification reactor in the flue gas inflow direction. According to the three-stage flue gas low-temperature combined desulfurization and denitrification system and method provided by the invention, flue gas is subjected to graded synergistic desulfurization and denitrification after being cooled, so that the problem of high-temperature ignition is avoided, the NO adsorption performance of a carbon-based adsorbent is improved, the desulfurization effect of the carbon-based adsorbent is greatly improved, and the SO2 removal efficiency in the first-stage reactor reaches 99% or above; the adverse effect of SO2on NO removal in the downstream reactor is avoided, the risk that the generated NH4HSO4 blocks the surface pores of the carbon-based adsorbent is reduced, the NO removal rate in the third-stage reactor achieves more than 90%, the efficient desulfurization and denitrification is achieved while the partial pollutants such as heavy metals, VOCs and the like can be synergistically removed, the structure is simple, and the application prospect is broad.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

A method for microwave coupled ultraviolet photocatalytic oxidative desulfurization and denitrification

ActiveCN110385038BFast and efficient oxidation removalUnique methodDispersed particle separationNitrate fertilisersPhotocatalytic reactionUltraviolet lights

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

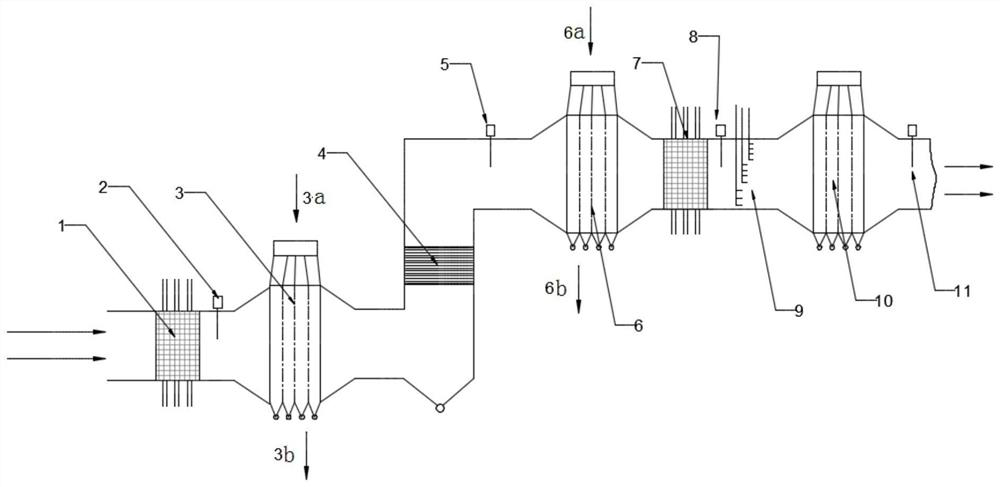

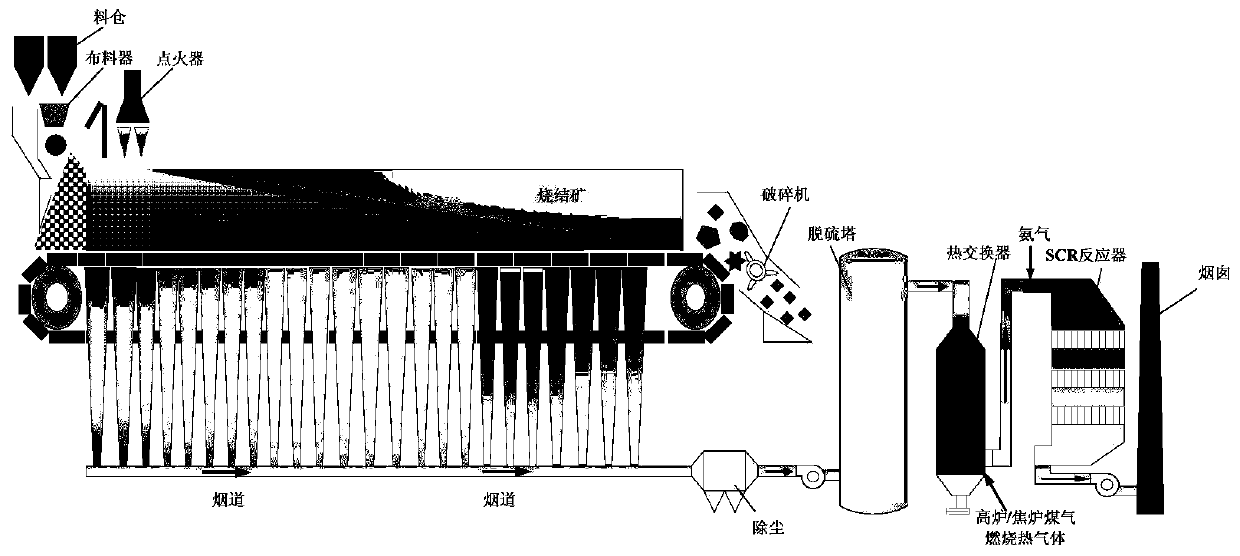

Integrated system for sintering ore cooling and sintering flue gas waste heat power generation, desulfurization and denitration

PendingCN109883208ALow running costLow investment costIncreasing energy efficiencyHandling discharged materialFlue gasAir blower

The invention discloses an integrated system for sintering ore cooling and sintering flue gas waste heat power generation, desulfurization and denitration, and relates to sintering ore cooling and sintering sensible heat recovery technology. The integrated system for sintering ore cooling and sintering flue gas waste heat power generation, desulfurization and denitration comprises a sintering machine, a vertical cooling kiln, a multi-tube dust collector II, an SCR denitration reactor, a waste heat boiler, an induced draft fan and a desulfurization tower, wherein the vertical cooling kiln, themulti-tube dust collector II, the SCR denitration reactor, the waste heat boiler, the induced draft fan and the desulfurization tower are connected in sequence. An inclined windlass with a trolley isarranged between the sintering machine and the vertical cooling kiln. A high-temperature steam outlet of the waste heat boiler is connected to a generator set. A separation air box is arranged below the sintering machine, and a low-temperature flue gas outlet of the separation air box is sequentially connected to the bottom of the vertical cooling kiln through a multi-tube dust collector I, an exhaust fan I and an air blower; a sub-low temperature flue gas outlet of the separation air box is divided into two paths after passing through an electric dust collector and an exhaust fan II in sequence, one of the two paths is connected to an air outlet of the multi-tube dust collector II, and the other path returns to the material surface at the top of the sintering machine through a circulatingfan. According to the integrated system for sintering ore cooling and sintering flue gas waste heat power generation, desulfurization and denitration, a sintering ore closed cooling process is adopted, the temperature of hot air is increased, and sintering flue gas is simultaneously subjected to high-efficiency desulfurization and denitration, so that high-efficiency recycling of sensible heat ofthe sintering ore is achieved.

Owner:TONGFANG ENVIRONMENT +1

Flue gas two-stage segmented desulfurization and denitrification system and method

PendingCN113975956AOvercome the technical problems of low temperature denitrificationEfficient desulfurization and denitrificationGas treatmentCalcium/strontium/barium sulfatesAtmospheric pollutionDenitrification

The invention discloses a flue gas two-stage segmented desulfurization and denitrification system and method, and belongs to the technical field of air pollution control. NO and SO2 in the flue gas are oxidized into NO2 and SO3 through sodium chlorite, the NO2 and SO3 are absorbed and converted into magnesium nitrate and magnesium sulfate solutions through magnesium hydroxide, the oxidation absorption process is ordered and crossed in a graded and segmented manner, and the purpose of efficient desulfurization and denitrification is achieved. By means of flue gas waste heat evaporation and purified flue gas desulfurization and denitrification liquid escape washing gas recovery, a closed-loop circulation system without solid waste and wastewater discharge and with system water balance is realized on the premise of flue gas ultra-clean discharge, and desulfurization science is combined on the basis of overcoming the technical problem of flue gas low-temperature denitrification, so that desulfurization and denitrification complement each other, and the method has great guiding significance in treating low-temperature desulfurization and denitrification flue gas.

Owner:邢台润天环保科技有限公司

A flue gas purification equipment and purification method for desulfurization and denitrification of industrial naphthalene waste gas

ActiveCN111871174BStable desulfurization and denitrification effectImprove desulfurization effectGas treatmentDispersed particle separationPurification methodsFlue gas

The invention discloses a flue gas purification equipment and purification method for industrial naphthalene waste gas desulfurization and denitrification, comprising: a combined tower body surrounded by multiple groups of branch towers, and multiple groups of water distribution rotations are arranged at equal intervals in the middle and lower parts of the branch towers device; the upper part of the support tower is equipped with a packing assembly; the reaction liquid warehouse is located at the bottom of the center of the combined tower body, and the reaction liquid warehouse is connected to each spray plate through the delivery liquid pump and hose; the top center of the reaction liquid warehouse is provided with a drive The motor, the connecting rod driving the output shaft of the motor is connected to the corresponding water distribution rotating device through each drive assembly; the exhaust chamber located on the top of the combined tower body is connected to the top of each support tower; the ring structure of the dust removal ring warehouse is sleeved on the combined tower The outer periphery of the lower end of the body communicates with the air inlets of each branch tower. The invention can carry out regular inspection and maintenance on the combined tower body or alternately replace the fillers in each branch tower, so that the combined tower body can maintain a stable desulfurization and denitrification effect under continuous operation.

Owner:江苏乾宏环保科技有限公司

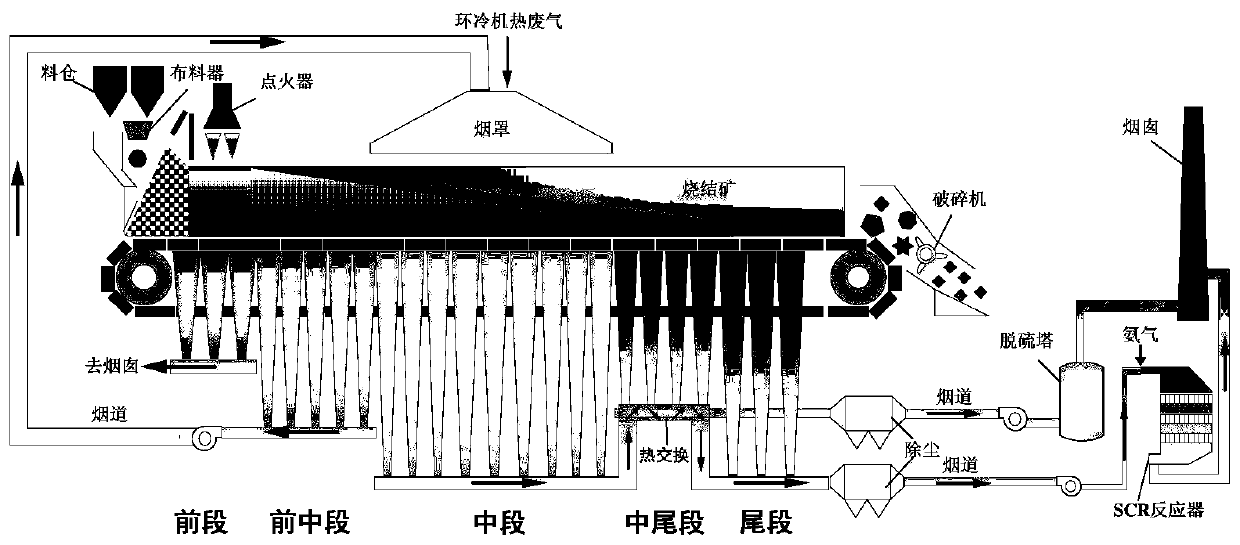

A method for concentrated and efficient desulfurization and denitrification of sintering flue gas

ActiveCN107930396BReduce processingMeet the temperature requirements for efficient denitrificationGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses a concentrated efficient desulfurization and denitration method for the sintering flue gas. The flue gas of a sintering machine is sequentially divided into five parts of a front section, a front middle section, a middle section, a middle tail section and a tail section from the feeding end to the discharging end, the flue gas in the front middle section is recycled, NOx isemitted to the flue gas in the middle section of the sintering machine in a concentrated manner, the high-NOx flue gas in the middle section and the flue gas in the middle tail section exchange heatthrough a heat exchanger and join with the high-temperature flue gas in the tail section, the temperature of the flue gas is higher than 250 DEG C, and the requirement of the SCR denitration is met. The heat-exchanged high-SOx flue gas in the middle tail section of the sintering machine is desulfurized. The desulfurized flue gas and the denitrated flue gas are combined with the flue gas in the front section of the sintering machine, and are emitted through a chimney. According to the method, the SOx and the NOx are enriched in a specific area and are desulfurized and denitrated in a concentrated manner, so that the handling capacity of the flue gas is greatly reduced, and the treatment cost of pollutants is lowered.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com