Patents

Literature

294 results about "Potassium oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of potassium oxalate. : any of three crystalline oxalates of potassium: a : the normal efflorescent soluble salt K 2C 2O 4.H 2O used chiefly in preventing the clotting of blood (as in blood tests) and formerly in photography. b.

Polyester polycondensation with catalyst and a catalyst enhancer

InactiveUS20020032300A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyesterPotassium

The present invention is based upon the discovery that nontitanyl oxalates can enhance the catalytic functionality of titanyl oxalate catalysts. This invention provides a novel catalytic composition containing a titanyl oxalate catalyst and a metallic oxalate catalyst enhancer and optionally containing a metallic cocatalyst such as an antimony based catalyst. A synergistic relationship has been discovered between titanyl oxalate catalyst and the catalyst enhancer. A synergistic relationship has also been discovered between the titanyl oxalate catalyst, catalyst enhancer and a metallic cocatalyst such as antimony oxide or antimony triacetate. Also provided is an improved process of producing polyester by the polycondensation of polyester forming reactants in the presence of a catalytically effective amount of a polycondensation catalyst, wherein the improvement comprises utilizing, as the polycondensation catalyst, the novel catalyst composition containing a titanyl oxalate such as lithium titanyl oxalate and a catalyst enhancer such as a nontitanyl metallic oxalate like lithium oxalate and optionally containing a metallic catalyst such as antimony oxide or antimony triacetate. The improved process produces an improved polyester having lower acetaldehyde numbers and good color. The titanyl oxalate / catalyst enhancer composition can be used as a polycondensation catalyst in combination with other catalysts to achieve synergistic catalytic activity. Preferred is a combination of lithium or potassium titanyl oxalate, Li2 or K2TiO(C2O4)2, lithium or potassium oxalate, Li2 or K2(C2O4)2 with antimony oxide or antimony triacetate or antimony trisglycoxide.

Owner:ARKEMA INC

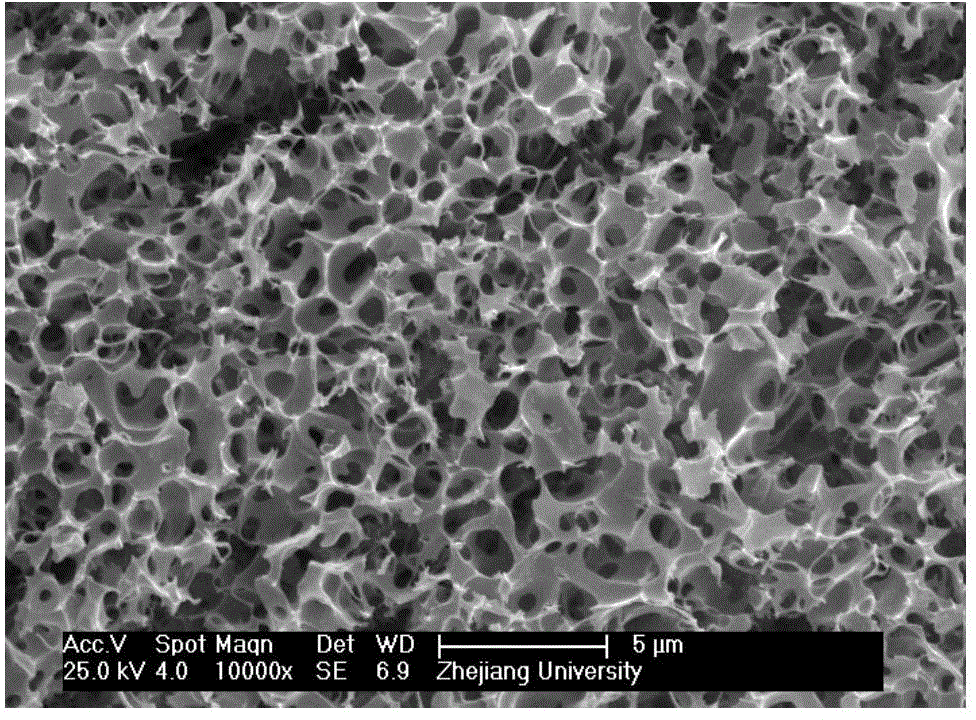

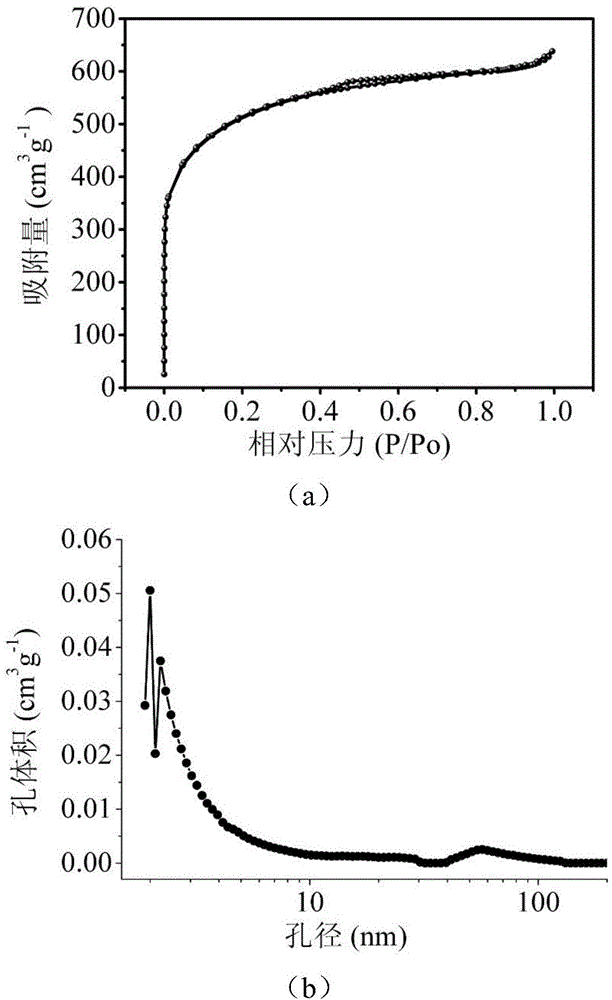

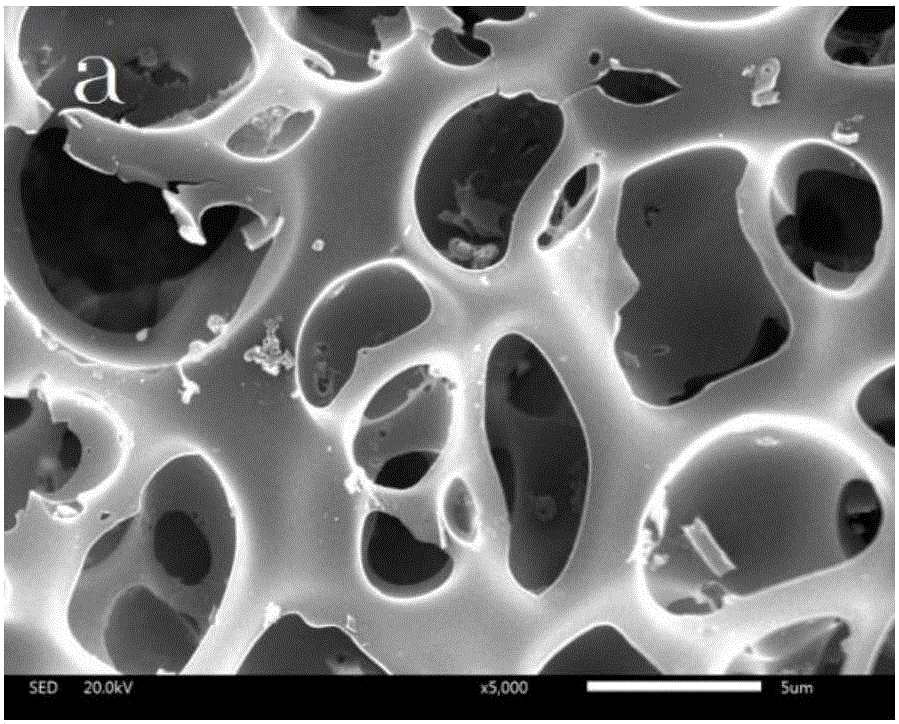

Preparation method and product of multistage porous carbon material

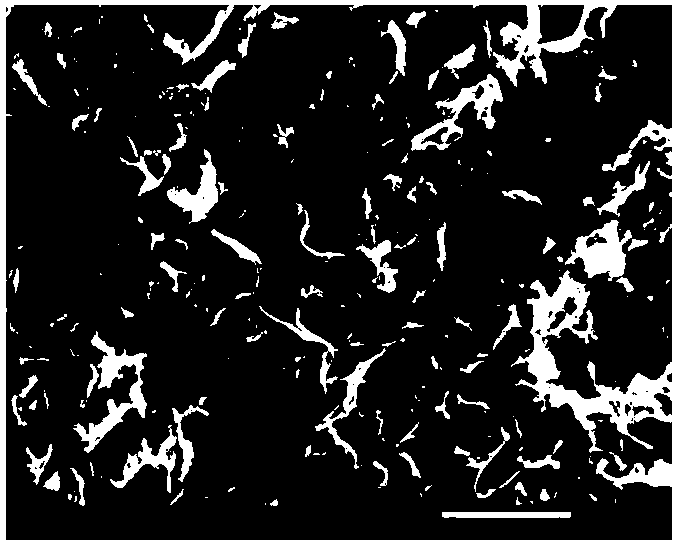

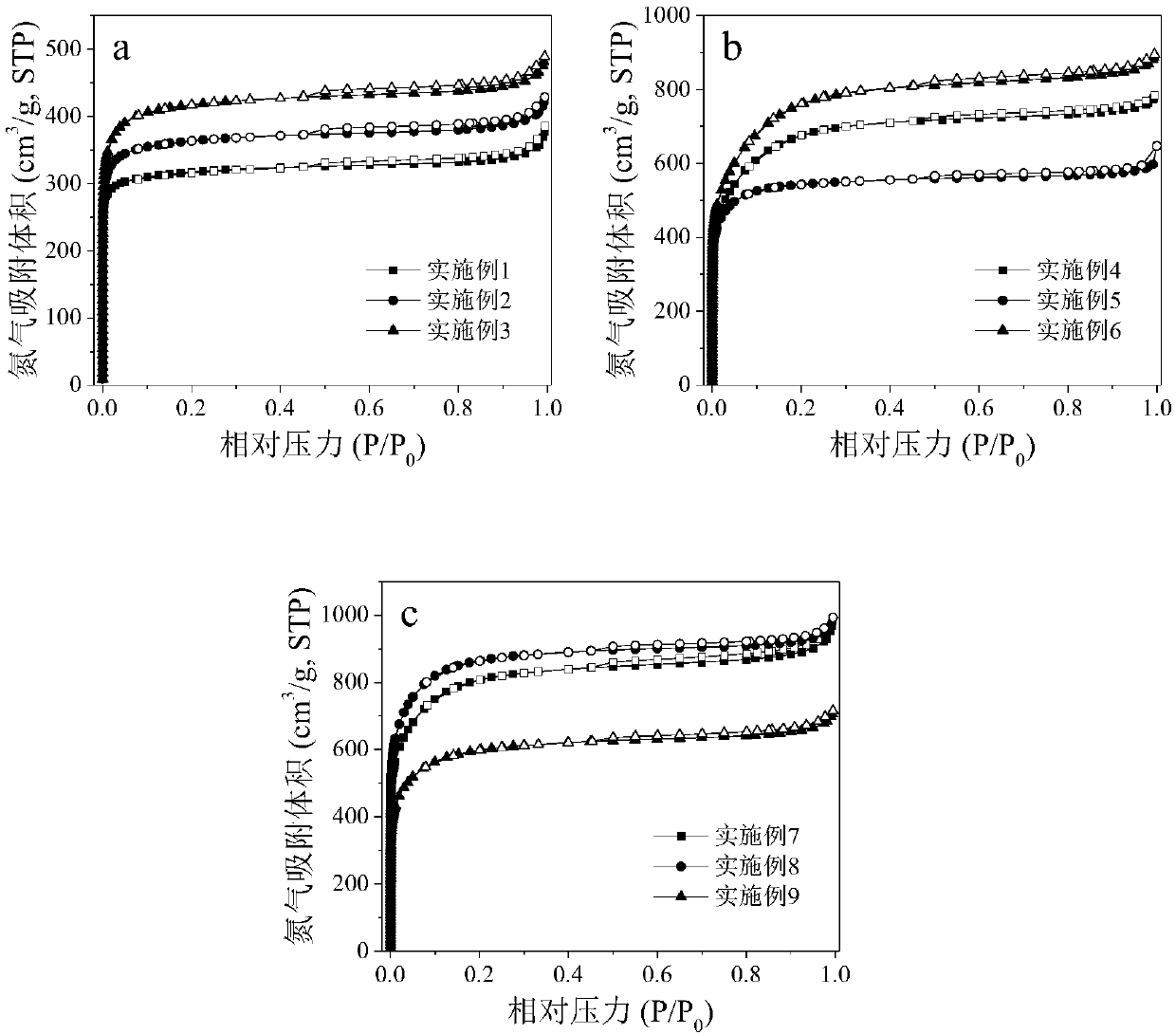

The invention discloses a preparation method of a multistage porous carbon material. The preparation method comprises the following steps: blending a carbon source with an activator, and performing two-step carbonization and after treatment to obtain the multistage porous carbon material, wherein the two-step carbonization comprises low-temperature carbonization and high-temperature carbonization, the temperature of the low-temperature carbonization is 200-400 DEG C, and the temperature for the high-temperature carbonization is 800-1200 DEG C; the carbon source is a biomass, monosaccharide, disaccharide or polysaccharide of which the cellulose content is more than 20%; and the activator is selected from ammonium oxalate, potassium oxalate, potassium hydrogen oxalate, potassium tetroxalate, sodium oxalate, sodium hydrogen oxalate, sodium tetroxalate, sodium hydrogen carbonate or potassium hydrogen carbonate. The invention provides the preparation method of the multistage porous carbon material rich in macropore, and according to the preparation method, physical expansion and chemical activation are utilized, and a carbon source is used as a raw material to match with a specific activator in order to prepare the multistage porous carbon material rich in macropore; and the raw material is low in price and easy to obtain, the method is simple and strong in sustainability and has a potential for large-scale production.

Owner:ZHEJIANG UNIV

Polyester polycondensation with catalyst and a catalyst enhancer

InactiveUS6372879B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyesterPotassium

Owner:ARKEMA INC

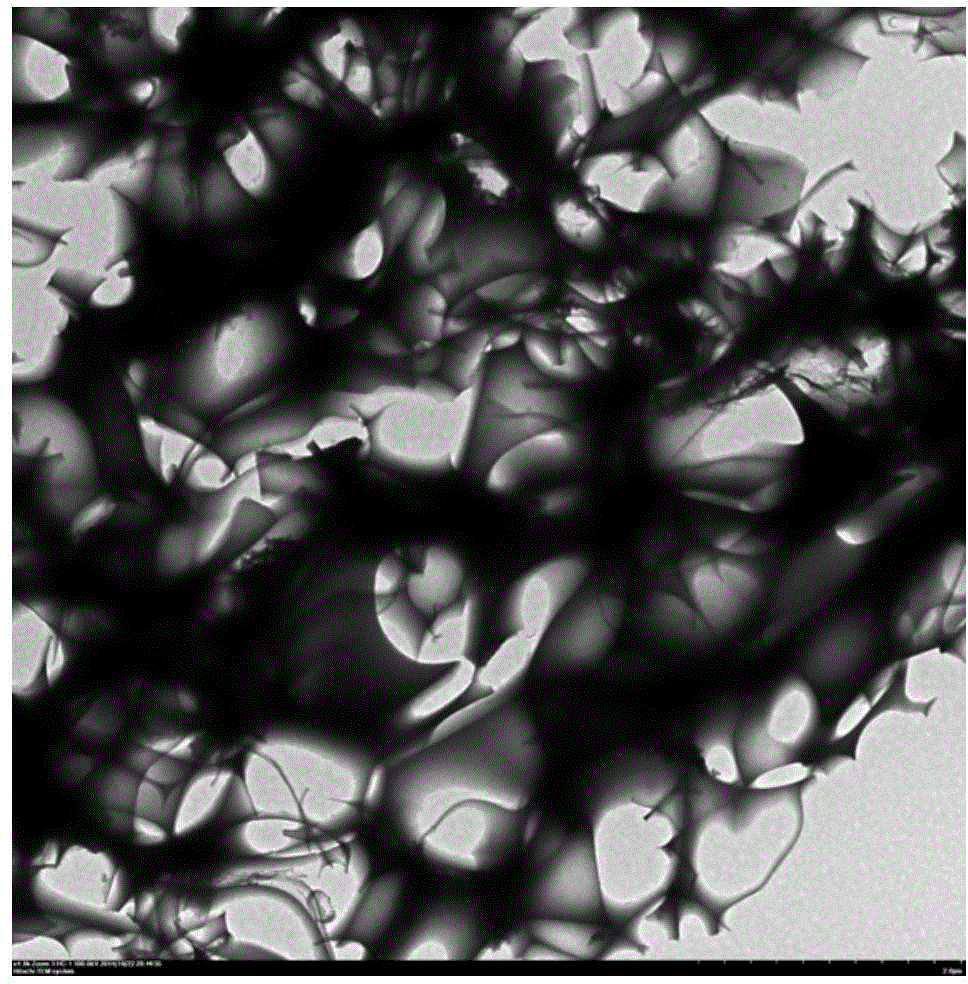

A kind of preparation method of mangosteen shell activated carbon with high specific surface area and rich in mesopores

InactiveCN102275917ALarge specific surface areaConducive to high-value utilizationSolid waste disposalActivated carbonPhysical chemistry

The invention discloses a preparation method of high-specific surface area mangosteen shell active carbon rich in mesopores. The preparation method comprises the following steps of cleaning waste mangosteen shells, drying in air, crushing, sieving by a 40 meshes of sieve, drying by an oven at a temperature of 105 to 110 DEG C for 12 to 24 hours to constant weight, mixing to dip the dried mangosteen shell powder with a potassium oxalate solution for 12 to 24 hours, drying by an oven at a temperature of 105 to 110 DEG C for 12 to 24 hours, placing the dried material obtained by the previous step into a muffle furnace, heating to a temperature of 700 to 900 DEG C, keeping the temperature for 1 to 3 hours, cooling in air, washing by a HCl solution for 30 to 45 minutes, washing by deionized water to a pH value of 7, and drying to obtain the high-specific surface area mangosteen shell active carbon rich in mesopores. The preparation method adopts mangosteen shell waste as a raw material andrealizes one-step preparation of the high-specific surface area mangosteen shell active carbon rich in mesopores through multiple high-efficiency activation produced by potassium oxalate stage pyrolysis products, and thus has excellent economic and ecological benefits.

Owner:FUJIAN AGRI & FORESTRY UNIV

Light blue jun porcelain and firing method thereof

ActiveCN106045563ADoes not affect strengthHelp to combineCeramic materials productionCeramicwareTin dioxidePotassium

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

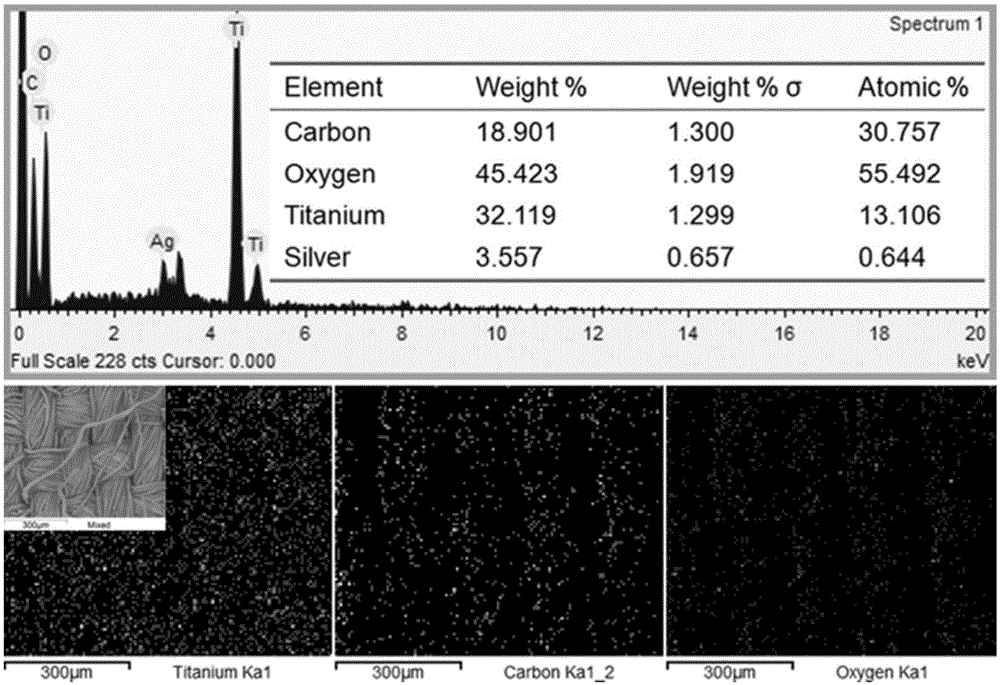

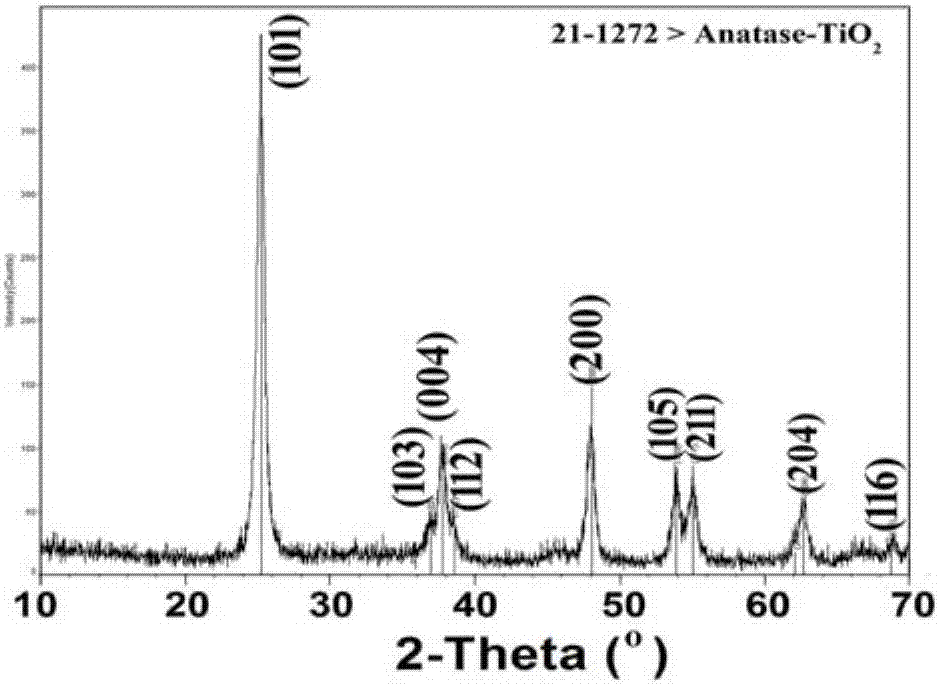

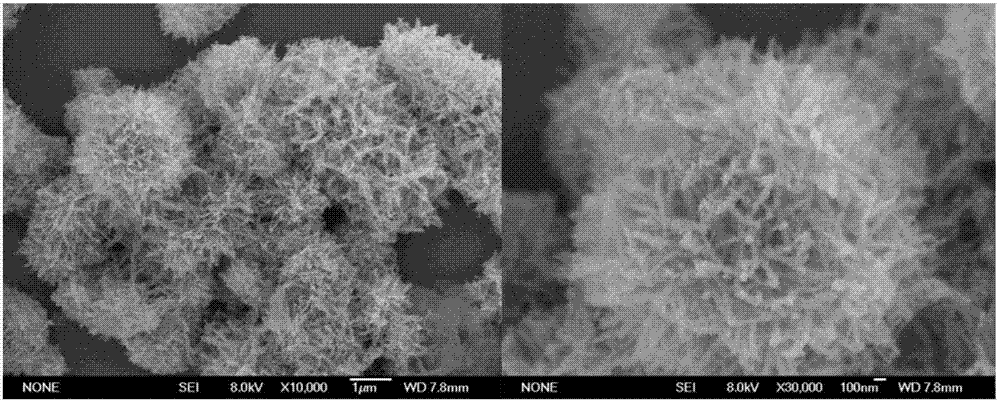

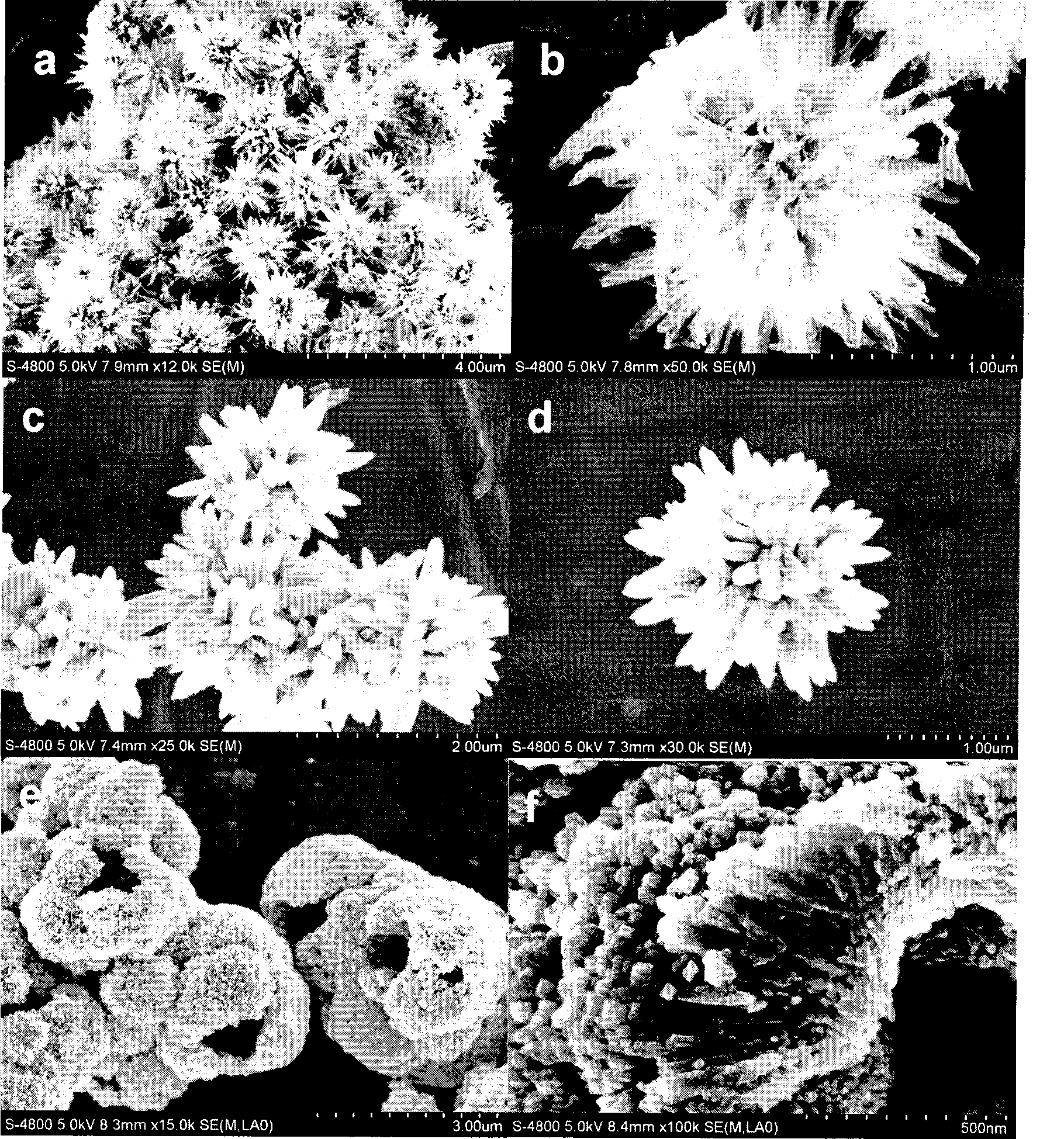

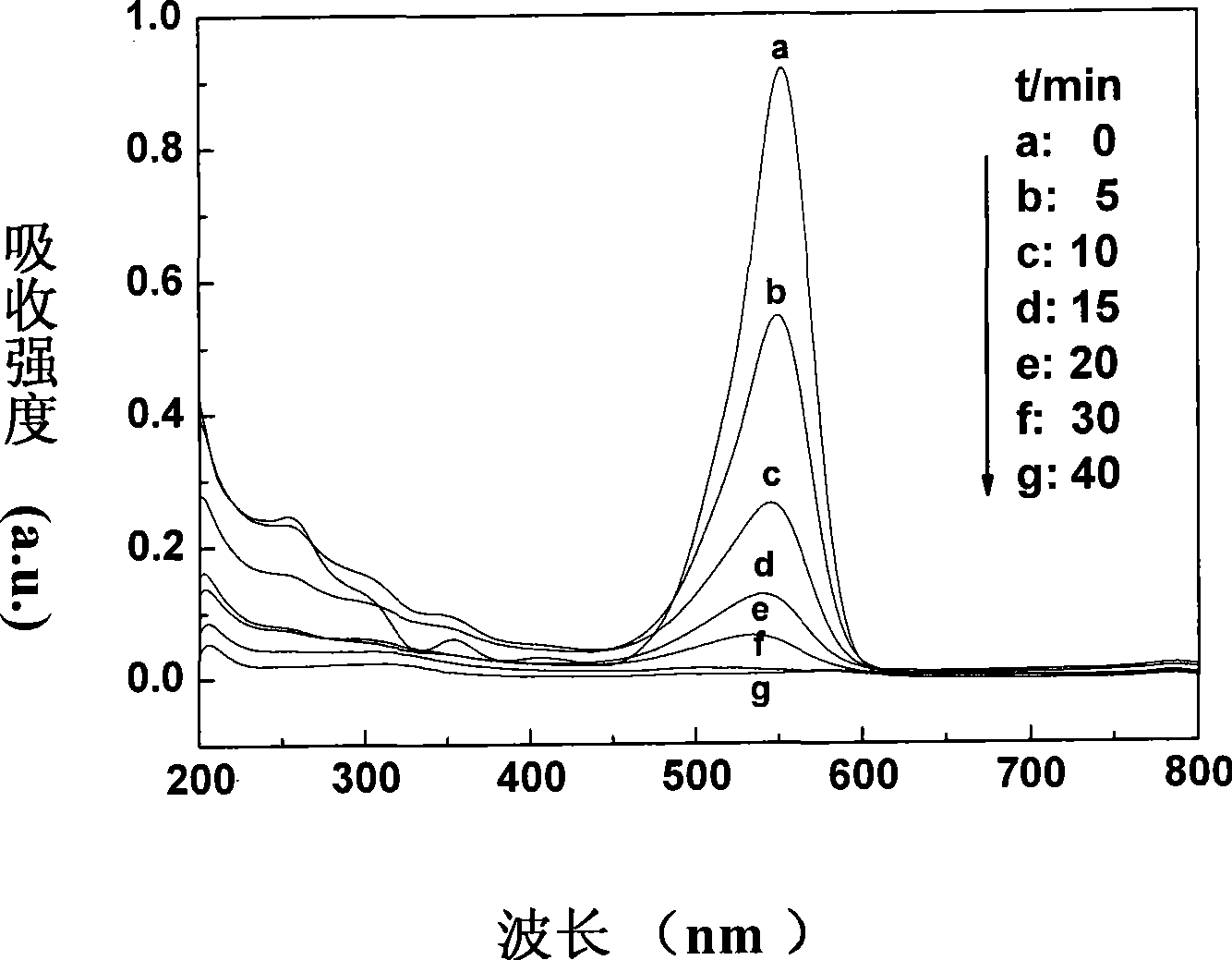

Method for preparing TiO2 hollow micro-sphere material

InactiveCN101444723AEasy to operateEasy to makePhysical/chemical process catalystsReaction temperatureOxygen

The invention discloses a method for preparing TiO2 hollow micro-sphere material which belongs to the technical field of preparing semiconductor photocatalysis material. In the method, titanium potassium oxalate, oxyful and concentrated hydrochloric acid are used as materials, and a hydrothermal synthesis method and the oxygen released in the reaction process are used as a template to prepare the TiO2 hollow micro-sphere material. The method has the advantages of simple operation, low reaction temperature and short reaction time; besides, the method takes the oxygen generated during the reaction process as the template, and does not need to include the techniques of specially preparing the template or removing the template in the preparing process; the whole preparing process is quite simple. The specific area of the prepared material is high; and the material is applied on the aspects of sterilization and gas storage in environment protection especially.

Owner:EAST CHINA NORMAL UNIV

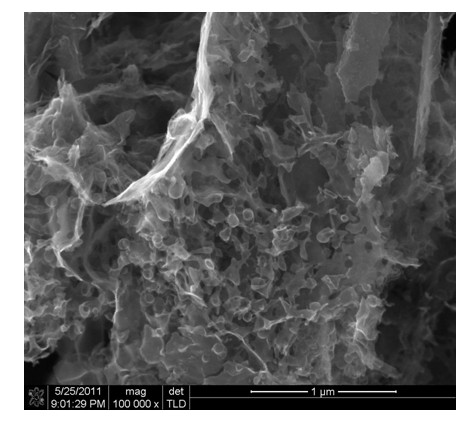

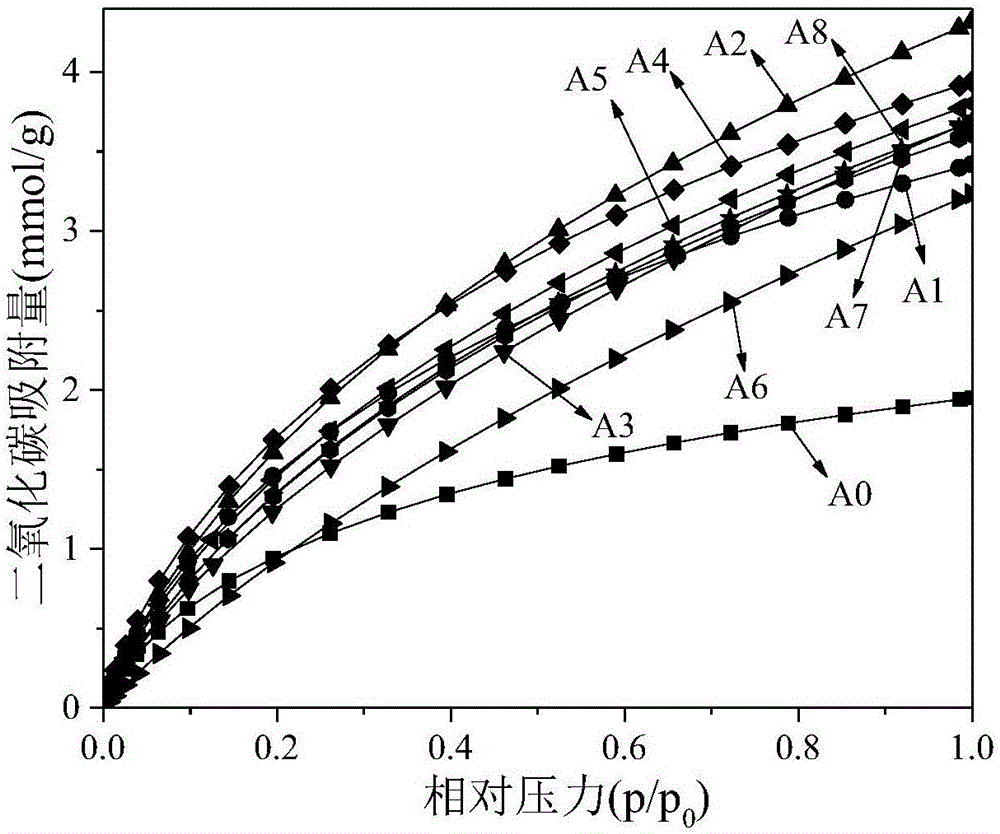

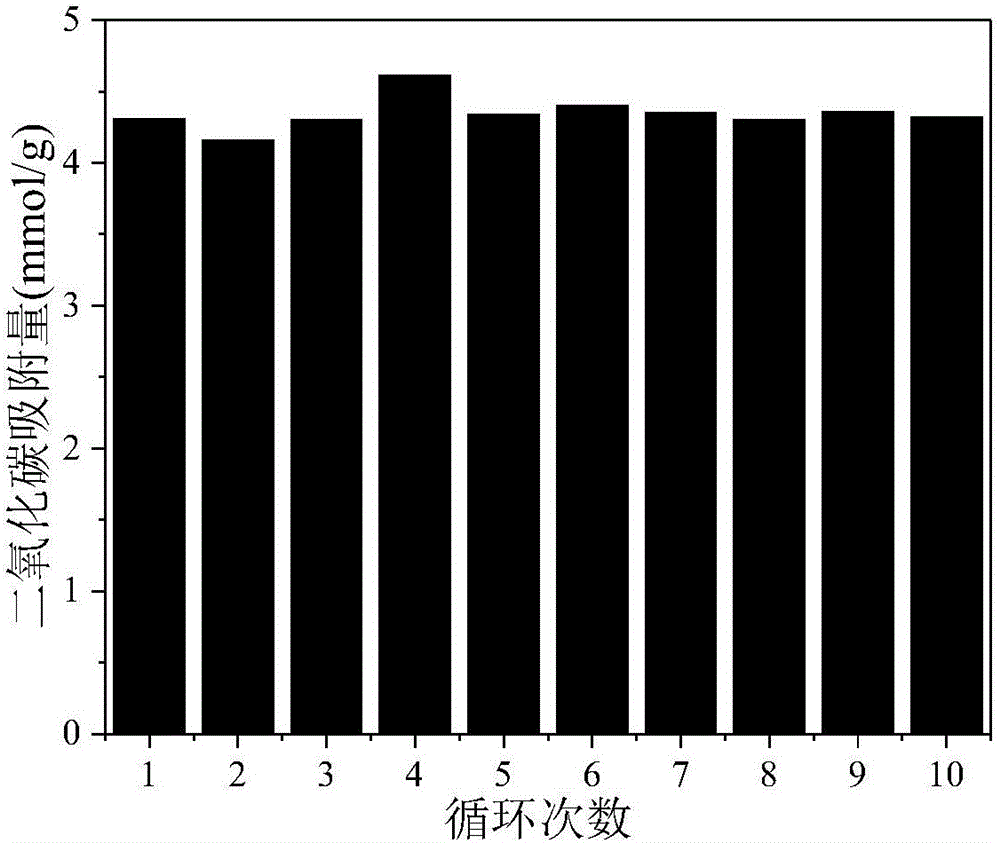

Preparation method of biomass based activated carbon with high CO2 adsorption efficiency

InactiveCN106517181ALow priceWide variety of sourcesProductsGas treatmentActivation methodCarbonization

The invention discloses a preparation method of biomass based activated carbon with high CO2 adsorption efficiency. The method includes the steps of (1) crushing cleaned and dried peanut shells, walnut shells or pecan shells to 20-40-mesh so as to obtain biomass shell powder; (2) mixing the biomass shell powder, potassium oxalate and distilled water evenly according to a certain mass ratio, and then transferring the mixture into a polytetrafluoroethylene lined reaction kettle to be subjected to a hydrothermal reaction to obtain a hydrothermal product; (3) drying the hydrothermal product, then carbonizing the dried product under an N2 atmosphere to obtain a carbonized material; and (4) washing the carbonized material with 0.1mol / L hydrochloric acid and distilled water repeatedly to be neutral, and performing drying to obtain activated carbon. According to the method provided by the invention, carbonization and activation are performed in one step, and the traditional post-activation method is replaced. The required raw materials are widely available and are low in cost, and the preparation process is simple. The prepared activated carbon with high specific surface area has excellent adsorption performance and stable recycling adsorption performance on CO2 under room temperature and atmospheric pressure.

Owner:WUHAN UNIV OF TECH

Antimicrobial moldproof agent for silk fabrics

ActiveCN103757893AWon't breakHas antibacterial and antifungal effectsAnimal fibresFiberPhosphoric acid

The invention discloses an antimicrobial moldproof agent for silk fabrics, which is prepared from the following components in parts by weight: 8-12 parts of citric acid, 7-11 parts of polyoxyethylene trimethyl ammonium chloride, 6-10 parts of vinyl siloxane, 5-9 parts of chitosan quaternary ammonium salt, 4-8 parts of tetrasodium metaphosphate, 3-7 parts of tin tetrachloride, 3-7 parts of potassium oxalate, 3-7 parts of sodium alginate, 5-9 parts of phenyl salicylate and 10-14 parts of amyl acetate. The antimicrobial moldproof agent has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:上海福晏精细化工有限公司

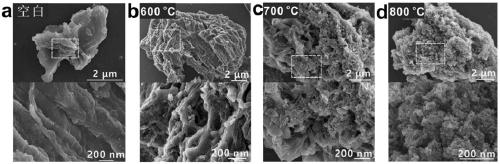

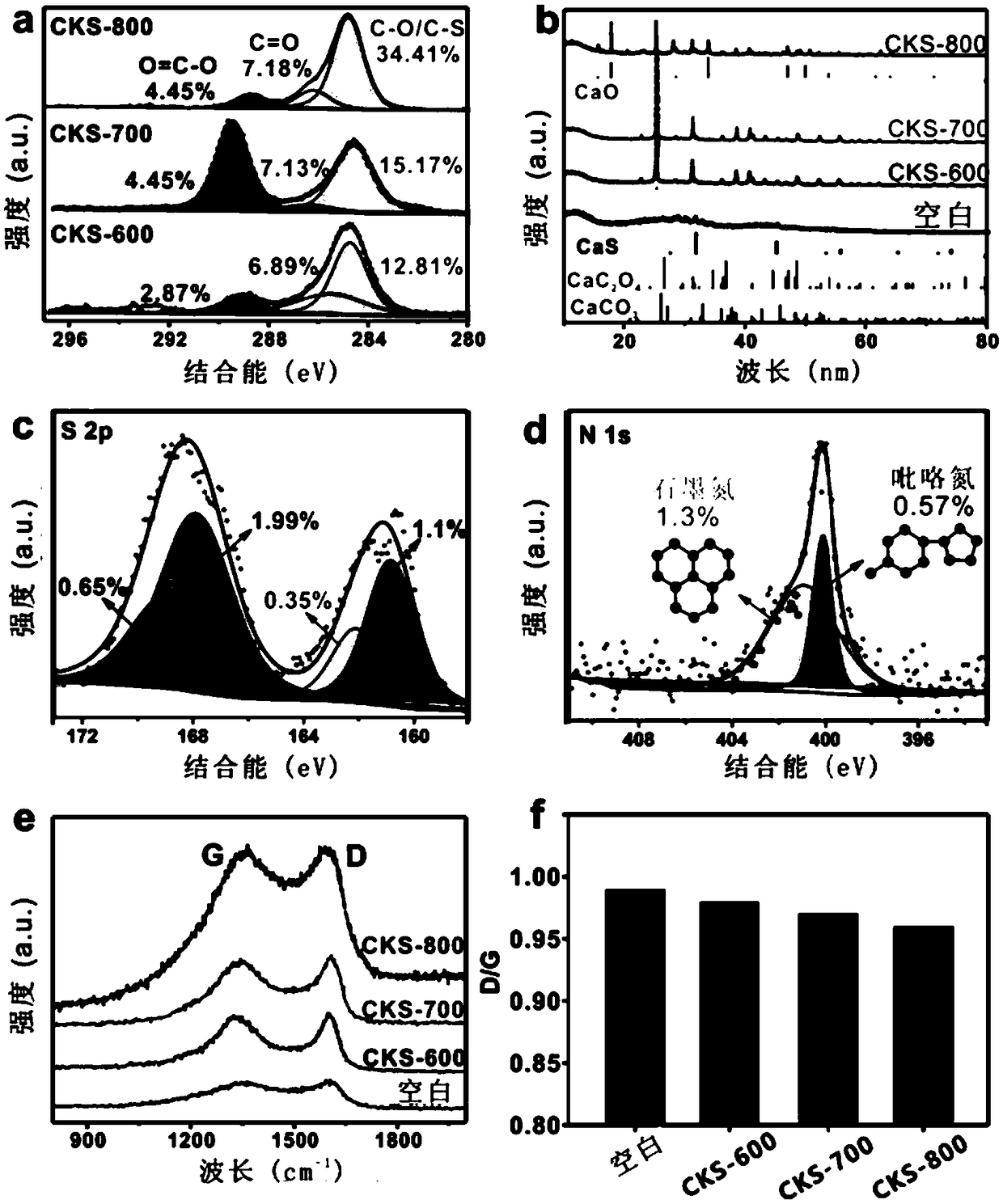

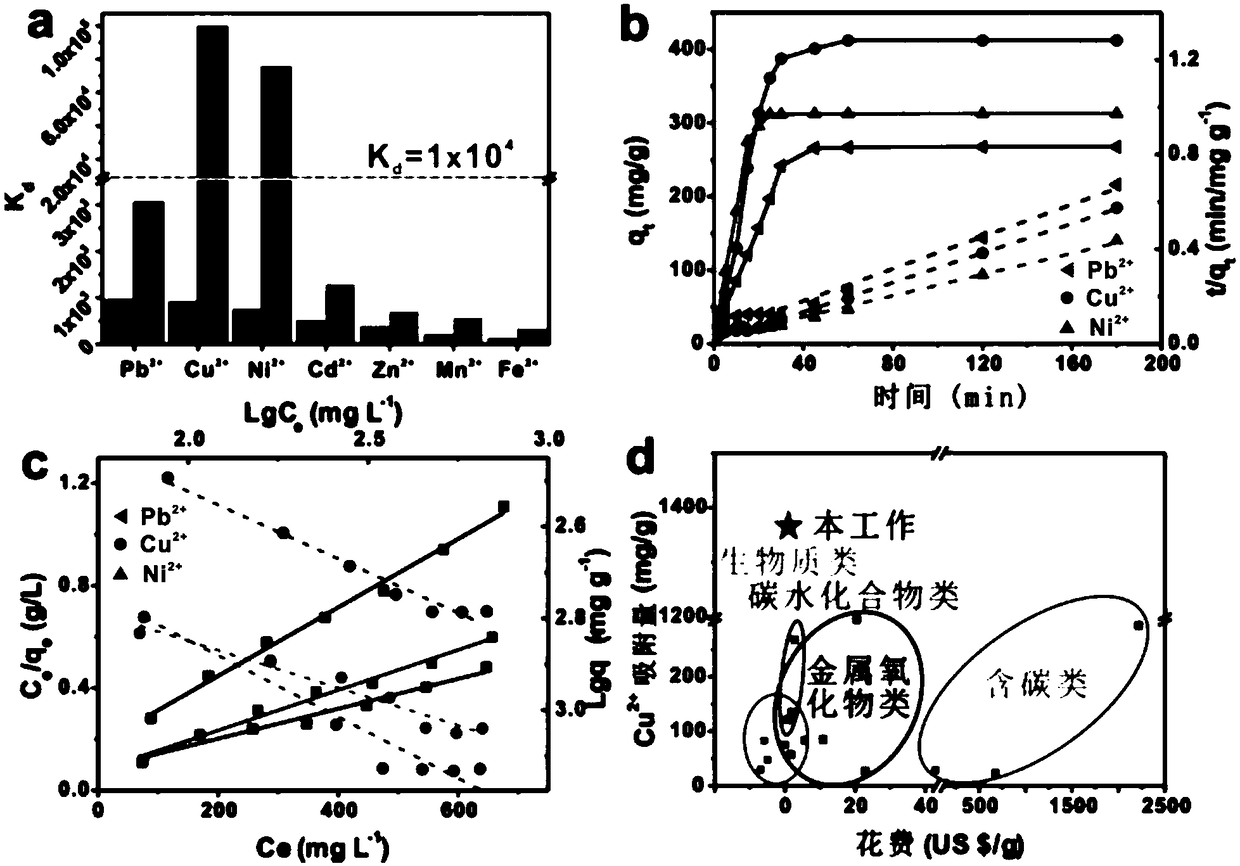

Sulfur-nitrogen-doped porous biochar, preparation method and application

InactiveCN108940191AEasy to operateModerate working conditionsPhysical/chemical process catalystsOther chemical processesFiberReduction treatment

The invention discloses a sulfur-nitrogen-doped porous biochar, a preparation method and an application. The preparation method uses calcium sulfate as a template, potassium oxalate as an activator and bean fibers as a carbon source, and employs calcination to prepare the sulfur-nitrogen-doped porous biochar. The sulfur-nitrogen-doped biochar is an environment-friendly adsorbent for treating heavymetal wastewaters with low cost and high efficiency, adsorption capacities for Cu<2+> and Ni<2+> ions are substantially superior to other biochars. At the same time, the sulfur-nitrogen-doped biocharcontaining adsorbed heavy metals can be subjected to a reduction treatment, and then the reduction-treated sulfur-nitrogen-doped biochar can be further used for catalytic degradation of pollutants inwater to realize recovery and application of the heavy metals.

Owner:NORTHWEST A & F UNIV

Alcohol-free fountain solution and preparation method thereof

The invention discloses an alcohol-free fountain solution and a preparation method thereof. The alcohol-free fountain solution is prepared by emulsifying a mixture formed by polyethylene glycol, glycerol, potassium oxalate, natural bone glue, oleic acid diethanolamide, coconut oil fatty acid diethanolamide, alkanolamide, sodium benzoate, fatty alcohol polyoxyethylene ether sodium sulfate, polyglycol ether, sodium oxalate and water at the temperature of 30-55 DEG C. By using the alcohol-free fountain solution, the aims of realizing safety and environmental friendliness, saving energy and reducing emission can be fulfilled, and a printing operator can be protected from chronic poisoning of alcohol or isopropanol; the original quality of the alcohol-free fountain solution is kept on the aspect of the quality of printed matters, and meanwhile the using amount can be controlled conveniently by operating personnel.

Owner:陕西天佑成纸业有限责任公司

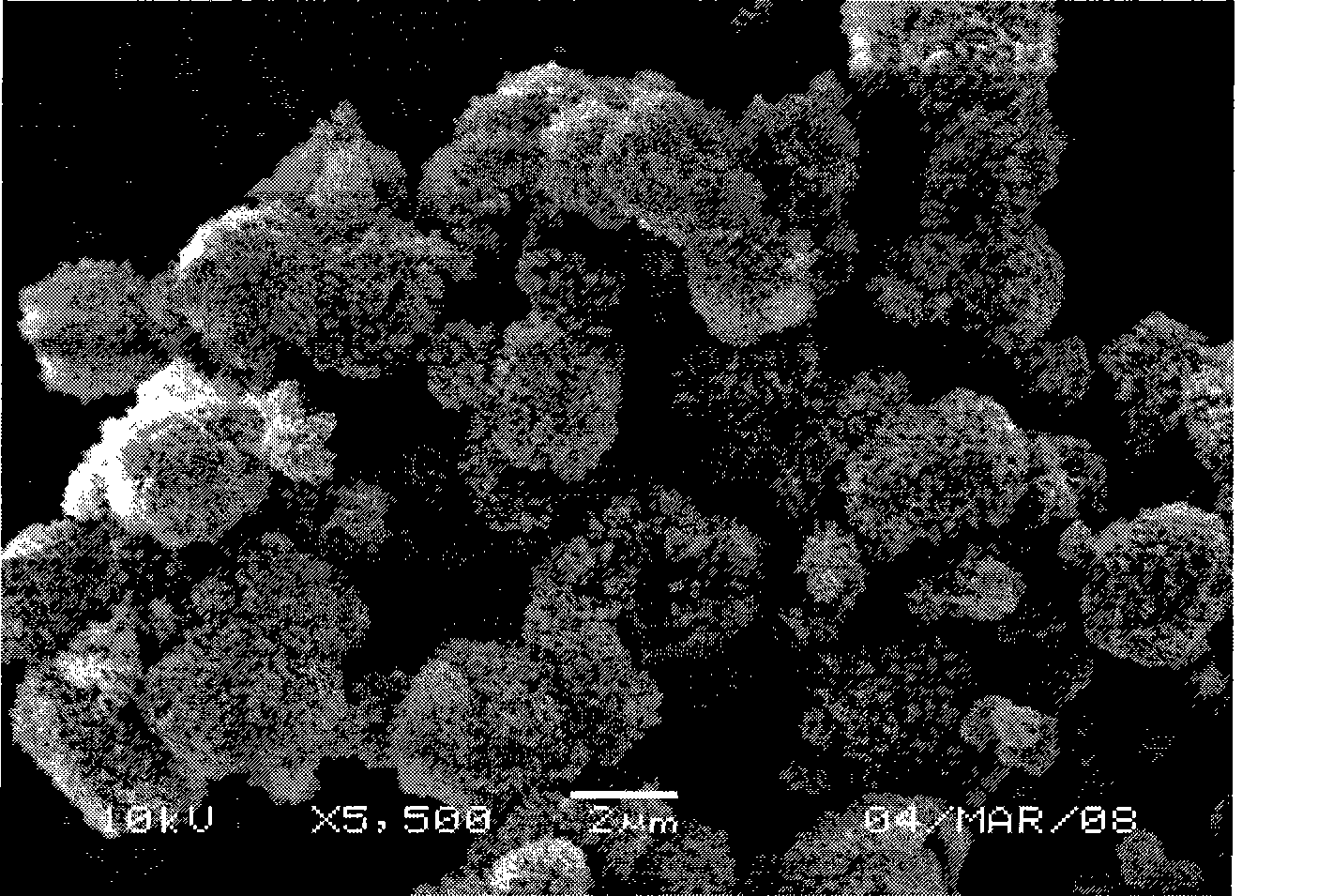

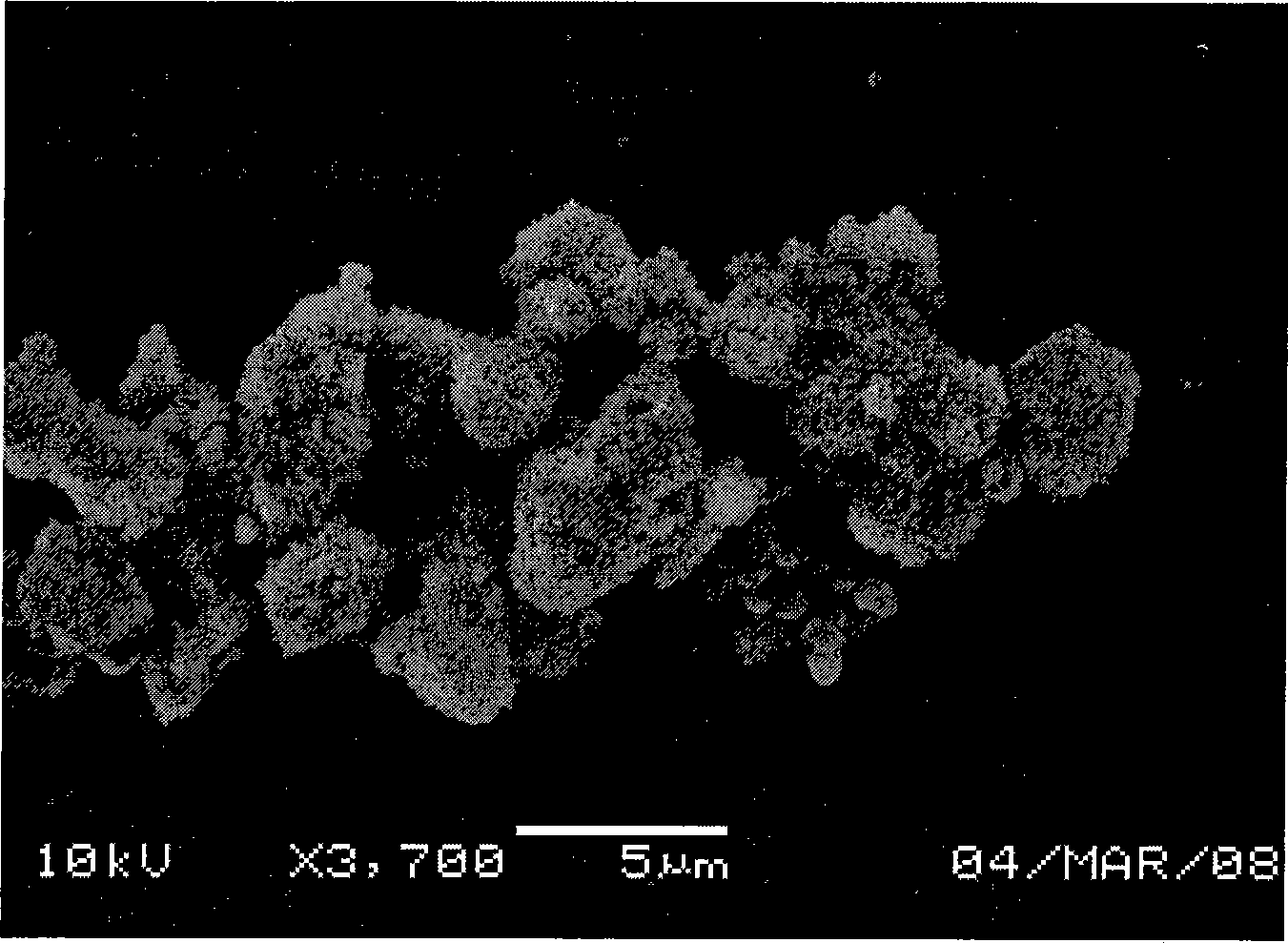

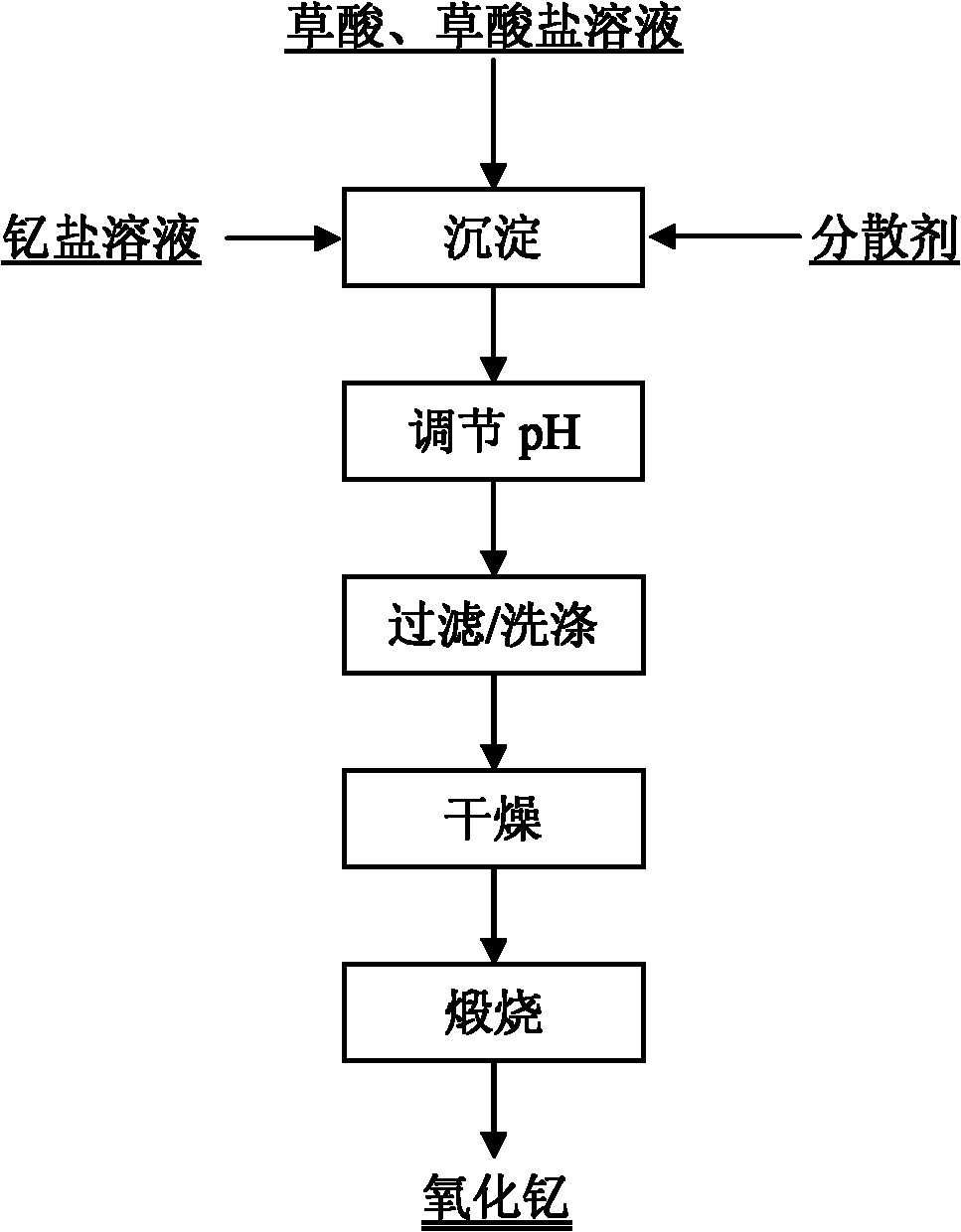

Submicron yttrium oxide and preparation method thereof

The invention relates to submicron yttrium oxide and a preparation method thereof. The preparation method comprises the following steps of: in the presence of a compound precipitator formed by oxalic acid and one oxalate of ammonium oxalate, ammonium hydrogen oxalate, sodium oxalate, sodium hydrogen oxalate, potassium oxalate and potassium hydrogen oxalate, adding a yttrium nitrate and / or yttrium chloride solution into a base solution under certain reaction conditions, regulating the pH value of precipitation size, filtering and washing precipitate for a plurality of times, drying, and calcining to obtain the submicron yttrium oxide. The yttrium oxide has the physical properties that D50 is less than 1.0Mum and more than 0.1Mum, D90 is less than or equal to 1.0Mum, the particle size distribution coefficient Q is less than or equal to 0.20 and the particles are square or spherical in shapes. The invention has the advantages of simple process, operation easiness, low requirement on equipment, low production cost, convenience in production process control, good precipitate dispersibility and filtering property in a technological process, easiness in implementation of industrialized production and stable quality of the prepared product.

Owner:QIANDONG RARE EARTH GRP

Composite zinc removing agent for treating wastewater containing zinc

InactiveCN102464397ASimple processLow running costWater contaminantsWater/sewage treatmentCompound organicSludge

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Method for preparing tert-butyl hydroperoxide

InactiveCN105523982AShort processReduce corrosionOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideDistillation

The invention relates to a method for preparing tert-butyl hydroperoxide. According to the invention, the raw materials are isobutane and di-tert-butyl peroxide, and steps of catalysis, underpressure distillation and crystallization are carried out on the raw materials according to a certain proportion under high temperature and high pressure. According to the invention, the raw materials are isobutane and the di-tert-butyl peroxide with mass ratio being 1:1-3; the high temperature and high pressure condition are 140-160 DEG C and 1.5-2.5 atmospheric pressure; a catalyst is ferric potassium oxalate; the underpressure distillation condition is 0.1-0.3 atmospheric pressure, and temperature is 30-40 DEG C; the crystallization step is characterized in that the collected liquid is dissolved by distilled water at temperature of 20-40 DEG C, then is cooled to the temperature of 1-5 DEG C, is slightly stirred, and is stood for crystallization. The process flow is short, reaction byproduct is less, environment pollution and corrosion degree on production equipment are low, and product purity is high.

Owner:茅海强

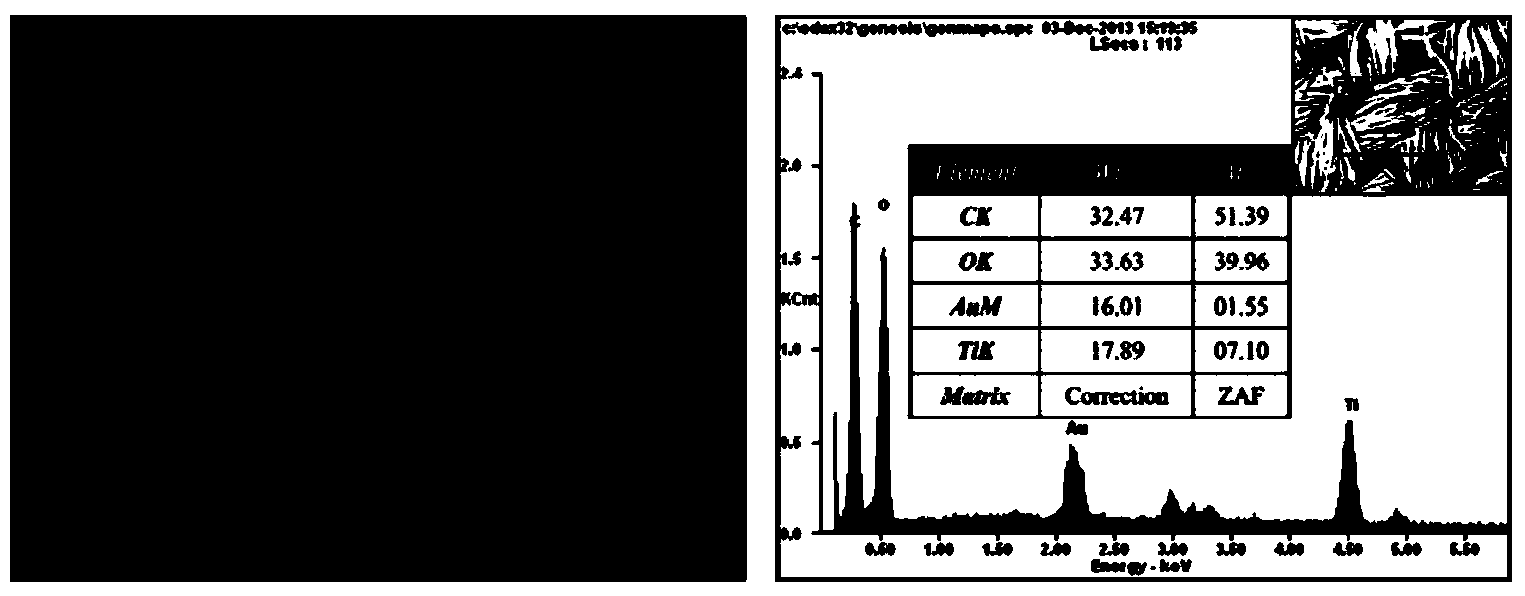

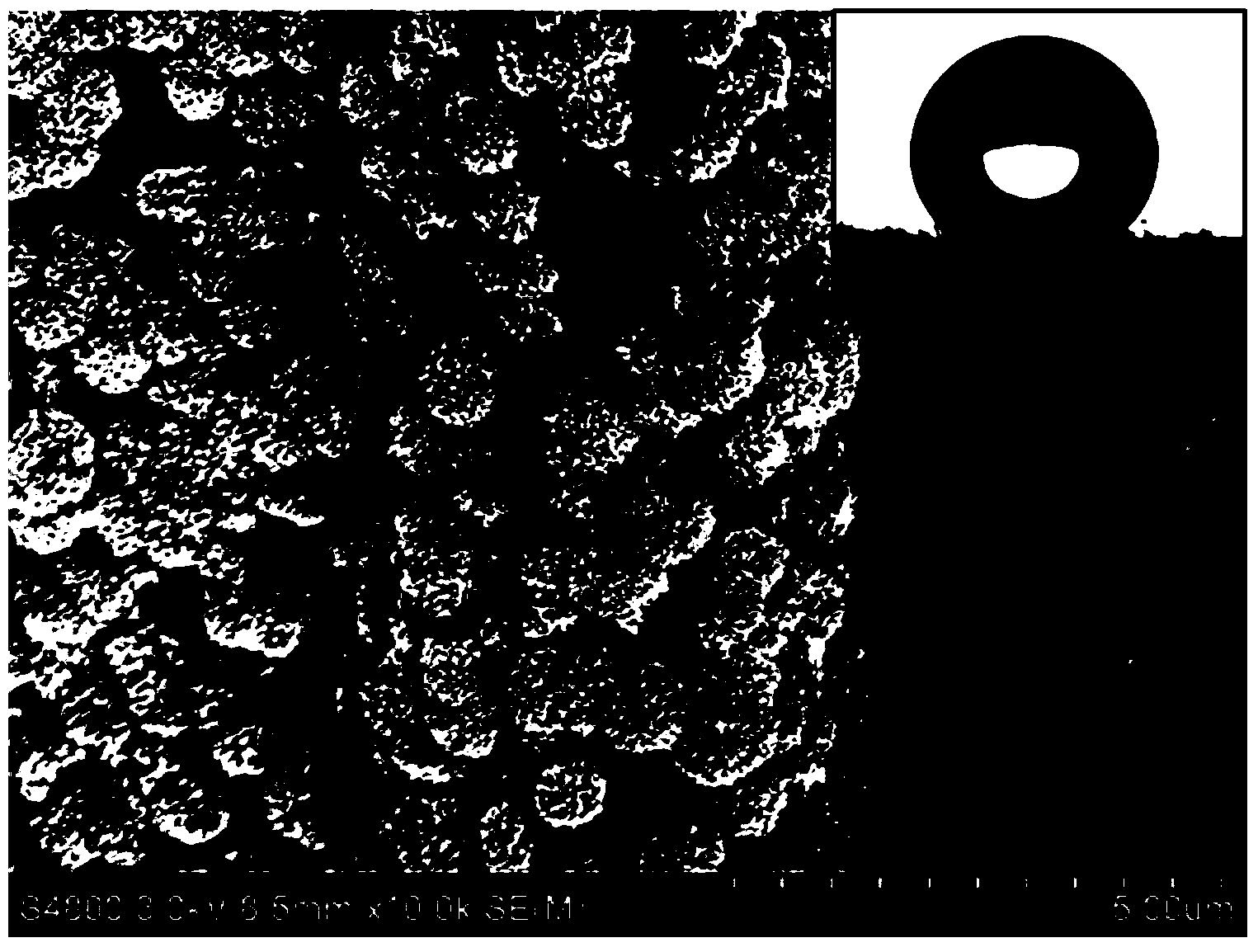

Preparation method of special-infiltration functional fabric surface with self-cleaning and oil-water separation functions

Owner:SUZHOU UNIV

Potassium glycyrrhizinate preparation method

The invention provides a potassium glycyrrhizinate preparation method, mainly comprising the processes of dissolution, column chromatography, ion exchange and crystallization. The preparation process of the invention has good repeatability, the obtained potassium glycyrrhizinate has low cost and reliable and controllable quality, and the preparation method is suitable for industrialized production.

Owner:JIANGSU TIANSHENG PHARMA

Dust-suppression and haze-reduction bituminous mixture and preparation method thereof

ActiveCN104803629AEffective absorptionIncrease moisture contentBuilding insulationsAluminium chlorideRoad surface

The invention discloses a dust-suppression and haze-reduction bituminous mixture which is a composite material and comprises mineral aggregate and dust-suppression and haze-reduction asphalt, wherein the dust-suppression and haze-reduction asphalt comprises matrix asphalt and a dust-suppression and a haze-reduction asphalt modifier; the dust-suppression and haze-reduction asphalt modifier comprises a dust-suppression component and an anti-stripping component; the dust-suppression component comprises one or more of calcium chloride, ferric chloride, aluminium chloride, calcium oxalate and potassium oxalate; the anti-stripping component comprises one or more of calcium lignosulphonate, sodium lignosulphonate and petroleum resin. The invention further discloses a preparation method of the dust-suppression and haze-reduction bituminous mixture. The preparation method comprises the following steps: preparing the dust-suppression and haze-reduction asphalt and mixing and stirring the dust-suppression and haze-reduction asphalt and mineral aggregate at certain temperature. The dust-suppression and haze-reduction bituminous mixture can absorb moisture in air and forms a water film on a road surface to increase moisture content of dust, so that the dust cannot be raised by passing vehicles easily, and the dual effects of dust-suppression and haze-reduction and water conservation are realized.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

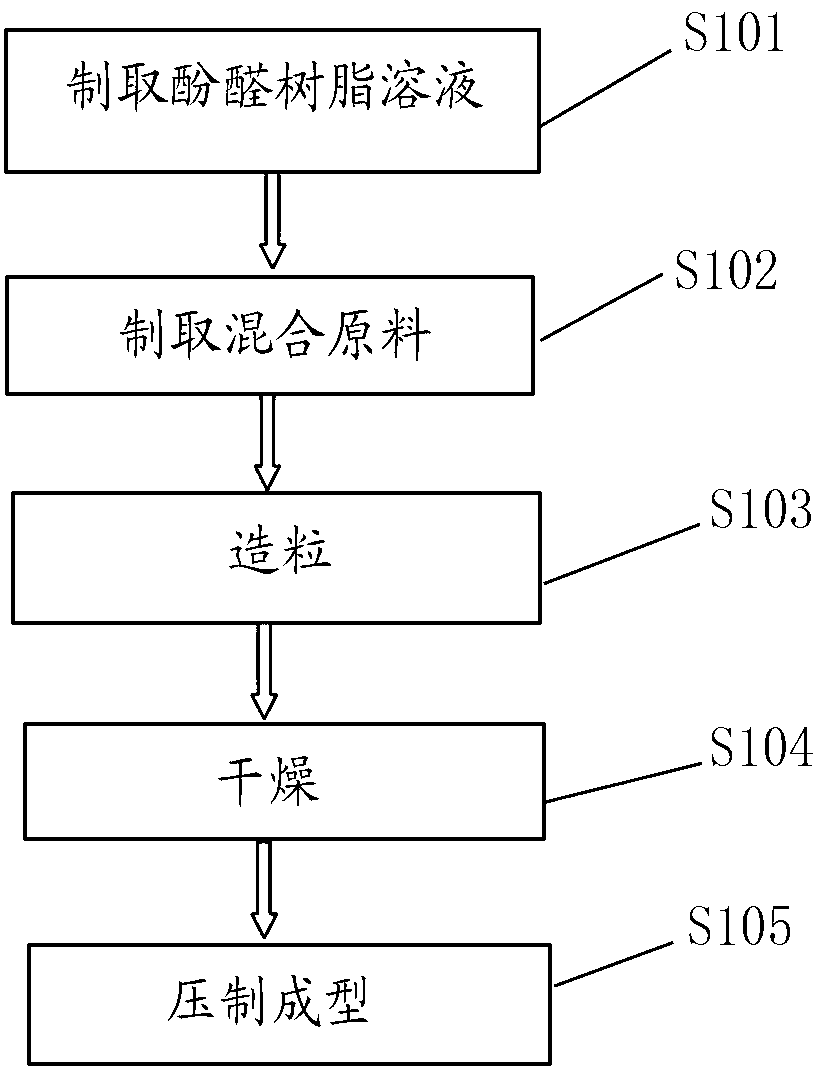

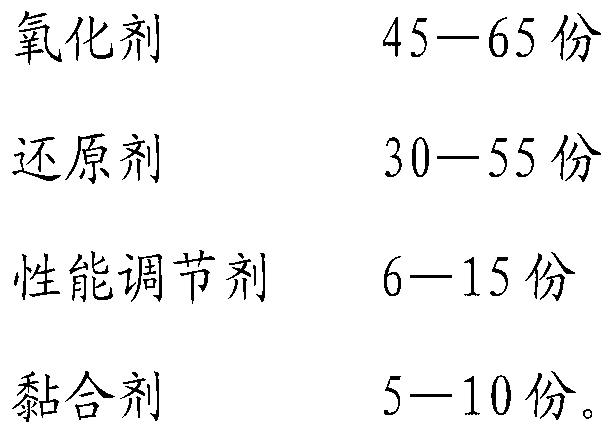

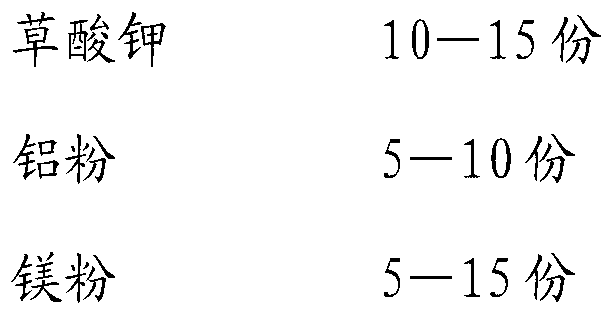

S-shaped aerosol extinguishing agent and preparation method thereof

InactiveCN103272360ALow reaction temperatureStrong reductionFire extinguisherAdhesiveReaction temperature

The invention discloses an S-shaped aerosol extinguishing agent and a preparation method thereof. The S-shaped aerosol extinguishing agent comprises the following components by weight: 45 to 65 parts of oxidant, 30 to 55 parts of reductant, 6 to 15 parts of property modifier, and 5 to 10 parts of adhesive, wherein the reductant comprises components such as potassium oxalate, aluminium powder, magnesium powder urea and the like. Through the adjustment of the components and the match, the reductant component and the proportion of the reductant in the extinguishing agent are changed; the reductant can have strong oxidation-reduction reaction with the oxidant by being added with potassium oxalate; meanwhile dissociated K and Sr can have frequent chain reactions with an active group H, OH and O during the burning in a moment; and the exothermic reaction among the active group H, OH and O can be consumed and inhibited, thereby playing a restraining effect on the burning reaction. Thorough the addition of potassium oxalate, magnesium, aluminium, functional additive magnesium carbonate and the like, the burning and ignition property can be improved; and the reaction temperature of the extinguishing agent can be reduced.

Owner:四川齐盛消防设备制造有限公司

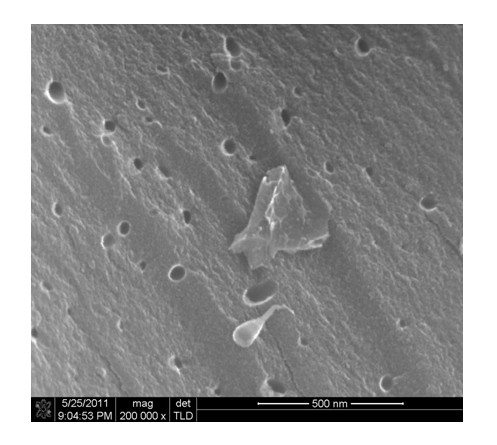

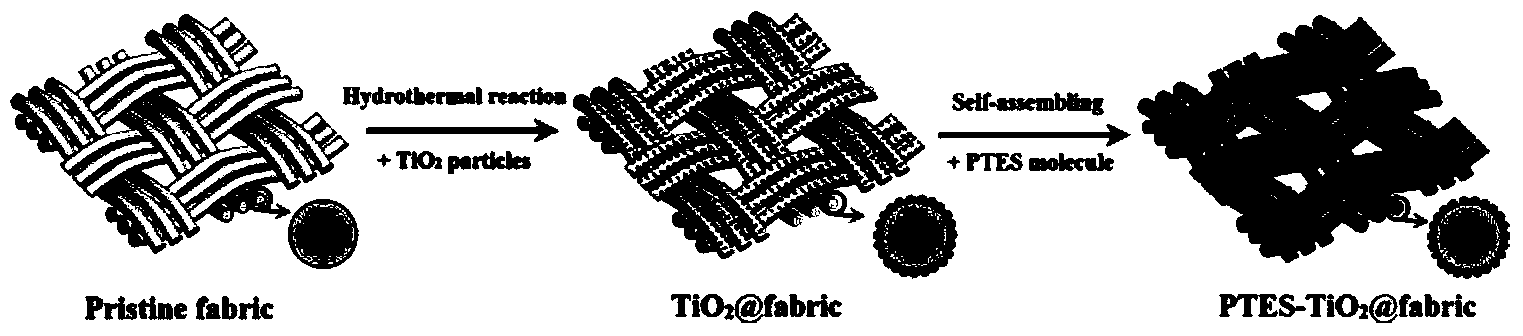

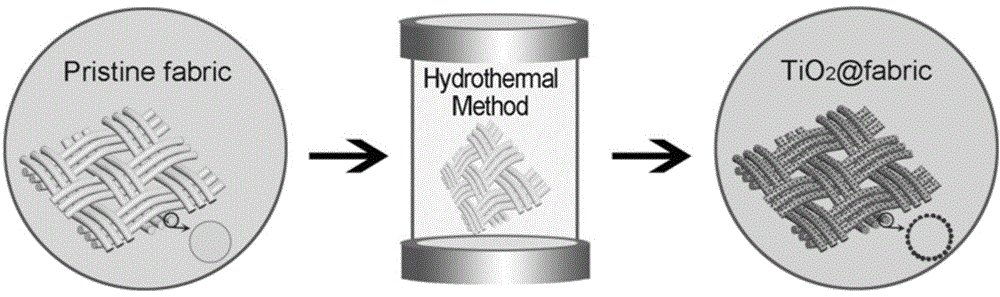

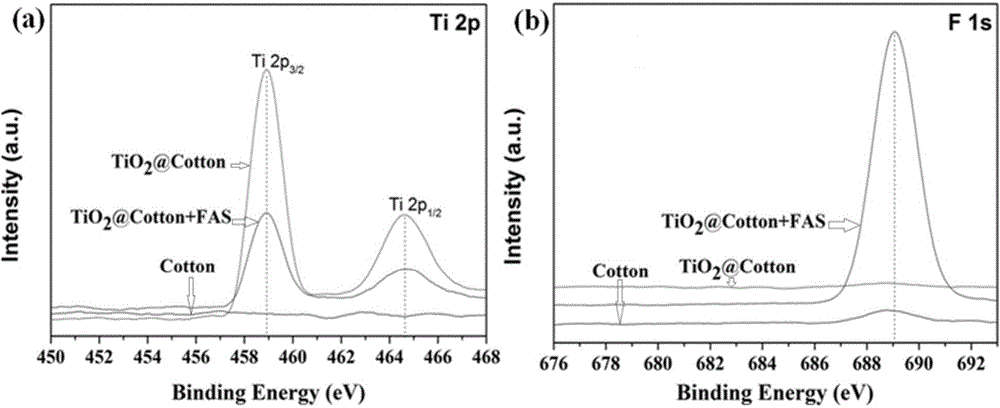

Method for constructing surface of fabric with ultraviolet protection and wash-resistant special wetting functions

The invention discloses a method for constructing a surface of a fabric with ultraviolet protection and wash-resistant special wetting functions. The method comprises the following steps: dissolving titanium potassium oxalate in a mixed solution of water and diethylene glycol; uniformly stirring under the action of a magnetic rotor; filling the prepared solution in a hydrothermal reaction kettle; adding a clean fabric into the hydrothermal reaction kettle and putting the kettle in an oven for reaction for preparing a fabric with a nano-TiO2 membrane surface; soaking the fabric with the nano-TiO2 membrane surface in a silane solution to react; and then taking out the fabric to be dried to prepare the fabric having the fabric surface with ultraviolet protection and wash-resistant special wetting functions. The method has the advantages of simple process, easiness in operation, controllable reaction condition, wide application range, wide source of raw materials, low cost, no pollution, excellent anti-ultraviolet property, wash resistance, lasting and stable super-hydrophobic self-cleaning property and good oil-water separation, and the fabric is excellent in comfortableness and air permeability.

Owner:SUZHOU UNIV

Neutral rust remover and preparation method thereof

The invention discloses a neutral rust remover and relates to the technical field of metal surface rust removal. The neutral rust remover is prepared from, by weight, 130-170 parts of hydroxy ethidenediphosphonic acid, 1-3 parts of sodium chloride and / or potassium chloride, 0.4-1.6 parts of potassium oxalate 0.4-1.6 parts of formic acid, 0.4-1.6 parts of phytic acid, 1-3 parts of citric acid, 0.4-1.6 parts of ethylenediaminetetraacetic acid and 3-7 parts of organic amine ester TPP. The invention further discloses a preparation method of the neutral rust remover. By the adoption of the neutralrust remover and the preparation method, the rust removal speed under the normal temperature is high, the rust removal effect is good, and secondary rusting time is long; meanwhile the rust remover is neutral, free of damage to a base body and free of influence on strength and ductility and malleability of metal; and all the components are environmentally-friendly, free of toxin, smoke and pungent odors, free of pollution to the environment and free of harm to the human body.

Owner:宁波际超新材料科技有限公司

Method for reducing iron and aluminum ions in wet phosphoric acid

InactiveCN101920946ASimple processReduce energy consumptionPhosphorus compoundsAluminum IonChemical reaction

The invention discloses a method for reducing iron and aluminum ions in wet phosphoric acid. The method comprises the following steps of: oxidizing wet phosphoric acid with hydrogen peroxide; and adding potassium oxalate and sodium carbonate to the oxidized wet phosphoric acid for carrying out chemical reaction treatment so as to partially removing iron and aluminum ions from the wet phosphoric acid. The method has the advantages of stable effect and simple and convenient operation for removing the iron and aluminum ions from the wet phosphoric acid, and a generated precipitate is not needed to be filtered and can be directly used as an additive for producing a compound fertilizer and added to products without influencing the quality of the compound fertilizer; meanwhile, materials used in the precipitate method has low cost, and can be obtained easily, therefore, the method has stronger competitive force and stronger advantages in industrialized production; and the iron and aluminum ions in the wet phosphoric acid purified by the method are better purified, wherein the purifying rate of iron ions can reach 20-70 percent, and the purifying rate of aluminum ions can reach 5-30 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +2

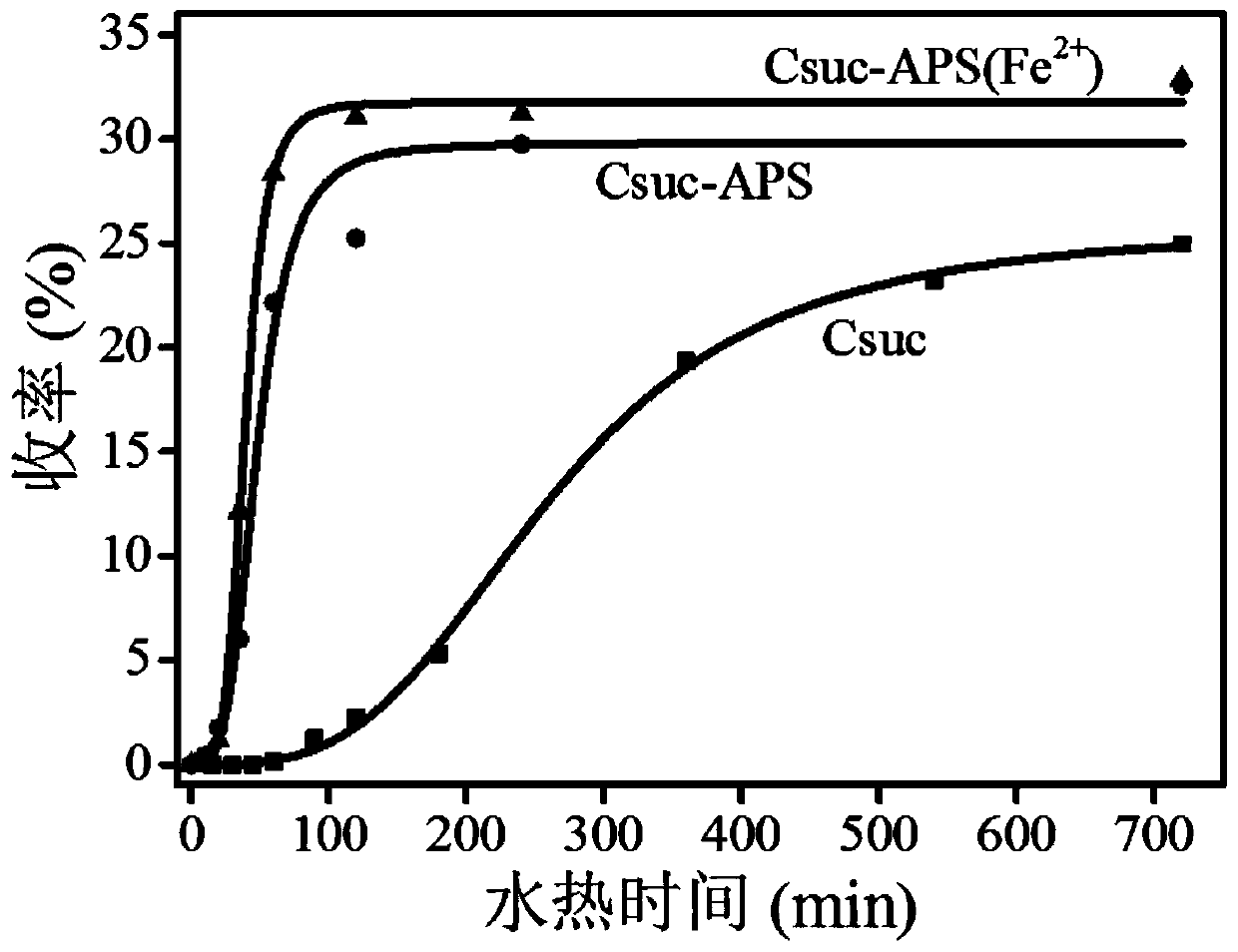

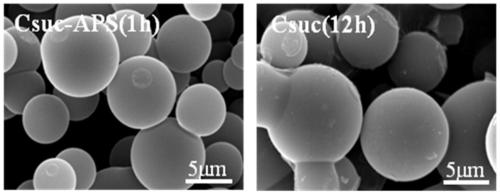

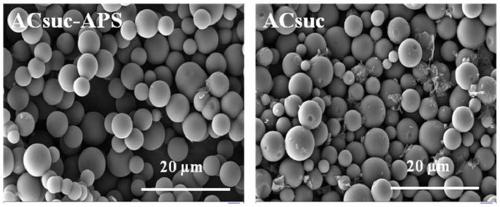

Method for rapidly preparing micron-sized carbon sphere with good dispersibility

ActiveCN109704337AGood dispersionIncrease oxygen contentProductsReagentsActivated carbonRoom temperature

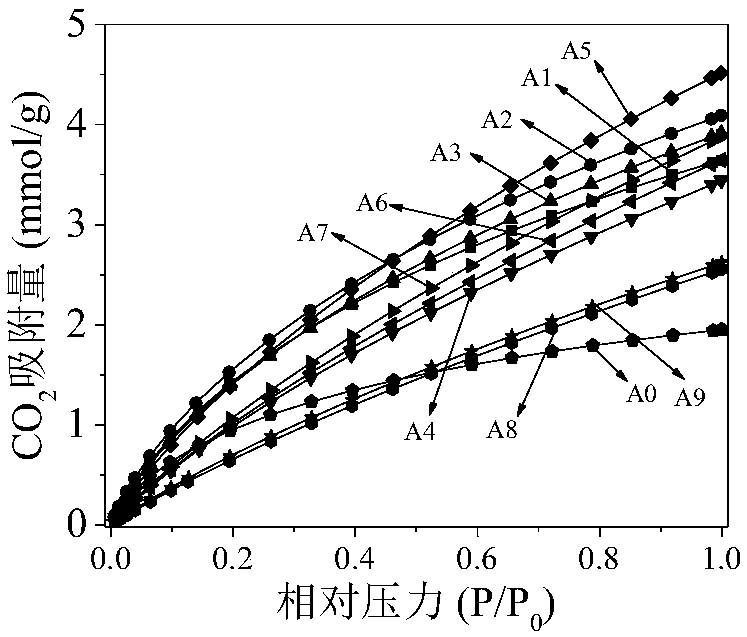

The invention belongs to the technical field of adsorption materials and discloses a method for rapidly preparing a micron-sized carbon sphere with good dispersibility. The method disclosed by the invention comprises the following steps: (1) mixing 6 parts by mass of sugar and 0.2-5 parts by mass of strong oxidant and FeSO4 in water, carrying out heating for a reaction, and carrying out separationto obtain a hydrothermal carbon sphere; and (2) mixing 1 part by mass of hydrothermal carbon sphere obtain in step (1) with 1-5 parts by mass of potassium oxalate, and carrying out high-temperature roasting at an inert atmosphere and the temperature of 500-900 DEG C for 1-5 h to obtain the micron-sized carbon sphere. The method disclosed by the invention is high in reaction speed, the carbon sphere is started to be generated within 5 min since heating is started, and the reaction is to be completed within 1-4 h, so that the reaction time is greatly shortened, and the energy consumption is reduced; the prepared porous activated carbon sphere has abundant micropores and good dispersibility and has the specific surface area of 975-1430 m<2> / g; the adsorption quantity of CO2 at normal temperature and normal pressure is 3.43-3.74 mmol / g; and the method can be used for capturing CO2 at room temperature.

Owner:GUANGZHOU UNIVERSITY

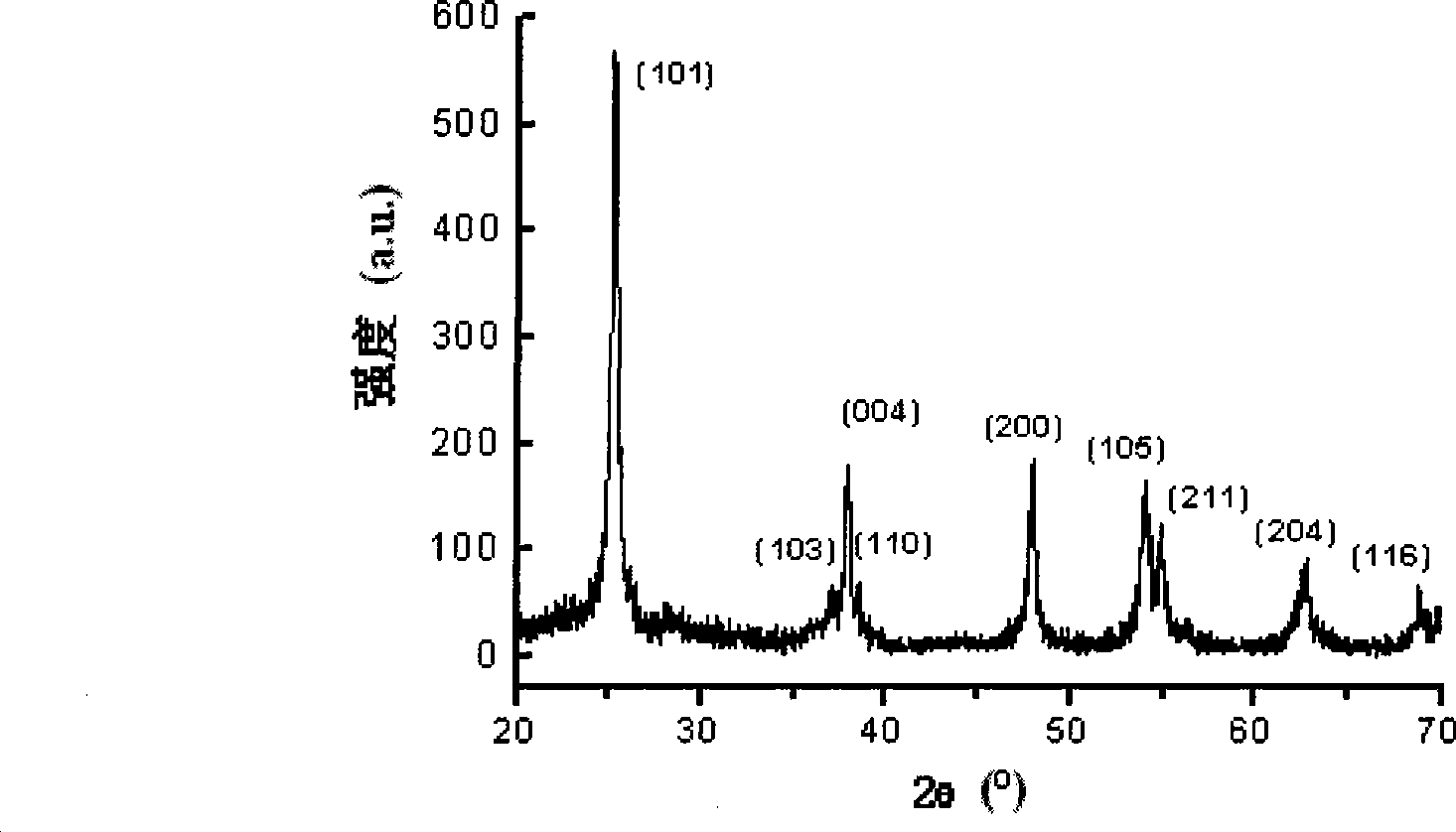

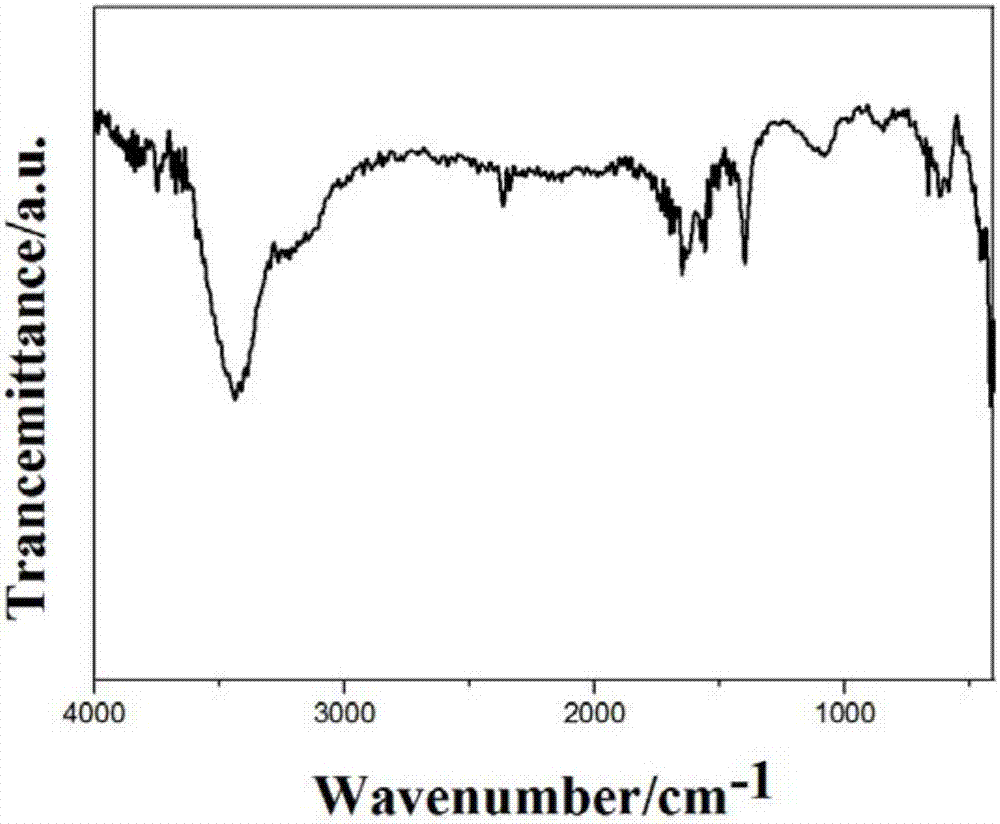

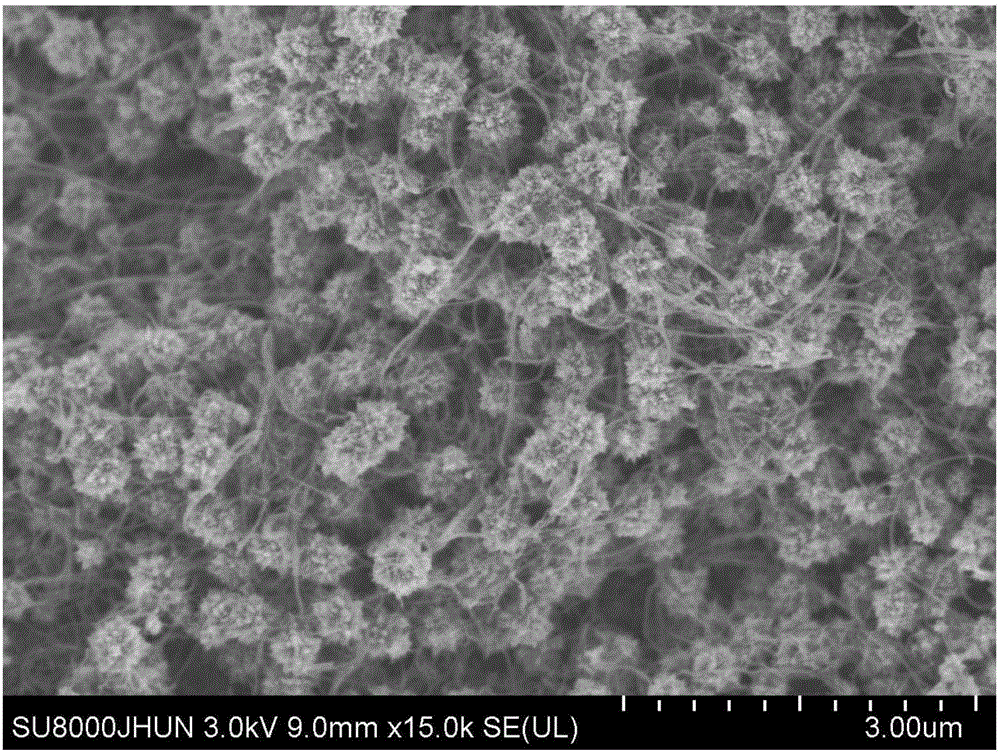

g-C3N4/TiO2 (graphite-carbon nitride/titanium dioxide) nanowire assembly structure photocatalyst and preparation method thereof

ActiveCN107115884AGuaranteed stabilitySmall specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationNanowirePolytetrafluoroethylene

The invention discloses a g-C3N4 / TiO2 (graphite-carbon nitride / titanium dioxide) nanowire assembly structure photocatalyst and a preparation method thereof. The g-C3N4 / TiO2 nanowire assembly structure photocatalyst is characterized in that inorganic titanium potassium oxalate, hydrogen peroxide, urea (or melamine and dicyandiamide) and the like are used as raw materials; the urea (or melamine and dicyandiamide) is loaded onto the surface of a TiO2 precursor of a nanowire assembly structure, so as to complete the condensation pyrolysis of the TiO2 precursor and the urea (or melamine and dicyandiamide) and the loading of g-C3N4 by one step. The preparation method comprises the following steps of firstly, dissolving the titanium potassium oxalate into deionized water, adding H2O2 (hydrogen peroxide) and NaOH (sodium hydroxide) solutions, transferring the obtained mixed solution into a reaction kettle lined with polytetrafluoroethylene to perform hydrothermal reaction, centrifuging, washing, and drying; soaking by diluted hydrochloric acid, washing to neural state, and drying; adding the urea (or melamine and dicyandiamide) dissolved by hot ethanol, evaporating the ethanol, and roasting, so as to obtain the uniformly dispersed g-C3N4-modified TiO2 nanowire assembly structure photocatalyst. The preparation method has the advantages that the technology is simple, the conditions are mild, and the cost is low; the product dispersivity and stability are high, and the dispersivity of g-C3N4 is easily controlled.

Owner:大庆中环评价检测有限公司

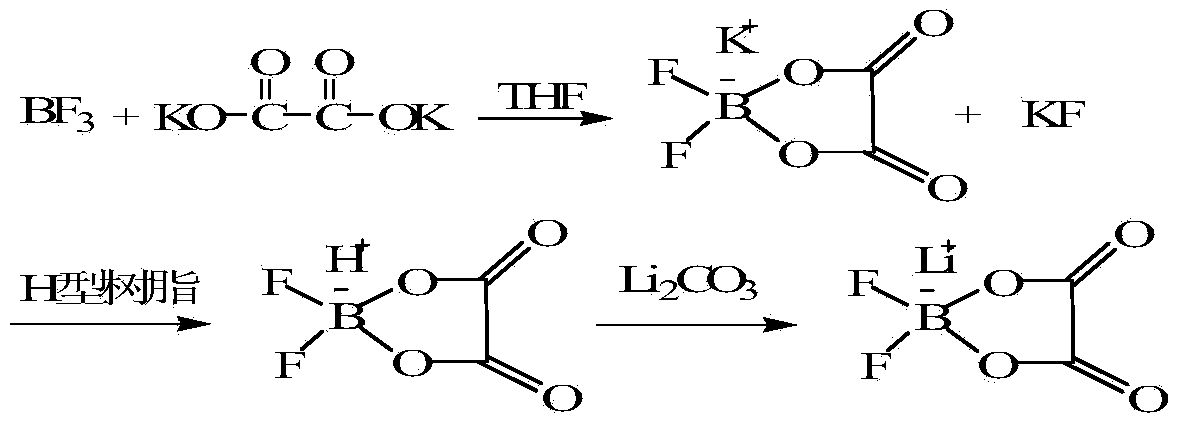

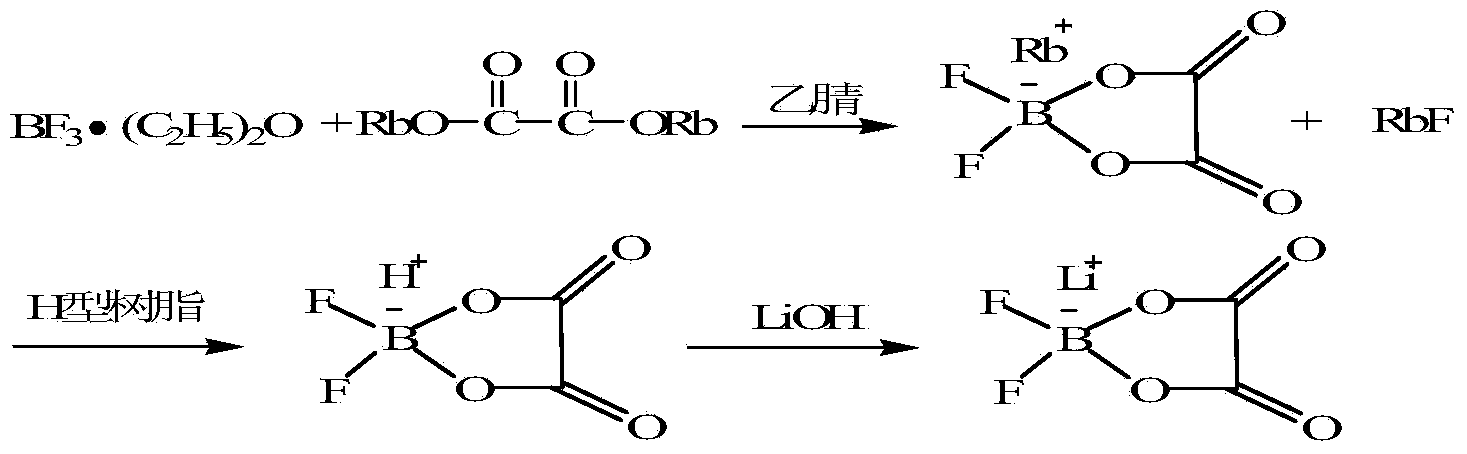

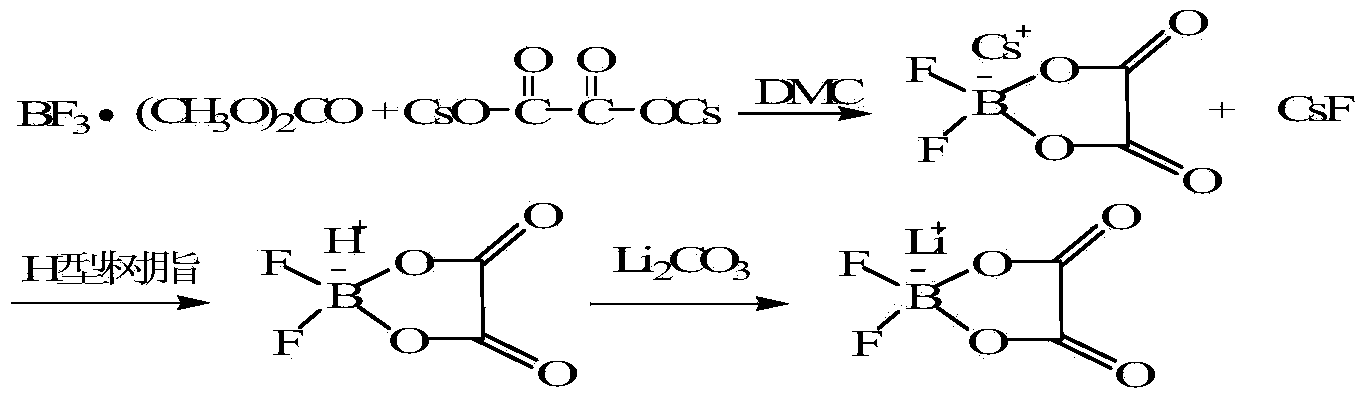

Method for preparing lithium oxalyldifluoroborate

The invention discloses a method for preparing lithium oxalyldifluoroborate. According to the method, first, a boracic compound reacts with potassium oxalate (rubidium or cesium) to form difluoro oxalic acid potassium borate (rubidium or cesium) through synthesis; then, a difluoro oxalic acid potassium borate (rubidium or cesium) water solution slowly flows through superacidulated cationic resin for exchange, and an appropriate amount of Li2CO3 or LiOH is added into a collected difluoro oxalic acid boric acid water solution for the neutral reaction to obtain a crude lithium oxalyldifluoroborate product; high-purify lithium oxalyldifluoroborate is obtained through recrystallization purification. The method has the advantages that operation steps are simple, preparation conditions are moderate, cost is low, ionic impurities can be effectively controlled, and the method is suitable for industrialized mass production.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Preparation method of CO2-adsorbing shrimp-shell-base nitrogenous activated carbon

InactiveCN106698425AReduce total usageHigh carbon and nitrogen contentCarbon compoundsCarbonizationBiological activation

The invention discloses a preparation method of CO2-adsorbing shrimp-shell-base nitrogenous activated carbon. The method comprises the following steps: (1) pulverizing cleaned and dried waste shrimp shells into 100-140 meshes, soaking in excessive 1 mol / L hydrochloric acid for 12 hours, filtering the soaked product, washing with distilled water to a neutral state, and drying to obtain the shrimp shell powder; (2) uniformly mixing the shrimp shell powder and potassium oxalate in a grinder in a certain mass ratio to obtain a mixture; (3) carbonizing the mixture in an N2 atmosphere to obtain a carbonized material; and (4) repeatedly washing the carbonized material with 1 mol / L hydrochloric acid and distilled water to a neutral state, and drying to obtain the shrimp-shell-base nitrogenous activated carbon. Carbonization and activation are completed within one step to substitute the traditional post-activation process; the required raw materials are environmentally friendly and renewable, and the preparation technique is simple; the method can implement in-situ nitrogen doping; and the prepared nitrogen-doped activated carbon has excellent adsorbability and stable cyclic regeneration adsorbability for CO2 under the conditions of room temperature and atmospheric pressure.

Owner:WUHAN UNIV OF TECH

Preparation method and application of modified cobalt manganese binary metal oxide catalyst

InactiveCN103877989ANo harmSimple compositionNitrous oxide captureDispersed particle separationPtru catalystManganese

The invention relates to a modified cobalt manganese binary metal oxide catalyst. The modified cobalt manganese binary metal oxide catalyst can be prepared by the following steps: synthesizing a cobalt manganese binary metal hydroxide by a weak base precipitation method, wherein the mass ratio of cobalt to manganese is (4.0-14.0):1; roasting at the temperature of 350 DEG C-550 DEG C so as to prepare a cobalt manganese binary metal oxide; impregnating the cobalt manganese binary metal oxide by auxiliary solutions of potassium carbonate, potassium oxalate or cesium carbonate and the like in equal volume; drying the cobalt manganese binary metal oxide which is impregnated by the auxiliaries at the temperature of 70 DEG C-90 DEG C; roasting the dried cobalt manganese binary metal oxide at the temperature of 350 DEG C-550 DEG C so as to obtain the modified cobalt manganese binary metal oxide catalyst. The raw materials for preparing the catalyst are all inorganic compounds and are harmless to human bodies and environments; moreover, the catalyst is simple in formation, can control preparation technological parameters, is high in activity of the catalyst, and has high cost performance.

Owner:YANTAI UNIV

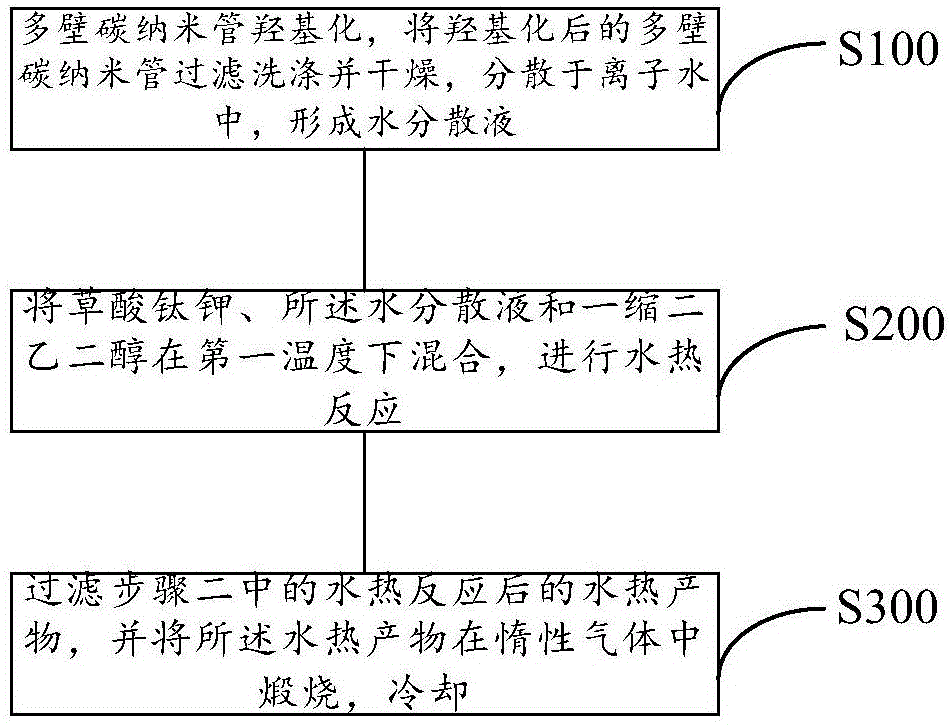

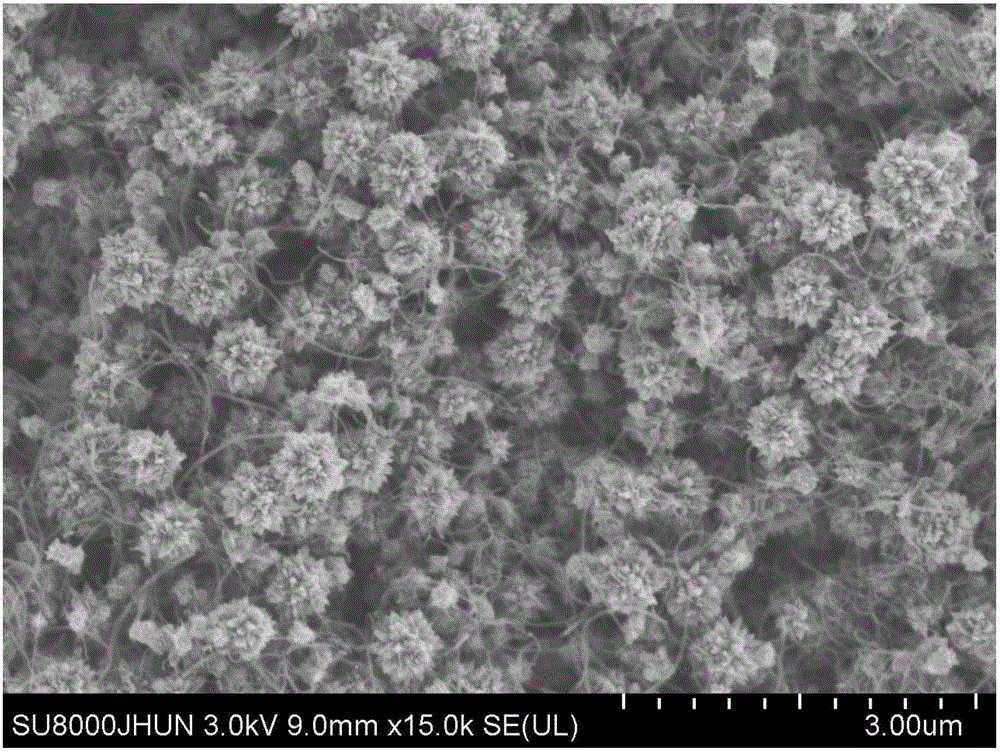

Preparation method for multi-walled carbon nanotube/titanium dioxide composite negative electrode material of lithium ion battery

InactiveCN106784648APromote circulationImprove conductivityCell electrodesNanotechnologySodium-ion batteryNanotube

The invention discloses a preparation method for a multi-walled carbon nanotube / titanium dioxide composite negative electrode material of a lithium ion battery. The preparation method comprises the steps of 1, performing hydroxylation of the multi-walled carbon nanotubes, and filtering, washing and drying the hydroxylated multi-walled carbon nanotubes, and dispersing into deionized water to form a water dispersing solution; 2, mixing titanium potassium oxalate, the water dispersing solution and diethylene glycol at a first temperature, and performing a hydrothermal reaction; and 3, filtering hydrothermal products obtained after the hydrothermal reaction in the step 2, and calcining the products in an inert gas, and cooling to obtain the multi-walled carbon nanotube / titanium dioxide composite negative electrode material of the lithium ion battery. The preparation method for the multi-walled carbon nanotube / titanium dioxide composite negative electrode material of the lithium ion battery provided by the invention achieves the technical effects of low cost of raw materials, simple process, high cycling performance, high conductivity, and high electrochemical activity.

Owner:JIANGHAN UNIVERSITY

Method of preparing high-performance TiO2 nanometer photocatalystic material

InactiveCN101444726ALow costSuitable for industrial mass productionPhysical/chemical process catalystsTitanium dioxideTitaniumSolvent

The invention discloses a method for preparing high-performance TiO2 nanometer photocatalysis materials in the self-cleaning photocatalysis field. Oxydol with no treatment is utilized, titanium potassium oxalate is used as material, and the adjustable TiO2 nanometer material with multiple micro-morphology and high photocatalysis performance is prepared through a simple solvent-thermal method. The invention has the characteristics of simple operation, low cost, good product photocatalysis performance, suitability for industrial production, etc.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Finishing process of knitted fabric

InactiveCN104452267AImprove wrinkle resistanceImprove antibacterial propertiesFibre treatmentMagnesium chloride hexahydrateAntibacterial property

The invention discloses a finishing process of a knitted fabric. The finishing process comprises the following steps: (1) putting 2.1 parts by mass of magnesium chloride hexahydrate, 1.2 parts by mass of potassium oxalate and 3.4 parts by mass of sodium hydroxide into 12.6 parts by mass of deionized water and stirring uniformly; (2) sequentially adding 1.7 parts by mass of solid nano titanium dioxide and 2.8 parts by mass of sodium tripolyphosphate and further stirring until the components are mixed uniformly so as to obtain finishing liquid; and (3) padding the fabric in the finishing liquid and drying at a constant temperature. According to the finishing process of the knitted fabric, the finished fabric is washable and has the excellent anti-wrinkle property and antibacterial property.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

Application of AK sugar crystal mother liquor and method for preparing sylvite by crystal mother liquor

ActiveCN102336647AReduce manufacturing costLower potassium levelsSulfate/bisulfate preparationCarboxylic acid salt preparationDouble saltPotassium oxalate

The invention provides an application of AK sugar crystal mother liquor produced by a sulfamic acid-sulfur trioxide method, which is a sylvite preparation by using crystal mother liquor, and a method for preparing sylvite by using AK sugar crystal mother liquor. The method comprises the following steps: mixing crystal mother liquor and organic acid or inorganic acid, keeping a mixture in an acidic property, cooling, filtering, and recrystallizing to obtain sylvite. The sylvite is prepared by the AK sugar crystal mother liquor which is originally taken as waste water for discharging by using the sulfamic acid-sulfur trioxide method. The sylvite comprises inorganic salts, such as potassium sulfate; organic salts, such as potassium oxalate; even double salts, such as potassium alum. The obtained sylvite can be a product for sale, so that the production cost of AK sugar can be reduced. Simultaneously, the potassium content in waste water can be reduced and the environmental pollution caused by waste water is minimized. The invention aims at reducing the cost of AK sugar, minimizing the environmental pollution caused by waste water from the process, raising the economic, social and environmental benefits of AK sugar production process by using the sulfamic acid-sulfur trioxide method.

Owner:CHUZHOU UNIV

Antimicrobial antistatic agent for silk fabrics

ActiveCN103757897AHas antibacterial and antistatic effectsGood effectAnimal fibresFiberHexamethylenetetramine

The invention discloses an antimicrobial antistatic agent for silk fabrics, which is prepared from the following components in parts by weight: 16-19 parts of dimethyl terephthalate, 11-14 parts of fatty alcohol polyethenoxy ether sodium sulfate, 8-12 parts of sodium tripolyphosphate, 18-22 parts of ethylene glycol, 10-12 parts of polyethyleneglycol, 5-9 parts of zinc acetate, 5-7 parts of ethoxylated straight-chain primary alcohol, 4-6 parts of potassium oxalate, 2-4 parts of amyl acetate, 5-8 parts of white soap powder and 2-5 parts of hexamethylenetetramine. The antimicrobial antistatic agent for silk fabrics has favorable antimicrobial and antistatic effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:烟台力量知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com