Preparation method for multi-walled carbon nanotube/titanium dioxide composite negative electrode material of lithium ion battery

A multi-wall carbon nanotube and ion battery technology, applied in the field of materials, can solve the problems of low conversion energy efficiency and low battery capacity, and achieve the effects of good electrical conductivity, high electrochemical activity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

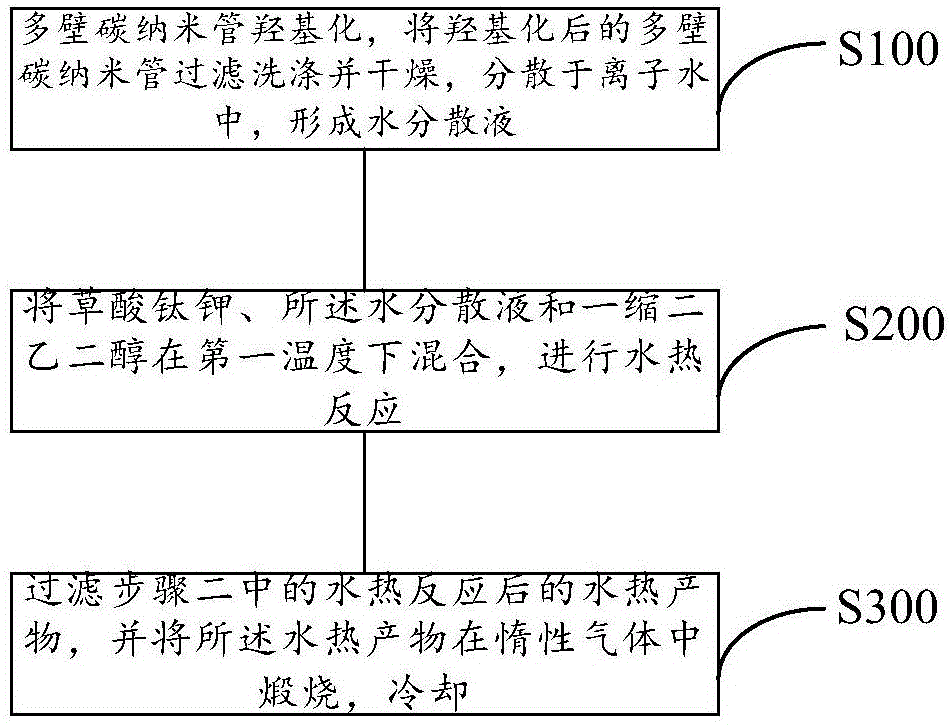

[0040] see figure 1 , the preparation method comprises:

[0041] Step 1 S100, the multi-walled carbon nanotubes are hydroxylated, and the hydroxylated multi-walled carbon nanotubes are filtered, washed and dried, and dispersed in ionized water to form an aqueous dispersion;

[0042] Specifically, the hydroxylation of the multi-walled carbon nanotubes in the step 1 is specifically:

[0043] Add 0.1-0.5 g of multi-walled carbon nanotubes into 3-5 moles per liter of nitric acid solution, and ultrasonically disperse for 1 hour.

[0044] Before being dispersed in deionized water in said step one, also include:

[0045] Condensation and reflux, the temperature of the condensation and reflux is 60-120 degrees Celsius, and the condensation and reflux time is 2-6 hours.

[0046] In the step 1, the hydroxylated multi-walled carbon nanotubes are filtered and washed, specifically:

[0047] Wash with deionized water until the filtrate becomes neutral.

[0048] Described in step 1 is d...

Embodiment 1

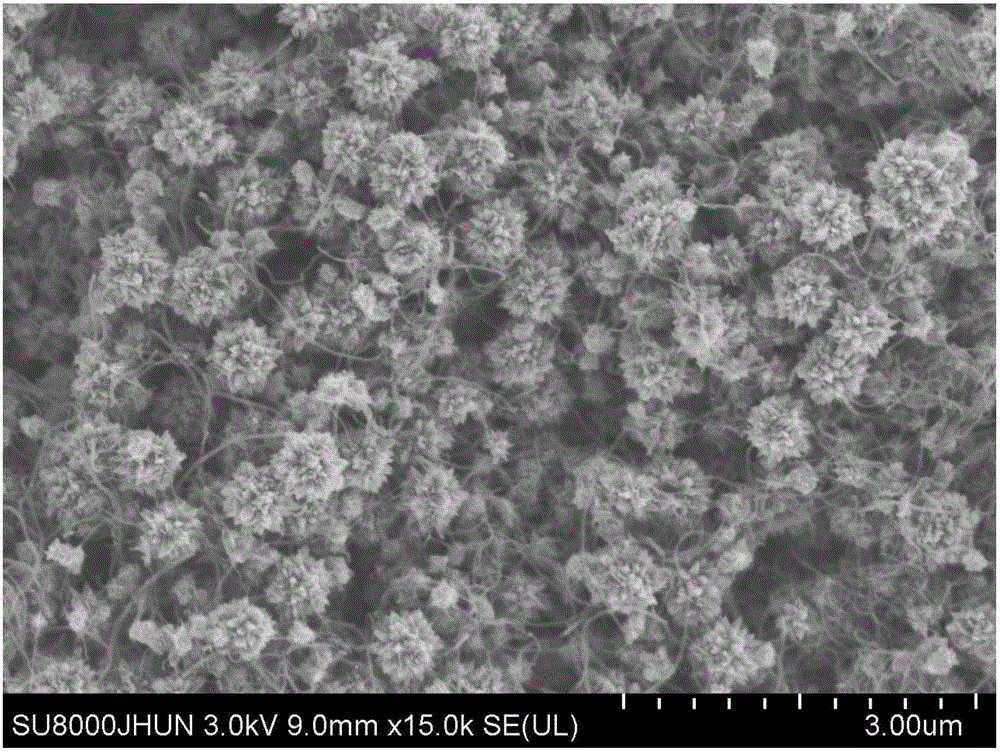

[0060] see figure 2 , figure 2 For the scanning electron micrograph of the lithium-ion battery negative pole multi-walled carbon nanotube / titanium dioxide composite material that this embodiment obtains, please refer to Figure 5 and Figure 6 .

[0061] (1) ultrasonically disperse 0.1 g of multi-walled carbon nanotubes into 3 moles per liter of nitric acid solution, condense and reflux at 120 degrees Celsius for 5 hours, filter and clean with deionized water until the filtrate becomes neutral, and dry at 80 degrees Celsius for 8 hours, The dried sample was added into deionized water, ultrasonically dispersed, and configured as an aqueous dispersion of hydroxylated multi-walled carbon nanotubes at 1 mg / ml.

[0062] (2) Mix 0.5 g of potassium titanium oxalate with 10 ml of aqueous dispersion of hydroxylated multi-walled carbon nanotubes with a concentration of 1 mg per ml and 30 ml of diethylene glycol, stir at a medium speed in a water bath at 60 degrees Celsius until Th...

Embodiment 2

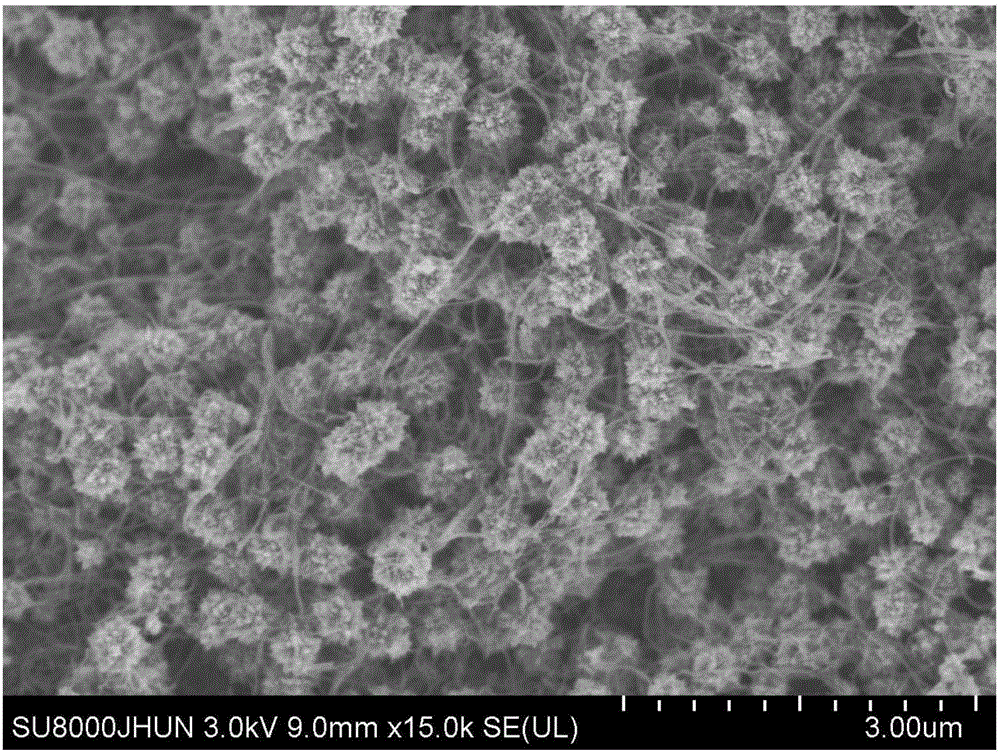

[0065] see image 3 , image 3 For the scanning electron micrograph of the lithium-ion battery negative pole multi-walled carbon nanotube / titanium dioxide composite material that this embodiment obtains, please refer to Figure 5 and Figure 6 .

[0066] (1) ultrasonically disperse 0.1 g of multi-walled carbon nanotubes into 3 moles per liter of nitric acid solution, condense and reflux at 120 degrees Celsius for 5 hours, filter and clean with deionized water until the filtrate becomes neutral, and dry at 80 degrees Celsius for 8 hours, The dried sample was added into deionized water and ultrasonically dispersed to form an aqueous dispersion of hydroxylated multi-walled carbon nanotubes at 2 mg / ml.

[0067] (2) 0.5 g of potassium titanium oxalate and 10 ml of aqueous dispersion of hydroxylated multi-walled carbon nanotubes with a concentration of 1 mg per ml and 30 ml of diethylene glycol were stirred at a medium speed in a water bath at 60 degrees Celsius until A uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com