Method for preparing potassium alum by utilization of activated clay production waste water

A technology for the production of wastewater and activated clay, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as production efficiency, low purity, high production cost, and long cycle , to achieve the effect of process optimization, low production cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

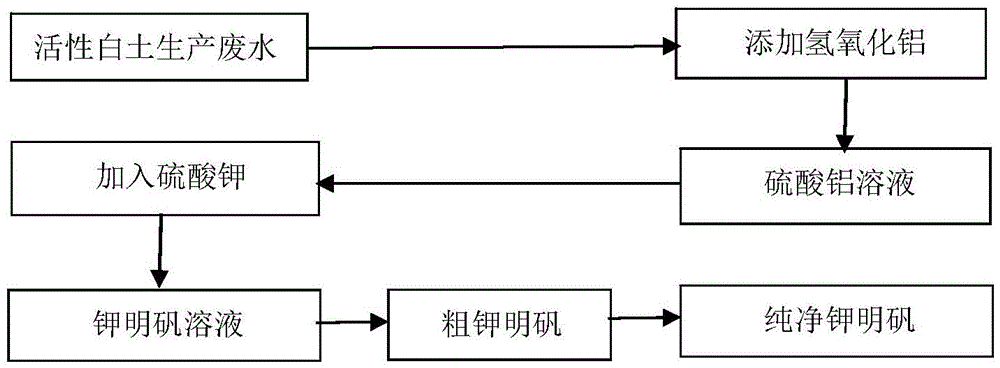

Image

Examples

Embodiment 1

[0022] A kind of method utilizing activated clay to produce waste water to prepare potassium alum, comprises the following steps:

[0023] S1: Add aluminum hydroxide to activated clay production wastewater, stir and dissolve aluminum hydroxide at a temperature of 80°C, add potassium sulfate to the above solution, and make K in the solution + :Al 3+ :SO 4 2- The molar ratio is 1:1:2, add potassium hydroxide solution to adjust the pH value to 3.2, filter the solution while it is hot to remove impurities, the resulting solution is cooled to 15°C to crystallize, and then press filter at a pressure of 0.9Mpa to obtain a filter cake crude potassium alum;

[0024] S2: Put the crude potassium alum into water, heat and stir to completely dissolve the crude potassium alum so that the mass concentration of the solution is 54%, remove impurities again while it is hot, and cool the obtained solution again to 15 ° C. After crystallization, the pressure is 0.9Mpa The filter cake was obta...

Embodiment 2

[0026] A kind of method utilizing activated clay to produce waste water to prepare potassium alum, comprises the following steps:

[0027] S1: Add aluminum hydroxide to activated clay production wastewater, stir and dissolve aluminum hydroxide at a temperature of 90°C, add potassium sulfate to the above solution, and make K in the solution + :Al 3+ :SO 4 2- The molar ratio is 1.08:1:2.08, add potassium hydroxide solution to adjust the pH value to 3.6, filter the solution while it is hot to remove impurities, the resulting solution is cooled at 13°C to crystallize, and then press filter at a pressure of 1.0Mpa to obtain a filter cake crude potassium alum;

[0028] S2: Put the crude potassium alum into water, heat and stir to completely dissolve the crude potassium alum and make the solution mass concentration 60%, remove impurities again while it is hot, and cool the obtained solution again to 13°C to crystallize, and then press it under a pressure of 0.9Mpa The filter cake...

Embodiment 3

[0030] A kind of method utilizing activated clay to produce waste water to prepare potassium alum, comprises the following steps:

[0031] S1: Add aluminum hydroxide to activated clay production wastewater, stir and dissolve aluminum hydroxide at a temperature of 85°C, add potassium sulfate to the above solution, and make K in the solution + :Al 3+ :SO 4 2- The molar ratio is 1.04:1:2.04, add potassium hydroxide solution to adjust the pH value to 3.4, filter the solution while it is hot to remove impurities, the resulting solution is cooled at 12°C to crystallize, and then press filter at a pressure of 0.95Mpa to obtain a filter cake crude potassium alum;

[0032] S2: Put the crude potassium alum into water, heat and stir to completely dissolve the crude potassium alum and make the solution mass concentration 57%, remove impurities again while it is hot, and cool the obtained solution again to 12°C for crystallization, and then press it under a pressure of 0.9Mpa Press fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com