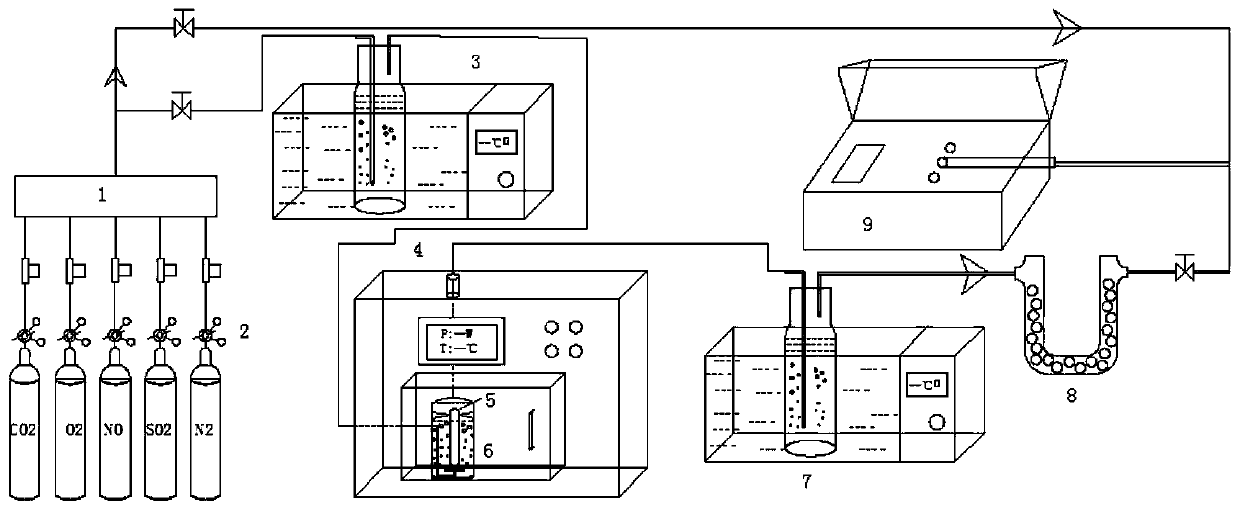

Flue gas purification method combining photocatalytic oxidation with double-cycle absorption

A technology of catalytic oxidation desulfurization and photocatalytic reactor, which is applied in the field of microwave-coupled ultraviolet photocatalytic oxidation desulfurization and denitrification, can solve the problems of high energy consumption, large floor area, large energy consumption, etc., and achieve reduced floor space and easy operation , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Liquid-phase composite oxidant: the concentration ratio of sodium chlorite and sodium persulfate is 0.1:10% wt, and the pH is 4.5.

[0081] Absorbent: sodium sulfite concentration of 5% wt, pH of 9.

[0082] The reaction conditions of the microwave-coupled ultraviolet photocatalytic oxidative desulfurization and denitrification system are shown in Table 2.

[0083] Table 2 Reaction conditions

[0084]

[0085]

[0086] Purify the flue gas according to the above conditions, and it is detected that the desulfurization efficiency reaches 97%, and the denitration efficiency reaches 86%.

Embodiment 2

[0088] Liquid-phase composite oxidant: the concentration ratio of sodium chlorite and sodium persulfate is 0.1:5%wt, and the pH is 4.5.

[0089] Absorbent: sodium sulfite concentration of 5% wt, pH of 9.

[0090] The reaction conditions of the microwave-coupled ultraviolet photocatalytic oxidative desulfurization and denitrification system are shown in Table 3.

[0091] Table 3 Reaction conditions

[0092] condition scope microwave set temperature 90℃ Microwave set power 300W Photocatalyst reactor energy density 300KW / m 3

[0093] Purify the flue gas according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, and the denitration efficiency reaches 83%.

Embodiment 3

[0095] Liquid-phase composite oxidant: the concentration ratio of sodium chlorite and sodium persulfate is 0.05:10% wt, and the pH is 5.

[0096] Absorbent: sodium sulfite concentration of 5% wt, pH of 9.

[0097] The reaction conditions of the microwave-coupled ultraviolet photocatalytic oxidative desulfurization and denitrification system are shown in Table 4.

[0098] Table 4 Reaction conditions

[0099]

[0100]

[0101]Purify the flue gas according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, and the denitration efficiency reaches 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com