Patents

Literature

30results about How to "Short rust removal time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

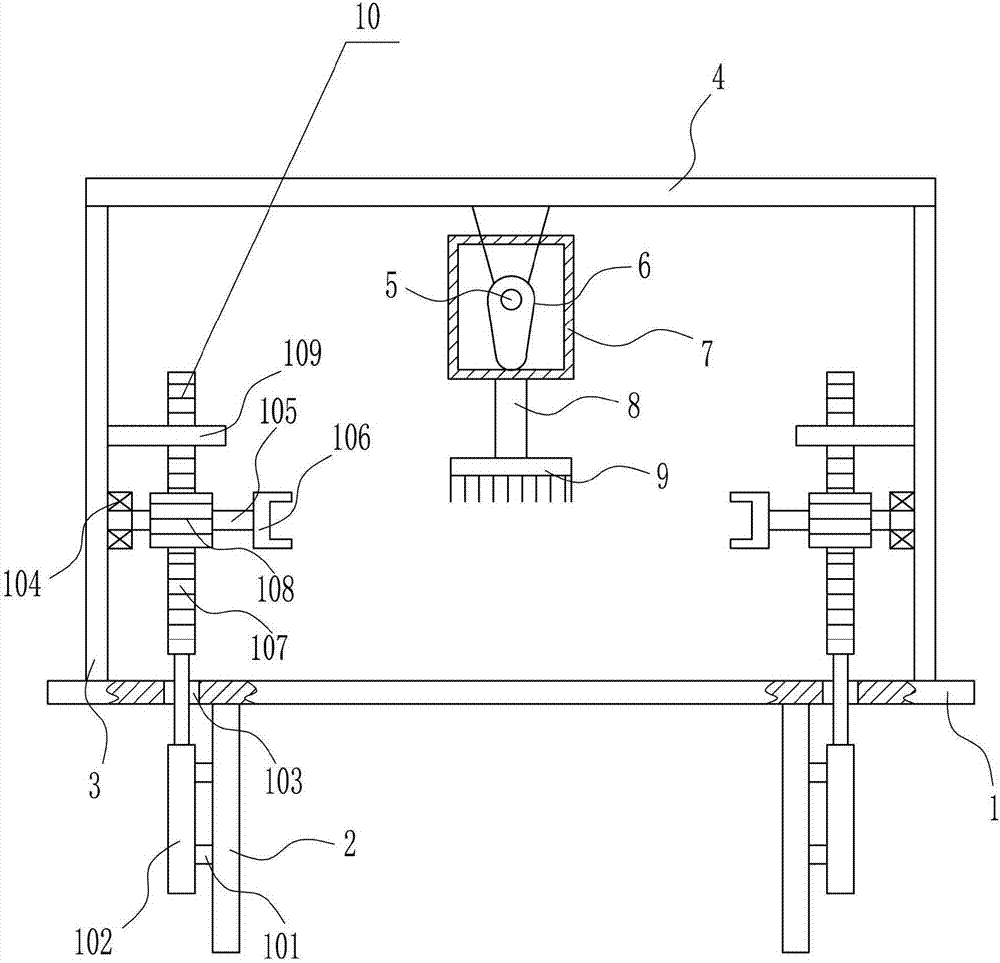

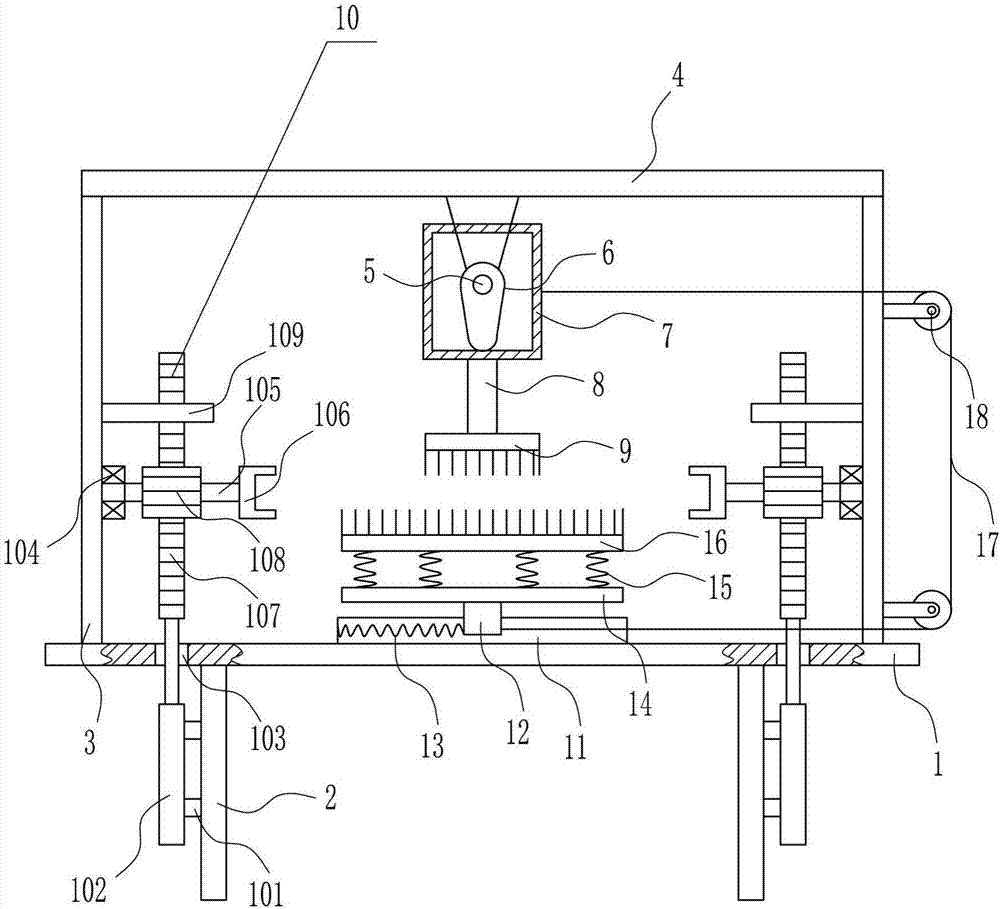

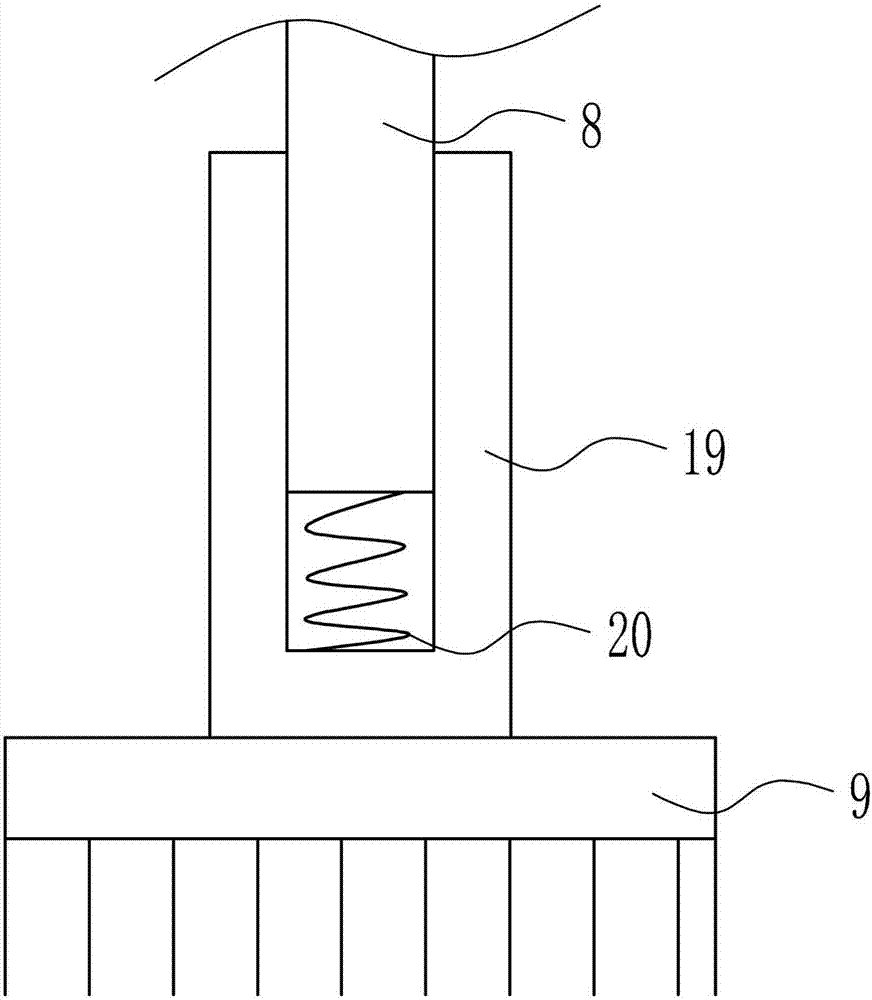

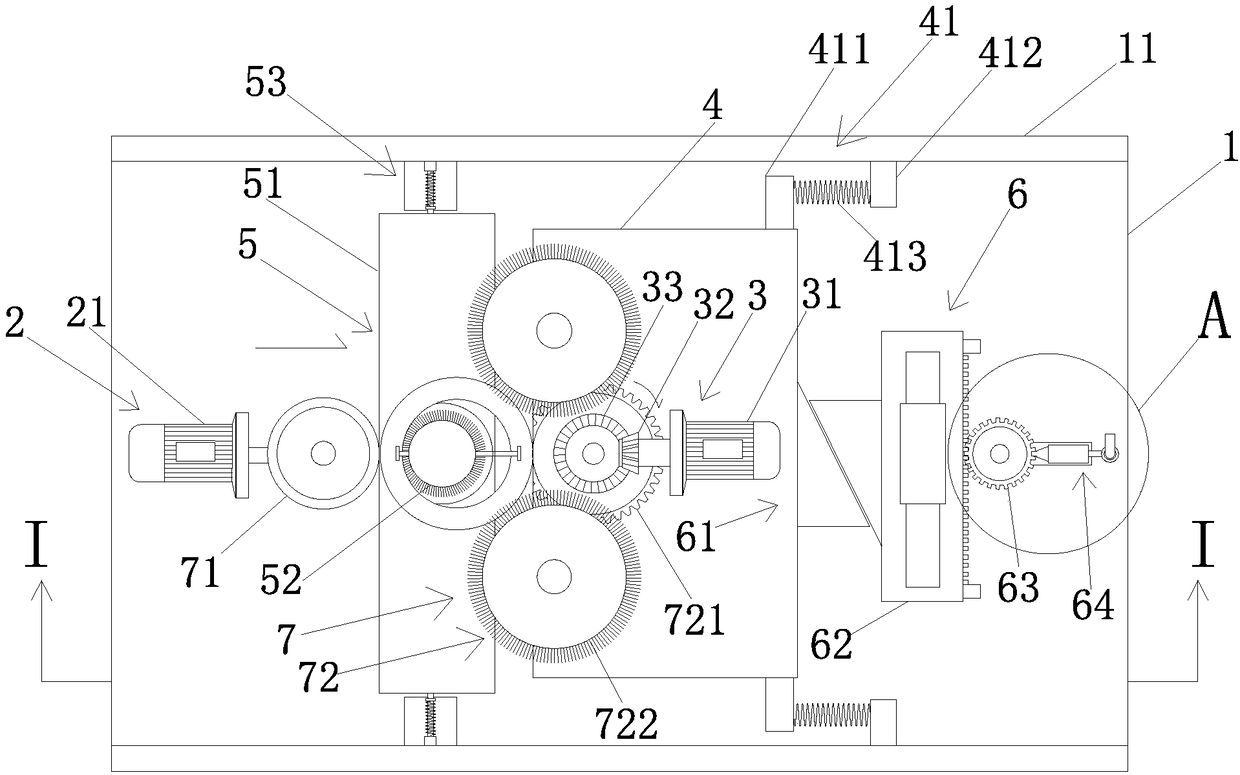

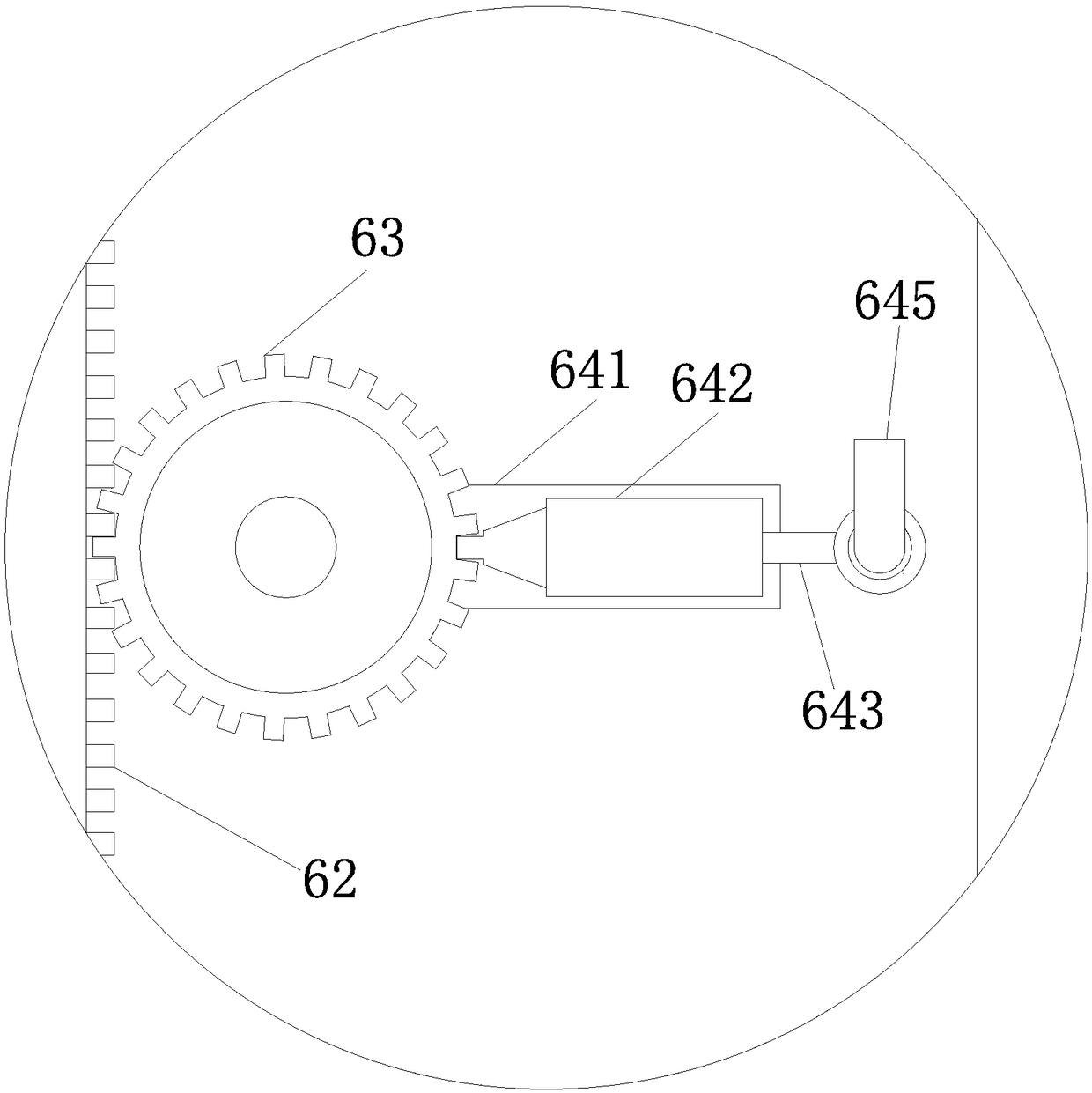

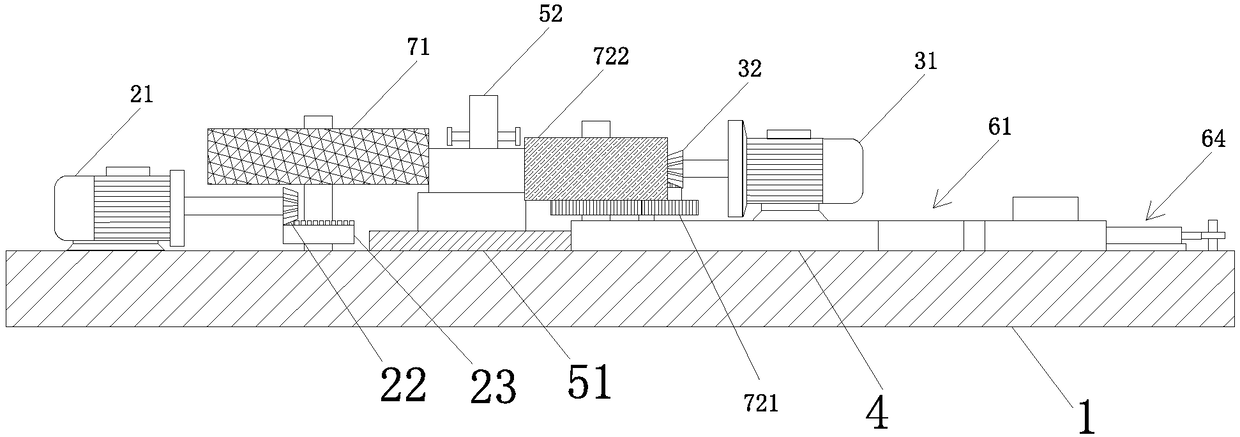

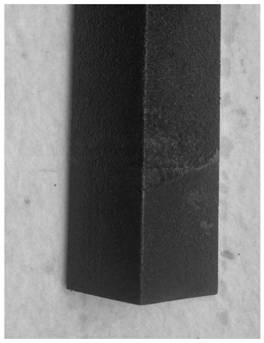

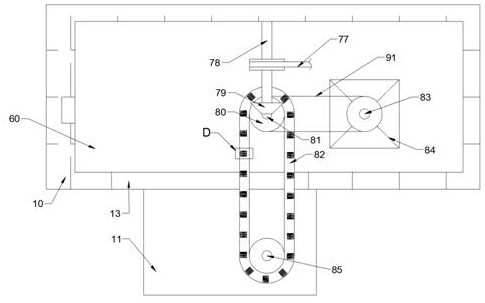

Efficient steel bar rust removing equipment for construction

InactiveCN106944908AComprehensive rust removalImprove rust removal effectGrinding carriagesGrinding drivesArchitectural engineeringEngineering

The invention relates to a derusting device for steel bars for construction, in particular to a high-efficiency derusting device for steel bars for construction. The technical problem to be solved by the present invention is to provide a high-efficiency derusting equipment for building steel bars that does not require a large amount of labor, has short derusting time, and is not easy to be injured during the derusting process. In order to solve the above technical problems, the present invention provides such a high-efficiency derusting equipment for steel bars for construction, which includes a bottom plate, legs, support plates, top plate, first motor, cam, frame, vertical bar, etc.; Outriggers are installed on the sides by bolts, support plates are installed on the left and right sides of the top of the bottom plate by bolts, and a top plate is installed on the top of the support plate by bolts. In the present invention, the first steel wire brush and the second steel wire brush move left and right to double derust the steel bar, so that the derusting effect of the steel bar is better, and at the same time, the rotation of the steel bar is improved.

Owner:孔军玲

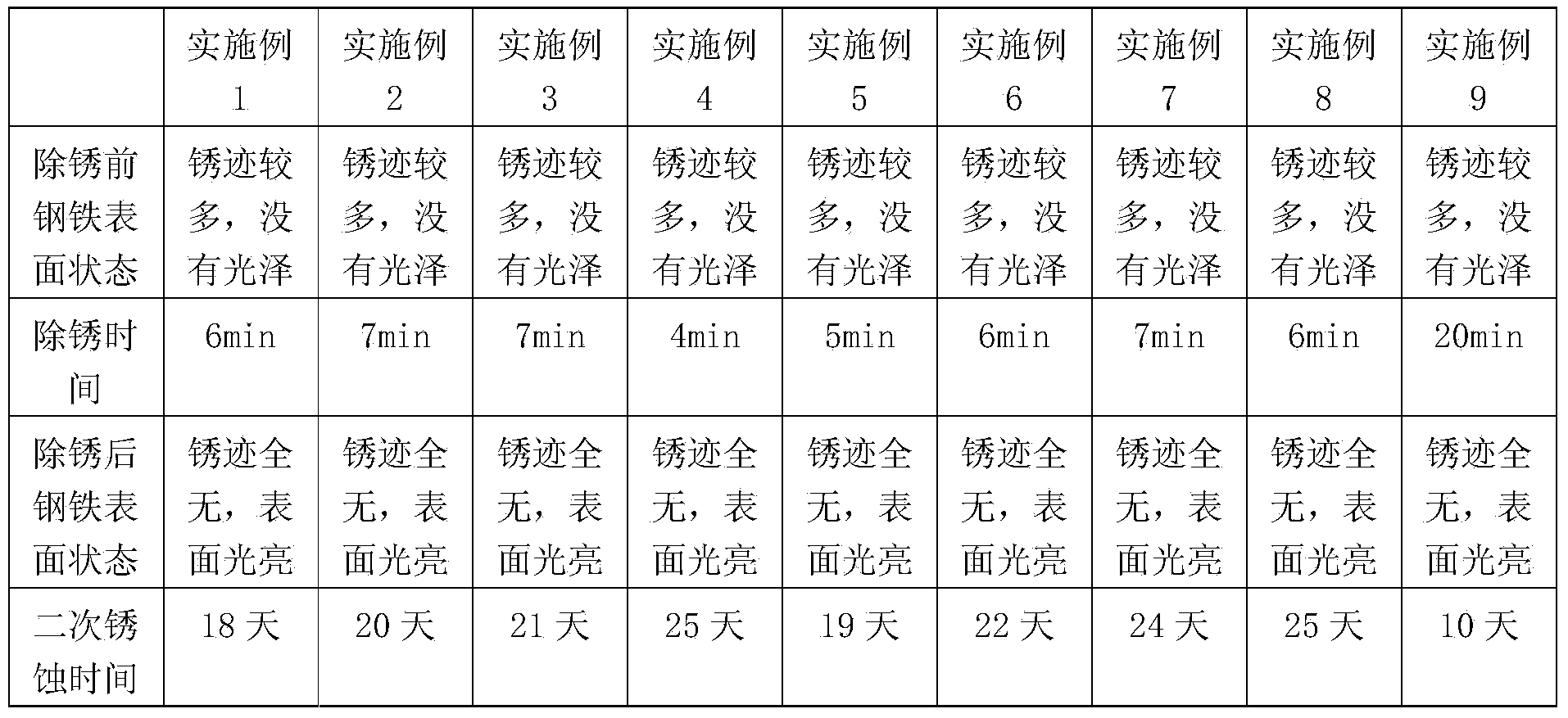

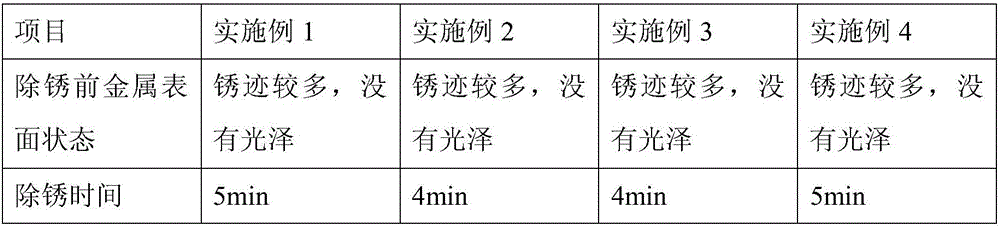

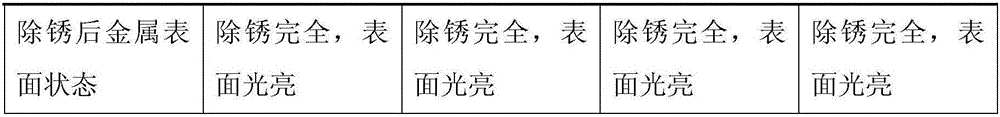

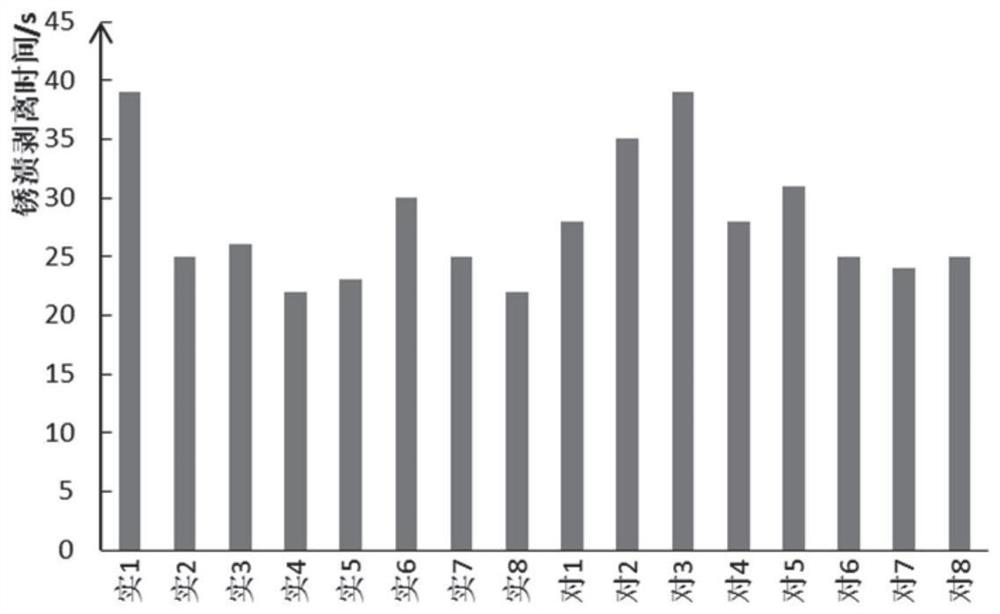

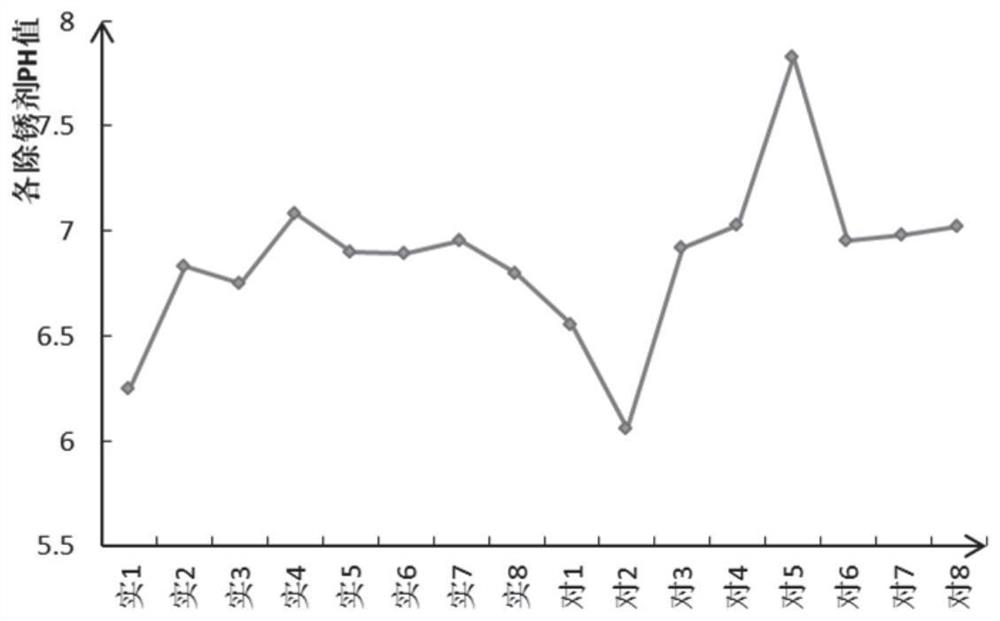

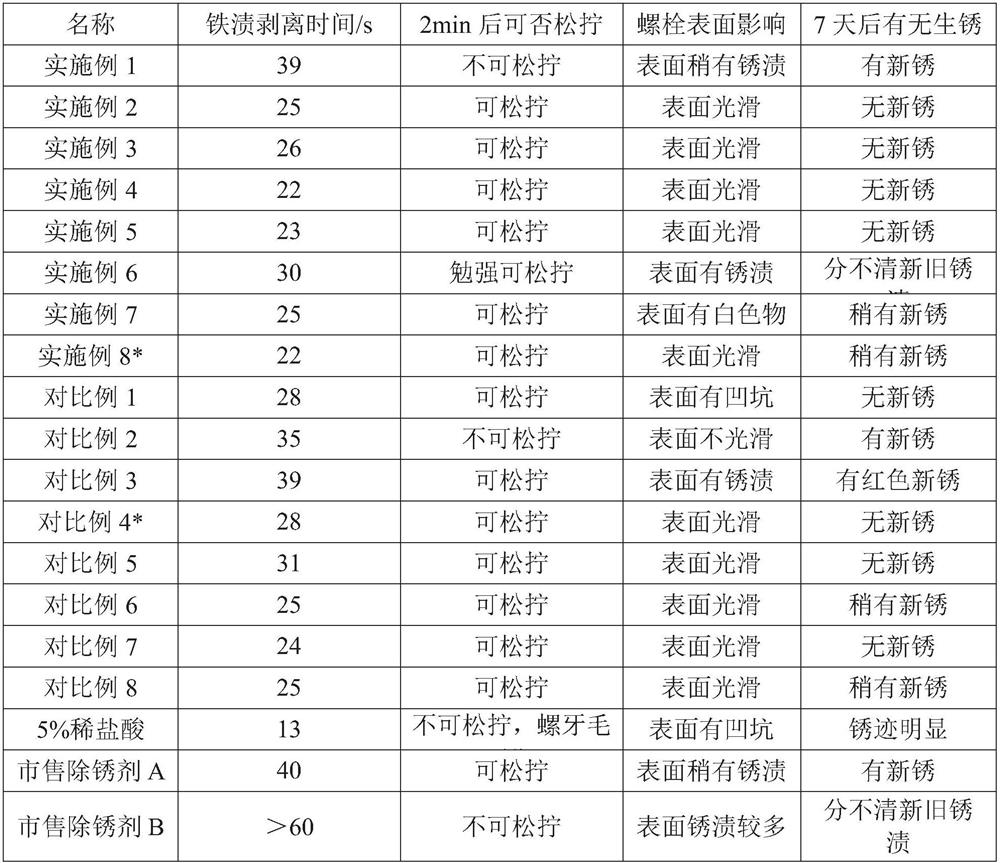

Steel rust removal fluid and preparation method thereof

InactiveCN103882454AImprove efficiencyShort rust removal timePolyvinyl alcoholHexamethylenetetramine

The invention provides steel rust removal fluid and a preparation method thereof. The steel rust removal fluid comprises the following components in parts by weight: 0.8-2.5 parts of oxalic acid, 1-7 parts of tartaric acid, 0.3-1.5 parts of lauryl sodium sulfate, 2-8 parts of phosphoric acid solution, 30-50 parts of hydrochloric acid solution, 0.2-0.9 part of fatty alcohol-polyoxyethylene ether, 0.1-0.8 part of hexamethylenetetramine, 1-5 parts of triethanolamine, 0.2-0.9 part of alkylphenol ethoxylates, 0.3-0.8 part of polyvinyl alcohol, 0.5-2.3 parts of paraffin, 0.1-1.5 parts of ammonium chloride, 0.2-2.5 parts of Tween-80, 0.5-1.5 parts of urotropine and 30-50 parts of water. The preparation method comprises the following steps: weighing the components, adding the phosphoric acid solution and hydrochloric acid solution into water, and adding other components. According to the rust removal fluid, rust on the steel surface can be removed in a short time, and the steel surface does not rust again for a long time after rust removal.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Liquid phase plasma derusting solution of steel and derusting process

The invention relates to a liquid phase plasma derusting solution of steel and a derusting process. The derusting solution comprises the following components: 1-4wt% of ammonium chloride, 0.5-3wt% of potassium sulfate, and the balance water. The derusting process consists of: a. conducting oil removing treatment on steel to be derusted; b. heating the liquid phase plasma derusting solution, immersing the deoiled steel in the liquid phase plasma derusting solution, introducing a rectifier positive electrode, and connecting a rectifier negative electrode with a negative plate in parallel to conduct derusting; c. taking the steel out after derusting, immersing the steel in deionized water, and then carrying out flushing with deionized water; and d. drying the flushed steel, thus obtaining a derusted steel end product. The liquid phase plasma derusting solution provided in the invention has no damage on operation staff and has no pollution on the environment. The derusting process has the advantages of short derusting time, high efficiency, and improvement of steel surface smoothness, etc.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

Metal water-based rust removal antirust solution and preparing method thereof

InactiveCN108018567AWide temperature rangeEmulsifyingMetallic material coating processesWater basedMesoporous silica

The invention provides a metal water-based rust removal antirust solution. The metal water-based rust removal antirust solution comprises raw materials including, by weight part, 2 to 6 parts of citric acid, 2 to 8 parts of lauryl sodium sulfate, 2 to 4 parts of tartaric acid, 1 to 5 parts of sodium citrate, 2 to 6 parts of polyaspartic acid, 0.4 to 1.2 parts of oxidized starch, 5 to 10 parts of cetyl-trimethyl ammonium bromide, 10 to 15 parts of polyoxyethylene fatty alcohol sodium sulfate, 1 to 2 parts of OP-10, 1 to 3 parts of chitosan, 2 to 8 parts of mesoporous silica, 10 to 20 parts of PEG200, 15 to 20 parts of propanediol butyl ether and 60 to 90 parts of water. The invention further provides a preparing method of the metal water-based rust removal antirust solution. The metal water-based rust removal antirust solution has multiple functions of rust removal, dirt removal, phosphatization, passivation and the like, a reaction is carried out at the normal temperature, the rust removal time is short, the antirust time is long, and corrosion to the metal is avoided.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

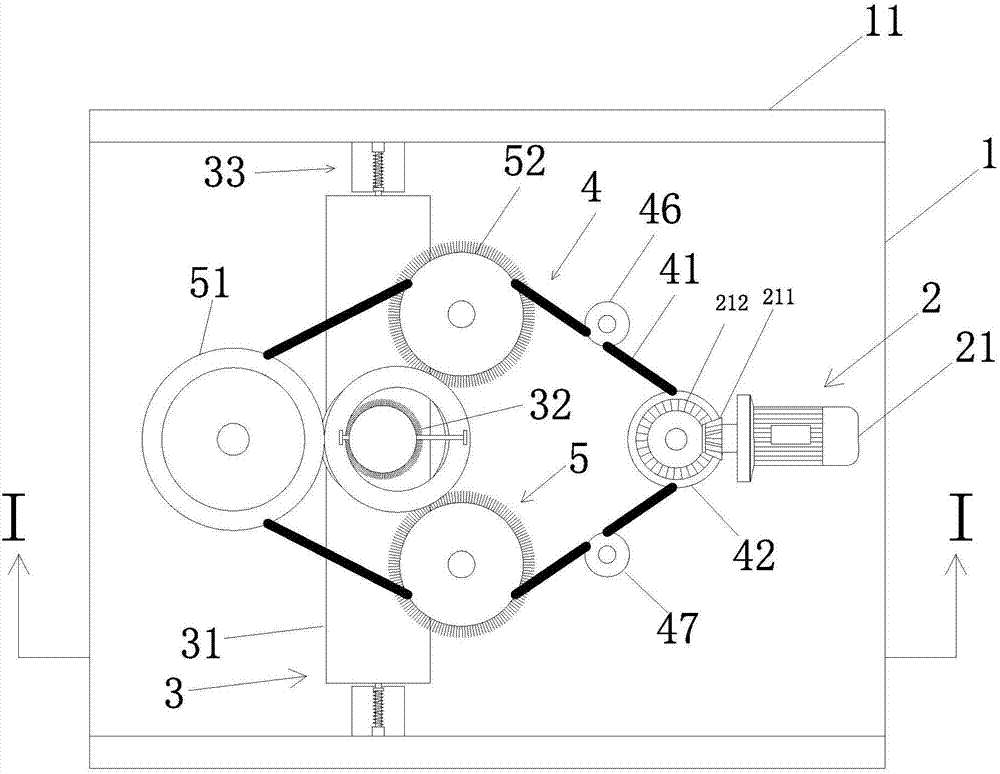

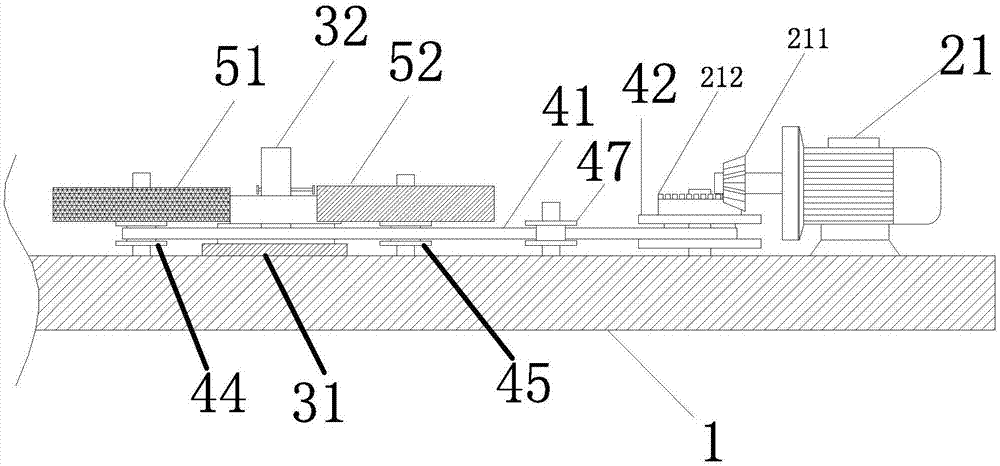

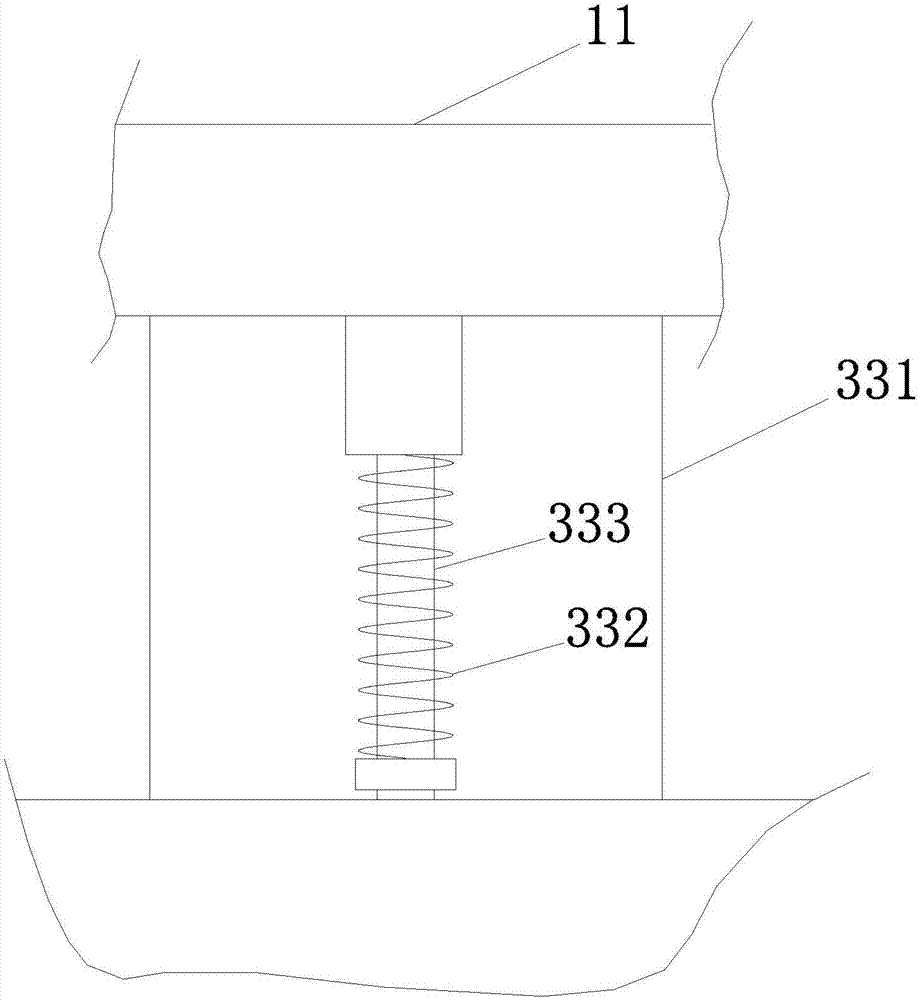

Bearing derusting device

PendingCN108145576AIngenious structureEasy to operateGrinding carriagesGrinding drivesSlide plateEngineering

The invention provides a bearing derusting device comprising a base, a driving assembly, a support assembly and an execution assembly; the driving assembly comprises a first driving assembly and a second driving assembly; the second driving assembly comprises a second driving motor, a third bevel gear and a fourth bevel gear; the second driving motor is fixedly arranged on a sliding plate; the sliding plate is arranged on the base; an output end of the second driving motor is provided with a third bevel gear; the fourth bevel gear is rotatably arranged on the sliding plate; the fourth bevel gear is arranged in the vertical direction and revolves around a center line of rotation, and the third bevel gear is meshed with the fourth bevel gear; the support assembly comprises a support plate and a support column; the support plate is arranged on the base; the support column is fixed on the support plate; the execution assembly comprises a compressing assembly and a derusting assembly; and rotating direction of the first driving motor is the same as that of the second driving motor. The bearing derusting device solves the problem of low efficiency of manual derusting in the prior art.

Owner:重庆捷科隆金属科技有限公司

Metal antirust agent

InactiveCN107447222AShort rust removal timeGood effectMetallic material coating processesDiethylene glycol monobutyl etherEmulsion

The invention relates to the technical field of metal antirust and anticorrosion, and is a metal antirust agent, which is composed of the following raw materials in weight fractions: 25-30 diethylene glycol monobutyl ether, 17-25 phosphoric acid, 8-15 corrosion inhibitors, Surfactant 8-10, acrylate emulsion 2-5, deionized water 25-30; the invention has mild formula, strong derusting ability, short derusting time, friendly to the environment, and is mainly used for metal antirust and anticorrosion.

Owner:皮方艳

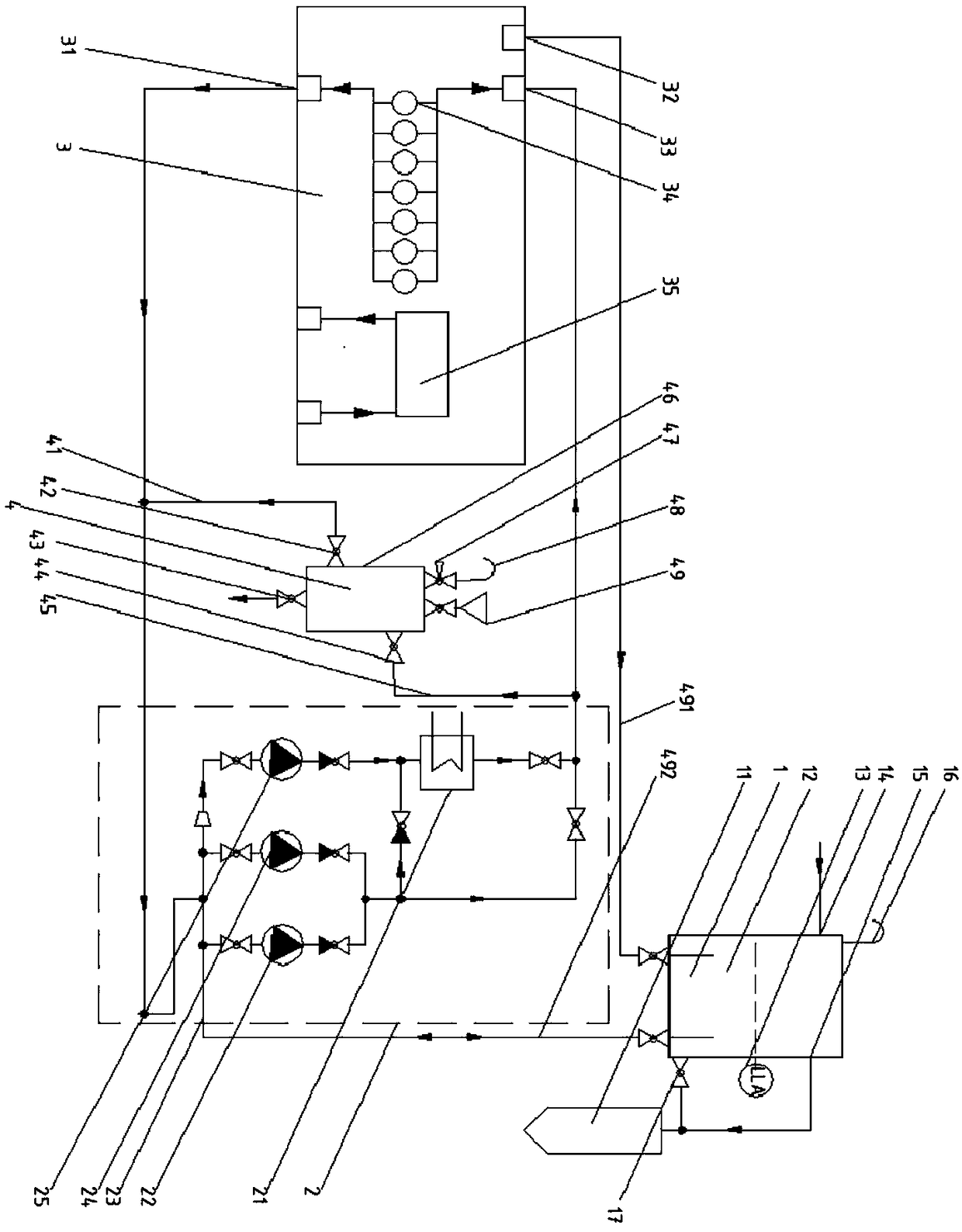

Fresh water cooling and dosing system

InactiveCN109252938APromotes fast and thorough mixingShort rust removal timeMachines/enginesEngine cooling apparatusHydrostatic pressureFresh water

The invention discloses a fresh water cooling and dosing system. The fresh water cooling and dosing system comprises a cylinder jacket water expansion water tank system, a cylinder jacket water circulating pump system, a main machine cylinder jacket system and a dosing device. A main body of the cylinder jacket water expansion water tank system is a second tank, and a main body of the dosing device is a first tank; the topmost portion of the first tank is lower than the bottommost portion of the second tank; a first branch is formed in a pipeline connected between an outlet of the cylinder jacket water circulating pump system and an inlet of the main machine cylinder jacket system; an inlet of the first tank is connected with the first branch; a second branch is formed in a pipeline connected between an inlet of the cylinder jacket water circulating pump system and a second outlet of the main machine cylinder jacket system; an outlet of the first tank is connected with the second branch. The fresh water cooling and dosing system has the advantages that the bottommost portion of the second tank of the cylinder jacket water expansion water tank system is higher than the topmost portion of the first tank of the dosing device; when liquid in the two tanks has hydrostatic pressure, a water pump in the fresh water cooling system circulates derusting liquid in a forced way, and the derusting liquid is fully mixed with fresh water quickly, so that the derusting time is shortened, and the derusting effect is improved.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Environment-friendly corrosion-prevention metal oil-rust removing agent and preparation process thereof

The invention provides an environment-friendly corrosion-prevention metal oil-rust removing agent and a preparation process thereof. The oil-rust removing agent is prepared from the following components in parts by weight: acetic anhydride, itaconic acid, 1,3-butylene glycol, oleic acid, nano-zirconia, 8-hydroxyquinoline, boric acid, caprolactam, nano-cerium oxide powder, disodium ethylene diamine tetraacetate, saponin powder, heterogeneous alcohol polyoxyethylene ether, matrine, methylisothiazolinone, thiourea, 3-amino-4-octanol, sodium citrate, deionized water and ethanol. The oil-rust removing agent provided by the invention has an integral oil-rust removing effect, the rust removing time is only 5-10 minutes, the surface of metal is bright and has no obvious rust trace after the rust removing treatment, obvious rust spot or rust trace is not generated after the metal which is subjected to oil-rust removal is placed at the room temperature for 1 month, and the metal is good in corrosion resistance, does not secondarily rust within 2 months and does not generate smoke, so that the oil-rust removing agent is safe to use, environmentally friendly and suitable for being popularized and used.

Owner:广东辉炜佳科技有限公司

Deruster and preparation method thereof

The invention relates to the technical field of chemical engineering and provides a deruster and a preparation method thereof. The deruster is composed, by weight, of 15-25 parts of trisodium phosphate, 12-16 parts of acrylic ester copolymers, 14-18 parts of antimony trioxide, 10-20 parts of inositol hexaphosphate, 16-20 parts of acrylamide, 6-8 parts of tolyl triazole, 16-24 parts of dodecyl phenyl succinic acid, 11-17 parts of diethoxy estersil ethane, 6-12 parts of dibutyl phthalate, 8-12 parts of fluorocarbon emulsion, 6-8 parts of modified vermiculite powder and 30-40 parts of deionized water. According to the deruster, the derusting time is short, the derusting effect is good, secondary rust of metal after derusting is not liable to occur, the component source is wide, the preparation process is simple, and the deruster is suitable for being popularized in the field of chemical engineering.

Owner:广西班奇供应链管理有限公司

Polishing boron sulfate rust remover

The application provides a polishing boron sulfate rust remover. The rust remover is prepared by mixing boron sulfate rust removers, alumina particles and / or zinc oxide particles and water, wherein the mass of the alumina particles accounts for 0.5%-1% of the total mass, and the mass of the water accounts for 1%-20% of the total mass. The efficient rust remover has a quick and simple rust removalfunction for severe rust, as well as inactivation and anti-oxidation functions; and not only can the rust removal effect is superior to the rust removal effect of strong acid or nitrogen and phosphorus rust removers, and the polishing boron sulfate rust remover is green and environmentally friendly, and has no toxic and side effects on human bodies.

Owner:镇江纳润特高新科技发展有限公司 +1

Preparation method of metal rust removing liquid

The invention discloses a preparation method of a metal rust removing liquid. The preparation method comprises steps as follows: sodium metasilicate, polyethylene glycol, polyvinyl alcohol, sodium citrate, lecithin and water are heated and mixed uniformly, and a first mixture is obtained; triethanolamine, ammonium molybdate, triethanolamine oleate, urea, sodium carboxymethylcellulose and water are taken and mixed uniformly, and a second mixture is obtained; etidronic acid is taken and added to the first mixture, an obtained mixture is heated under the inert gas shielding condition, the second mixture is added during stirring of the obtained mixture, stirring is continued after addition of the second mixture, then ethanediamine and acetic anhydride are dropwise added and mixed uniformly to reach the room temperature, and the metal rust removing liquid is obtained. The metal rust removing liquid is convenient to use, all that is required is to soak the metal requiring rust removal into the metal rust removing liquid, rust is removed thoroughly, the rust removing time is short, and the metal surface is not damaged after rust removal.

Owner:WUXI YONGXING METAL HOSE

Rust removal and rust prevention liquid and preparation method thereof

InactiveCN108018563AWide temperature rangePromote chelationMetallic material coating processesMesoporous silicaFatty alcohol

The invention provides a rust removal and rust prevention liquid. The liquid comprises the raw materials of, by weight, 5-9 parts of long-oil alkyd resin, 2-6 parts of citric acid, 2-8 parts of laurylsodium sulfate, 2-4 parts of tartaric acid, 1-2 parts of ethylene diamine tetraacetic acid disodium, 2-6 parts of polyaspartic acid, 0.4 -1.2 part of oxidized starch, 5-10 parts of trimethyl cetyl ammonium bromide, 10-15 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 1-2 parts of turkey red oil, 1-3 parts of carboxymethyl cellulose, 2-8 parts of mesoporous silica, 10-20 parts of ethylene glycol, 15-20 parts of propylene glycol butyl ether and 60-90 parts of water. The invention further provides a preparation method of the rust removal and rust prevention liquid. The provided rust removal and rust prevention liquid has multiple functions such as rust removal, decontamination, phosphatization and passivation; and reaction can be carried out at normal temperature, the rust removal time is short, the rust prevention time is long, and the liquid does not corrode the metal.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

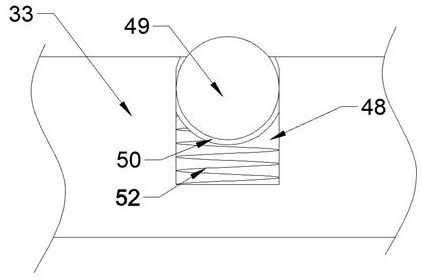

Bearing derusting device

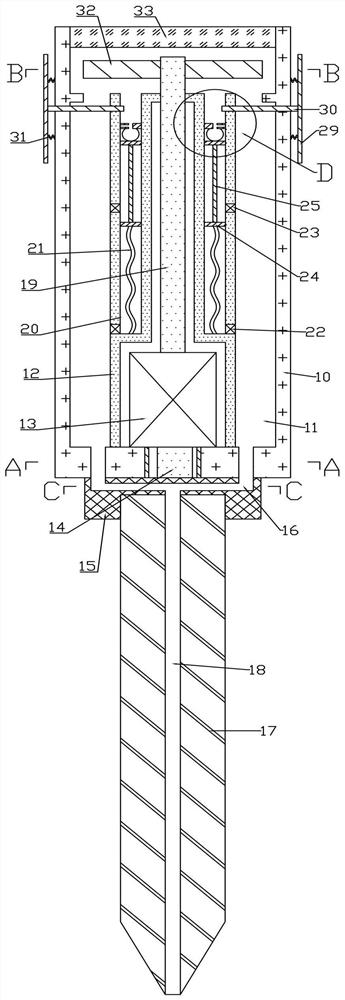

PendingCN107971909ASimple structureLow failure rateGrinding drivesGrinding machinesDrive wheelDrive shaft

The invention provides a bearing derusting device. The bearing derusting device comprises a base, a driving assembly, a supporting assembly, a transmission assembly and an actuating assembly, whereinthe supporting assembly comprises a supporting plate and a supporting column; the supporting plate is mounted on the base; the supporting column is vertically fixed to the supporting plate and used for penetrating through a bearing; a plurality of fixing holes are formed in the supporting column; each fixing pin can penetrate through the corresponding fixing hole; the bearing can be limited between the fixing pins and the supporting plate through the fixing pins; the transmission assembly comprises a belt, a first bevel gear, a second bevel gear, a first belt wheel, a second belt wheel, a third belt wheel and a fourth belt wheel; the actuating assembly comprises a driving wheel and two turning wheels; the center of the driving wheel is fixed to the center of the third belt wheel through asecond transmission shaft; and the two turning wheels are fixed to the center of the third belt wheel and the fourth belt wheel through two third transmission shafts correspondingly. The problem thatin the prior art, the efficiency of manual bearing derusting is lower is solved, and the bearing derusting device has the effects of being simple in structure and low in energy consumption.

Owner:重庆捷科隆金属科技有限公司

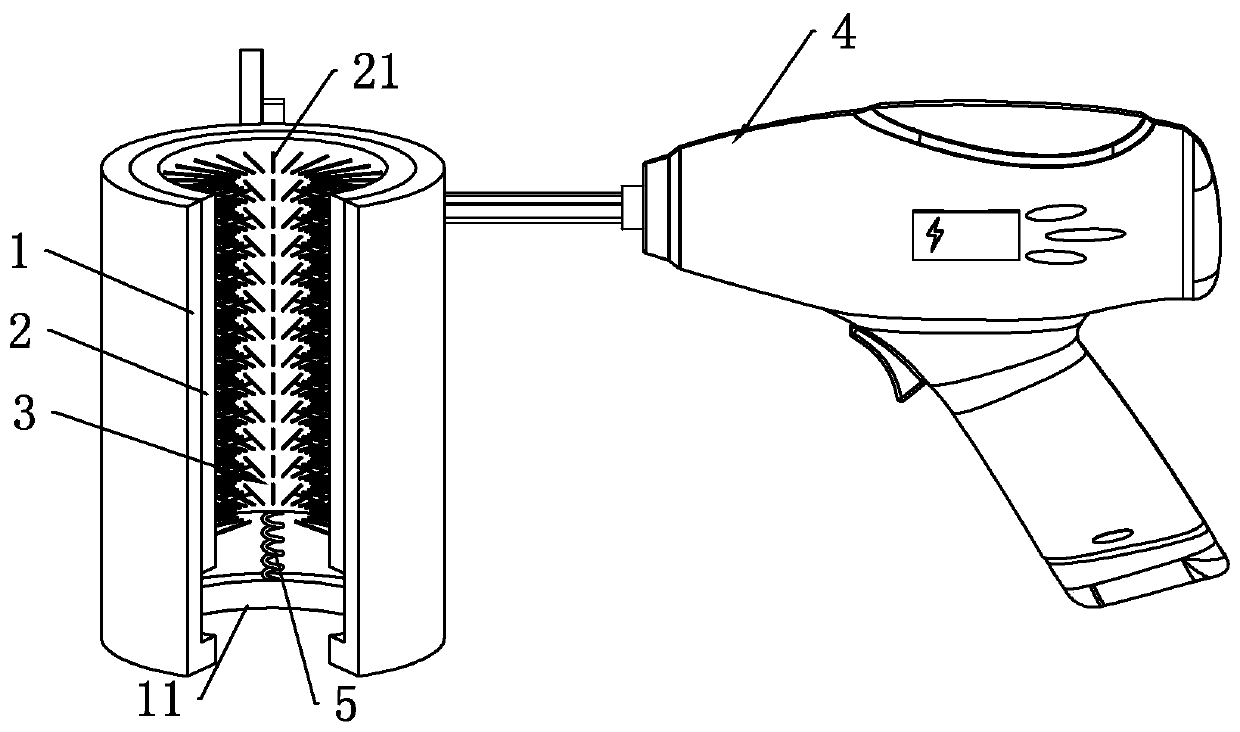

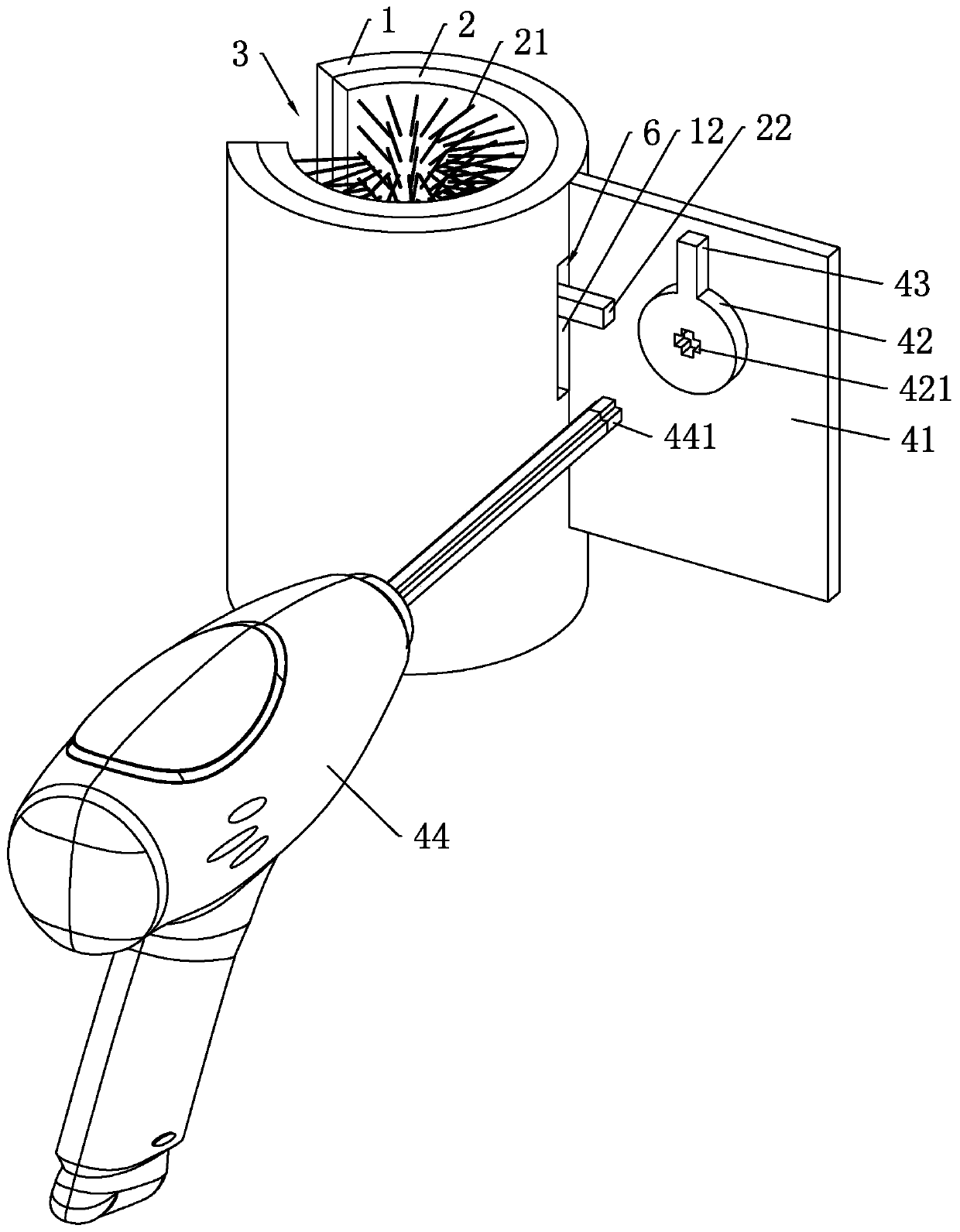

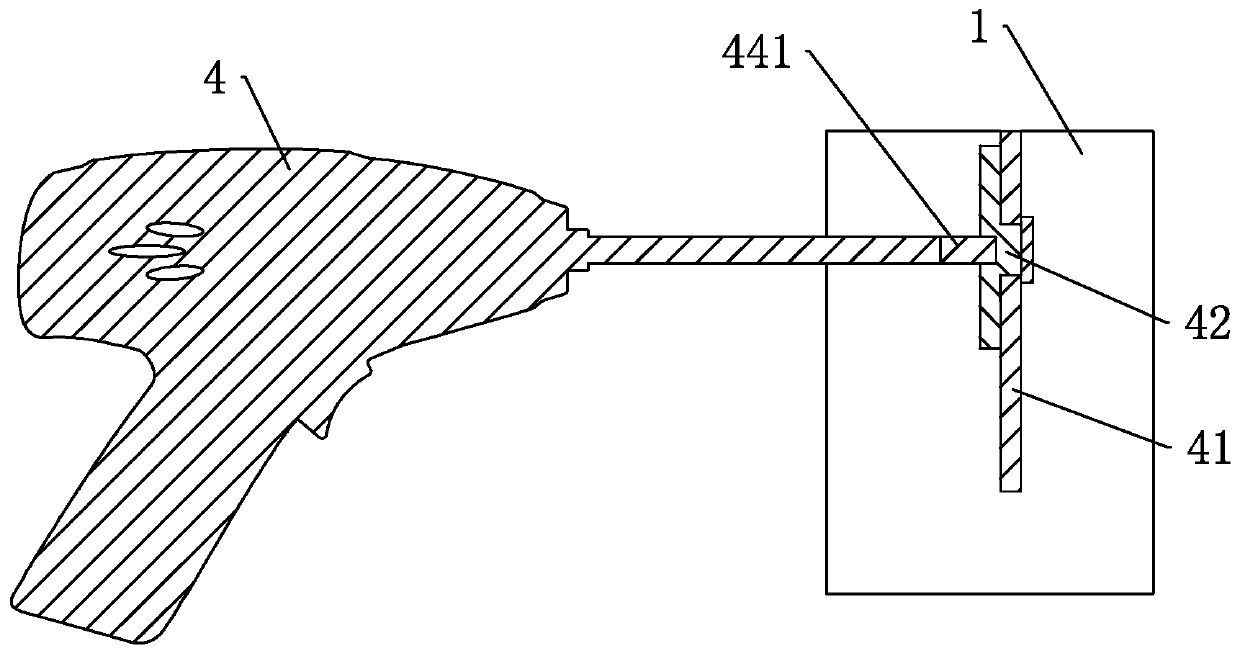

Screwdriver for screwing rusty screws

InactiveCN111958529AEasy to cleanControl doseSpannersWrenchesStructural engineeringIndustrial engineering

The invention provides a screwdriver for screwing rusty screws, belongs to the technical field of hardware, and solves the problems of large odor, long time and low efficiency when screwing rusty screws after spraying a rust remover. The screwdriver for screwing rusty screws comprises a shell with an open upper end, wherein a working space is defined in the shell, a power mechanism is installed inthe shell, discharging mechanisms are respectively provided at the left and right ends of the power mechanism, the two discharging mechanisms are symmetrically distributed left and right with respectto the center line of the power mechanism, and the end faces of the left and right sides of the shell are also distributed with limit mechanisms that control the start and stop of the discharging mechanisms. The screwdriver used for screwing rusty screws is more convenient, labor-saving and more efficient.

Owner:温州骐烨机械有限公司

Hardware surface efficient rust remover and preparation method thereof

The invention discloses a hardware surface efficient rust remover. The hardware surface efficient rust remover comprises the following raw materials of, by weight, 10-20 parts of acetic anhydride, 5-15 parts of hydrochloric acid, 3-9 parts of 1,3-butanediol, 3-9 parts of oleic acid, 1-4 parts of nanometer zirconium dioxide, 5-10 parts of nano cerium oxide powder, 1-2 parts of sodium dodecyl sulfate, 6-12 parts of Chinese honeylocust fruit powder, 4-12 parts of alkylphenol ethoxylate, 3-9 parts of matrine, 1-5 parts of sodium citrate, 80-100 parts of deionized water and 10-30 parts of ethanol. A preparation method of the hardware surface efficient rust remover comprises the following steps that (1) all the raw materials are weighed; (2) a solution A is prepared; (3) a solution B is prepared; and (4) mixing and standing are conducted. The hardware surface efficient rust remover is good in rust removal effect, short in rust removal time and capable of removing oil contamination and rust on the surface of metal, and the corrosion phenomenon does not occur to the metal. After rust removal, the surface of hardware is bright and is free of rust marks, smoke is not produced, usage is safe, the environment-friendly effect is achieved, and the hardware surface efficient rust remover is suitable for wide usage and popularization.

Owner:SHAOXING KOUFU FOOD

A kind of boron sulfate rust remover for electrolysis

The invention provides a boric sulphate rust remover for electrolysis. The rust remover comprises the following preparation steps that 1, nonyl phenol or nonyl phenol polyoxyethylene is thrown into areaction kettle, and heated to 100-150 DEG C, then boric acid is added slowly, and after adding is completed, the reaction is carried out for 100-140 minutes; 2, after the reaction is completed, the temperature is lowered to 60-100 DEG C, a booster is added, and the temperature is naturally lowered to normal; 3, S2O3 or SO3 is added slowly in vacuum, stirring is carried out while the S2O3 or the SO3 is added, after adding is completed, the temperature is raised to 50-90 DEG C, and the reaction is carried out for 100-180 minutes; and 4, after the reaction is completed, the temperature is lowered below 50 DEG C, the booster is added, the reaction is carried out for 100-180 minutes, then molybdate is added to obtain the rust remover. The rust remover has a rapid and thorough rust removing ability, the rust removing effect is better than that of a strong acid rust remover or a nitrogen and phosphorus rust remover, and the rust remover is environmentally friendly, and has no toxic and sideeffect on the human body.

Owner:苏州纳孚林科金属表面技术有限公司 +1

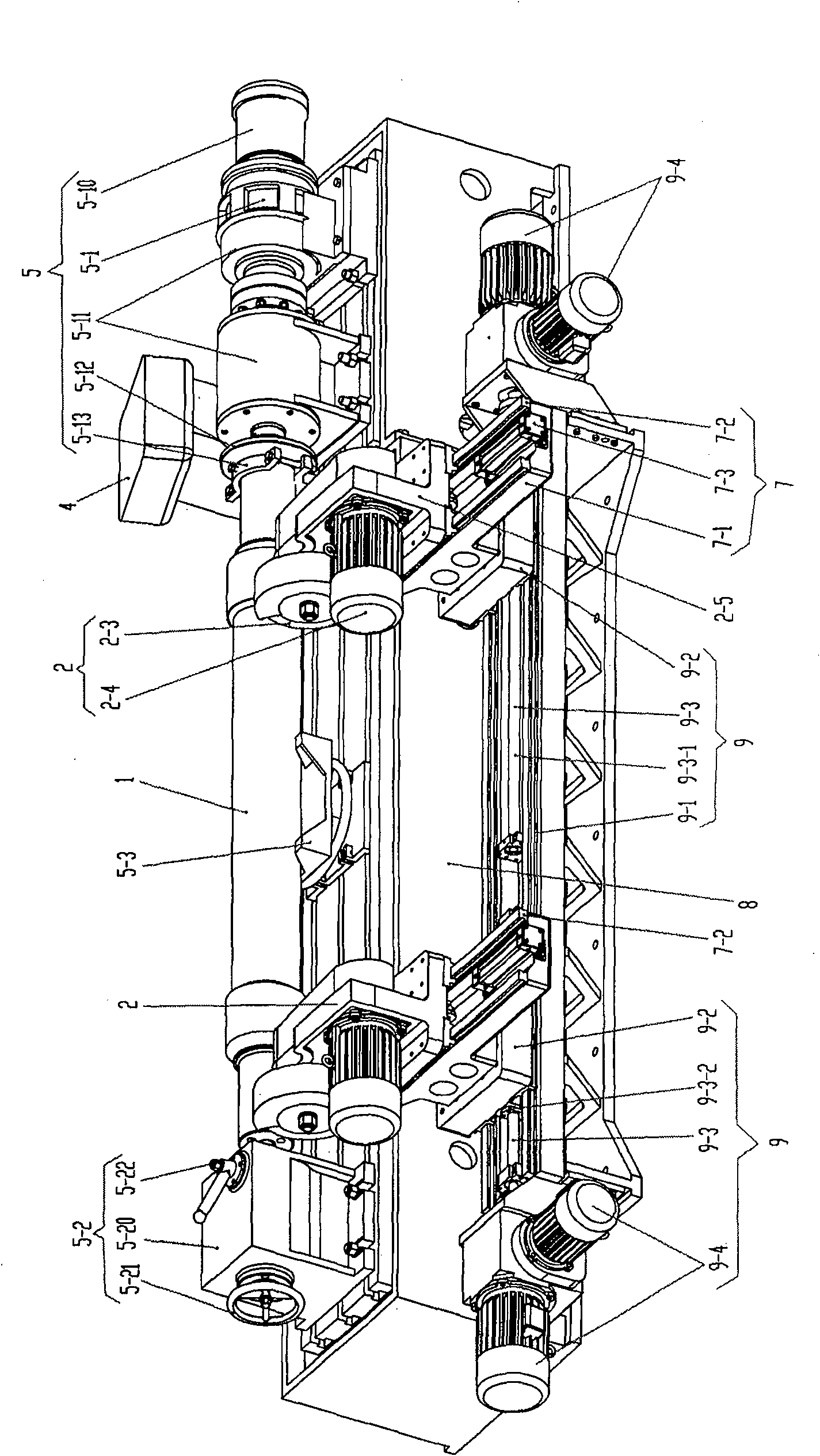

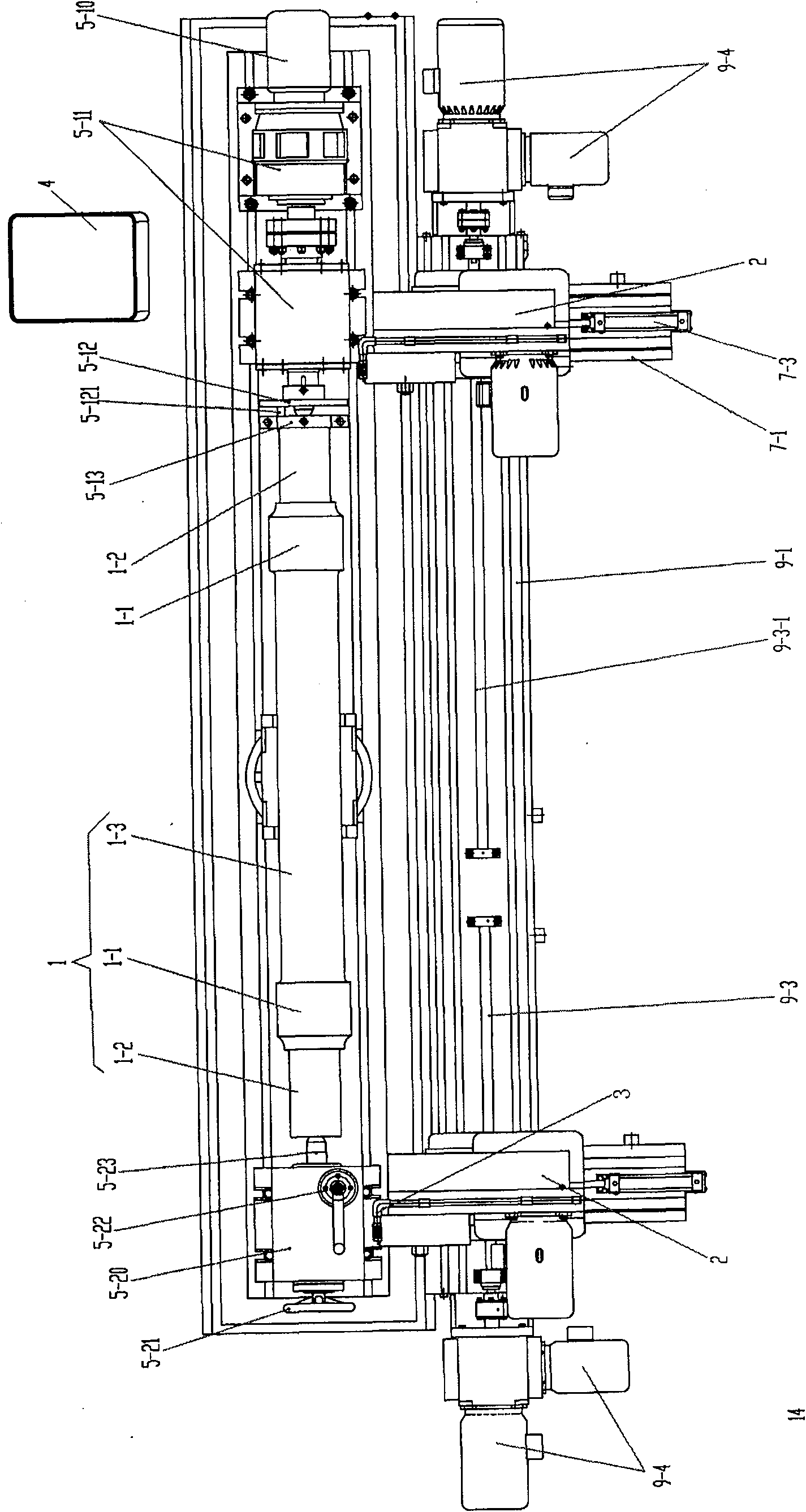

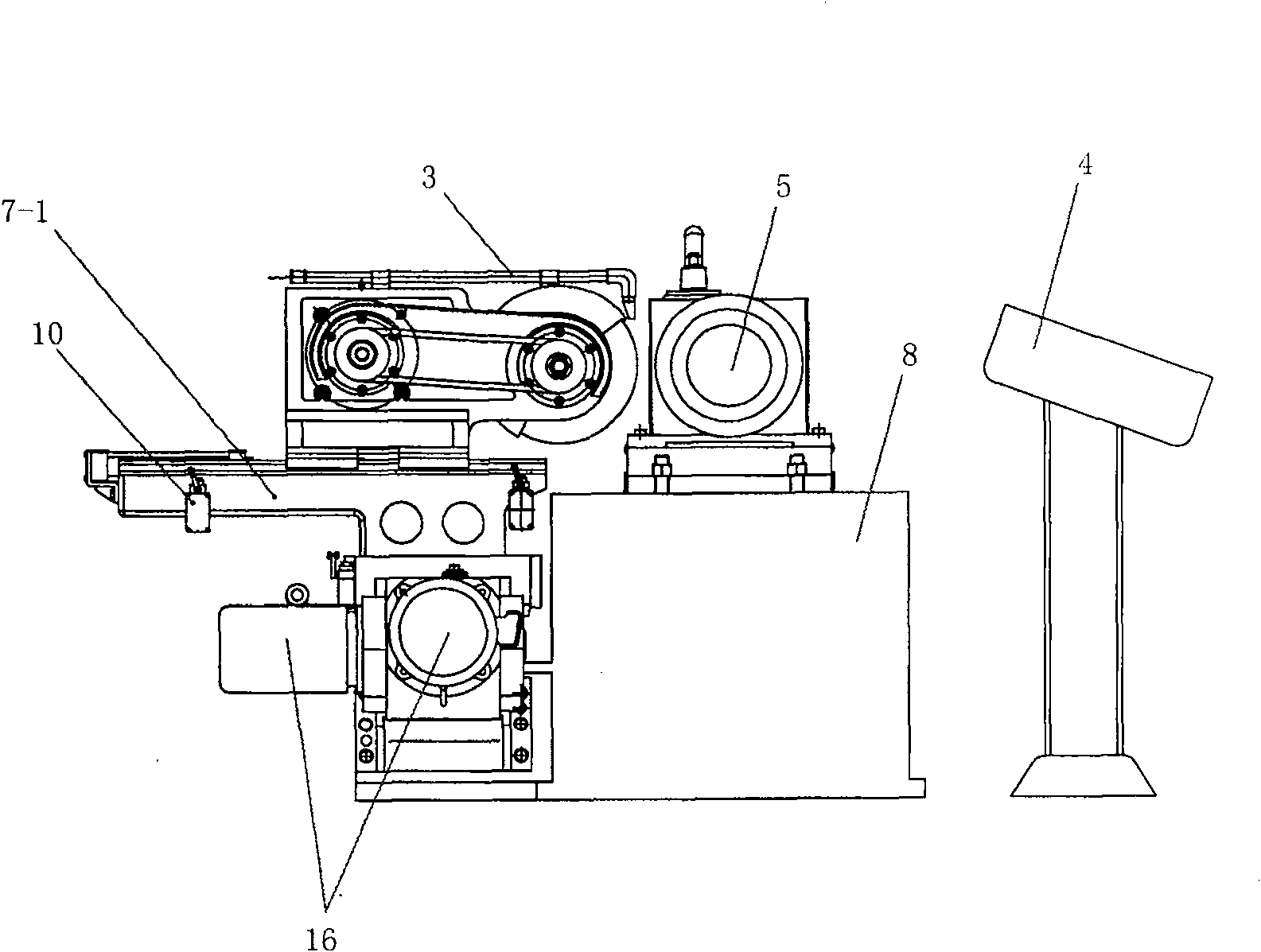

Rust remover of motorcycle axle

The invention relates to a locomotive axle derusting machine, aiming at solving the technical problem of the automatic derusting of the locomotive axle. The locomotive axle dedusting machine comprises a machine tool body, an axle transmission device which is used for driving the axle to rotate along the axle direction, a wheel throwing machine, a first displacement device and a second displacement device; the first displacement device is used for driving the wheel throwing machine to carry out the linear displacement in the direction which is vertical to the axial direction of the axle; the second displacement device is used for driving the first displacement device to carry out the linear displacement along the axial direction of the axle; the wheel throwing machine, the first displacement device and the second displacement device are controlled by an automatic control device. When in use, the axle is arranged on the machine tool; the axle transmission device is then started to drive the axle to rotate along the axle direction; under the action of the second displacement device, the wheel throwing machine reaches the derusting position required by the axle and leads the throwing wheel of the wheel throwing machine to contact with the position where the derusting is required and to carry out the derusting operation under the action of the first displacement device.

Owner:CRRC QISHUYAN CO LTD

Boric sulphate rust remover for electrolysis

The invention provides a boric sulphate rust remover for electrolysis. The rust remover comprises the following preparation steps that 1, nonyl phenol or nonyl phenol polyoxyethylene is thrown into areaction kettle, and heated to 100-150 DEG C, then boric acid is added slowly, and after adding is completed, the reaction is carried out for 100-140 minutes; 2, after the reaction is completed, the temperature is lowered to 60-100 DEG C, a booster is added, and the temperature is naturally lowered to normal; 3, S2O3 or SO3 is added slowly in vacuum, stirring is carried out while the S2O3 or the SO3 is added, after adding is completed, the temperature is raised to 50-90 DEG C, and the reaction is carried out for 100-180 minutes; and 4, after the reaction is completed, the temperature is lowered below 50 DEG C, the booster is added, the reaction is carried out for 100-180 minutes, then molybdate is added to obtain the rust remover. The rust remover has a rapid and thorough rust removing ability, the rust removing effect is better than that of a strong acid rust remover or a nitrogen and phosphorus rust remover, and the rust remover is environmentally friendly, and has no toxic and sideeffect on the human body.

Owner:苏州纳孚林科金属表面技术有限公司 +1

A liquid plasma ion rust removal solution and rust removal process for steel

The invention relates to a liquid phase plasma derusting solution of steel and a derusting process. The derusting solution comprises the following components: 1-4wt% of ammonium chloride, 0.5-3wt% of potassium sulfate, and the balance water. The derusting process consists of: a. conducting oil removing treatment on steel to be derusted; b. heating the liquid phase plasma derusting solution, immersing the deoiled steel in the liquid phase plasma derusting solution, introducing a rectifier positive electrode, and connecting a rectifier negative electrode with a negative plate in parallel to conduct derusting; c. taking the steel out after derusting, immersing the steel in deionized water, and then carrying out flushing with deionized water; and d. drying the flushed steel, thus obtaining a derusted steel end product. The liquid phase plasma derusting solution provided in the invention has no damage on operation staff and has no pollution on the environment. The derusting process has the advantages of short derusting time, high efficiency, and improvement of steel surface smoothness, etc.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

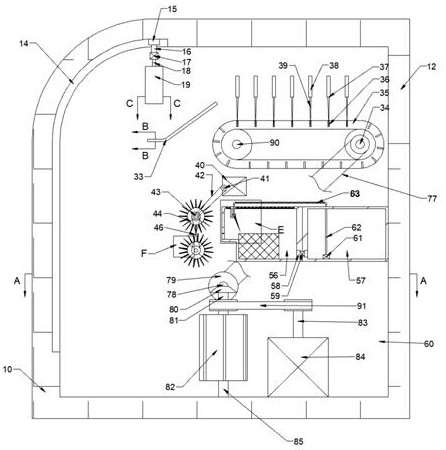

Rusty scraper knife recycling and machining equipment

InactiveCN111701915AFully automatedImprove rust removal efficiencyDrying gas arrangementsCleaning using toolsHigh pressure waterKnife blades

The invention discloses rusty scraper knife recycling and machining equipment, which comprises a working box. A working cavity is fixedly formed in the working box, a feeding shaft and a transmissionshaft are rotationally arranged on the rear wall of the working cavity, a feeding belt pulley is arranged between the feeding shaft and the transmission shaft in a transmission connection mode, 22 clamping grooves are fixedly formed in the feeding belt pulley in an arrayed mode, scraper knives are inserted into the clamping grooves, and the scraper knives comprise first handles and second handles.The scraper knives are inserted into input grooves of the input belt pulley, a handle sleeve in the equipment automatically locks a handle, the scraper knives are driven to move into a derusting cavity, rust on the surfaces of blades of the scraper knives is cleared by a high-pressure water gun, and wastewater generated after derusting is filtered and then recycled into a water tank; and the scraper knives are dried by a brush capable of blowing air and then inserted into an output belt pulley, a worker takes the scraper knives down from the equipment, automatic derusting of the scraper knives is realized, the derusting time is greatly saved, and the derusting efficiency and quality of the scraper knives are improved by automatic derusting.

Owner:台州椒江行陈环保科技有限公司

Water-based rust-removal and rust-prevention solution and preparation method thereof

InactiveCN108018569AWide temperature rangeNot corrosiveMetallic material coating processesWater basedMesoporous silica

The invention provides a water-based rust-removal and rust-prevention solution. The water-based rust-removal and rust-prevention solution comprises the following raw materials in parts by weight: 2-6parts of citric acid, 2-8 parts of lauryl sodium sulfate, 2-4 parts of tartaric acid, 1-2 parts of ethylene diamine tetraacetic acid, 2-6 parts of polyaspartic acid, 0.4-1.2 parts of oxidized starch,5-10 parts of cetyl-trimethyl ammonium bromide, 10-15 parts of ethoxylated lauryl alcohol sulfate, 1-2 parts of OP-10, 1-3 parts of carboxymethyl cellulose, 2-8 parts of mesoporous silica, 10-20 partsof ethylene glycol, 15-20 parts of propanediol butyl ether and 60-90 parts of water. The invention further provides a preparation method for the water-based rust-removal and rust-prevention solution.The water-based rust-removal and rust-prevention solution provided by the invention has various functions such as rust removal, decontamination, phosphorization and passivation, and is short in rustremoval time, is long in rust-prevention time and is free of corrosion on metal during reaction at the normal temperature.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

A kind of environment-friendly anti-corrosion metal degreasing and derusting agent and preparation process thereof

The invention provides an environment-friendly corrosion-prevention metal oil-rust removing agent and a preparation process thereof. The oil-rust removing agent is prepared from the following components in parts by weight: acetic anhydride, itaconic acid, 1,3-butylene glycol, oleic acid, nano-zirconia, 8-hydroxyquinoline, boric acid, caprolactam, nano-cerium oxide powder, disodium ethylene diamine tetraacetate, saponin powder, heterogeneous alcohol polyoxyethylene ether, matrine, methylisothiazolinone, thiourea, 3-amino-4-octanol, sodium citrate, deionized water and ethanol. The oil-rust removing agent provided by the invention has an integral oil-rust removing effect, the rust removing time is only 5-10 minutes, the surface of metal is bright and has no obvious rust trace after the rust removing treatment, obvious rust spot or rust trace is not generated after the metal which is subjected to oil-rust removal is placed at the room temperature for 1 month, and the metal is good in corrosion resistance, does not secondarily rust within 2 months and does not generate smoke, so that the oil-rust removing agent is safe to use, environmentally friendly and suitable for being popularized and used.

Owner:广东辉炜佳科技有限公司

A kind of polishing type boron sulfate ester derusting liquid

The application provides a polishing boron sulfate rust remover. The rust remover is prepared by mixing boron sulfate rust removers, alumina particles and / or zinc oxide particles and water, wherein the mass of the alumina particles accounts for 0.5%-1% of the total mass, and the mass of the water accounts for 1%-20% of the total mass. The efficient rust remover has a quick and simple rust removalfunction for severe rust, as well as inactivation and anti-oxidation functions; and not only can the rust removal effect is superior to the rust removal effect of strong acid or nitrogen and phosphorus rust removers, and the polishing boron sulfate rust remover is green and environmentally friendly, and has no toxic and side effects on human bodies.

Owner:镇江纳润特高新科技发展有限公司 +1

Neutral oil and rust remover as well as preparation method and application thereof

The invention provides a neutral oil and rust removal agent and a preparation method and application thereof, and relates to the technical field of oil and rust removal. The neutral oil and rust removing agent is prepared from fatty alcohol-polyoxyethylene ether, HEDP-4Na, citric acid, EDPA-2Na, sodium tripolyphosphate, potassium chloride, thiourea, formic acid and water. The neutral oil and rust remover disclosed by the invention has the characteristics of no corrosion to a metal body, high rust removal rate, short rust removal time and long rust prevention period in a rust removal process. The neutral oil and rust removing agent further has the advantages of being simple in preparation process and low in cost, and has good large-scale industrial production and use prospects.

Owner:河北濡春新能源集团有限公司

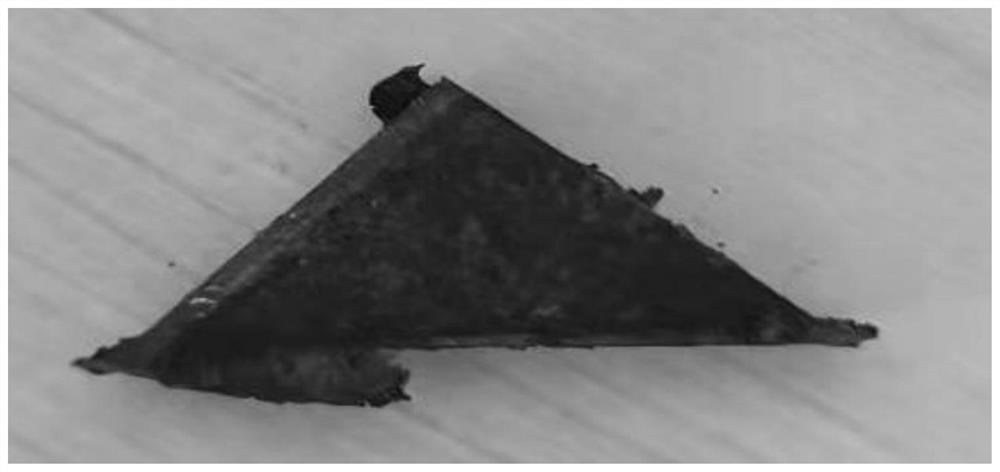

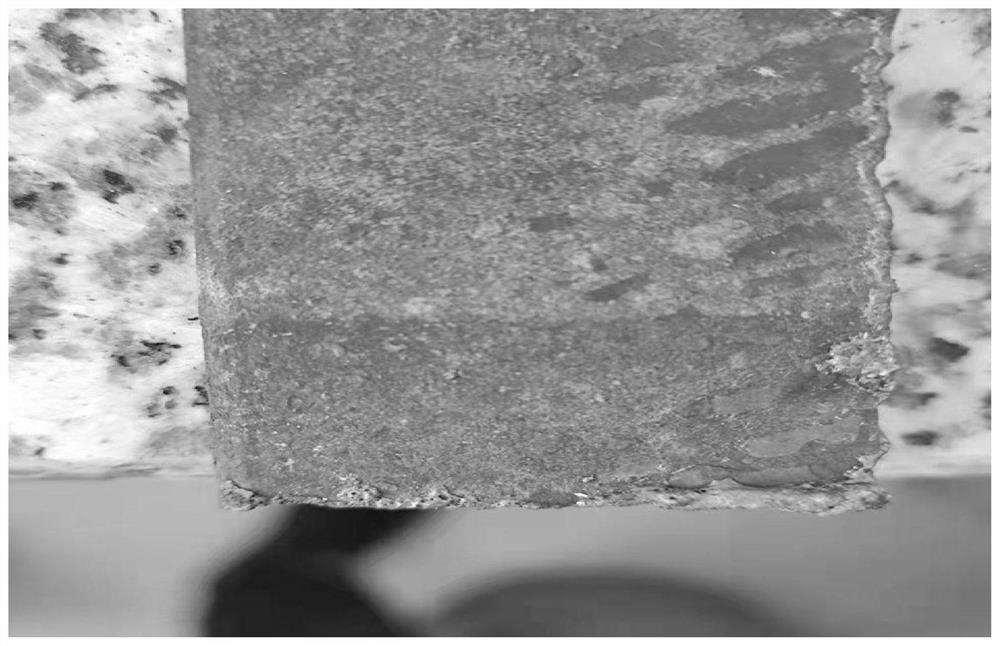

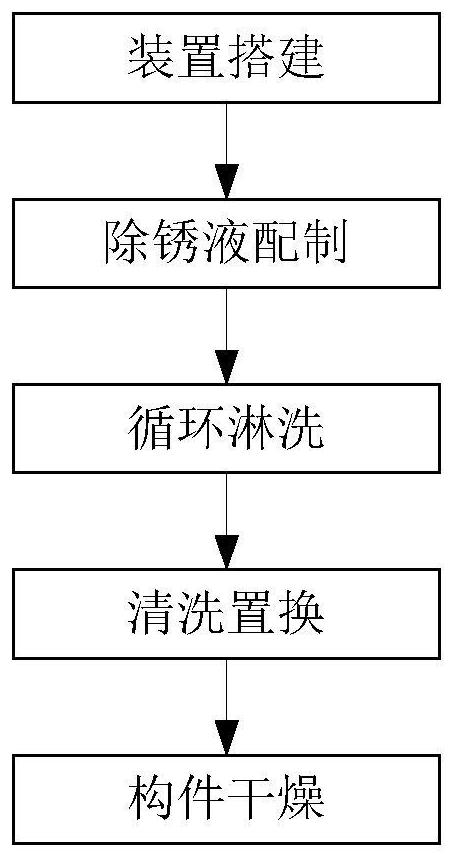

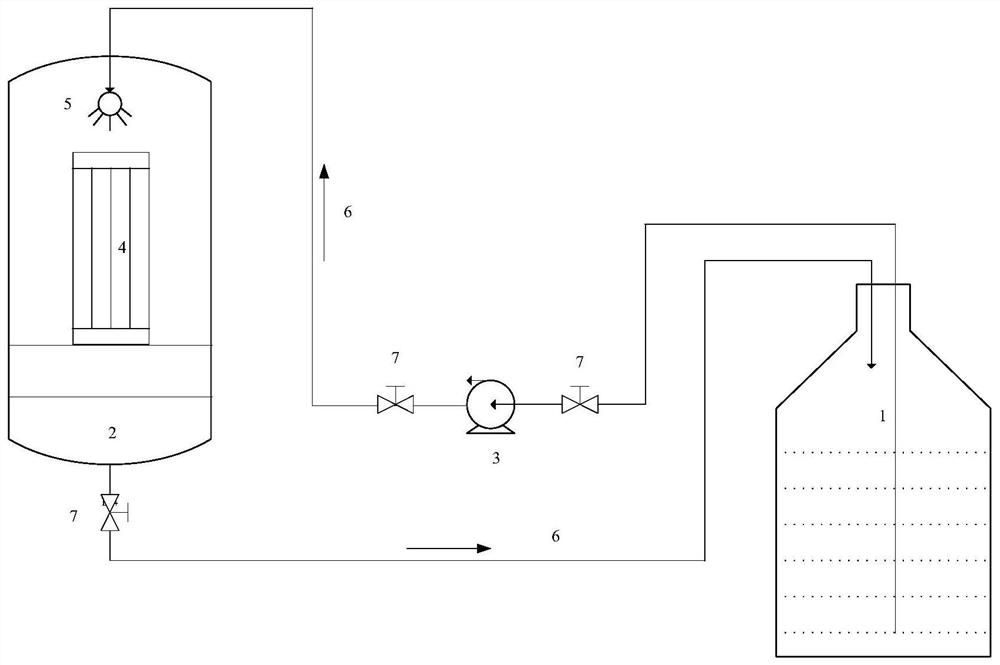

Method for removing rust stains on porous quartz ceramic wave-transmitting material

The invention relates to a method for removing rust stains on a porous quartz ceramic wave-transmitting material. According to the method, a solution containing hydrochloric acid and oxalic acid serves as a rust remover, a rust removal device serves as a hardware support, and rust stains are removed through the technological processes of leaching dissolution, replacement and drying. The combination of hydrochloric acid and oxalic acid is adopted as a rust removal component, the strong acidity of hydrochloric acid, the strong reducibility of oxalic acid and the complexing property on iron ions are utilized respectively, the rust removal rate can be greatly increased, the rust removal time is shortened, and the rust removal rate is increased; the components of the derusting liquid are easy to decompose and volatilize after being heated, and no redundant material residue is generated after the derusting treatment of the ceramic part; the rust removal device is simple in structure, easy and convenient to operate, stable in process, high in pollutant removal efficiency and high in construction economy; the method is suitable for acid-resistant porous ceramic materials of different fiber types and fabric structures, and the process adaptability is high.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Rust remover and preparation method and application thereof

PendingCN114574867AImprove securityShort rust removal timeMetallic material coating processesOrganic acidO-Phosphoric Acid

The invention discloses a rust remover and a preparation method and application thereof. The rust remover comprises the following components in parts by weight: 100-300 parts of organic acid and / or organic acid salt, 5-20 parts of phosphoric acid, 3-10 parts of chelating agent, 0.5-2 parts of acid making agent, 1-3 parts of molybdate, 2-5 parts of interfacial agent, 80-200 parts of cosolvent and the balance of water. The rust remover is free of strong acid and fluoride salt, the safety of the rust remover is enhanced, low-toxicity, environment-friendly and efficient perfluoroalkyl acetate is introduced for the first time, and the perfluoroalkyl acetate has ultrahigh surface activity and certain lubricity, so that the prepared rust remover is short in rust removal time and obvious in rust removal effect, and the rust remover is suitable for industrial production. And meanwhile, a good anti-rust effect is achieved.

Owner:苏州工业园区科瑞达新材料技术有限公司

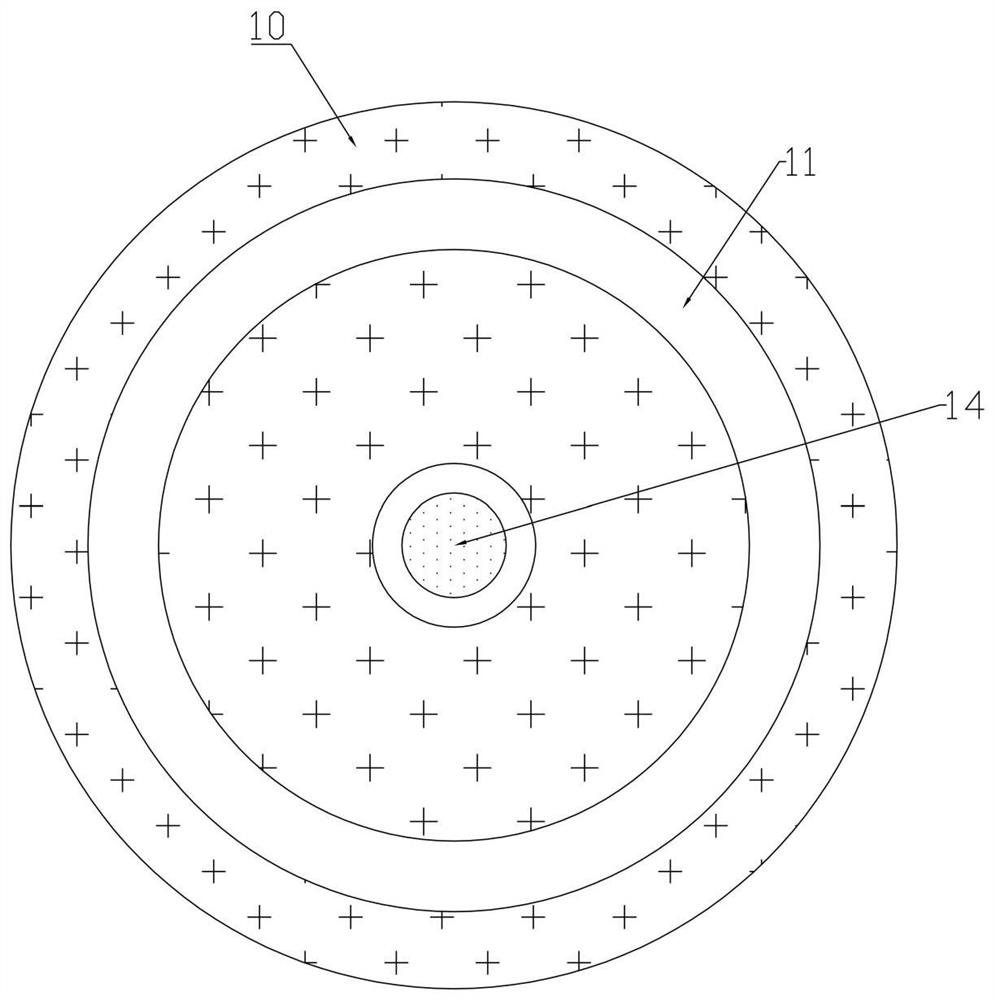

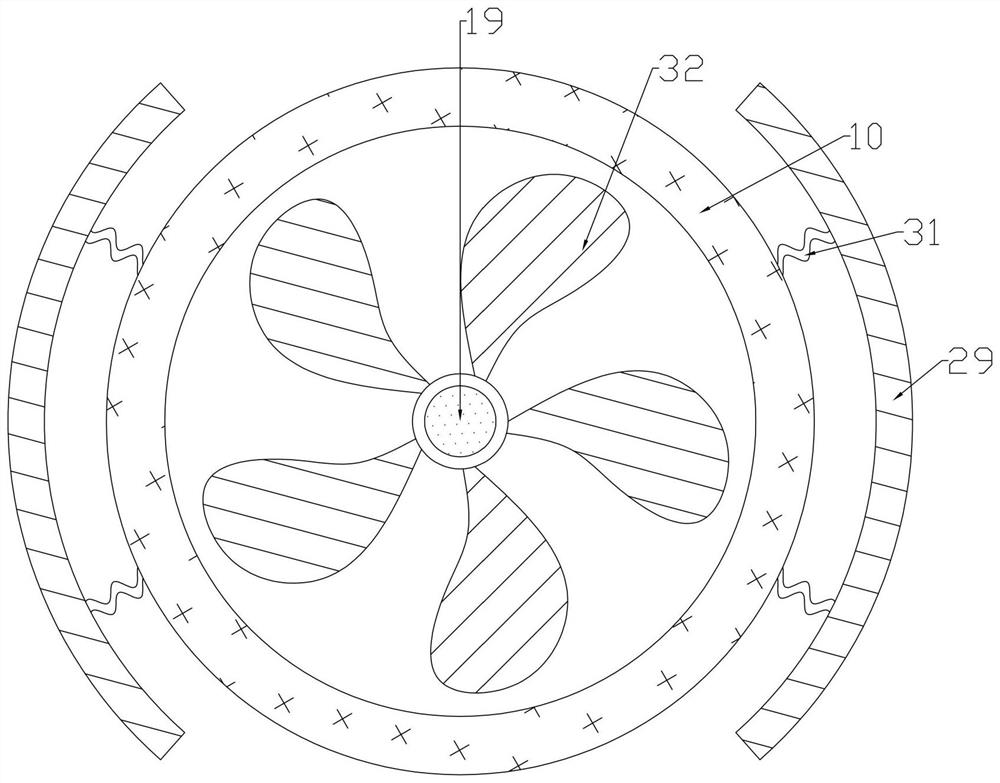

Novel steel bar rust removal device

PendingCN110900409AReduce physical exertionFast rust removalPortable grinding machinesGrinding/polishing safety devicesPilot holeMining engineering

The invention relates to a novel steel bar rust removal device. The device is characterized by comprising a first protective cylinder and a second protective cylinder arranged in the first protectivecylinder in a sleeved mode, wherein steel wire brushes are uniformly distributed on an inner wall of the second protective cylinder, notches are vertically and downwards formed on the same sides of the first protective cylinder and the second protective cylinder, a cylinder bottom is formed at a bottom end of the first protective cylinder, a plurality of return springs are vertically arranged in the circumferential direction of the cylinder bottom, a top end of the reset spring is fixedly connected with a bottom end of a cylinder wall of the second protective cylinder, a guide hole is vertically formed in the middle section of the cylinder wall, deviating from the notch side, of the first protective cylinder, a guide block extending out of the guide hole is horizontally and fixedly connected with the cylinder wall, deviating from the notch side, of the second protective cylinder, and a driving device for repeatedly shifting the guide block to enable the guide block to vertically reciprocate in the guide hole is arranged outside the cylinder wall, close to one side of the guide block, of the first protective cylinder. The device is advantaged in that on the premise that the construction progress is guaranteed, rust on surfaces of steel bars can be evenly removed, the rust removing effect is good, efficiency is high, and the labor burden of workers is relieved.

Owner:一山(北京)岩土工程有限公司

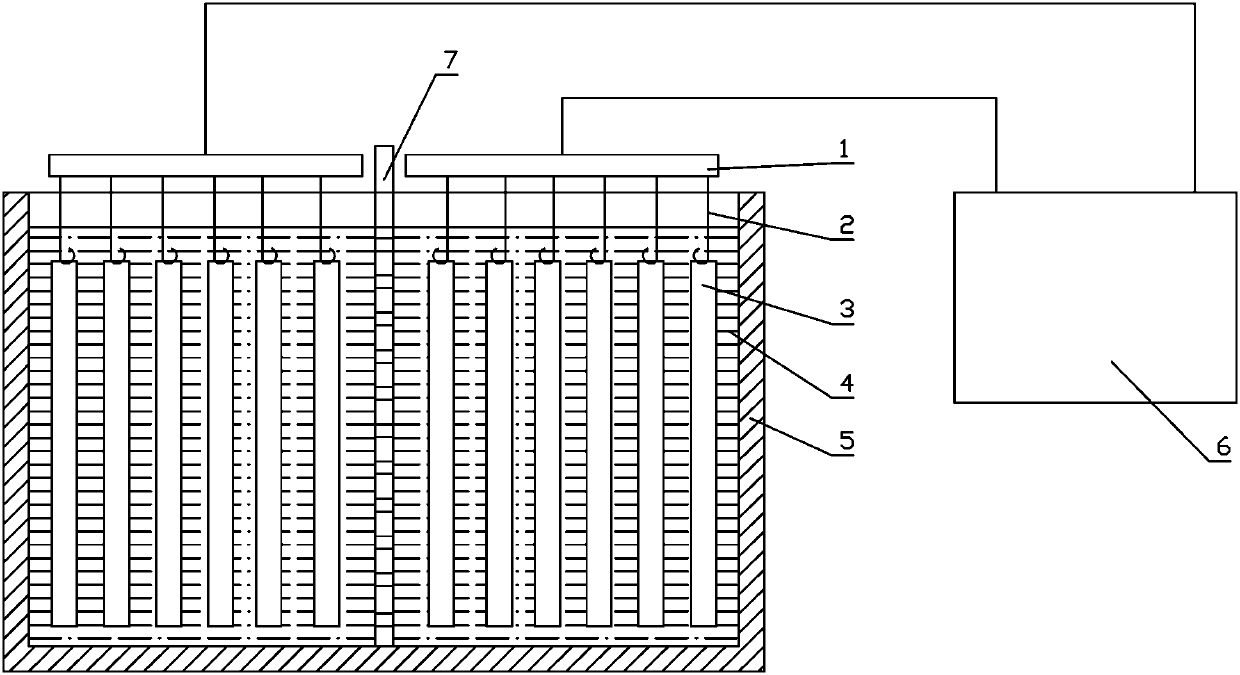

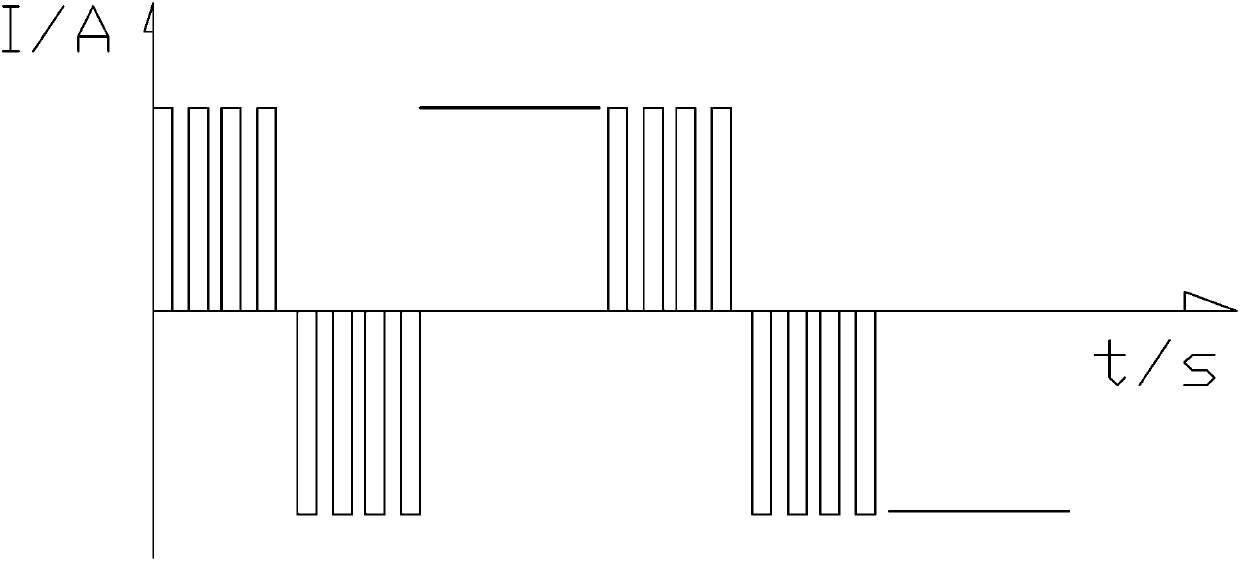

A high-frequency pulse low-temperature rapid rust removal device and method

InactiveCN103343381BSimple structureReduce processing costsElectrolysis componentsElectricityEngineering

The invention discloses a high-frequency impulse and low-temperature quick derusting device comprising a derusting tank body for accommodating a derusting liquid and a workpiece. The device is further provided with an electrode plate communicated with the workpiece. The electrode plate is electrically connected with a power source. A quick derusting method using the device comprises the following steps of: 1, putting the derusting liquid into the derusting tank body, wherein the derusting liquid is prepared from 3-13wt% of 36wt% HCl, 2-7% of 98wt% H2SO4, 3-6wt% of Na3PO4 and the balance of water; 2, after the workpiece is connected with the electrode plate, immerging the workpiece into the derusting liquid in the derusting tank body; 3, turning on the power source, wherein the output current is 30-400A, the frequency is 0-30kHz and the derusting time is 3-5 minutes. The quick derusting of the workpiece is realized by the steps. The device disclosed by the invention has advantages of simple structure, low processing cost, short derusting time and high working efficiency. The device disclosed by the invention can be used for greatly reducing the preparation concentration of acid and eliminating the influence of hydrogen embrittlement on the surface of a steel piece.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

Metal derusting and antirusting agent and preparation method thereof

ActiveCN103046036BSimple production processShort processing timeMetallic material coating processesAluminium hydroxideStrong acids

The invention provides a metal derusting and antirusting agent as well as a preparation method and an application of the metal derusting and antirusting agent. The metal derusting and antirusting agent comprises phosphoric acid, zinc oxide, aluminium hydroxide, sodium tripolyphosphate, organic acid, a surfactant, a thickener and deionized water. The metal derusting and antirusting agent can be used for finishing derusting, passivating and phosphating for a metal surface via one-step treatment, is free from any strong acid and strong base, non-toxic, smokeless and non-smell-volatile, and is free from environment pollution; and the treated metal surface can be antirust for more than half a year and has a strong binding force with a paint layer. The metal derusting and antirusting agent is a derusting and antirusting product which is safe and reliable, less in pollution, simple in process and low in cost.

Owner:ANHUI WEILAI SURFACE TECH

A kind of water-based derusting antirust liquid and preparation method thereof

InactiveCN103882450BNot corrosiveNo pollution in the processMetallic material coating processesWater basedPhosphoric acid

The invention relates to a water-based rust-proof derusting liquid, which is prepared from following raw materials in parts by weight: 1-2 parts of octyl phenol polyoxyethylene ether, 2-3 parts of oleic acid polyoxyethylene ester, 20-23 parts of ethyl alcohol, 1-2 parts of citric acid, 2-3 parts of zinc phosphate, 1.3-2.4 parts of sodium lauryl sulfate, 1.2-2.3 parts of 2,6-di-tert-butyl-alpha-dimethylamino phenol, 1-2 parts of isopropanol, 10-12 parts of ethoxylated trimethylolpropane triacrylate, 1-2 parts of EDTA disodium, 4-5 parts of additive, and 300 parts of water. The rust-proof derusting liquid has multiple functions like rust removal, decontamination, phosphorization, passivation, surface conditioning and the like, can form a thin film on the surface of a metal due to the combined action of an organic high-molecular polymer monomer and a chelating agent, so as to play roles in isolating air and preventing oxidization; the preparation method for the rust-proof derusting liquid is simple; the rust-proof derusting liquid is easy to clear, has low cost, reacts at room temperature, can remove the rust in short time, has long rust protection time, does not corrode the metal, contains no toxic or harmful substances, and does not pollute the environment.

Owner:珠海市志邦化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com