Preparation system and preparation method of agriculture and forestry biomass fuel

A biomass, agricultural and forestry technology, applied in the preparation system and field of agricultural and forestry biomass fuels, can solve the problems of secondary pollution, difficult to control, homologous viruses, etc., to achieve increased calorific value, high utilization rate, and reduced oxygen/carbon than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

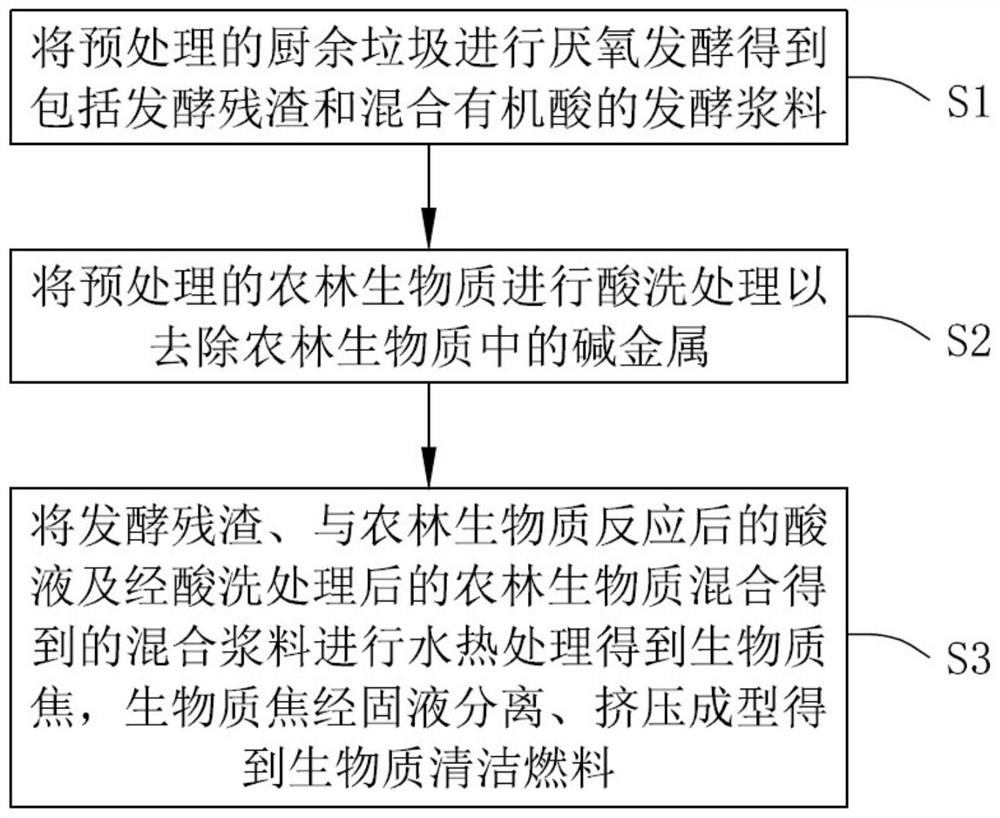

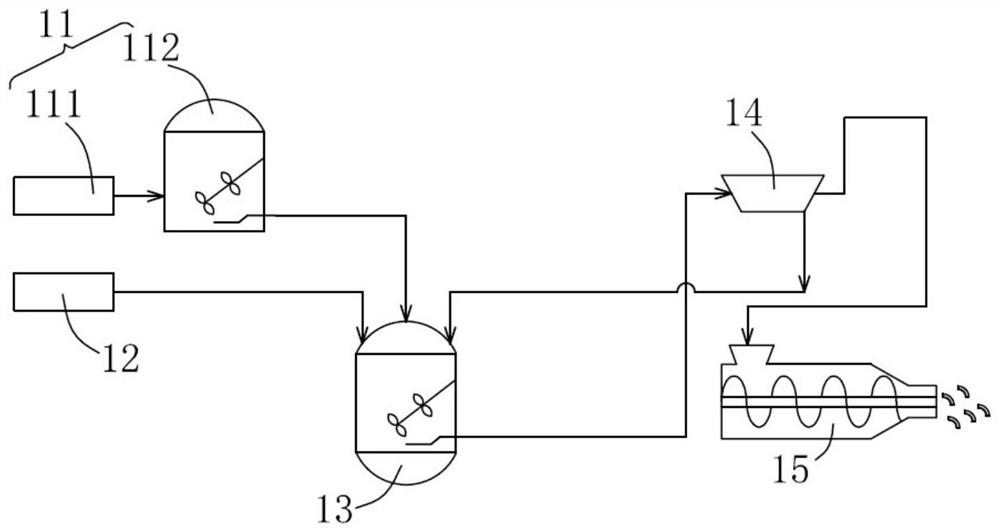

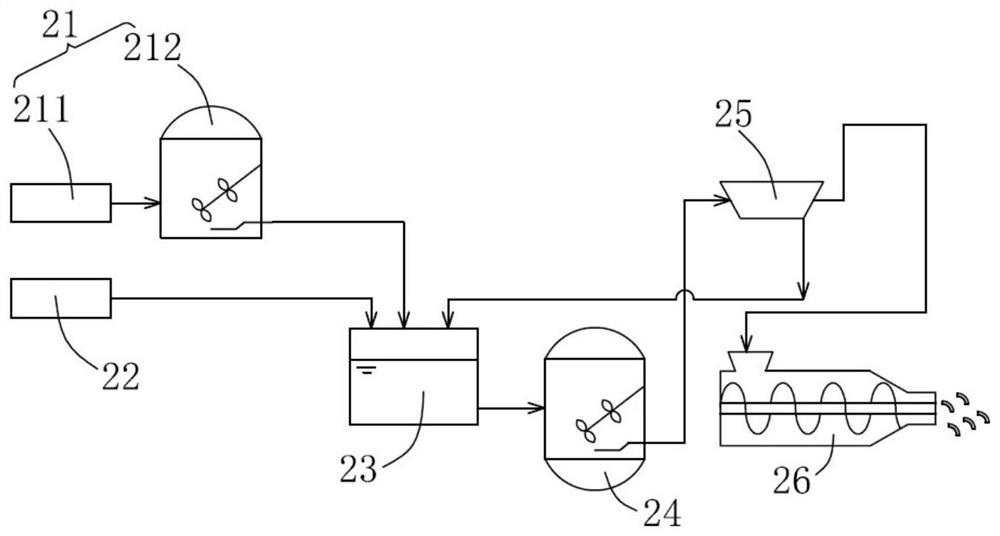

[0041] see figure 1 , the present invention provides a kind of preparation method of agricultural and forestry biomass clean fuel, and described preparation method comprises the following steps:

[0042] S1, performing anaerobic fermentation on the pretreated kitchen waste to obtain a fermentation slurry including fermentation residue and mixed organic acids;

[0043] Specifically, first sort and remove large pieces of sand, stones, plastics, etc. in the raw materials of kitchen waste, and then carry out crushing and screening treatment. The particle size of the kitchen waste obtained by pretreatment is 2-4mm; The final kitchen waste is placed in a fermentation tank, and the activated sludge is used as an inoculum for anaerobic fermentation. The anaerobic fermentation temperature is 20-50°C, preferably 37°C, and the anaerobic fermentation time is 4-6 days.

[0044] Preferably, the content of the mixed organic acid is 3-10 wt%, preferably 6-8 wt%.

[0045] Preferably, the mix...

Embodiment 1

[0063] (1) Crush kitchen waste to a particle size of 2-4 mm, use activated sludge as an inoculum, and perform anaerobic fermentation at 37°C for 5 days to obtain a fermentation slurry, which includes fermentation residue and mixed Organic acid, the pH value of the mixed organic acid is 4.5, and the mass content is 7wt%;

[0064] (2) Crushing and sieving the corn stalks to a particle size of 2-4 mm, then mixing it with the fermentation slurry, and stirring at a constant temperature of 60° C. for 24 hours to obtain a mixed slurry;

[0065] (3) Put the mixed slurry obtained in step (2) in a high-temperature reactor for hydrothermal treatment to obtain biomass coke. The hydrothermal treatment time is 60 minutes, the hydrothermal treatment temperature is 180° C., and the pressure is saturated vapor pressure. The mixed The solid-to-liquid ratio of the slurry is 1:12;

[0066] (4) After the liquid components are removed from the biomass coke produced by the hydrothermal treatment, t...

Embodiment 2

[0068] Embodiment 2~7 is identical with embodiment 1 preparation method, and its difference is that hydrothermal treatment time is not the same, specifically, the hydrothermal treatment time of embodiment 1 is 60min, and the hydrothermal treatment time of embodiment 2 is 10min; The heat treatment time is 30min, and the hydrothermal treatment time of embodiment 4 is 45min; The hydrothermal treatment time of embodiment 5 is 90min; The hydrothermal treatment time of embodiment 6 is 100min; The hydrothermal treatment time of embodiment 7 is 120min; The heat treatment time is 180min.

[0069] The results of solid product yield and industrial analysis of the biomass clean fuel prepared in Examples 1 to 8 are shown in Table 1 (subtraction method).

[0070] The biomass solid product productive rate of table 1 different hydrothermal treatment time, industrial analysis form (%)

[0071] Hydrothermal treatment time Yield Volatile matter Ash moisture fixed carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com