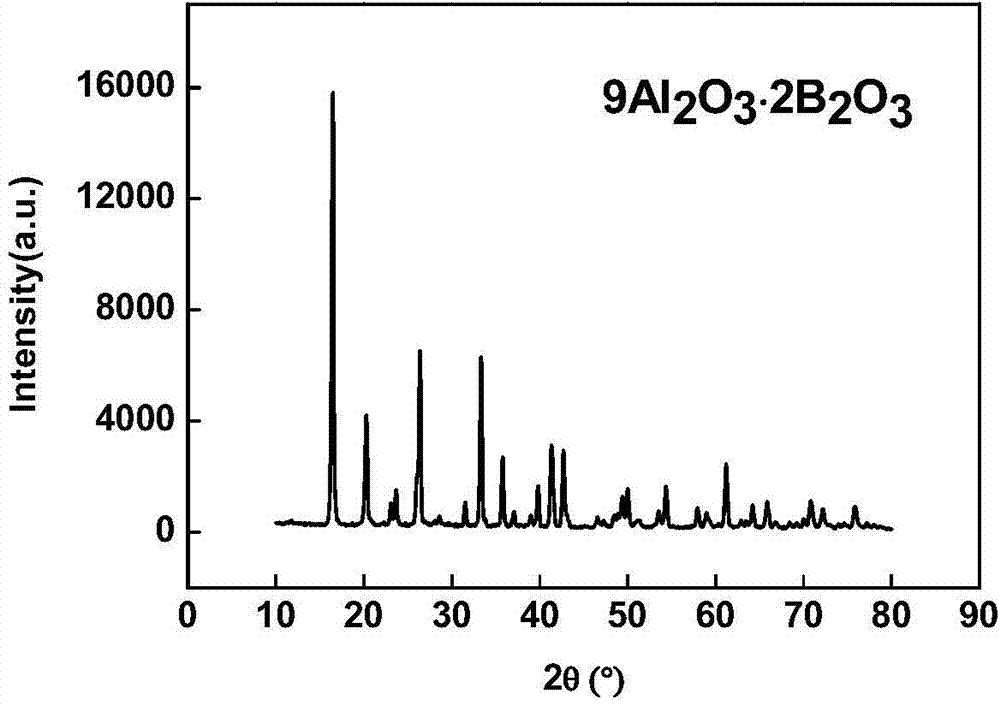

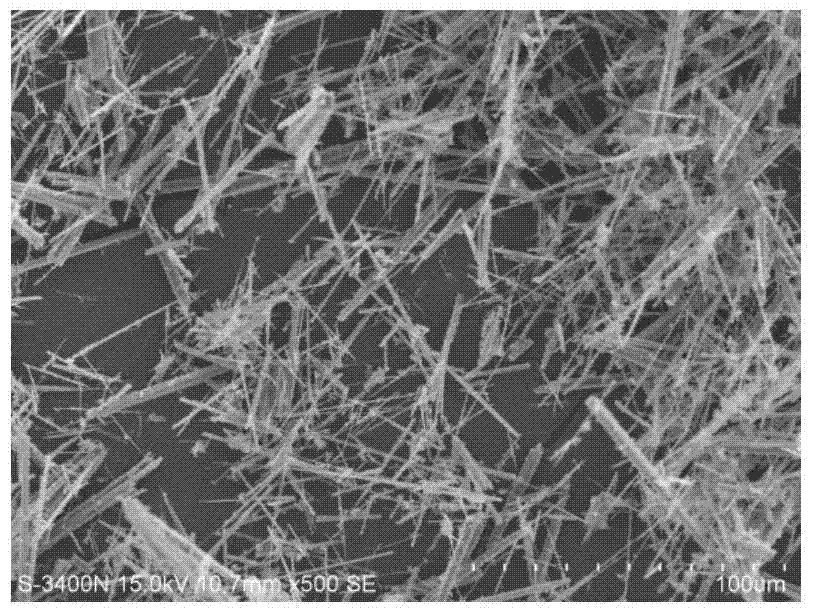

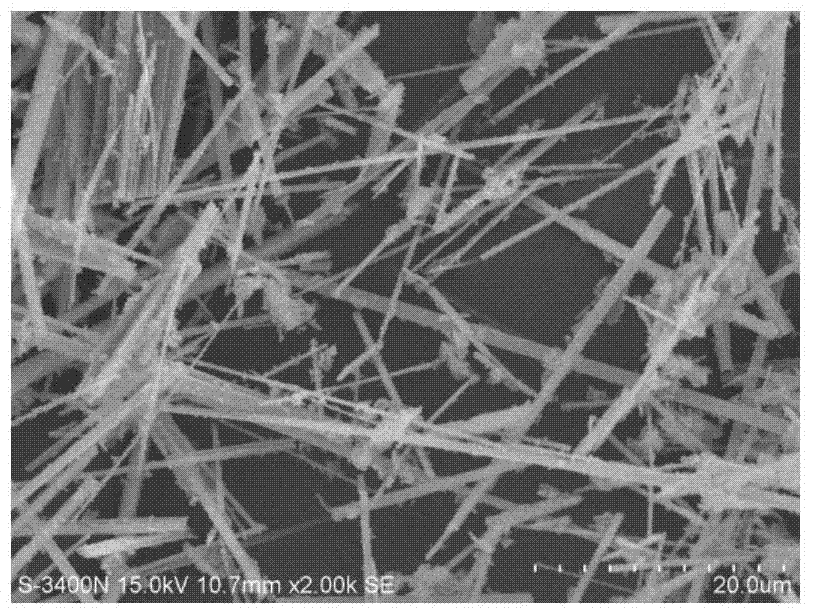

Preparation method of aluminum borate whisker

A technology of aluminum borate whiskers and boric acid, which is applied in the field of preparation of aluminum borate whiskers, can solve problems such as small size of aluminum borate whiskers, uneven distribution of whiskers, and influence on practical application, so as to reduce production costs, broaden industrialization prospects, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix the pretreated alum, boric acid, and potassium sulfate in a molar ratio of 3:1:4, fully mix them by ball milling, put the mixed ingredients into a mold with a diameter of 30mm, adjust the pressure to 30kN, and press the ingredients into tablets. A cylindrical batch with a diameter of 30 mm was produced. Put the prepared cylindrical ingredients into a corundum crucible, place them in a temperature-programmed furnace, raise the temperature to 1100°C at a heating rate of 5°C / min, keep the temperature constant for 4 hours, and cool naturally after the reaction to obtain a sintered block. Soak and stir the agglomerate in hot water at 80°C, the mass ratio of water to agglomerate is 10:1, and filter after 4 hours; soak and stir the obtained filter cake in hot water at 80°C again, and after 1 hour Filtration; the obtained filter cake was immersed in hot water at 80° C. for the third time, stirred, and filtered again after 1 hour. The obtained white filter cake was dried in...

Embodiment 2

[0032] Mix the pretreated alum, boric acid, and potassium sulfate in a molar ratio of 2:1:3, fully mix them by ball milling, put the mixed ingredients into a mold with a diameter of 30mm, adjust the pressure to 60kN, and press the ingredients into tablets. A cylindrical batch with a diameter of 30 mm was produced. Put the prepared cylindrical ingredients into a corundum crucible, place them in a temperature-programmed furnace, raise the temperature to 1200°C at a heating rate of 10°C / min, keep the temperature constant for 2 hours, and cool naturally after the reaction to obtain a sintered block. Soak and stir the sintered block in hot water at 80°C, the mass ratio of water to sintered block is 8:1, filter after 4 hours; soak and stir the obtained filter cake in 1mol / L hydrochloric acid at 80°C again, 1 Filter after 1 hour; the obtained filter cake is soaked and stirred again in hot water at 80° C. for the third time, and then filtered again after 1 hour. The obtained white fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com