Preparation method and product of multistage porous carbon material

A technology of carbon materials and multi-level pores, which is applied in the field of porous carbon materials, can solve problems such as unsustainability, and achieve the effects of great application value, strong sustainability, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Taking cellulose as a precursor

[0041] Weigh 1.2g of cellulose and 4.8g of potassium hydrogen oxalate for mechanical mixing, then transfer to a 30ml crucible. A two-step calcination was then performed in a nitrogen furnace. Firstly, the temperature was raised to 300°C at 15°C / min, kept for 30 minutes, then heated to 900°C at the same rate, and calcined for 1 hour; then the temperature was naturally cooled to room temperature. Grinding the calcined mixture, adding water, stirring and washing, then filtering, washing until neutral, and drying to obtain a carbon material.

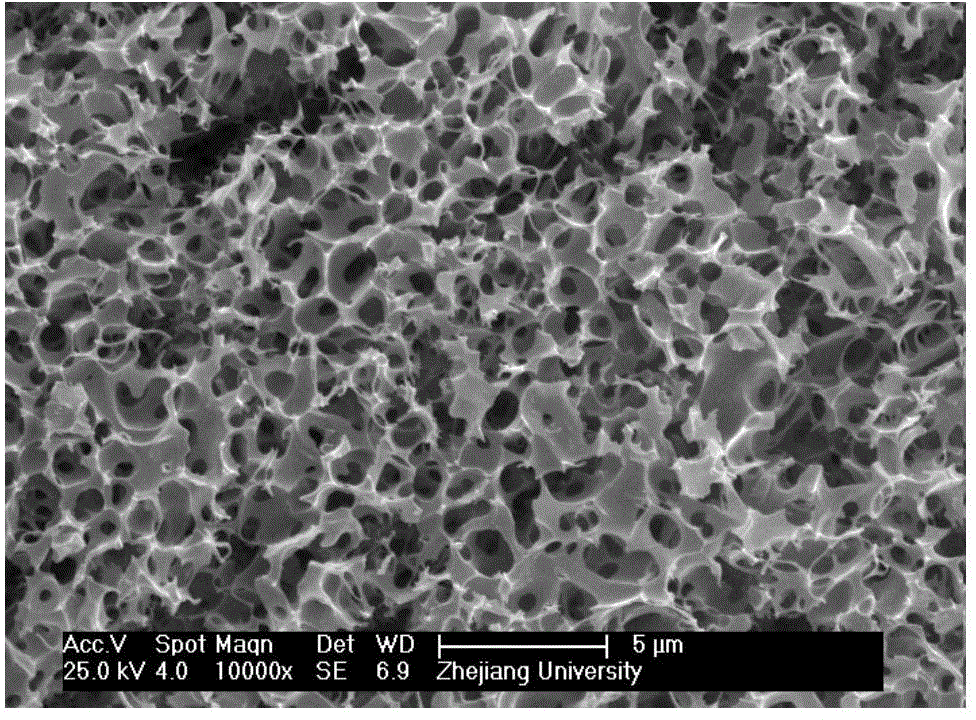

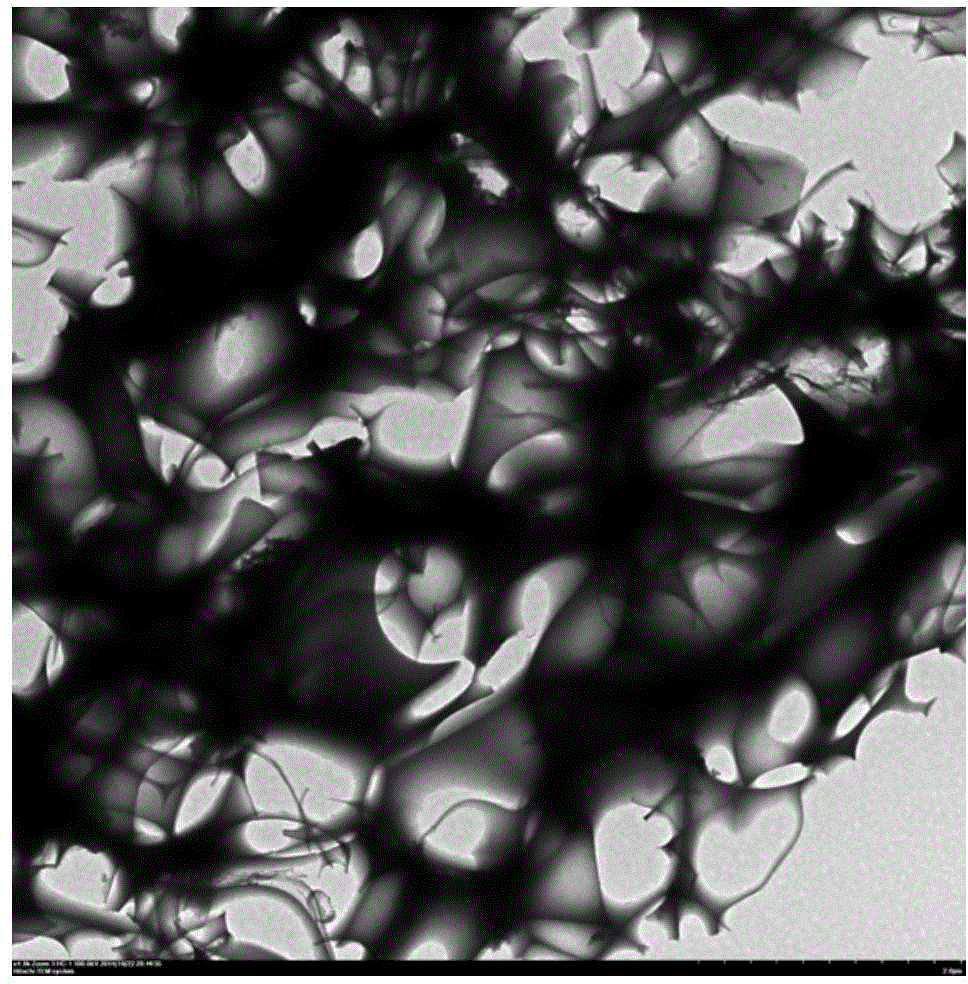

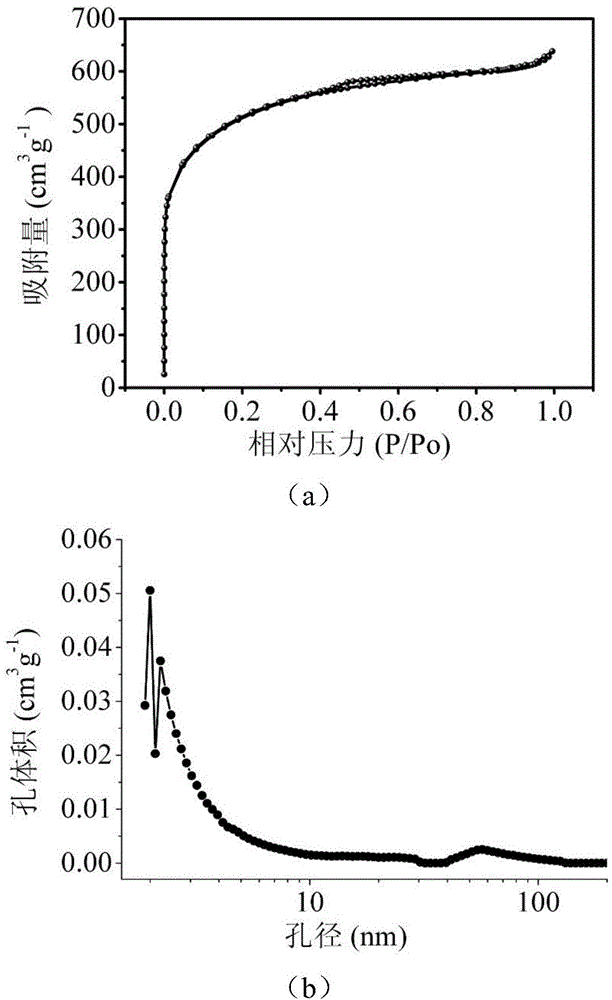

[0042] The scanning electron microscope image of the hierarchical porous carbon material prepared in this example is as follows figure 1 ,Such as figure 1 As shown, the hierarchically porous carbon material prepared in this example has a well-developed hierarchical pore structure, and the hierarchically porous carbon material contains macropores of 500 nm. Large pores facilitate mass...

Embodiment 2

[0054] Embodiment 2: Take bamboo as precursor

[0055] Weigh 1.2g of bamboo powder and 4.8g of sodium oxalate for mechanical mixing, then transfer to a 30ml crucible. A two-step calcination was then performed in a nitrogen furnace. Firstly, the temperature was raised to 300°C at 15°C / min, kept for 30 minutes, then heated to 900°C at the same rate, and calcined for 1 hour; then the temperature was naturally cooled to room temperature. Grinding the calcined mixture, adding water, stirring and washing, then filtering, washing until neutral, and drying to obtain a carbon material. Its scanning electron microscope (SEM) image is as Figure 9 shown.

Embodiment 3

[0056] Embodiment 3: Take xylose as precursor

[0057] Weigh 1.2g xylose and 4.8g sodium bicarbonate for mechanical mixing, then transfer to a 30ml crucible. A two-step calcination was then performed in a nitrogen furnace. First, heat up to 250°C at a rate of 15°C / min, hold for 30 minutes, then heat up to 900°C at this rate, and calcinate for 1 hour; then cool down to room temperature naturally. Grinding the calcined mixture, adding water, stirring and washing, then filtering, washing until neutral, and drying to obtain a carbon material. Its scanning electron microscope (SEM) image is as Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com