Submicron yttrium oxide and preparation method thereof

A sub-micron yttrium oxide technology, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of difficult particle size control, large product particle size, high cost of equipment, etc., and achieve precipitation dispersibility and Good filtration performance, stable product quality and performance, and convenient production process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

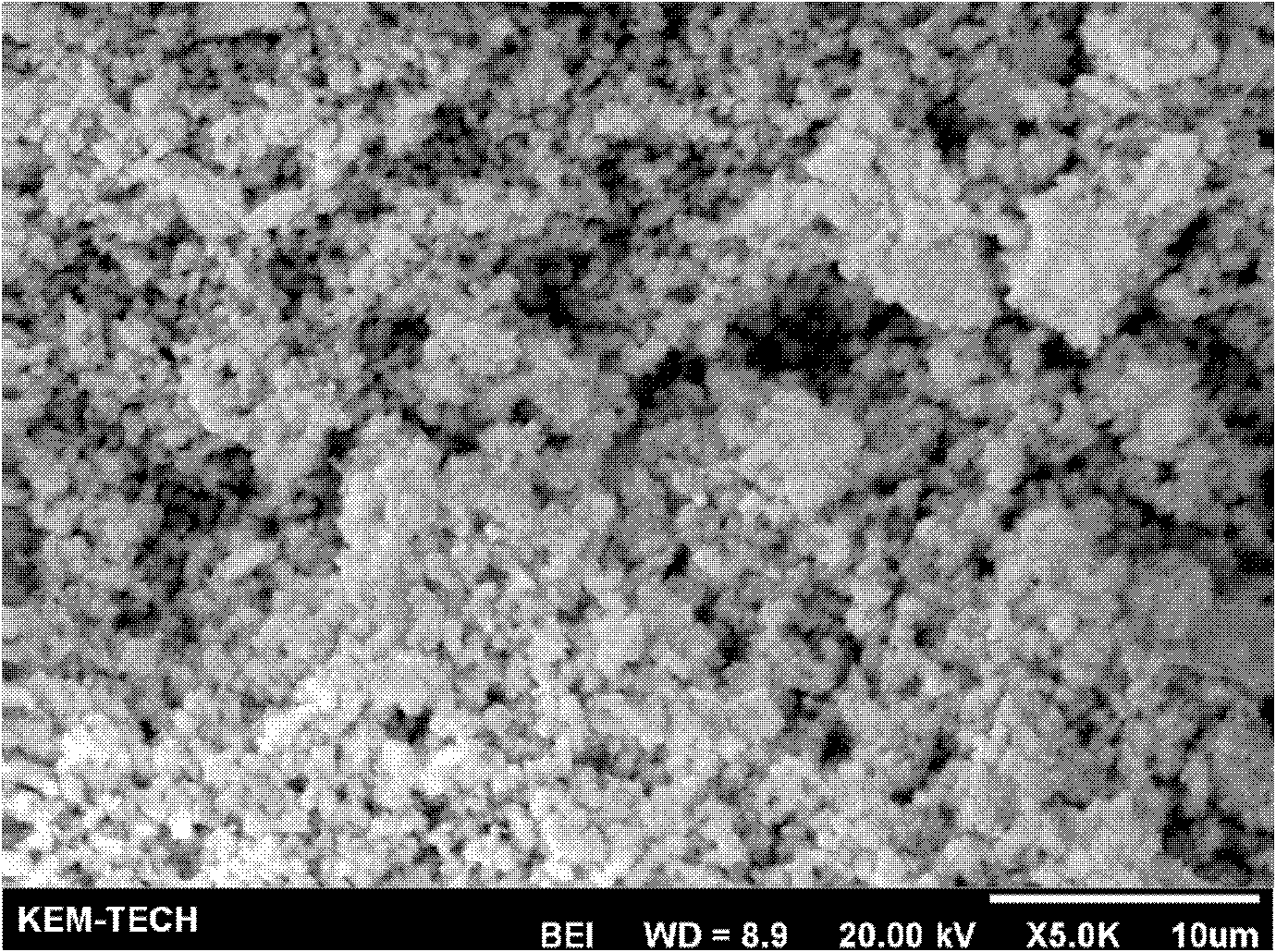

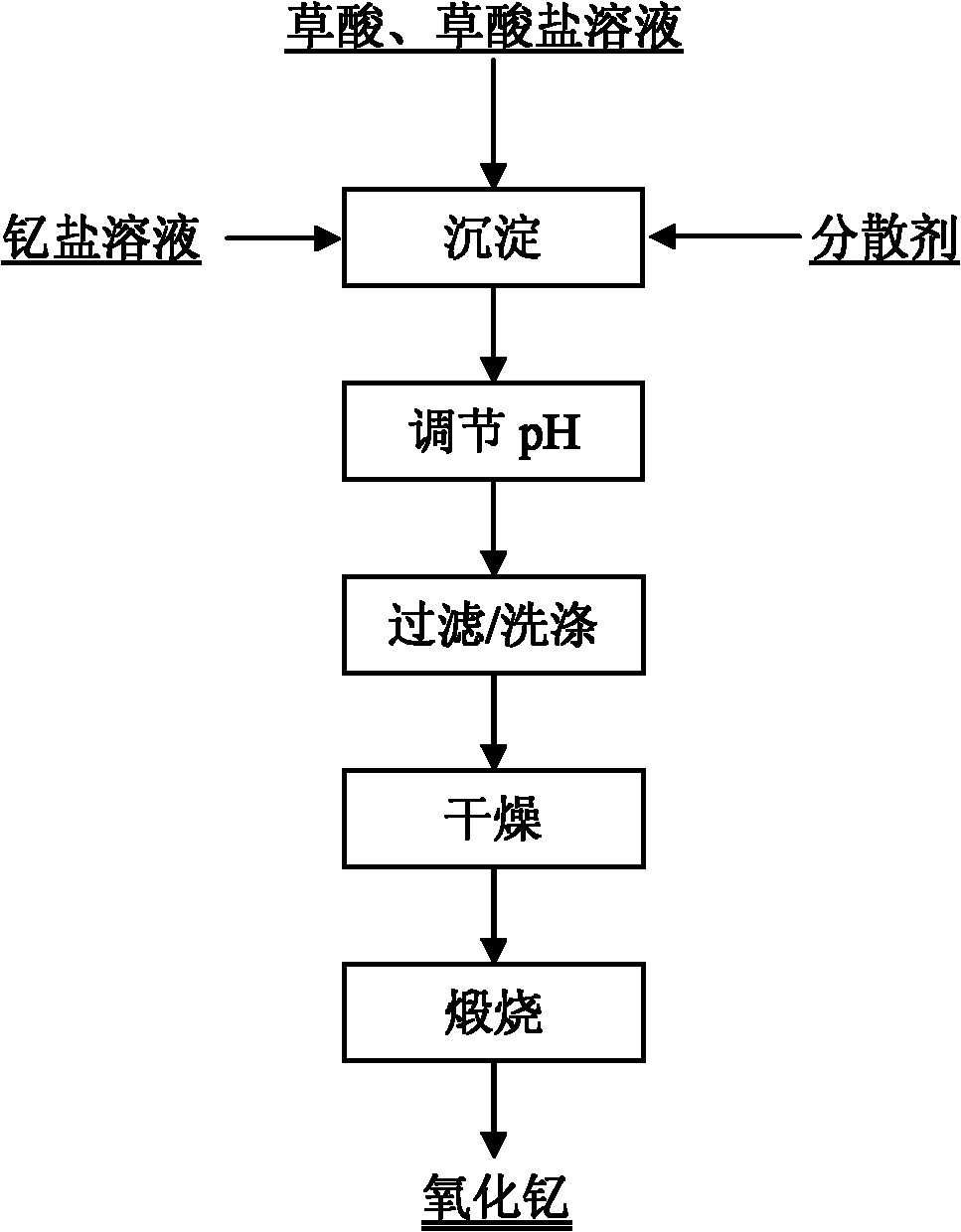

[0035] See attached image 3 , Weighed 72.6g of oxalic acid, 27.3g of ammonium oxalate and 7.7g of PEG2000, dissolved in water and made C 2 o 4 2- Concentration of 0.1mol / L solution 7680ml, ultrasonic dispersion, under the condition of 10℃ in the bottom liquid, add 0.1mol / L yttrium nitrate solution 4800ml, then adjust the pH value to 2.5 with ammonia water, stir and age for 4h, filter the precipitate, After washing several times, it was dried in an oven at 105°C, and then calcined in a muffle furnace at 700°C for 1 hour to obtain 53.3g of yttrium oxide powder. The results of the implementation are shown in Attached Table 1 and Attached figure 1 .

Embodiment 2

[0037] See attached image 3 , respectively weighed 60.8g of oxalic acid, 60.2g of ammonium hydrogen oxalate and 9.6g of PVA17, dissolved in water to make 1920ml of a solution with a concentration of 0.5mol / L, stirred, and added 0.5mol / L of chlorinated 960ml of yttrium solution, then adjusted the pH value to 3.0 with ammonia water, stirred and aged for 2h, filtered the precipitate, washed several times, dried in an oven at 105°C, and calcined in a muffle furnace at 800°C for 1 hour to obtain 53.3g of yttrium oxide powder. See attached table 1 for the implementation results.

Embodiment 3

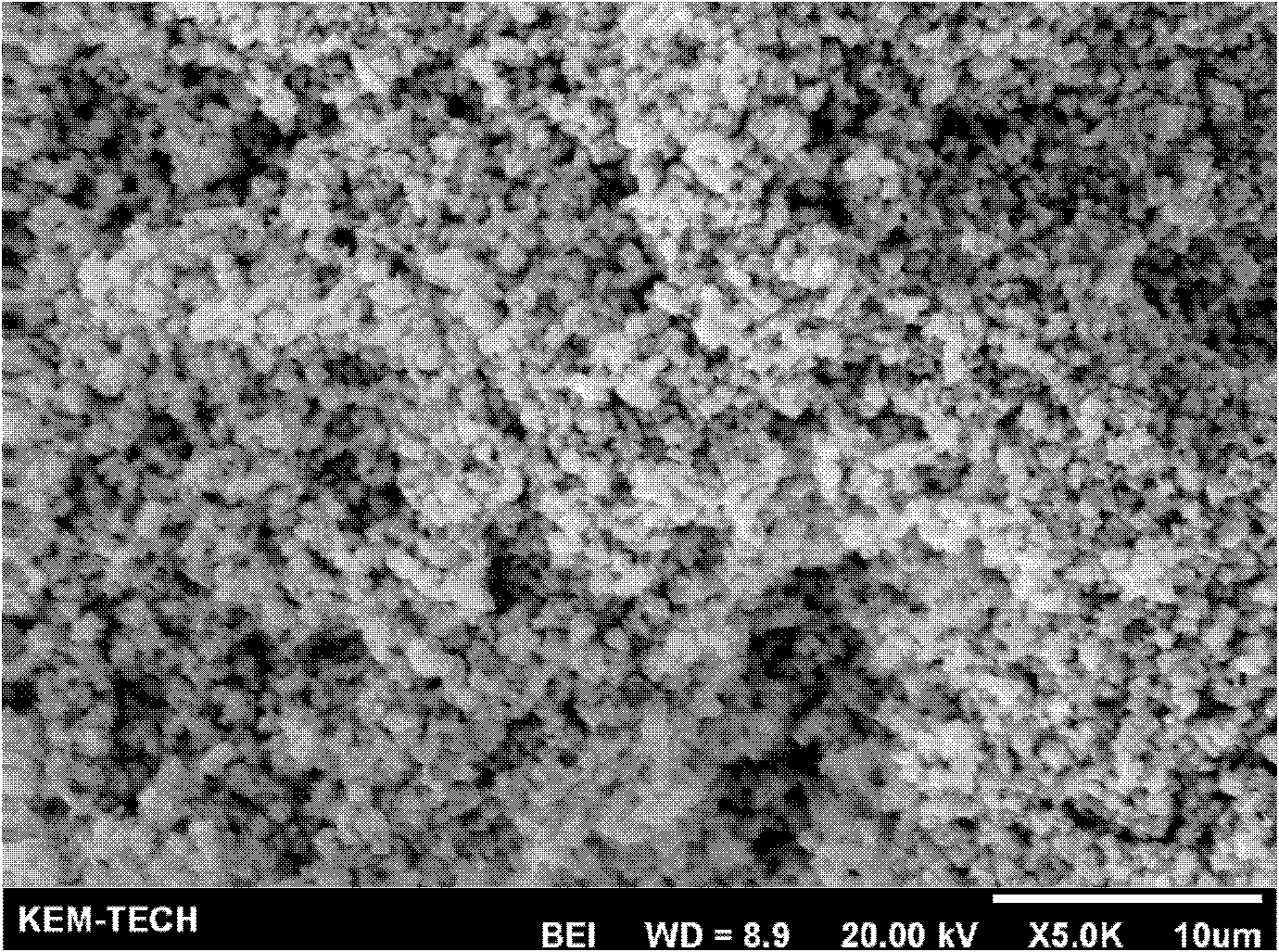

[0039] See attached image 3, respectively weigh 72.6g of oxalic acid and 58.4g of sodium oxalate, add water to dissolve and make 480ml of a solution with a concentration of 2mol / L, stir and disperse with ultrasonic waves at the same time, add 240ml of 2mol / L yttrium nitrate solution at 70°C, and then Adjust the pH value to 5.0 with ammonia water, stir and age for 1 hour, filter the precipitate, wash several times, dry it in an oven at 105°C, and calcinate it in a muffle furnace at 850°C for 1 hour to obtain 53.5g of yttrium oxide powder. The results of the implementation are shown in Attached Table 1 and Attached figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com