Method for preparing high-purity potassium alum and aluminum sulfate from alunite ore

A kind of technology of alunite and potassium alum, which is applied in the field of preparing high-purity potassium alum and aluminum sulfate, and can solve the problems that the gains outweigh the losses, the market volume of potassium alum is small, and the alumite ore cannot be effectively recovered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

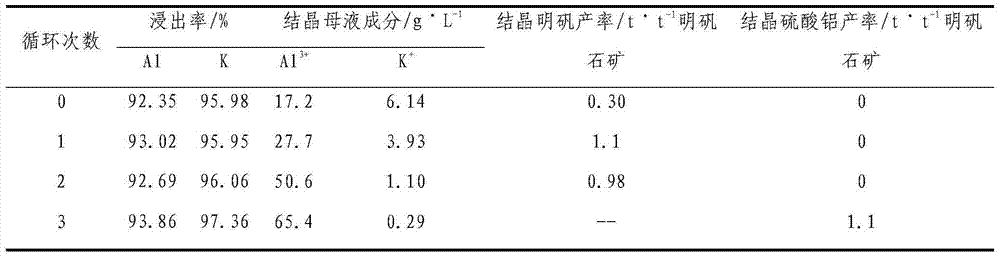

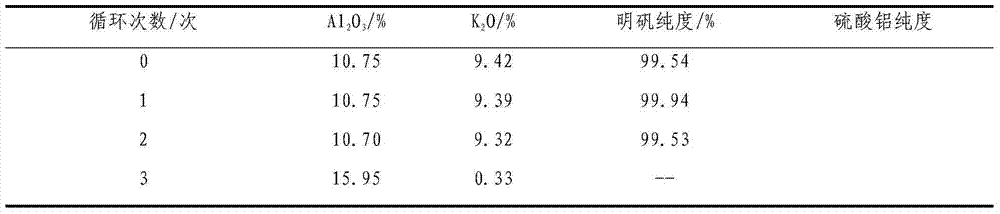

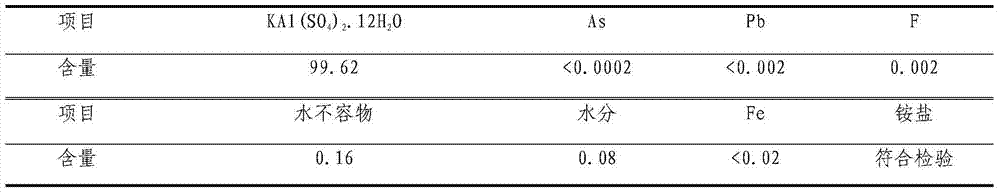

[0018] Example 1: Take 100g of Zijinshan associated alunite ore in a crucible and place it in a muffle furnace for roasting and dehydration at a temperature of 550°C for 2 hours. The dehydrated alum is leached under the condition of a solid ratio of 5, the leaching solution naturally crystallizes potassium alum, the crystalline potassium alum mother liquor is added with a certain amount of acid, and then returns to leaching, and the leaching solution is circulated to crystallize potassium alum, and after 3 cycles, the crystalline potassium alum mother liquor crystallizes aluminum sulfate. The dehydrated alunite cyclic leaching-crystallization test results are shown in Table 1, the purity of crystalline alum and aluminum sulfate in different cyclic leaching times of dehydrated alunite is shown in Table 2, and the multi-element analysis results of crystalline potassium alum are shown in Table 3. The results of multi-element analysis are shown in Table 4. From the results of Tabl...

example 2

[0019] Example 2: Take 100g of Zijinshan associated alunite ore, put it in a crucible and place it in a muffle furnace for roasting and dehydration at a temperature of 550°C for 1.5 hours, and then use a sulfuric acid dosage of 350kg / t alunite ore, a temperature of 70°C, and liquid-solid The dehydrated alum is leached under the condition of ratio 7, the leaching solution naturally crystallizes gallium alum, and after crystallizing potassium alum, the mother liquor is added a certain amount of acid and then returns to leaching, and the leaching solution is circulated to crystallize potassium alum, and after 4 cycles, the crystallization mother liquor crystallizes aluminum sulfate. The obtained potassium alum has a purity of 99.48%, and the Al2O3 content in the crystalline aluminum sulfate is 16.05%. The chemical detection of crystalline potassium alum and aluminum sulfate is carried out according to GB1895-2004 and HG / T2225-2001 respectively, and the indicators of potassium alum...

example 3

[0020] Example 3: Take 100g of primary alunite ore from Wenzhou Alum Mine, roast and dehydrate it in a muffle furnace at a temperature of 500°C for 1 hour, and then dehydrate it under the conditions of a sulfuric acid dosage of 300kg / t alunite ore, a temperature of 80°C, and a liquid-solid ratio of 6 Dehydrated alum is leached under the bottom, the leaching solution naturally crystallizes gallium alum, and after crystallizing potassium alum, the mother liquor is added a certain amount of acid and then returns to leaching, and the leaching solution is circulated to crystallize potassium alum. The content of Al2O3 in aluminum sulfate is 15.98%. The chemical detection of crystalline potassium alum and aluminum sulfate is carried out according to GB1895-2004 and HG / T2225-2001 respectively, and the indicators of potassium alum and aluminum sulfate meet the technical requirements of GB1895-2004 food additives and HG / T2225-2001 first-class products respectively.

[0021] Table 1 Resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com