Method of for desulfurization by wet oxidation of hydrogen sulfide at medium-high temperature

A technology of wet oxidation and hydrogen sulfide, applied in the direction of catalytic conversion gas purification of impurities, etc., can solve the problems of difficult regeneration of desulfurizer, difficult recovery of sulfur from desulfurization products, reduction of catalyst activity concentration, etc., so as to avoid waste of sensible heat and latent heat. , Fast and efficient oxidation removal, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

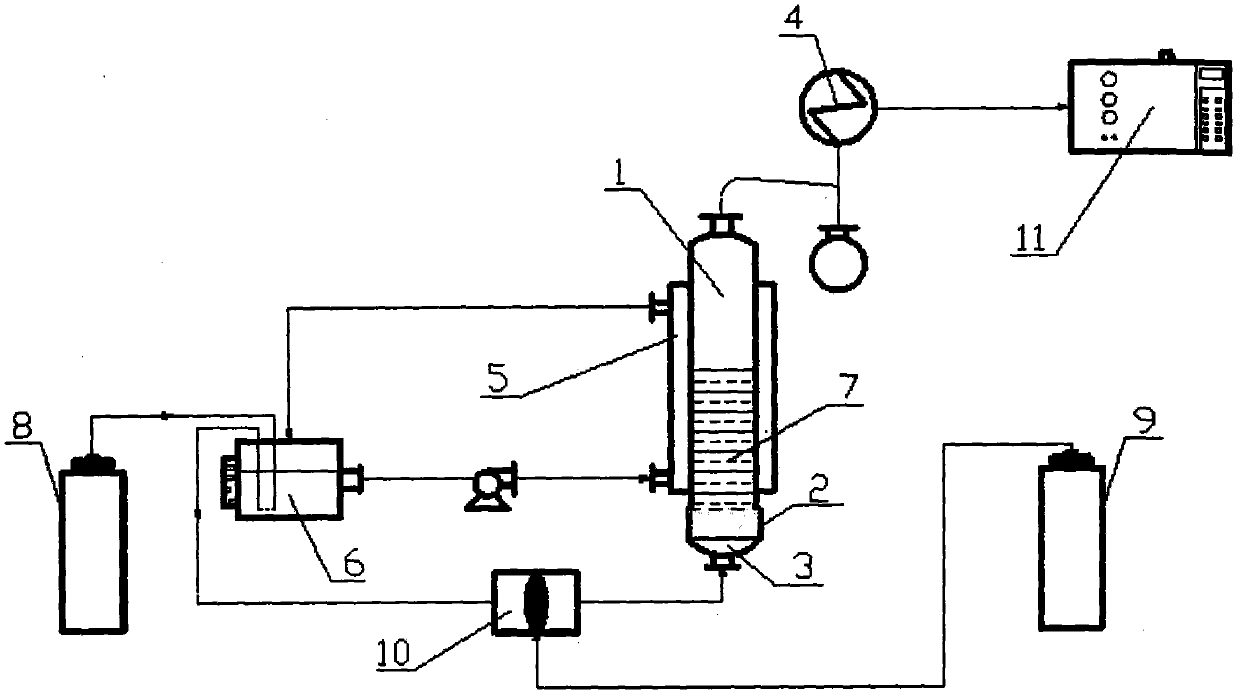

Method used

Image

Examples

Embodiment 1

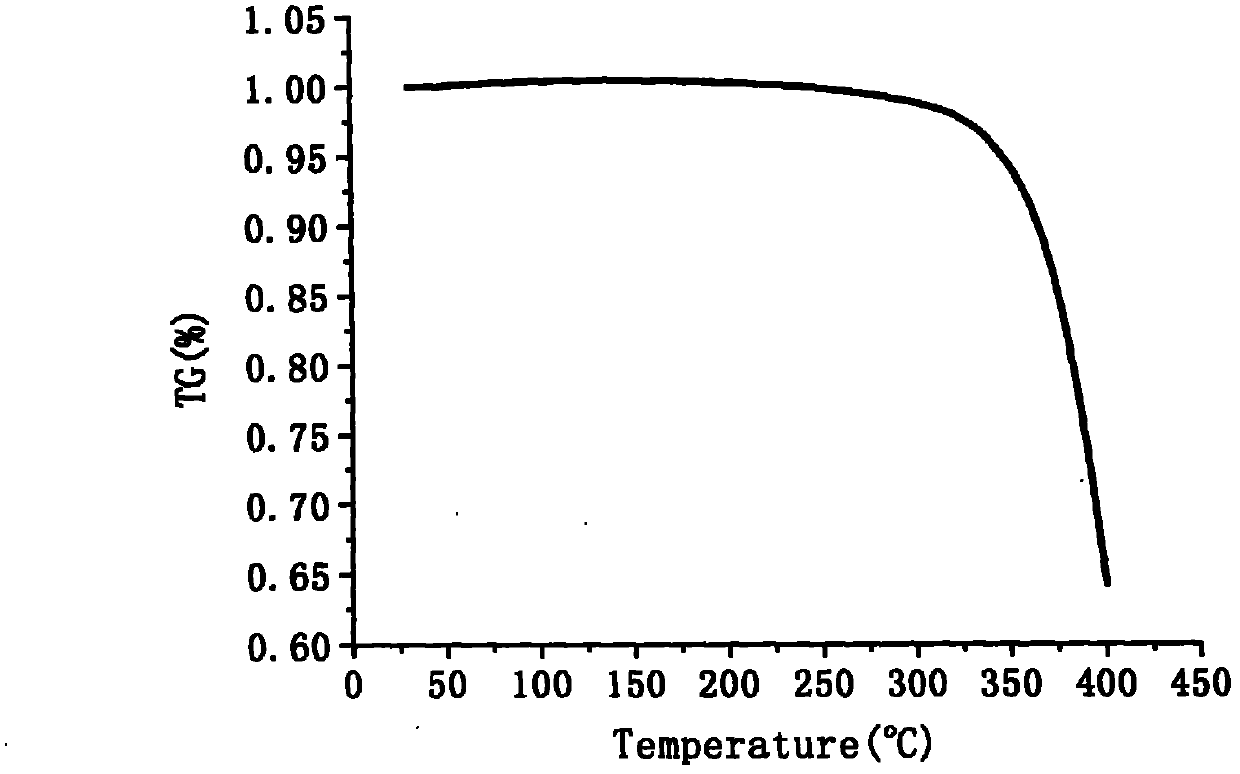

[0032] With 1-butyl-3-methylimidazole chloride (BmimCl) and ferric chloride hexahydrate (FeCl 3 ·6H 2 O) is the synthesis of iron-based ionic liquid for raw materials with a molar ratio of 1:2. figure 2 It is the thermogravimetric analysis result of the iron-based ionic liquid between 30°C and 400°C. The iron-based ionic liquid has almost no weight loss at 30°C-250°C, and the weight loss is only about 0.2% at 300°C, which has good thermal stability.

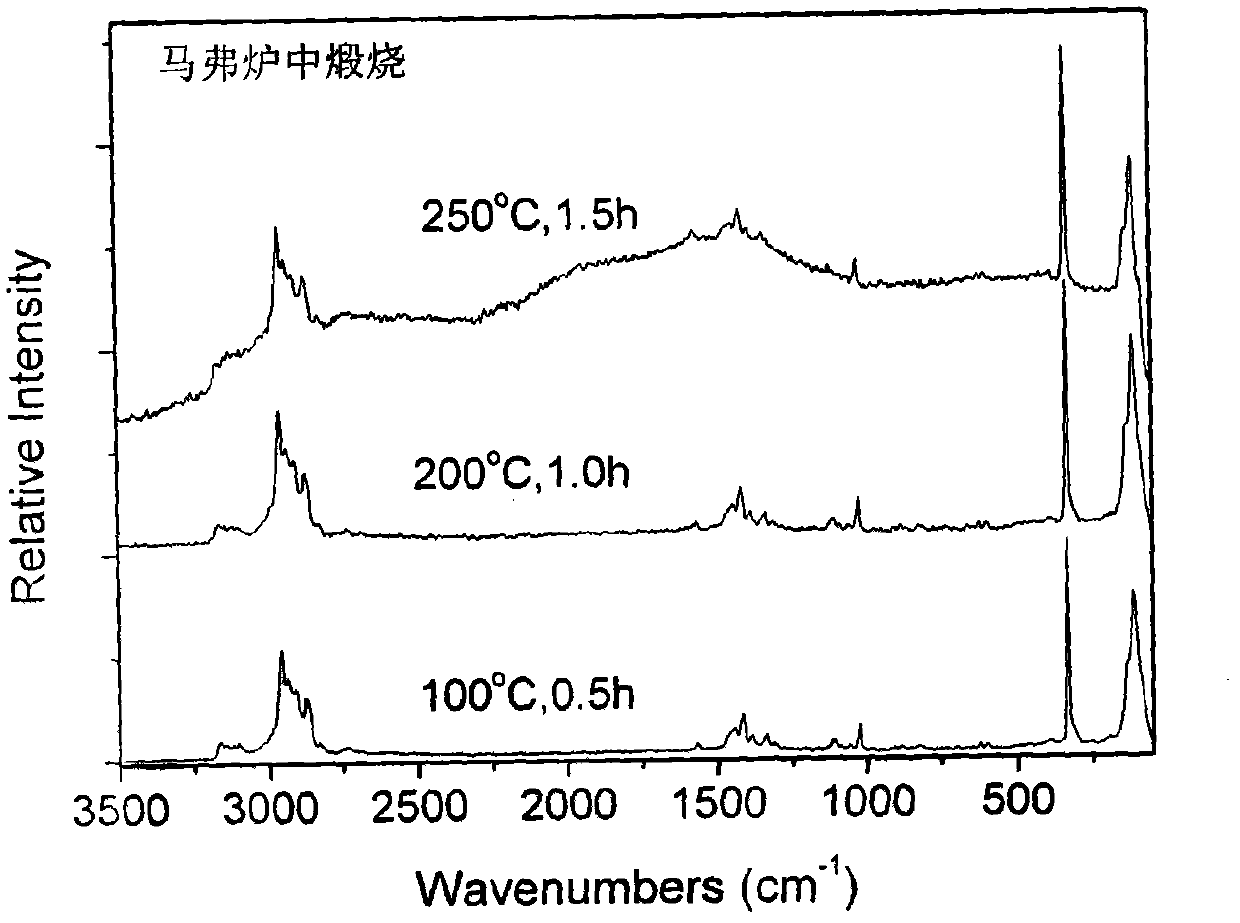

[0033] Take a little sample in a crucible and put it in a muffle furnace, and calcine it at a certain temperature. Depend on image 3 It can be seen that after being treated in a muffle furnace at 200 °C for 1 h, there is no difference between the imidazolium chloride-based ionic liquid and the sample at 100 °C. The baseline drifted, which was the same as the variable temperature Raman spectrum at 240°C. At this time, the fluidity of the imidazolium chloride-based ionic liquid became worse, indicating that the physical prope...

Embodiment 2

[0035] Add 200mL of the iron-based ionic liquid in Example 1 to the reactor, control the reaction temperature by the oil bath, and pass the hydrogen sulfide standard gas with a concentration of 10000ppm into the desulfurizer at a flow rate of 120mL / min. Figure 4 It shows that when the temperature is not lower than 120°C, the desulfurization rate of the iron-based ionic liquid is all above 99% within 2 hours, and the desulfurization efficiency can be significantly improved by increasing the temperature.

Embodiment 3

[0037] Add 200mL of the iron-based ionic liquid in Example 1 to the reactor, adjust the reaction temperature to 140°C with an oil bath, and pass hydrogen sulfide standard gas into the desulfurizer at a flow rate of 120mL / min. Figure 5 It shows that when the concentration of hydrogen sulfide is 10000ppm, the removal rate of hydrogen sulfide can reach 100% within 2 hours of reaction time; as the concentration of hydrogen sulfide gradually increases to 50000ppm, the desulfurization rate finally decreases to 74.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com