Efficient desulfurization and denitration absorbing agent and preparation method thereof

A technology for desulfurization and denitrification and absorbent, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of complex preparation process of desulfurization and denitrification absorbent, low desulfurization and denitrification efficiency, and high process consumption, so as to ensure desulfurization and denitrification Efficiency, uniform shape, mature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

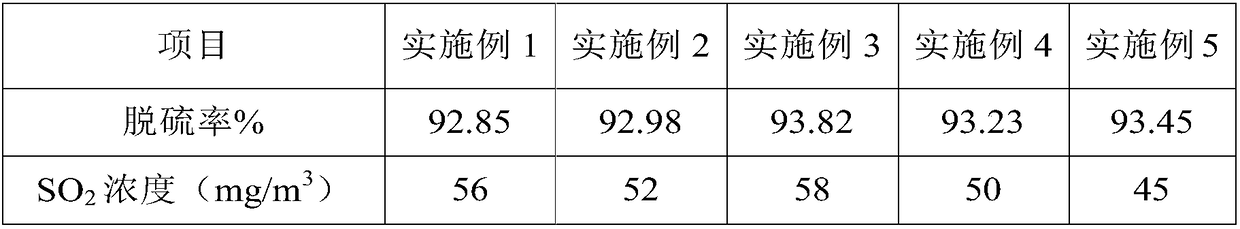

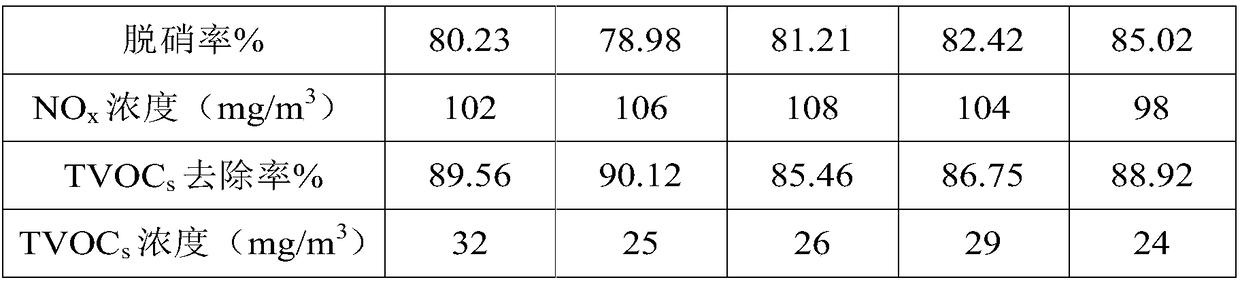

Examples

Embodiment 1

[0030] A high-efficiency desulfurization and denitrification absorbent

[0031] Raw material and ingredient composition: (unit: g)

[0032] The raw materials for preparing the high-efficiency desulfurization and denitrification absorbent consist of the following parts by weight: 50 g of ammonium sulfate, 20 g of urea, 20 g of alum, 12 g of magnesium hydroxide, 30 g of complexing agent, 10 g of borax, and 45 g of forming solution.

[0033] Among the above raw materials, the complexing agent is a combination of dimercaptopropanol and polyacrylic acid with a mass ratio of 2:3; the forming solution is a tetramethylammonium hydroxide solution with a mass fraction of 3%, and phosphoric acid with a mass fraction of 1.0% Sodium hydrogen disodium solution, the mass ratio of the two is 5:1.

[0034] The preparation method of the above-mentioned high-efficiency desulfurization and denitrification absorbent comprises the following steps:

[0035] S10, mix the complexing agent and deioni...

Embodiment 2

[0039] A high-efficiency desulfurization and denitrification absorbent

[0040] Raw material and ingredient composition: (unit: g)

[0041] The raw materials for preparing the high-efficiency desulfurization and denitrification absorbent consist of the following parts by weight: 150g of ammonium sulfate, 60g of urea, 100g of alum, 26g of magnesium hydroxide, 45g of complexing agent, 20g of borax, and 65g of forming solution.

[0042] Among the above raw materials, the complexing agent is a combination of sodium ethylenediamine tetramethylene phosphate and sulfosalicylic acid with a mass ratio of 1:5; the forming solution is a tetramethylammonium hydroxide solution with a mass fraction of 5%. It includes disodium hydrogen phosphate solution with a mass fraction of 1.2%, and the mass ratio of the two is 5:1.

[0043] The preparation method of the above-mentioned high-efficiency desulfurization and denitrification absorbent comprises the following steps:

[0044] S10, mix the com...

Embodiment 3

[0048] A high-efficiency desulfurization and denitrification absorbent

[0049] Raw material and ingredient composition: (unit: g)

[0050] The raw materials for preparing the high-efficiency desulfurization and denitrification absorbent consist of the following parts by weight: 80g of ammonium sulfate, 30g of urea, 30g of alum, 16g of magnesium hydroxide, 36g of complexing agent, 12g of borax and 55g of forming solution.

[0051] Among the above raw materials, the complexing agent is triethanolamine; the forming solution is a tetramethylammonium hydroxide solution with a mass fraction of 3%, and also includes a disodium hydrogen phosphate solution with a mass fraction of 1.0%, and the mass ratio of the two is 5:1 .

[0052] The preparation method of the above-mentioned high-efficiency desulfurization and denitrification absorbent comprises the following steps:

[0053] S10, mix the complexing agent and deionized water according to the mass ratio of 5:1.2, and add the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com