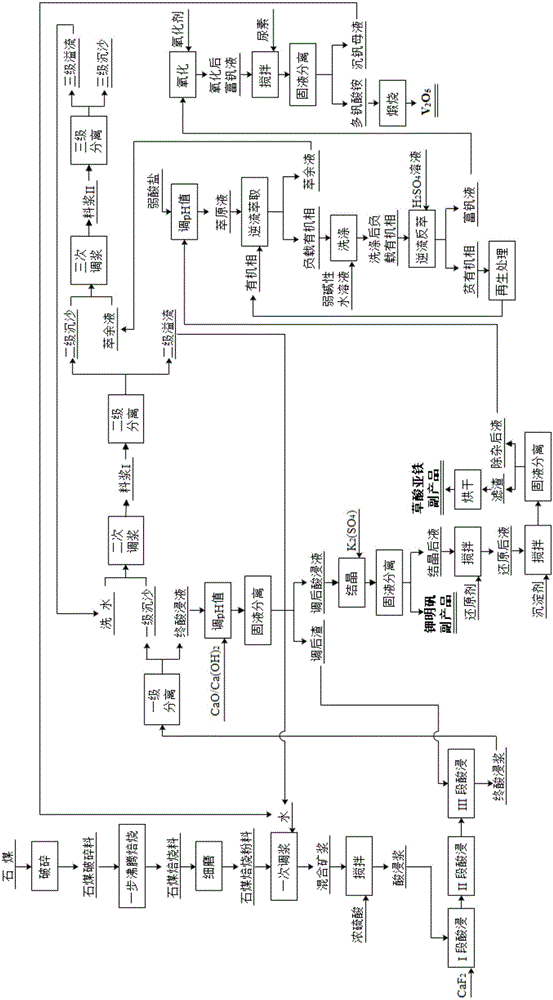

Method for preparing high-purity vanadium pentoxide by use of stone coal one-step method

A technology for vanadium pentoxide and stone coal is applied in the field of one-step preparation of high-purity vanadium pentoxide from stone coal, which can solve the problems of high energy consumption, serious pollution, long process and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The invention discloses a method for preparing high-purity vanadium pentoxide by one-step method from stone coal. The specific steps of the method described in this embodiment are as follows:

[0090] Step 1, one-step boiling roasting of stone coal

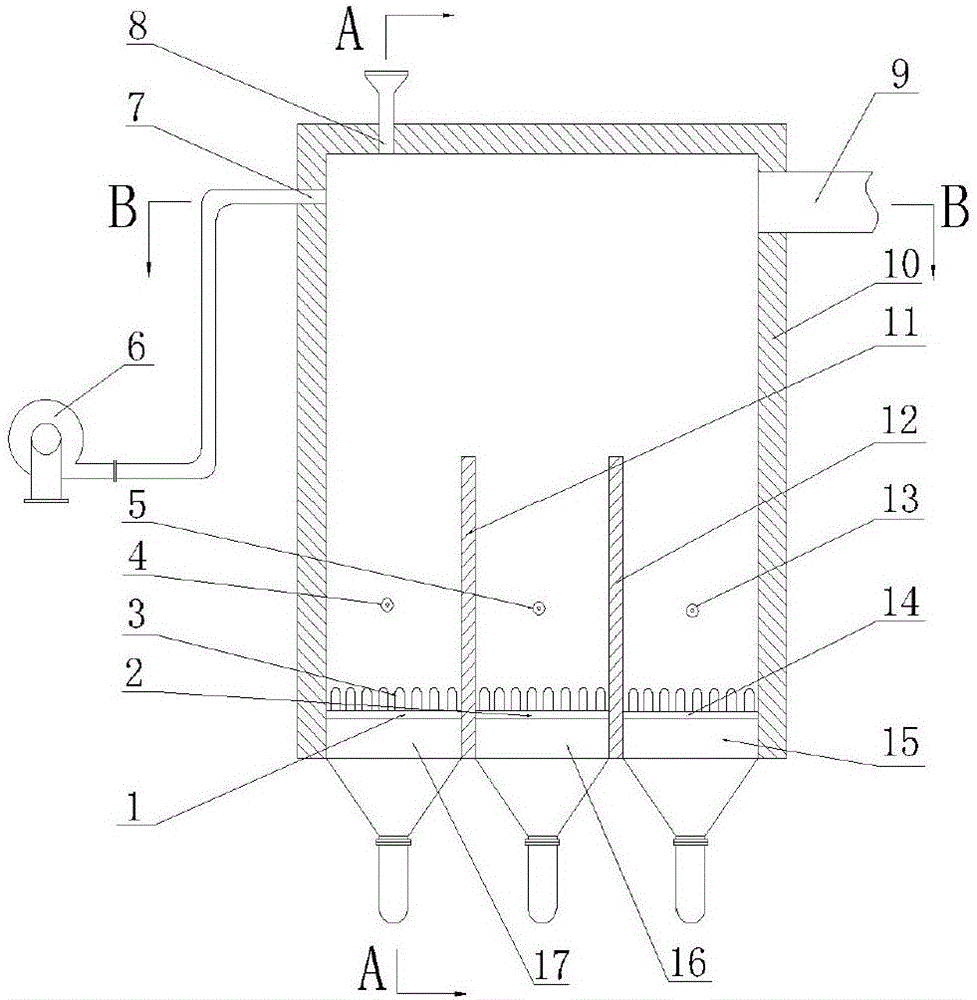

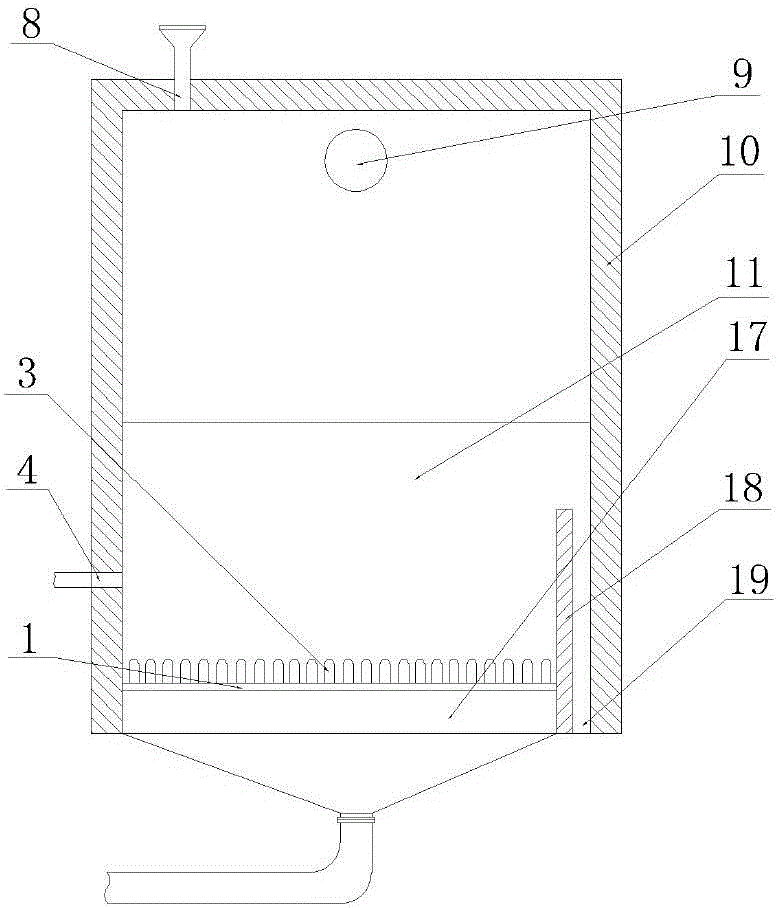

[0091] Step 1.1, the equipment adopted in the one-step boiling roasting of stone coal is "a fluidized fluidized furnace for one-step roasting of stone coal", and the specific structure is:

[0092] Near the bottom of the furnace body 10, a first fluidized bed 1, a second fluidized bed 2 and a third fluidized bed 14 are sequentially arranged from left to right, and the first fluidized bed 1 and the second fluidized bed 2 are formed by the first fluidized bed The fire wall 11 separates, the second fluidized bed 2 and the third fluidized bed 14 are separated by the second fire wall 12, the first air chamber 17 and the second air chamber 16 are separated by the first fire wall 11, the second The air chamber 16 and the third a...

Embodiment 2

[0134] The invention discloses a method for preparing high-purity vanadium pentoxide by one-step method from stone coal. The specific steps of the method described in this embodiment are as follows:

[0135] Step 1, one-step boiling roasting of stone coal

[0136] Step 1.1 is the same as step 1.1 in Example 1.

[0137] Step 1.2, one-step boiling roasting method of stone coal

[0138] The stone coal is crushed until the particle size is less than or equal to 15mm, and the stone coal crushed material is obtained. Turn on the fourth fan 6, adjust the wind speed of the tuyere 7 to 11-13m / s, and feed the stone coal crushed material into the furnace body 10 through the feed port 8 at a rate of 90-120kg / h. More than 90% of the stone coal crushed material with a particle size greater than 8mm and less than or equal to 15mm falls into the first fluidized bed 1, and more than 90% of the stone coal crushed material with a particle size greater than 3mm and less than or equal to 8mm fa...

Embodiment 3

[0170]The invention discloses a method for preparing high-purity vanadium pentoxide by one-step method from stone coal. The specific steps of the method described in this embodiment are as follows:

[0171] Step 1, one-step boiling roasting of stone coal

[0172] Step 1.1 is the same as step 1.1 in Example 1.

[0173] Step 1.2, one-step boiling roasting method of stone coal

[0174] The stone coal is crushed until the particle size is less than or equal to 15mm, and the stone coal crushed material is obtained. Turn on the fourth fan 6, adjust the wind speed of the tuyere 7 to 13-15m / s, and simultaneously feed the stone coal crushed material into the furnace body 10 through the feeding port 8, and the feeding amount is 120-150kg / h. More than 90% of the stone coal crushed material with a particle size greater than 8mm and less than or equal to 15mm falls into the first fluidized bed 1, and more than 90% of the stone coal crushed material with a particle size greater than 3mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com