Patents

Literature

208 results about "Potassium alum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium alum, potash alum, or potassium aluminium sulfate is a chemical compound: the double sulfate of potassium and aluminium, with chemical formula KAl(SO₄)₂. It is commonly encountered as the dodecahydrate, KAl(SO₄)₂·12H₂O. It crystallizes in cubic structure with space group P a -3 and lattice parameter of 12.18 Å. The compound is the most important member of the generic class of compounds called alums, and is often called simply alum.

Method for recovering and preparing alum from activated clay production waste liquid

InactiveCN101671048ANo secondary pollutionReduce manufacturing costWater/sewage treatment by flocculation/precipitationAluminium sulfatesPotassiumWastewater

The invention discloses a method for recovering and preparing alum from activated clay production waste liquid, comprising the following steps of using sulfuric acid, aluminum sulfate in the activatedclay production waste liquid to react with aluminum hydroxide and stronger ammonia water or potassium hydroxide, filtering, evaporating to obtain ammonium alum or potassium alum, purifying, removingimpurities to obtain ammonium alum or potassium alum products with more than 99% of purity. The invention solves the problem existing in the management and recycling method of the activated clay production waste liquid, lowers cost for preparing alum in industry and has the advantages of environment protection, energy conservation and the like.

Owner:HEFEI UNIV OF TECH +1

Method for comprehensively recycling copper, selenium and uranium from stone coal extraction vanadic acid immersion liquid

InactiveCN102747225APrecipitation completeParticles grow upProcess efficiency improvementElemental selenium/telluriumPotassiumCoal

The invention relates to a method for comprehensively recycling copper, selenium and uranium from a stone coal extraction vanadic acid immersion liquid, which mainly comprises the following steps: crystallizing potassium alum or ammonia alum from stone coal sulfuric acid leach solution to remove aluminum, adding a copper-containing material and a phosphorus-rich material into the solution to regulate the copper concentration and the uranium / phosphorus ratio of the solution, adding an alkali to regulate the pH value, and adding a reducer to reduce and precipitate copper, selenium and uranium in the solution, thereby implementing efficient separation and enrichment of the copper, selenium and uranium in the stone coal vanadium extraction process. The invention has the advantages of simple technique, high copper / selenium / uranium recycling rate, low reagent consumption, low recycling cost, environment friendliness and the like.

Owner:CENT SOUTH UNIV +1

Multifunctional waterproof anti-leakage liquid for cement mortar and a preparation method thereof

The invention relates to multifunctional waterproof anti-leakage liquid for cement mortar, which is prepared from 60 to 70 weight parts of stearate solution, 20 to 30 weight parts of modified water-glass solution, 5 to 1 weight part of beta-naphthalene sulfonic acid formaldehyde condensation sodium salt and 900 weight parts of water, wherein the stearate solution is prepared from stearic acid, soda ash, ammonia water, potassium hydratem sodium chloride and water, the modified water-glass solution is prepared from polyvinyl alcohol, sodium silicate solution, potassium alum, dibutyl phthalate and water. The invention overcomes the defect of the reduced cement mortar strength of other rigid waterproof agents, has good waterproof effect, avoids the fault caused by the adding amount which can not be easily mastered, and has low price, simple production and low cost. The plastering mortar mixed with the product has excellent spreading performance and work degree of satisfaction.

Owner:河南省绿韵建材有限公司

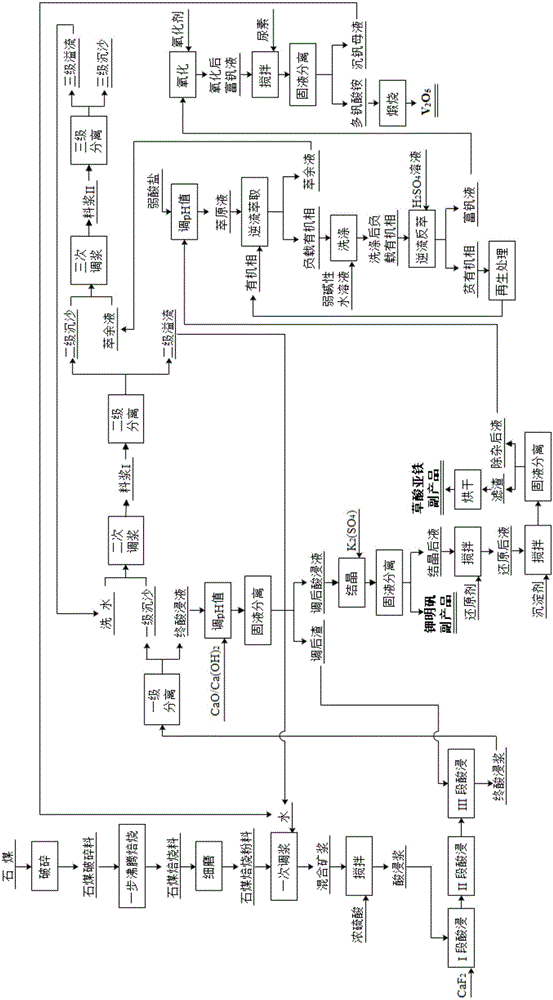

Method for preparing high-purity vanadium pentoxide by use of stone coal one-step method

The invention relates to a method for preparing high-purity vanadium pentoxide by use of a stone coal one-step method. The technical solution is as follows: a fluidized bed furnace for one-step roasting of stone coal is adopted to perform one-step fluidized bed roasting on the stone coal; roasted materials are leached in three segments, final pickling slurry is subjected to primary separation so as to obtain final pickle liquor, secondary overflow is returned to be subjected to primary size mixing, and tertiary overflow is returned to be subjected to secondary size mixing; the pH value of the final pickle liquor is regulated, and slags obtained after regulation are returned to a segment III so as to be leached; the regulated pickle liquor is crystallized to obtain a potassium alum byproduct; after crystallization, the liquid is subjected to reduction and precipitation-based impurity removal, and filter residues are dried to obtained a ferrous oxalate byproduct; after impurity removal, pH value regulation is performed on the liquid by use of weak acid salt, then counter-current extraction is performed on the liquid, and extraction raffinate is returned to be subjected to tertiary size mixing; after being washed, the loaded organic phase is subjected to countercurrent reverse extraction; a lean organic phase is regenerated and then is returned to be extracted; after a vanadium-rich solution is oxidized, urea is added, stirring is performed, the obtained molybdenum precipitation mother solution is returned to be subjected to primary size mixing, and ammonium polyorthovanadate is calcinated to prepare vanadium pentoxide. The method has the characteristics of short process flow, less pollution, low energy consumption, less chemical usage, high vanadium recovery rate and high product purity.

Owner:WUHAN UNIV OF SCI & TECH

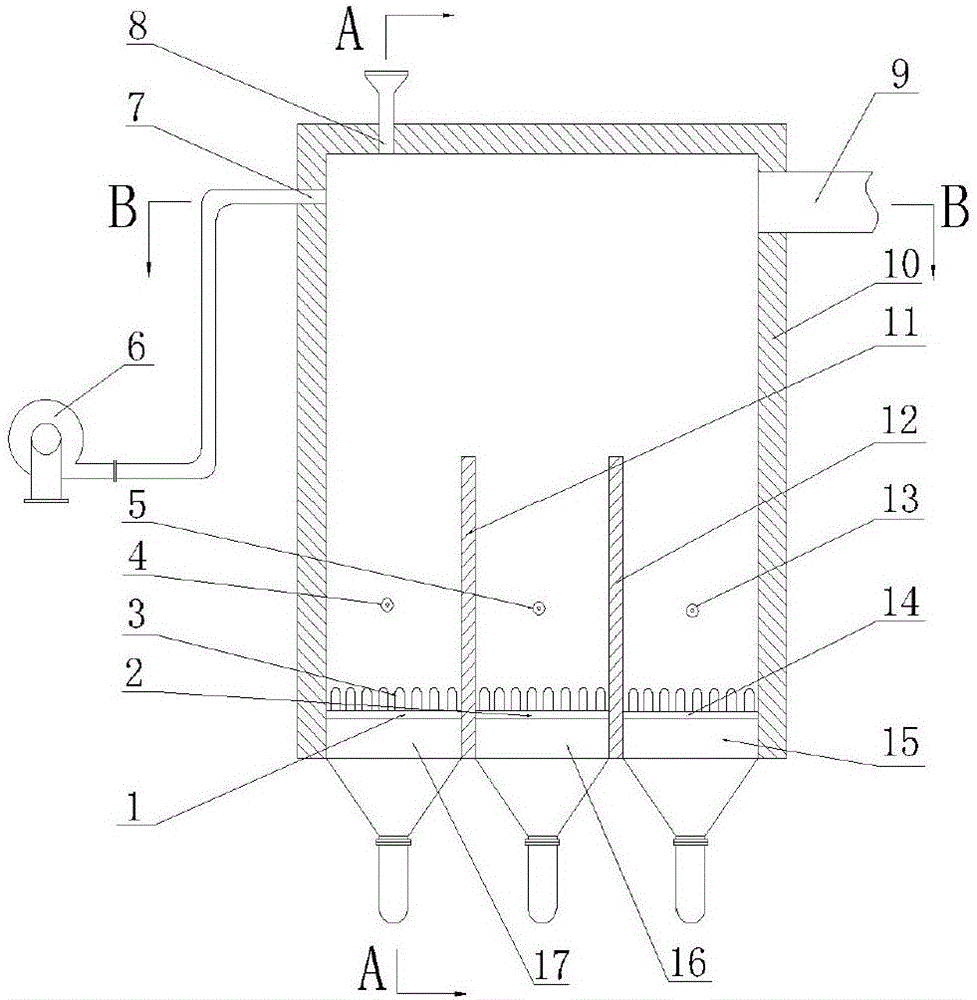

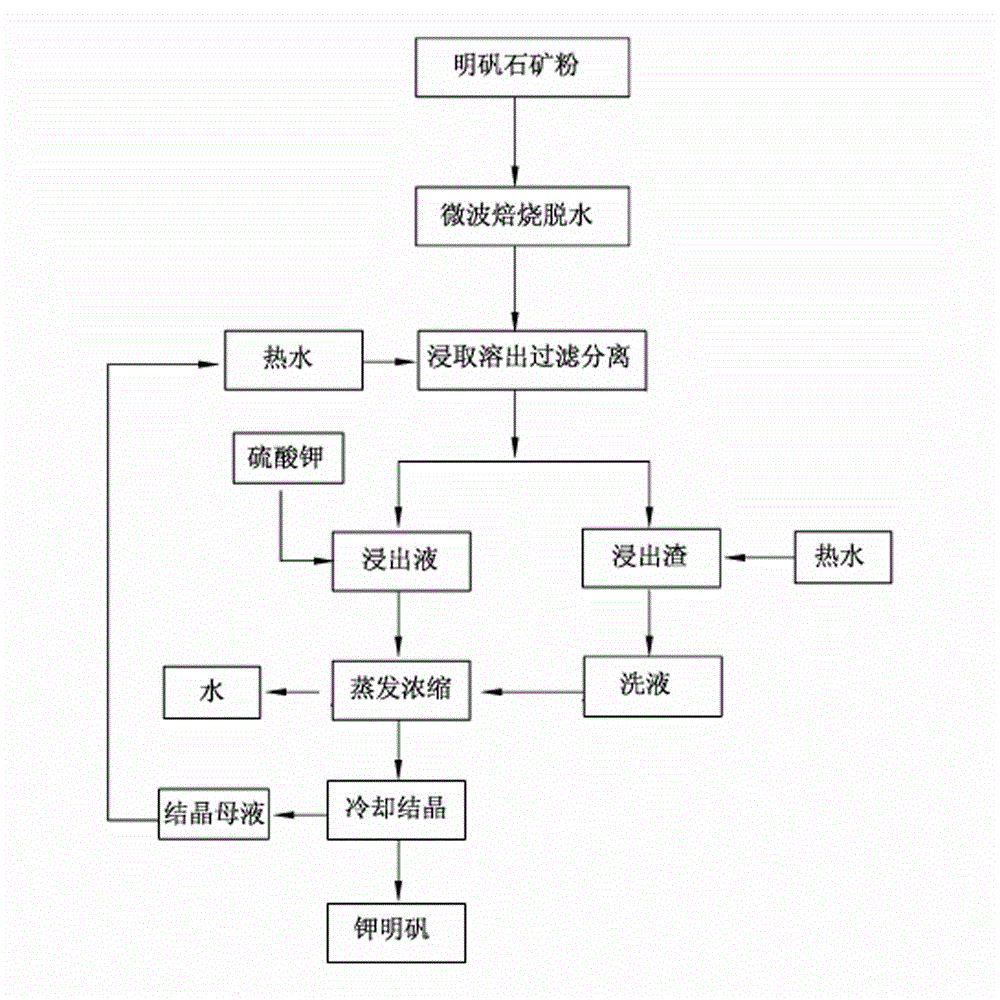

Method for producing alum by utilizing alunite

The invention relates to a method for producing alum by utilizing alunite, comprising the steps that alunite mineral powder is selected and used, the mineral powder is dehydrated by microwave roasting, sulfuric acid solution is leached and dissolved out, the filtering separation is carried out, the leaching agent is evaporated and concentrated, and the leaching agent is cooled and alum is crystallized. Potassium sulphate is added to the leaching agent, and potassium alum is completely produced; potassium sulphate is not added to the leaching agent, potassium alum is produced, and aluminum sulfate is co-produced; and crystallization mother liquor is recycled. Compared with the existing alum refining technology adopting 'water immersion method' and a vertical coal kiln, the method for producing alum by utilizing alunite has the beneficial effects that the utilization rate of resources is improved, the yield of alum is increased, the production cycle of the alum is shortened, energy sources are saved, the production cost is reduced, waste residues and waste gases are reduced, and the environment is protected.

Owner:广西北部湾粮油技术研究有限公司

Impurity removing method for vanadium contained leaching agent

ActiveCN106244828AReduce loss rateEfficient separationProcess efficiency improvementLoss rateMass ratio

The invention relates to an impurity removing method for a vanadium contained leaching agent. According to the technical scheme, potassium sulphate is added into the vanadium contained leaching agent according to the mass ratio of the potassium sulphate to aluminum in the vanadium contained leaching agent being (2.5-4.0):1, crystallization is carried out, primary solid-liquid separation is carried out, and liquid obtained after crystallization and potassium alum are obtained. A reducing agent is added into the liquid obtained after crystallization according to the ratio of the amount of total matter in the reducing agent to the amount of the Fe(III) matter in the liquid obtained after crystallization being (1.5-3.5):1, stirring is carried out, and liquid obtained after reducing is obtained. A precipitator is added into the liquid obtained after reducing according to the ratio of C2O4<2-> matter in the precipitator to the amount of iron matter in the liquid obtained after reducing being (2-15):1, stirring is carried out, secondary solid-liquid separation is carried out, and the vanadium contained leaching agent obtained after impurity removing and filter residues are obtained; the vanadium contained leaching agent obtained after impurity removing is used for the follow-up vanadium enrichment process; and the filter residues are dried, and therefore the oxalates compound by-products of iron are obtained. The impurity removing method has the beneficial effects of being good in vanadium and impurity ion separating effect, simple in process, small in reagent consumption, low in vanadium loss rate and capable of achieving resource utilization.

Owner:WUHAN UNIV OF SCI & TECH

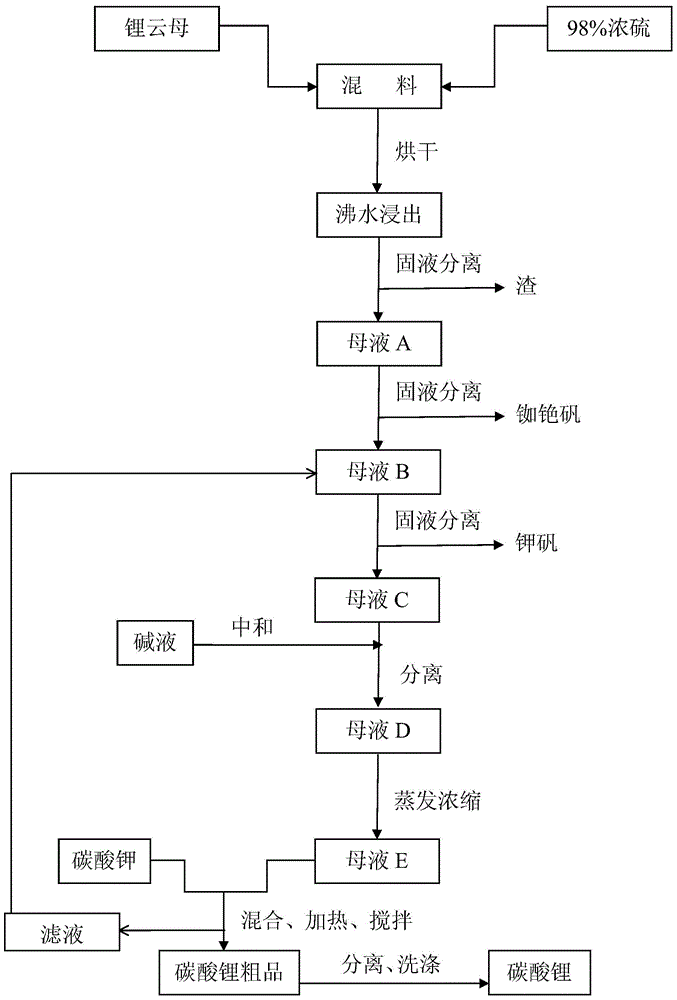

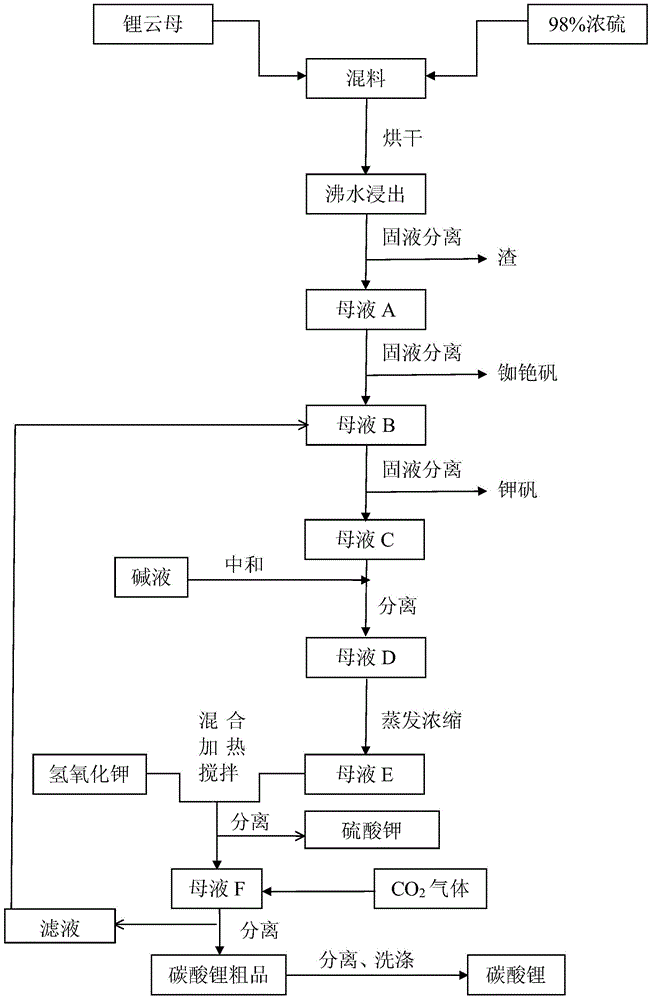

Method for preparing lithium carbonate from lepidolite

InactiveCN106145164AImprove leaching rateAdequate responseLithium carbonates/bicarbonatesFiltrationSlag

The method for preparing lithium carbonate from lepidolite comprises the following steps: take lepidolite (100-500 mesh), add 98% concentrated sulfuric acid in a mass ratio of 1: [0.8-3], stir, and dry step by step to obtain clinker , and crush the clinker into 100-500 mesh, add water to soak, stir, and boil to obtain a mixed solution; centrifuge the mixed solution while it is hot to obtain mother liquor A, cool the mother liquor A in a reaction vessel to 20-80°C, and crystallize Rubidium cesium alum is extracted, and then centrifuged to obtain mother liquor B; the mother liquor B is cooled to -30~20°C in the reaction vessel, potassium alum is crystallized, and then centrifuged to obtain mother liquor C; mother liquor C is neutralized with lye to the pH value After centrifugation, the mother liquor D is obtained, and then the mother liquor D is evaporated and concentrated, and then filtered to obtain the mother liquor E; the mother liquor E is mixed with potassium carbonate or sodium carbonate solution, heated to 80-100°C, and completed under stirring. That is, the crude product of lithium carbonate is prepared, and the crude product is centrifuged, washed and dried to obtain the finished battery grade lithium carbonate. The invention improves the leaching rate of lithium, saves raw materials, generates less slag, and lowers requirements on equipment.

Owner:深圳前海南锂新材料有限公司

Flower preservative and preparation method thereof

InactiveCN101933507AApplicable for keeping freshReduce dosageDead plant preservationSolubilityNon toxicity

The invention provides a flower preservative and a preparation method thereof. The flower preservative comprises the following main components in percentage by weight: 1 to 5 percent of potassium alum, 2 to 6 percent of ammonium alum, 1 to 3 percent of gelatin and 5 to 10 percent of silver thiosulfate. The flower preservative has an obvious effect; the flower treated by the product can keep the color and the aroma unchanged; and the medicament attached to the surface of the flower has the advantages of water solubility, easy cleaning, non-toxicity, safe use and no harm to people and animals.

Owner:张家港市塘桥镇春禾农业生产专业合作社

New method for producing potassium alum

ActiveCN102815737AReduce productionReduce consumptionAluminium sulfatesAluminium hydroxideAluminum sulphate

The invention relates to a new method for producing potassium alum. The method comprises the following process steps: carrying out a pressurized reaction of bauxite and sulfuric acid to obtain an aluminum sulfate solution; adding a certain amount of the aluminum sulfate solution to an acid resistance normal pressure reactor; adding a proper amount of aluminum hydroxide under stirring; adding a certain amount of concentrated sulfuric acid into the reactor; adopting dilution heat of the concentrated sulfuric acid and reaction heat of the aluminum hydroxide to carry out the complete reaction; and adding a proper amount of potassium sulfate, carrying out a reaction, and carrying out sedimentation, wherein the mother liquid is transferred to a crystallization tank to carry out crystallization. According to the present invention, the aluminum hydroxide is introduced to the raw materials, and the bauxite and the aluminum hydroxide are combined so as to greatly improve product appearance, improve product quality, reduce bauxite residue production, and reduce influence on the environment; and heat emission of the reaction of the aluminum hydroxide and the concentrated sulfuric acid can be completely utilized, external steam is not required, and the potassium alum crystal is naturally dried without further drying so as greatly save steam consumption, reduce energy consumption cost, and provide characteristics of high product purity, high density, high dehydration yield, and the like.

Owner:HENGYANG JIANHENG IND DEV

Comprehensive utilization method for waste aluminum-plastic paper composite packing material

InactiveCN102671913AQuality improvementSolid waste disposalHydrogen productionHydrogenLow temperature curing

The invention discloses a comprehensive utilization method for a waste aluminum-plastic paper composite packing material. The method comprises the following steps: crushing, cleaning and drying the waste aluminum-plastic paper composite packing material; heating, pyrolyzing and gasifying the dried material in a vacuum high-pressure high-temperature kettle, and performing low temperature curing recovery; putting the pyrolyzed and gasified aluminum-plastic paper mixed material into a reaction kettle, adding a caustic potash solution for reaction, and recovering the generated hydrogen serving as a special fuel; neutralizing the rest material by using dilute sulfuric acid, and performing filter pressing and washing to obtain a filter cake, namely the available water pulp; and filtering off the water pulp, evaporating and crystallizing the obtained filtrate, and centrifuging to remove residue so as to recover potassium alum with wide application.

Owner:张文知

Application of AK sugar crystal mother liquor and method for preparing sylvite by crystal mother liquor

ActiveCN102336647AReduce manufacturing costLower potassium levelsSulfate/bisulfate preparationCarboxylic acid salt preparationDouble saltPotassium oxalate

The invention provides an application of AK sugar crystal mother liquor produced by a sulfamic acid-sulfur trioxide method, which is a sylvite preparation by using crystal mother liquor, and a method for preparing sylvite by using AK sugar crystal mother liquor. The method comprises the following steps: mixing crystal mother liquor and organic acid or inorganic acid, keeping a mixture in an acidic property, cooling, filtering, and recrystallizing to obtain sylvite. The sylvite is prepared by the AK sugar crystal mother liquor which is originally taken as waste water for discharging by using the sulfamic acid-sulfur trioxide method. The sylvite comprises inorganic salts, such as potassium sulfate; organic salts, such as potassium oxalate; even double salts, such as potassium alum. The obtained sylvite can be a product for sale, so that the production cost of AK sugar can be reduced. Simultaneously, the potassium content in waste water can be reduced and the environmental pollution caused by waste water is minimized. The invention aims at reducing the cost of AK sugar, minimizing the environmental pollution caused by waste water from the process, raising the economic, social and environmental benefits of AK sugar production process by using the sulfamic acid-sulfur trioxide method.

Owner:CHUZHOU UNIV

Hydrolytic agent for treating wastewater containing tetrafluoroborate and application thereof

ActiveCN102336460AImprove hydrolysis effectWide range of application conditionsWater contaminantsWater/sewage treatmentAluminium chlorideCerium nitrate

The invention provides a hydrolytic agent for treating wastewater containing tetrafluoroborate and application thereof. The hydrolytic agent consists of at least one aluminum salt and at least one water-soluble cerate. The aluminum salt is selected from alum, aluminum chloride or hydrate of the aluminum chloride, aluminum sulfate or hydrate of the aluminum sulfate, and preferable the alum; and the water-soluble cerat is selected from cerium nitrate, cerous sulfate and cerium chloride, and the preferable the cerium chloride. The hydrolytic agent disclosed by the invention is used for treating the wastewater containing tetrafluoroborate, thus the consumption of the aluminum salt contained in the hydrolytic agent can be reduced on the one hand and the concentration of the tetrafluoroborate in the hydrated wastewater can be reduced on the other hand, which provide advantages for subsequent treatment. After the wastewater is continuously precipitated by lime milk or CaOH2, the concentration of the tetrafluoroborate and the concentration of fluorinion are respectively reduced and reach the discharge stand, and thus the etrafluoroborate and the fluorinion can be directly discharged and further the subsequent treatment flow is shortened.

Owner:CHINA PETROLEUM & CHEM CORP

Method for processing chestnut in syrup

The invention relates to a method for processing chestnut in syrup, belonging to the technical field of methods for processing food. The invention aims at providing a method for preserving a high sugar degree can under the condition of high temperature sterilization so that the high sugar degree can is kept in a certain water holding state for a long time. The technical scheme of the invention is as follows: chestnut is cleaned, shucked and sliced into a jewel shape, and the original color is maintained; precooking and rinsing: 0.15 percent of potassium alum and 0.15 percent of disodium ethylene diamine tetraacetate need to be added to precooking solution, and the mixture is rinsed in circulating water; liquid syrup preparation: liquid syrup of which the syrup content is 50 percent is prepared; and air exhaust and can seal: a can is led into an exhaust box and then is processed by the steps of heating and air exhaust for 40 minutes, so as to lead the central temperature in the can to be no less than 85 DEG C, and finally the can is sealed. The preparation method of the invention has the advantages of easy operation and simple process, and contributes to the fresh keeping.

Owner:WUHU XINXIN FOOD INDAL

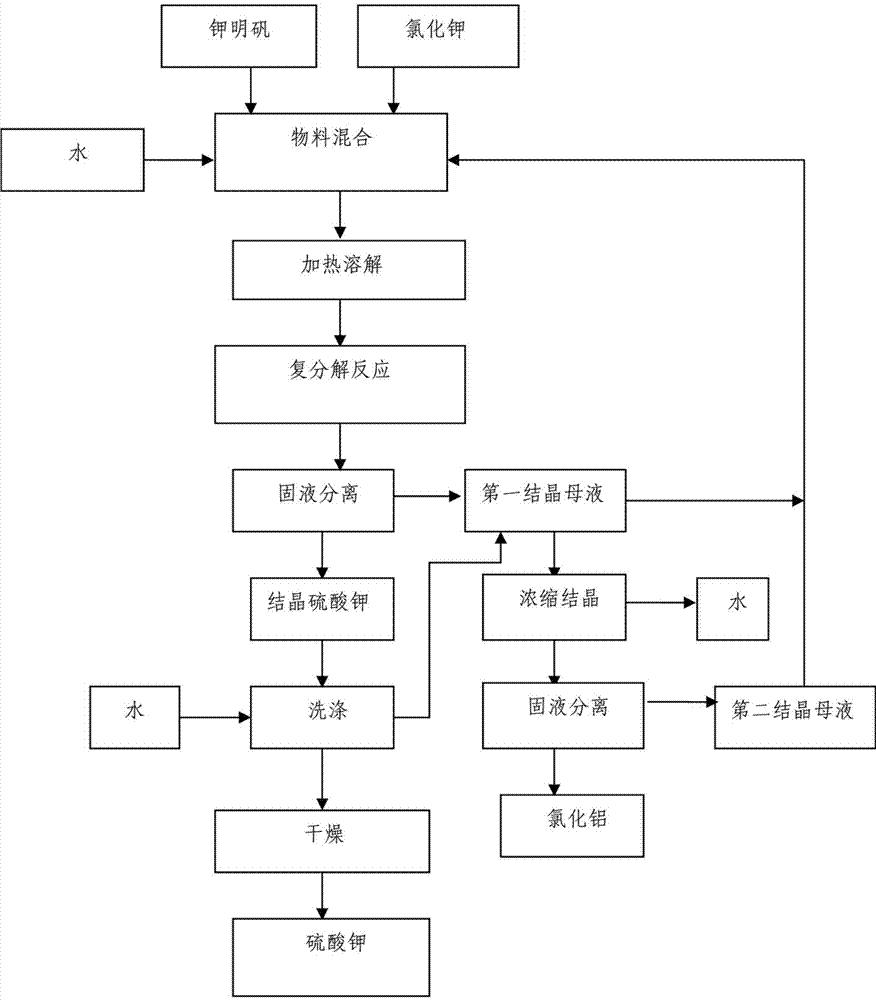

Method for producing potassium sulphate and aluminium chloride by utilizing potassium alum

InactiveCN104743583ANo pollution in the processIncrease profitSulfate/bisulfate preparationAluminium chloridesAluminium chloridePhysical chemistry

The invention relates to a method for producing potassium sulphate and aluminium chloride by utilizing potassium alum. According to the method, the selected materials are the potassium alum, potassium chloride and water as a solvent, and the weight ratio of the potassium alum and the potassium chloride is 1.5-2.5:1. The produduction method comprises a stage for preparing the potassium sulphate through a potassium alum / potassium chloride complex decomposition reactive crystallization method, and a stage for preparing the aluminium chloride through evaporation and concentration crystallization, wherein the potassium sulphate preparation stage can be carried out for one time or several times circularly; during the stage, the replacement reaction temperature is larger than or equal to 60 DEG C, the reaction time is larger than or equal to 20min, the solid-liquid separation and insulation temperature is larger than or equal to 50 DEG C, and the evaporation and concentration crystallization temperature is larger than or equal to 90 DEG C. Compared with the existing method for producing the potassium sulphate and the aluminium chloride by utilizing the potassium alum, the method has the beneficial effects of short technological process (one-step conversion), easiness in solid-liquid separation, low energy consumption, no environment pollution, low production cost, easiness in industrialization implementation, high material utilization ratio and the like.

Owner:傅培鑫 +1

Method of extracting aluminium hydroxide from potassium- and aluminium-containing ores

InactiveCN104445325AIndustrial development has good economic benefitsIncrease valueAluminium compoundsAluminium hydroxidePotassium

The invention discloses a method of extracting aluminium hydroxide from potassium- and aluminium-containing ores. The method comprises the following process steps: reacting the potassium- and aluminium-containing ores in a reaction system containing sulphur acid, obtaining a leaching solution containing aluminium sulphate and potassium sulphate through solution leaching and liquid-solid separation, separating out the crystal of potassium alum by lowering the temperature, carrying out a slurry mixing reaction with lime and water to obtain gypsum residue containing aluminium hydroxide, carrying out a leaching reaction with the aluminium hydroxide solution, cooling and diluting the slurry to obtain a sodium aluminate solution, adding a seed crystal, and cooling and crystallizing to obtain an aluminium hydroxide crystal. The method disclosed by the invention realizes the purpose of comprehensively extracting aluminium, potassium and by-product semi-hydrated gypsum from the potassium- and aluminium-containing ores, realizes the comprehensive utilization of the ores, and has a high aluminium yield and good comprehensive benefits.

Owner:FUZHOU UNIV

Lotus root starch sheets

InactiveCN1711906AGood Vegetable IngredientsFull of nutritionFood preparationPotassiumCassava (food)

Owner:杨爱彬

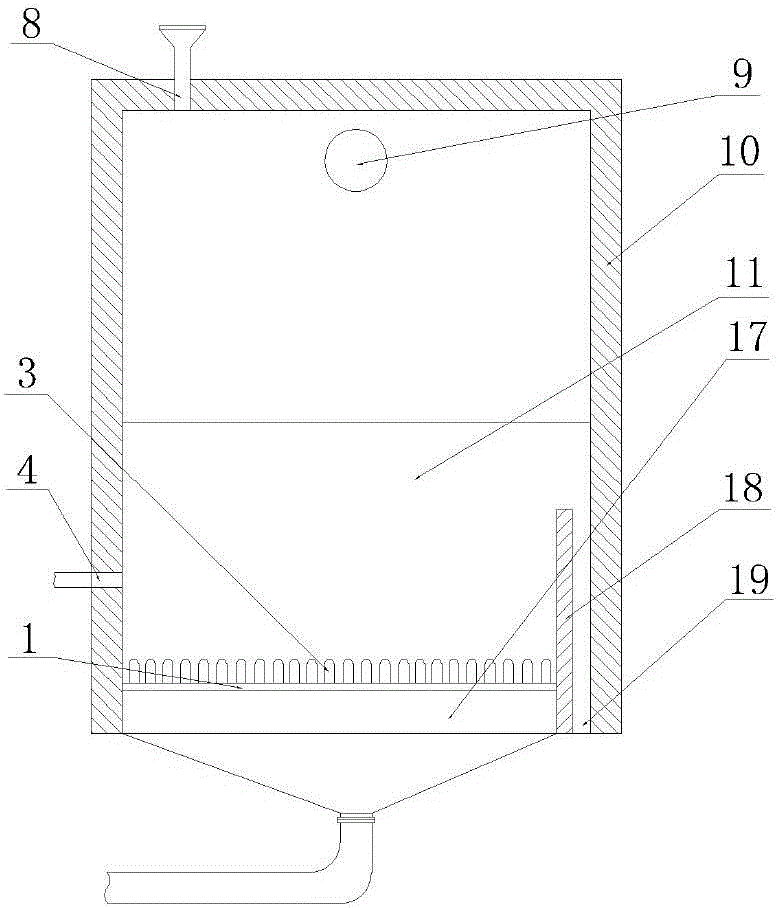

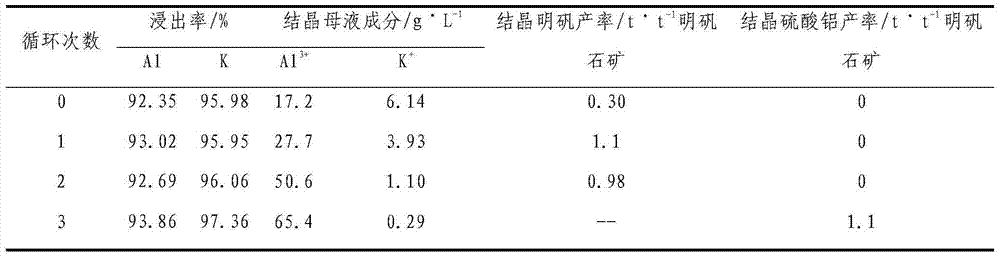

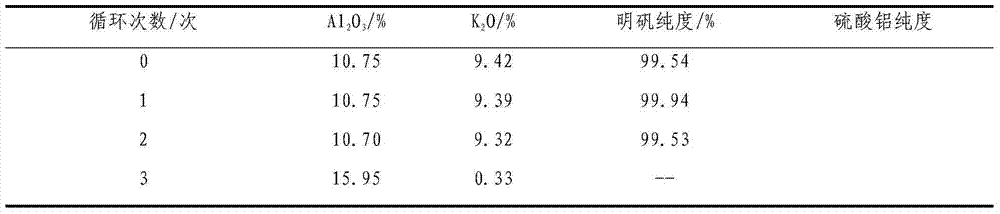

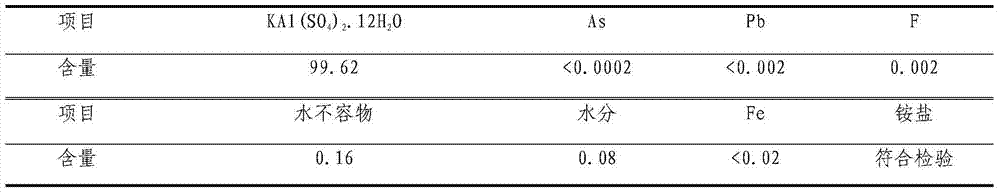

Method for preparing high-purity potassium alum and aluminum sulfate from alunite ore

InactiveCN103787396AReduce K+ contentHigh purityProcess efficiency improvementAluminium sulfatesAluminium sulfatePregnant leach solution

The invention relates to a method for preparing high-purity potassium alum and aluminum sulfate from alunite ore. The method comprises the following steps: firstly, roasting the alunite ore to remove crystal water; secondly, performing sulfuric acid leaching on dehydrated alunite to obtain aluminum and potassium, and crystallizing the potassium alum in leaching liquid; thirdly, adding a certain quantity of acid into crystallization mother liquid, returning to a circulating leaching process, and crystallizing the potassium alum in circulating leaching liquid; and finally, crystallizing the aluminum sulfate in potassium alum crystallization mother liquid circulated for a certain number of times. The purpose of the invention is to provide the method for preparing the high-purity potassium alum and the aluminum sulfate from the alunite ore, which is simple in process, low in production cost and easy to industrialize in allusion to the comprehensive utilization problem of the alunite ore.

Owner:ZIJIN MINING GROUP

Method for producing hydrogen and potassium alum from waste aluminum cans

InactiveCN102295270ASave bauxiteSave energySolid waste disposalHydrogen productionSizingRaw material

It is undoubtedly a good way to kill two birds with one stone by using waste aluminum cans to produce new energy hydrogen and environmental protection products potassium alum. Hydrogen has many uses. Hydrogen burns in oxygen and releases a lot of heat. The temperature of its flame-oxygen flame reaches 3000°C, which can be used for welding or cutting metals. As a fuel, hydrogen has the characteristics of abundant resources, high combustion calorific value and less pollution. Potassium alum plays an important role in water purification, paper sizing, paint printing and dyeing, lake pigment pharmaceuticals, paint making, tanning, fiberboard processing, as well as rubber and metallurgy, colored glass, food industry, agriculture, etc. . The invention uses waste aluminum cans as raw materials, produces hydrogen through potassium hydroxide solution, further neutralizes potassium aluminate solution with sulfuric acid, and obtains high-quality potassium alum through crystallization, filtration, washing and centrifugal dehydration. The invention not only eliminates pollution, but also can achieve the purpose of turning waste into wealth and utilizing waste, and is a good method that kills two birds with one stone.

Owner:刘方旭

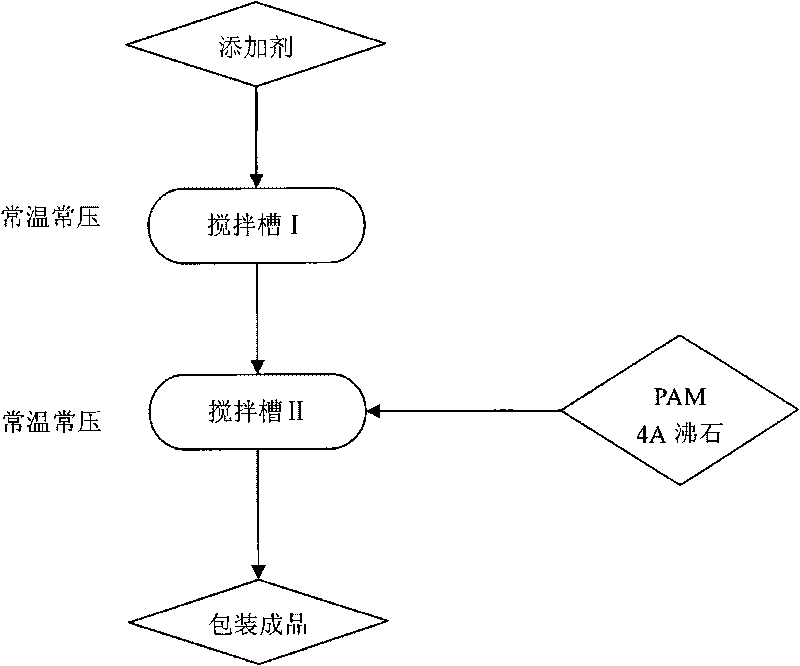

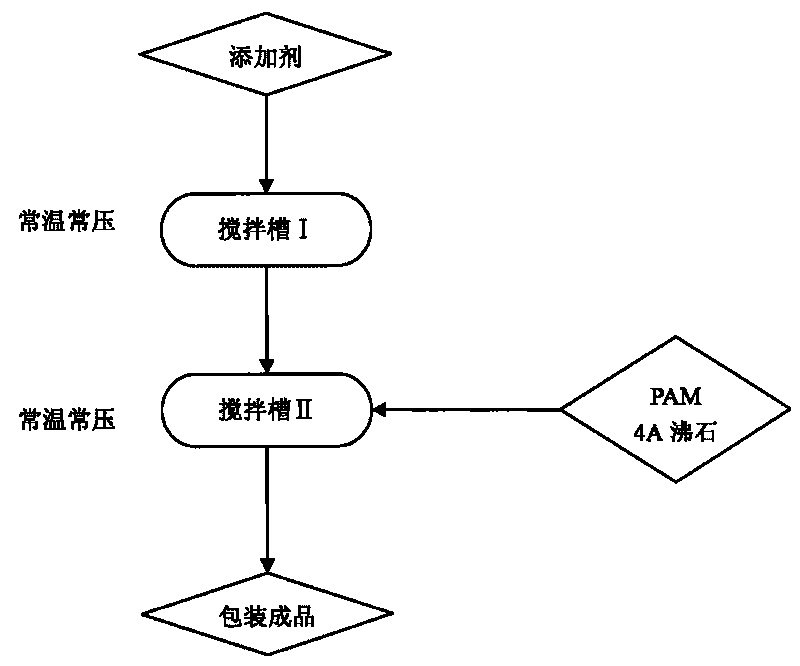

Inorganic-organic composite flocculating agent and preparation method thereof

InactiveCN101708879AHigh removal rateQuick buildWater/sewage treatment by flocculation/precipitationPotassiumPotassium alum

The invention provides an inorganic-organic composite flocculating agent, which comprises the following components in percentage by weight: 90 percent of polyacrylamide, and 5 percent of 4A-zeolite and 5 percent of additive. The additive comprises the following components in percentage by weight: 30 to 50 percent of ammonium sulfate, 30 to 50 percent of sodium sulfate, 5 to 15 percent of sodium silicate, and 5 to 15 percent of potassium alum. The preparation method comprises the following steps: firstly, stirring and mixing the additive; then, mixing the additive with the polyacrylamide (PAM) and the 4A-zeolite to obtain the composite flocculating agent. The flocculating agent has simple production technology, high production capacity, mild reaction conditions, low energy consumption, no three wastes emission; and the composite flocculating agent has quick growth, wide pH application range, quick sedimentation velocity and high COD removal rate.

Owner:SHANGHAI WSHINE CHEM

Mildew-proof and mothproof treating fluid for treating willow rattans

ActiveCN104354202AExtended use timeHas a softening effectWood treatment detailsReed/straw treatmentSodium bicarbonateToxic material

The invention provides mildew-proof and mothproof treating fluid for treating willow rattans, and relates to the technical field of production of wicker products. The treating fluid is prepared from the following components in parts by weight: 5 to 9 parts of table vinegar, 3 to 7 parts of alcohol, 3 to 7 parts of potassium alum, 1 to 5 parts of lysimachia foenum-graecum hance, 4 to 8 parts of babysbreath, 1 to 5 parts of fineleaf schizonepeta herb, 1 to 3 parts of Chinese parsnip root, 1 to 5 parts of sodium bicarbonate, 2 to 6 parts of sodium silicate, 3 to 7 parts of radix isatidis, 4 to 8 parts of honeysuckles, 1 to 5 parts of tabasheer, 1 to 3 parts of borax, 1 to 13 parts of cassia twig, 2 to 6 parts of sandalwood, 3 to 7 parts of as arum sieboldii, 6 to 12 parts of Chinese honeylocust fruits, 2 to 4 parts of wild peppers, 3 to 7 parts of kadsura root-bark, 5 to 11 parts of semen perillae acutae, 2 to 6 parts of aconitum carmichaelii, 5 to 11 parts of pepperweed seeds, 1 to 3 parts of radix euphorbiae lantu, 2 to 8 parts of radix stemonae, 5 to 9 parts of evodia rutaecarpa, 5 to 11 parts of pyrethrum and 2 to 4 parts of rehmannia glutinosa. According to the mildew-proof and mothproof treating fluid, the release of toxic substances is avoided in a using process, good mildew-proof and mothproof effects are achieved, the service life of a wicker product is greatly prolonged, mildew and moth can be prevented for more than 5 years, and the wicker product can also be kept fragrant, and has side effects on a human body; the mildew-proof and mothproof treating fluid also has a softening effect on willow rattans, and is favorable for weaving.

Owner:GP TOPARTS MFR ANHUI

Composition For The Treatment Of Joint Conditions

ActiveUS20160095890A1Effectively swellingEffectively deformityBiocideAnthropod material medical ingredientsPost injuryPotassium

Owner:STANCIOIU FELICIAN +1

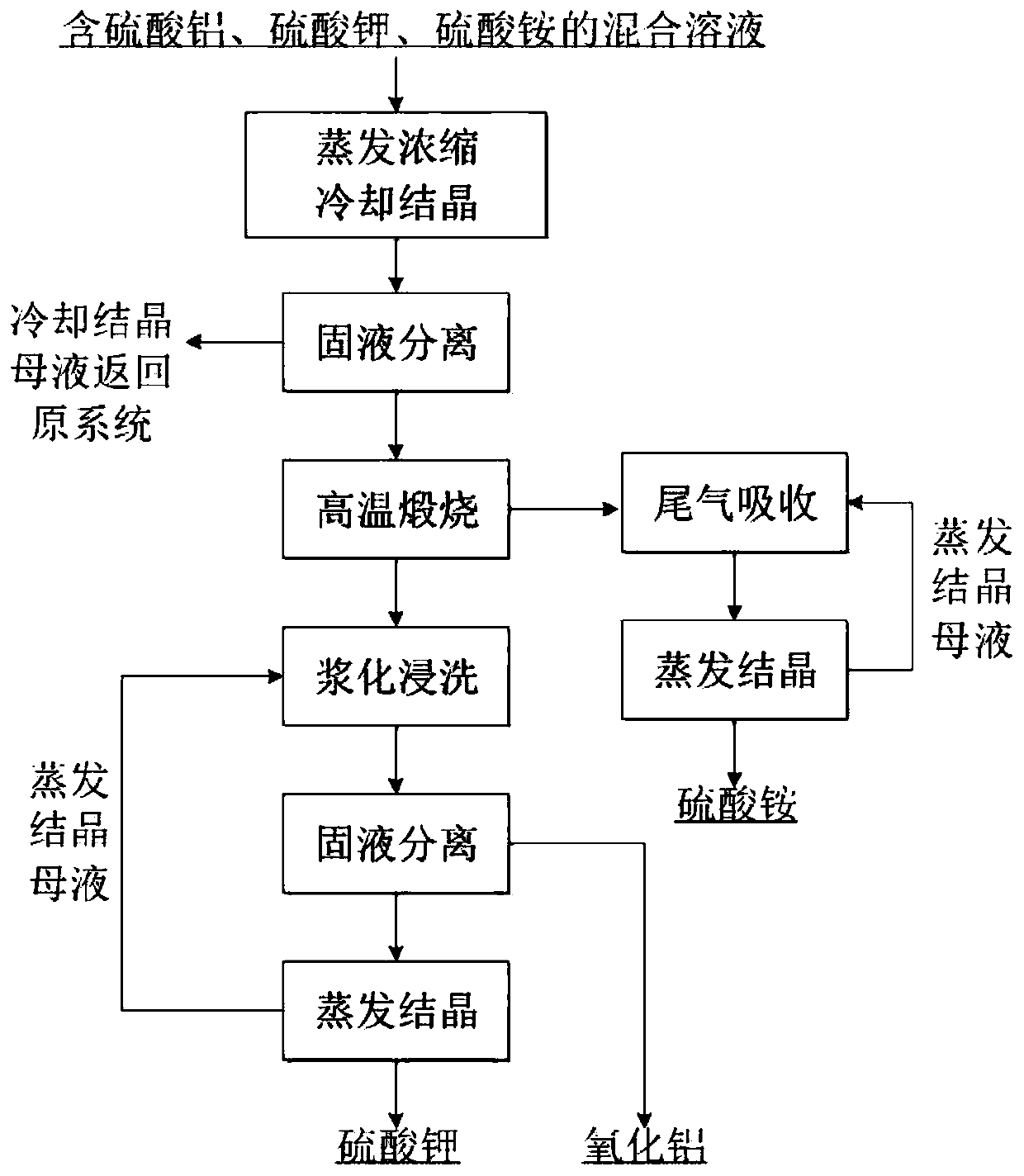

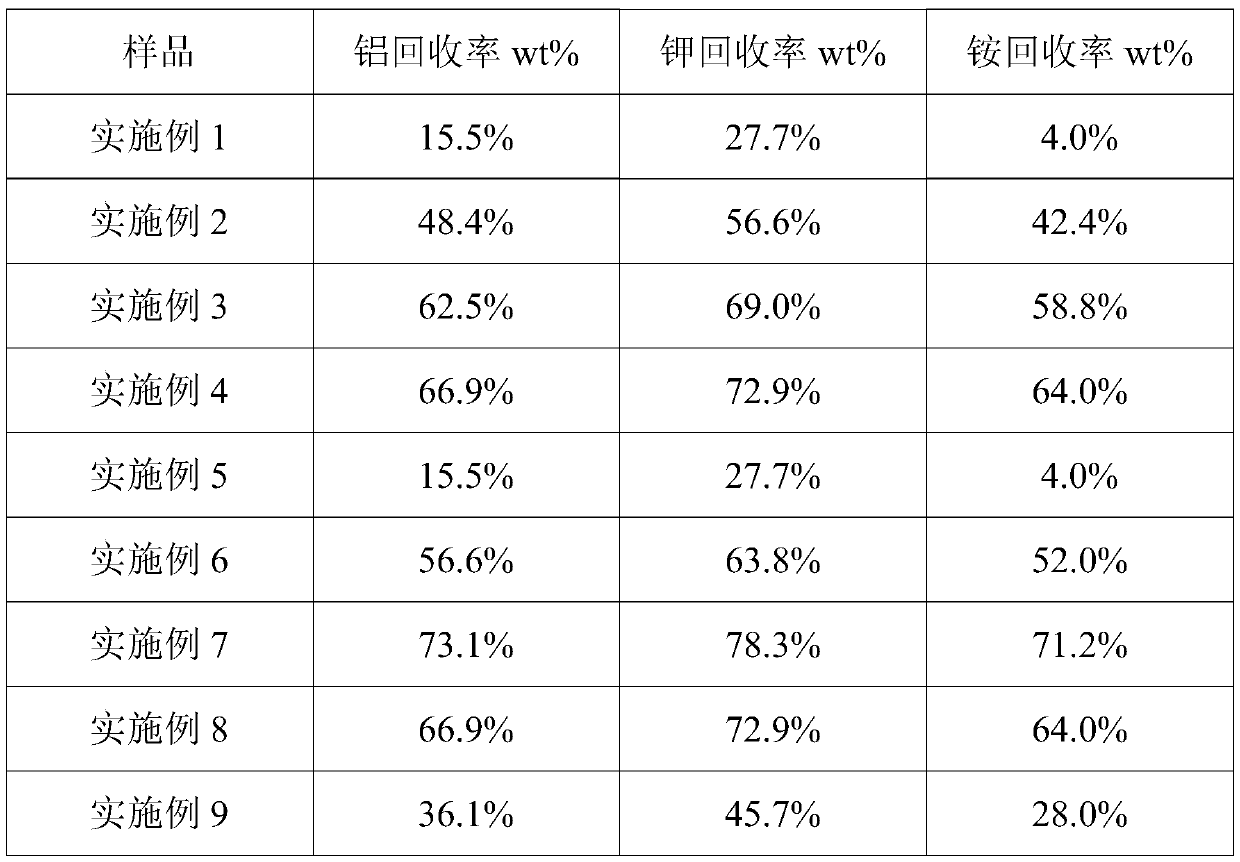

Method of separating and recovering aluminum, potassium, and ammonium from mixed solution containing aluminum sulfate, potassium sulfate, and ammonium sulfate

ActiveCN110510648AAchieve separationRealize separation and recoveryAluminium oxide/hydroxide preparationAmmonium sulfatesWastewaterPotassium sulfate

The invention provides a method of separating and recovering aluminum, potassium, and ammonium from a mixed solution containing aluminum sulfate, potassium sulfate, and ammonium sulfate. The method comprises following steps: evaporating and condensing the mixed solution, cooling the condensate to carry out crystallization to obtain mixed crystals of potassium alum and ammonium alum, burning the mixed crystals at a high temperature to prepare alumina, and recovering potassium sulfate and ammonium sulfate at the same time. The provided method can efficiently recover aluminum, potassium, and ammonium, and obtains high purity alumina, potassium sulfate, and ammonium sulfate, furthermore, the energy consumption is low, the investment is little, the production is carried out in an enclosed environment, no waste solid, waste gas or wastewater is discharged, the devices are easy to enlarge, and the industrial application prospect is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

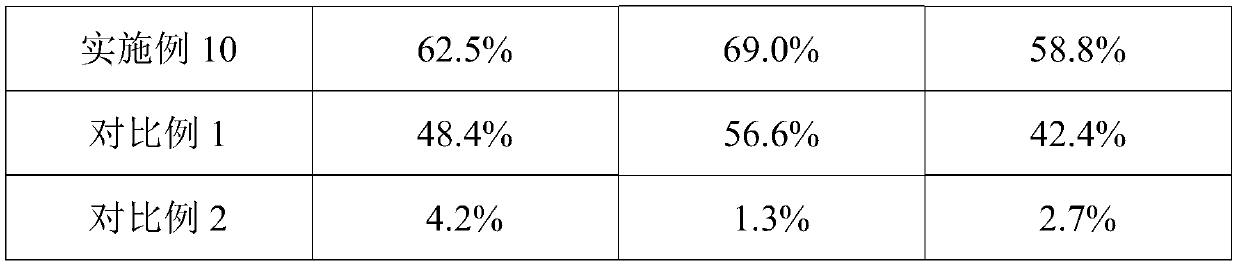

Method for producing potassium alum

The invention discloses a method for producing potassium alum by utilizing industrial leftovers, namely waste aluminum residues. The method comprises the following steps: (1) preparing aluminum residue slurry by using the waste aluminum residues; (2) enabling the aluminum residue slurry to react with concentrated sulfuric acid so as to generate aluminum sulfate crude liquor; (3) performing settling separation on the aluminum sulfate crude liquor; (5) cooling and crystallizing the aluminum sulfate crude liquor; and (6) washing, airing and packaging, thereby obtaining the finished potassium alum product. According to the method disclosed by the invention, the waste aluminum residues are taken as raw material, the production cost is saved, the amount of waste residues is small, the additional benefits can be brought, and wastewater can be recycled; and moreover, the method is simple in process, convenient to operate, high in safety, low in energy consumption and low in production cost and is suitable for large-scale production.

Owner:广西北部湾粮油技术研究有限公司

Technology for continuously producing cesium rubidium alum and aluminum potassium sulfate

InactiveCN105366701AHigh yieldContinuous stable operationChemical industryAluminium sulfatesCentrifugationPhysical chemistry

A technology for continuously producing cesium rubidium alum and aluminum potassium sulfate comprises the following steps: (1) performing single / multiple effect vacuum cooling crystallization on a mother solution containing cesium, rubidium, potassium and aluminium, so as to obtain a cesium rubidium alum crystal slurry; (2) performing centrifugation separation, so as to obtain crude cesium rubidium alum and a mother liquid; (3) performing thermal dissolving, recrystallization and centrifugation separation on crude cesium rubidium alum, so as to obtain the cesium rubidium alum product; (4) performing multi-effect forced circulating refrigeration crystallization on the mother liquid with the aluminum potassium sulfate content of 6 wt% or more according to a forward flow, so as to obtain a aluminum potassium sulfate crystal slurry; and (5) performing centrifugation separation and drying, so as to obtain the aluminum potassium sulfate product. The technology realized continuous large-batch production, the product quality is stable, yield is high, the purity of obtained cesium rubidium alum is 95% or more, and the purity of aluminum potassium sulfate is 97% or more. The solid concentration of each-stage crystallizer is easy to control. Cold energy can be fully utilized, and the energy-saving synergic effect can be reached. The technology effectively prevents large-area obstruction of pipes and obstruction of equipment. Equipment structure is simple, operation and maintenance are convenient, automatic control is easy to realize, and large-scale industrial production can be realized.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Water purifying agent specially used for waste water treatment and preparation method of water purifying agent

ActiveCN108557943AFormulation ScienceReasonable formulaWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSodium BentonitePotassium fluoride

The invention discloses a water purifying agent specially used for waste water treatment. The water purifying agent is prepared from the following raw materials in parts by weight: 10-20 parts of bentonite, 15-25 parts of kaolin, 8-14 parts of modified attapulgite, 6-12 parts of aluminum hydroxide, 5-10 parts of sodium hydroxide solution, 6-11 parts of hydrochloric acid, 7-13 parts of activated coal ash, 3-7 parts of calcium carbonate, 2-5 parts of potassium alum, 3-8 parts of Chinese yam, 5-9 parts of active carbon, 0.2-0.6 part of hydrogen peroxide, 0.3-0.7 part of pore-enlarging agent, 1-2parts of dispersing agent, 1-2 parts of bactericide and a proper amount of water, wherein the activated coal ash is prepared through mixing common coal ash with potassium fluoride and then placing ina high-temperature environment to roast; the mass fraction concentration of the sodium hydroxide solution is 30%. The water purifying agent specially used for waste water treatment is scientific and reasonable in formula, good in purification performance, low in cost and good in stability, and can be used for large-scale industrial production.

Owner:广州市芦苇环保科技有限责任公司

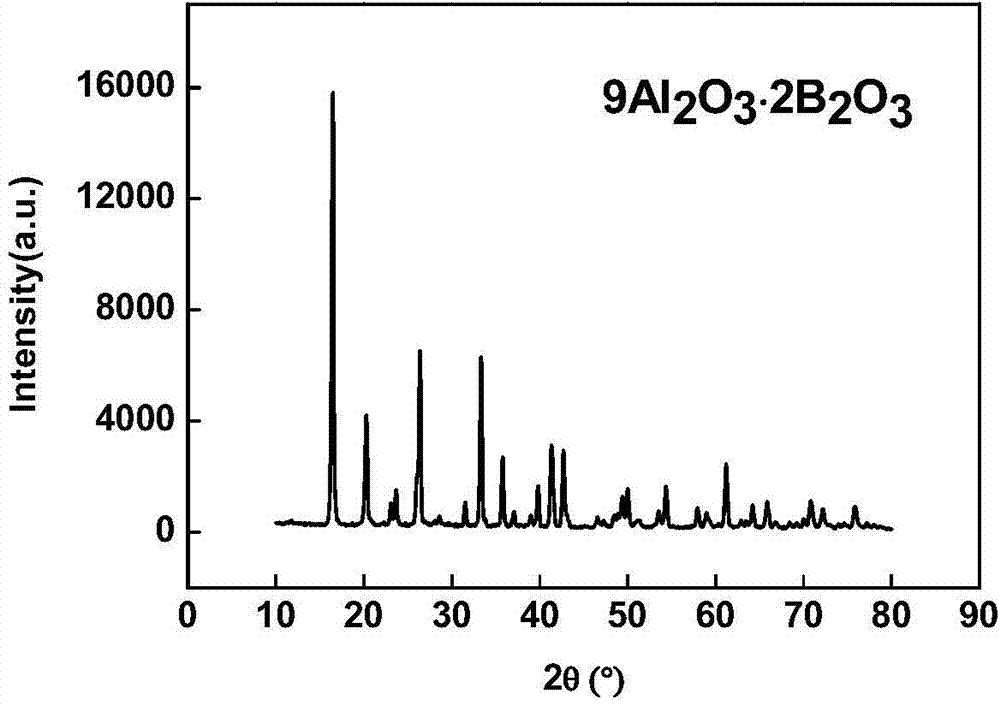

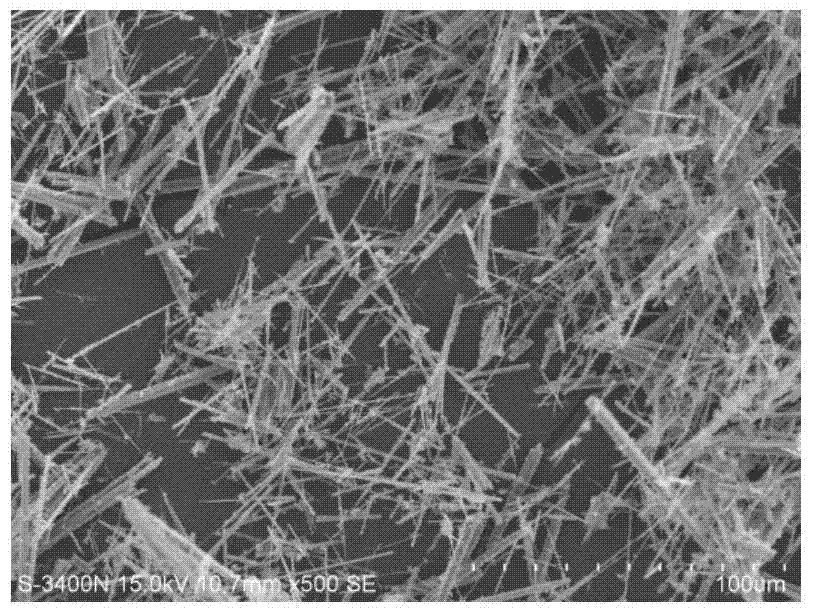

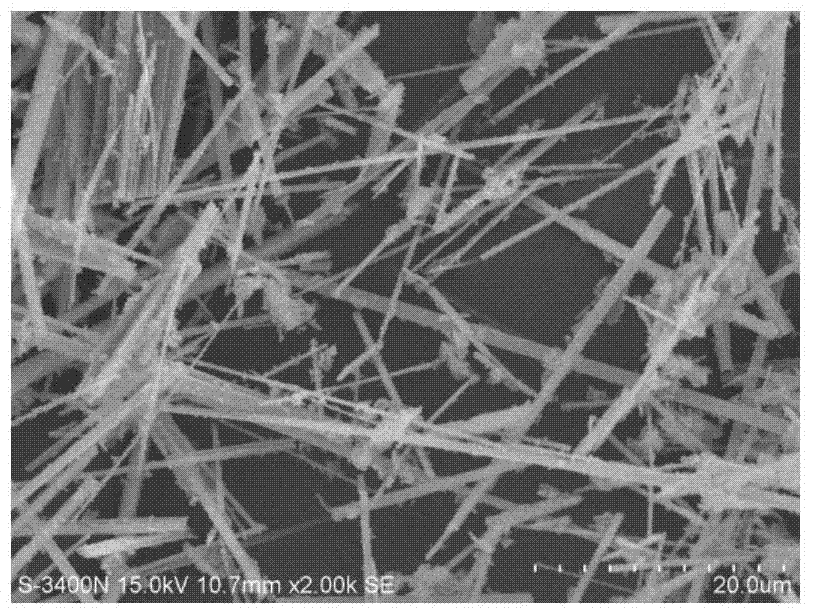

Preparation method of aluminum borate whisker

InactiveCN104328496AHigh densityImprove fullyPolycrystalline material growthFrom melt solutionsBoric acidPotassium alum

The invention relates to a preparation method of aluminum borate whisker, and particularly relates to a preparation method of the aluminum borate whisker. The preparation method of the aluminum borate whisker comprises the following steps of (1) pretreating alumen: calcining the alumen for 2-6 hours at a temperature of 250-350 DEG C, grinding or ball-milling and screening with a 120-mesh sieve; (2) mixing auxiliary materials: mixing pretreated alumen with boric acid and a fluxing agent by fully grinding or ball-milling, wherein a molar ratio of the pretreated alumen to boric acid is (1-4.5):1 and a molar ratio of the pretreated alumen and boric acid to the fluxing agent is 1:(0.5-2); and (3) tabletting the auxiliary materials: putting the mixed auxiliary materials in a mold with a diameter of 10-30 mm, regulating a pressure to 20-80 kN, tabletting the auxiliary materials to obtain a cylindrical auxiliary material; and sintering, leaching and drying the cylindrical auxiliary material to obtain the aluminum borate whisker. The preparation method is simple in process; the produced aluminum borate whisker has excellent qualities; an alum mineral product of alumen and boron resource in Qarhan salt lake are fully utilized; production cost is reduced; and the preparation method has wide industrialization prospects.

Owner:JIANGXI FENGZHU NEW MATERIAL TECH

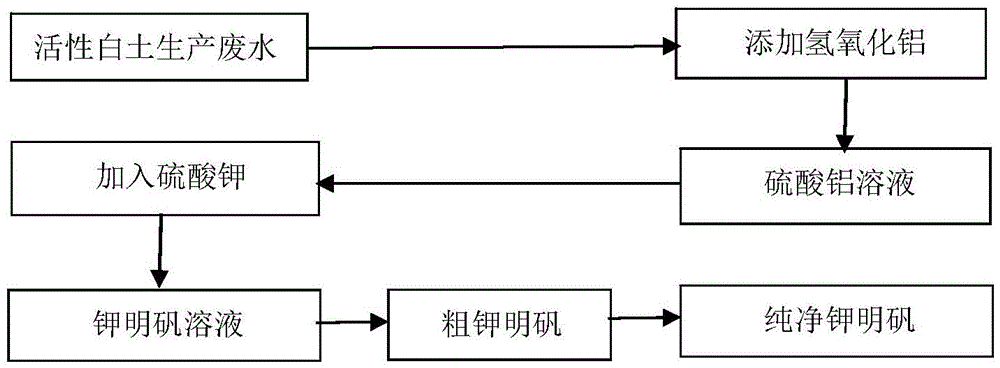

Method for preparing potassium alum by utilization of activated clay production waste water

InactiveCN105271341AEasy to handleTake advantage ofMultistage water/sewage treatmentAluminium sulfatesAluminium hydroxideFiltration

The invention discloses a method for preparing potassium alum by utilization of activated clay production waste water, and belongs to the activated clay waste water processing and inorganic salt preparation technology fields. Sulfuric acid and aluminum sulfate in activated clay production waste water are reacted with aluminum hydroxide and potassium sulfate, and a potassium alum product with a purity of more than 99.5% is prepared after steps of impurity removal, crystallization, press filtration, dewatering and the like. Activated clay waste water can be processed effectively, sulfuric acid and aluminum sulfate in activated clay production waste water can be utilized fully, and purposes of energy saving, emission reduction and changing waste into valuables are achieved. When the method is compared with the prior art, potassium sulfate with a lower price is employed to replace potassium hydroxide, and the production cost is low. centrifuge dewatering is employed to replace heating dewatering, the production efficiency is high, and the cycle is short. Through technology optimization, the purity of potassium alum is high.

Owner:GUANGXI LONGAN RUIFENG IND TRADING CO LTD

Sweet potato starch noodle production technology

The invention discloses a sweet potato starch noodle production technology, which comprises the following steps: washing, grinding, screening and precipitating, drying starch, pulping, producing noodles, cooling, freezing, deicing and drying noodles, thus obtaining the finished sweet potato noodle product; the screening and precipitation steps comprise the following substeps: adding a proper amount of water into the ground sweet potato, and filtering sequentially through a 90-mesh screen, a 120-mesh screen and a 250-mesh screen; precipitating the filtered starch suspension liquid for 8-10 hours; and then placing the precipitated starch into a container, adding water and stirring to form starch suspension liquid, then filtering through a 300-mesh screen, and precipitating the filtered starch suspension liquid for 8-10 hours for later use. According to the sweet potato starch noodle production technology, smooth and chewy sweet potato noodles can be produced without addition of potassium alum, and are unlikely to be broken during the production process.

Owner:贾海安

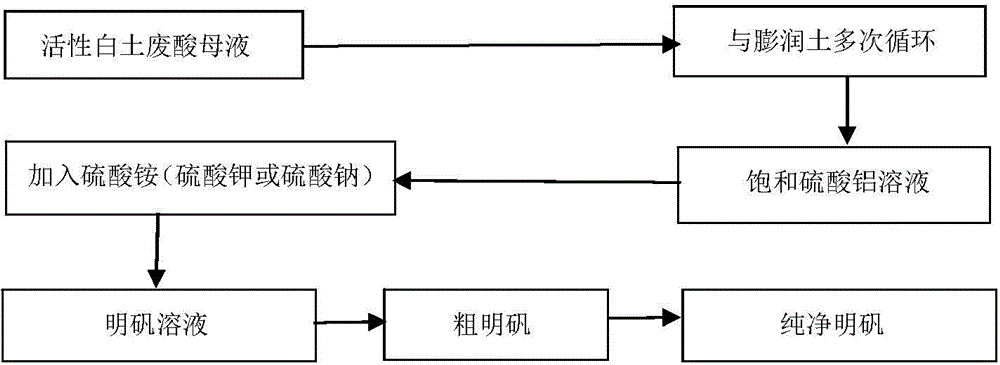

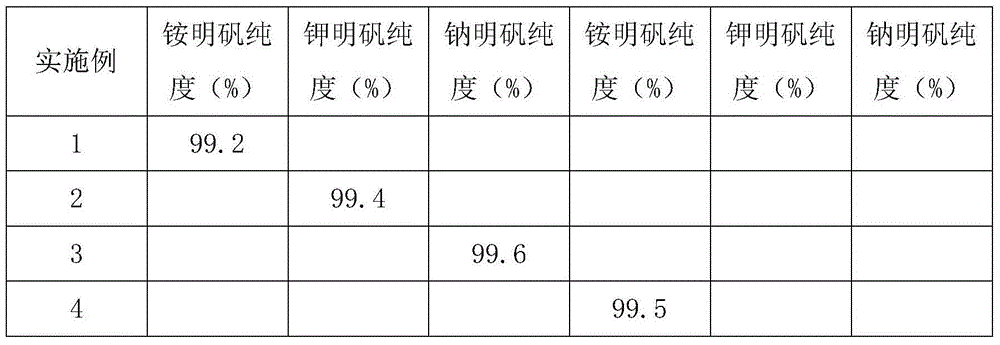

Method for preparing alum by utilization of activated clay waste acid mother solution

InactiveCN105271342AReduce manufacturing costShorten the production cycleAluminium sulfatesSodium BentoniteWater processing

The invention discloses a method for preparing alum by utilization of activated clay waste acid mother solution, and belongs to the waste water processing and inorganic salt preparation technology fields. By utilization of multiple cycles of an activated clay waste acid mother solution and bentonite, dissolved aluminum sulfate reaches a saturation state, then a reaction with ammonium sulfate (potassium sulfate or sodium sulfate) is carried out, and alum with a purity of more than 99.2% is prepared after crystallization for two times. The aluminum element in the activated clay production waste water mother solution is utilized comprehensively, waste water and obtained gypsum reach industrial application requirements, and the foundation is laid for environmental protection and emission reduction of the next production link. In addition, the cost for preparing alum can be lowered and the production cycle can be shortened.

Owner:GUANGXI LONGAN RUIFENG IND TRADING CO LTD

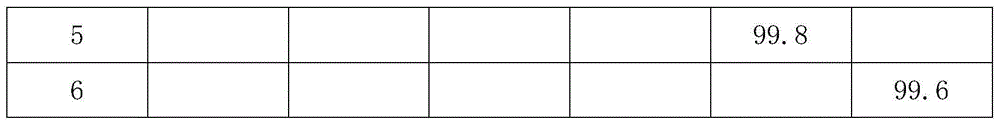

Method for CO2 mineralization with blast furnace slag and co-production of aluminum ammonium sulfate

The invention discloses a method for CO2 mineralization with blast furnace slag and co-production of aluminum ammonium sulfate. The method comprises the following steps: 1, ammonium sulfate decomposition of blast furnace slag: mixing blast furnace slag and ammonium sulfate at a certain temperature and roasting to convert valuable metal oxide in the blast furnace slag into corresponding ammonium sulfate complex salt; 2, preparation of aluminum ammonium sulfate crude liquor: leaching the roasted product obtained in the step 1 by the use of water so as to obtain aluminum ammonium sulfate crude liquor and leaching residue; 3, cooling for crystallization: cooling the aluminum ammonium sulfate crude liquor to obtain crystallization mother liquor and aluminum ammonium sulfate crystals, washing and airing to obtain aluminum ammonium sulfate; 4, magnesium-rich solution mineralization: adding ammonia water into the crystallization mother liquor obtained in the step 3 and introducing CO2 to generate magnesium carbonate so as to realize CO2 mineralization and obtain first mineralization mother liquor; 5, leaching residue mineralization: adding ammonia water into the leaching residue obtained in the step 2 and introducing CO2 to generate calcium carbonate so as to realize CO2 mineralization and obtain second mineralization mother liquor; and 6, ammonium sulfate circulation: mixing the mineralization mother liquors, carrying out evaporative concentration and cooling for crystallization so as to obtain ammonium sulfate solids and recycling.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com