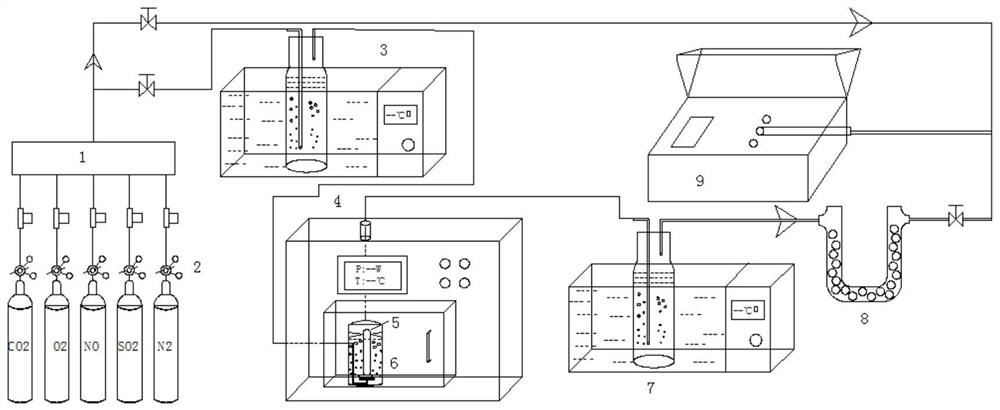

A method for microwave coupled ultraviolet photocatalytic oxidative desulfurization and denitrification

A technology of catalytic oxidation desulfurization and ultraviolet light, which is applied in the field of flue gas purification, can solve the problems of high cost, large floor area, and large energy consumption, and achieve good environmental and economic benefits, low infrastructure and operating costs, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

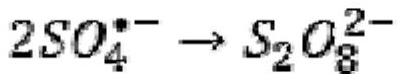

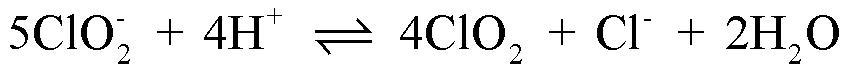

[0080] Liquid-phase composite oxidant: the concentration ratio of sodium chlorite and sodium persulfate is 0.1:10%wt, and the pH is 4.5.

[0081] Absorbent: Sodium sulfite concentration 5%wt, pH 9.

[0082] The reaction conditions of the microwave-coupled ultraviolet photocatalytic oxidation desulfurization and denitrification system are shown in Table 2.

[0083] Table 2 Reaction Conditions

[0084] condition scope microwave set temperature 50℃ Microwave set power 300W Photocatalyst reactor energy density 300KW / m 3

[0085] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 97%, and the denitrification efficiency reaches 86%.

Embodiment 2

[0087] Liquid-phase composite oxidant: the concentration ratio of sodium chlorite and sodium persulfate is 0.1:5%wt, and the pH is 4.5.

[0088] Absorbent: Sodium sulfite concentration 5%wt, pH 9.

[0089] The reaction conditions of the microwave-coupled ultraviolet photocatalytic oxidation desulfurization and denitrification system are shown in Table 3.

[0090] Table 3 reaction conditions

[0091] condition scope microwave set temperature 90℃ Microwave set power 300W Photocatalyst reactor energy density 300KW / m 3

[0092] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, and the denitrification efficiency reaches 83%.

Embodiment 3

[0094] Liquid-phase composite oxidant: the concentration ratio of sodium chlorite and sodium persulfate is 0.05:10%wt, and the pH is 5.

[0095] Absorbent: Sodium sulfite concentration 5%wt, pH 9.

[0096] The reaction conditions of the microwave-coupled ultraviolet photocatalytic oxidation desulfurization and denitrification system are shown in Table 4.

[0097] Table 4 reaction conditions

[0098] condition scope microwave set temperature 70℃ Microwave set power 300W Photocatalyst reactor energy density 300KW / m 3

[0099] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, and the denitrification efficiency reaches 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com