A high-frequency pulse low-temperature rapid rust removal device and method

A high-frequency pulse and fast technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of low efficiency, long pickling time, difficult harmless treatment, etc. The effect of product technical content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

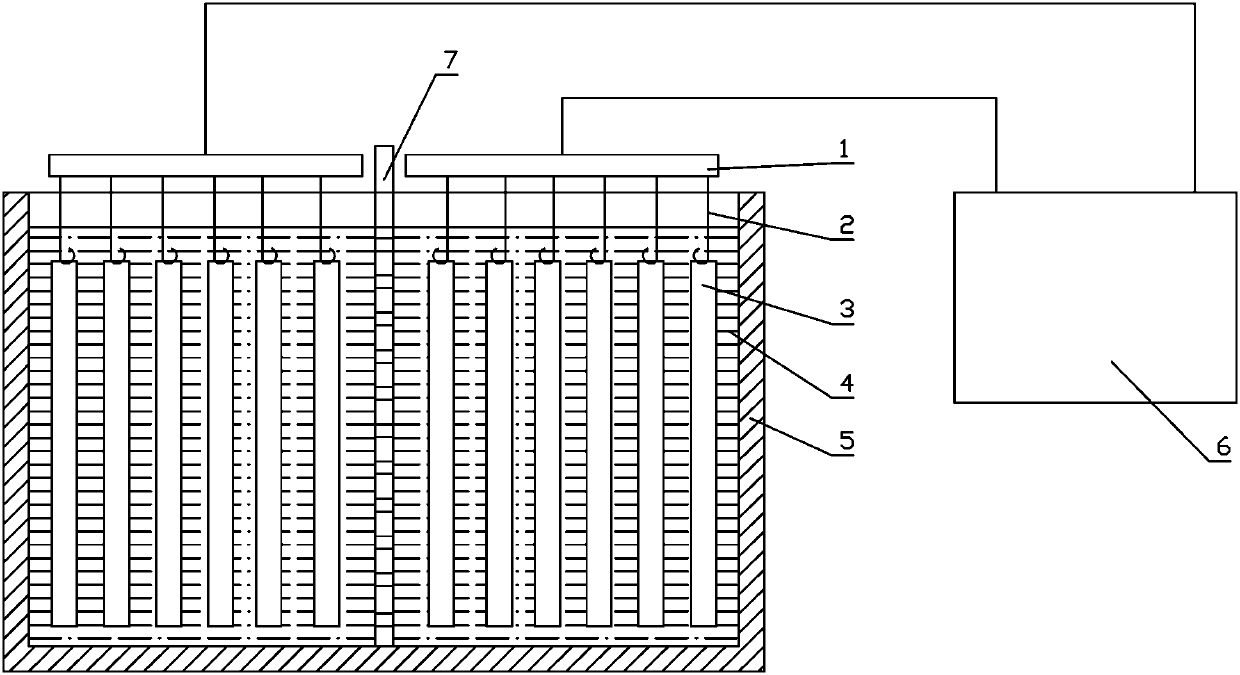

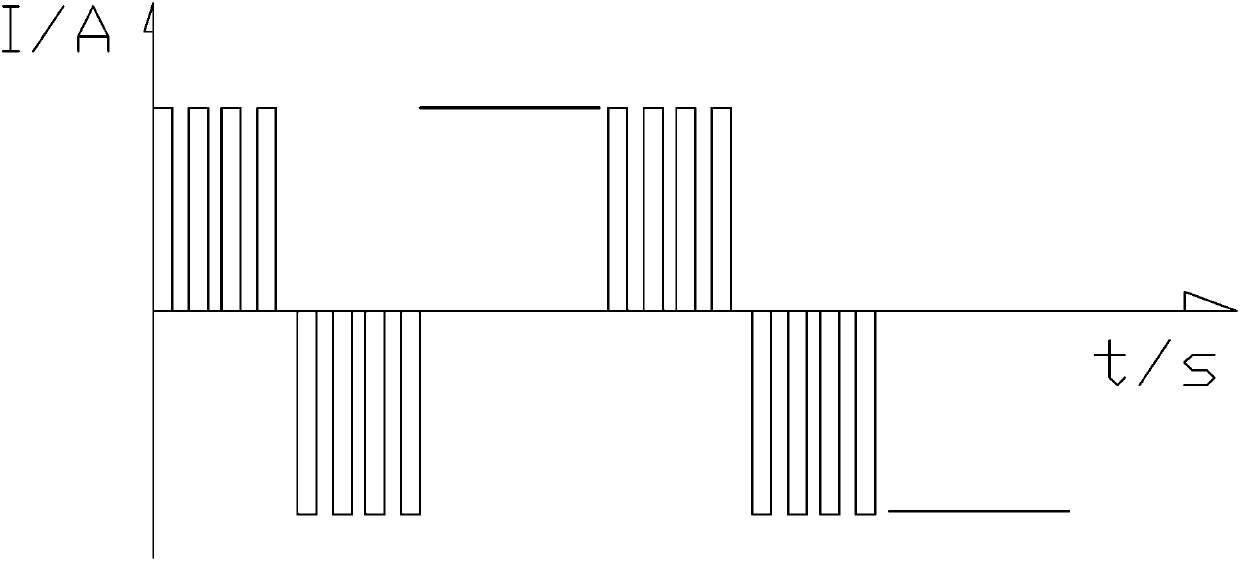

Embodiment 1

[0045] 36%wtHCl, 3% 98%wtH of mass fraction 9% are prepared in the derusting tank body 5 in the above-mentioned device 2 SO 4 , 5% Na 3 PO 4 , the balance is the derusting solution of water. Each electrode plate 1 is hung with 15 pieces of 50# angle steel made of Q235, the power supply 6 is turned on, the current value is 50A, the frequency is 8kHz, and the rust removal time is 5min.

Embodiment 2

[0047] Prepare 36%wtHCl, 5% 98%wtH of mass fraction 13% in the derusting tank body 5 in the above-mentioned device 2 SO 4 , 6% Na 3 PO 4 , the balance is the derusting solution of water. Each electrode plate 1 is hung with 15 pieces of 50# angle steel made of Q235, the power supply 6 is turned on, the current value is 50A, the frequency is 25kHz, and the rust removal time is 4.8min.

Embodiment 3

[0049] Prepare 36%wtHCl, 5% 98%wtH of mass fraction 13% in the derusting tank body 5 in the above-mentioned device 2 SO 4 , 6% Na 3 PO 4 , the balance is the derusting solution of water. Each electrode plate 1 is hung with 15 pieces of 50# angle steel made of Q235, the power supply 6 is turned on, the current range is 200A, the frequency is 30kHz, and the rust removal time is 3.2min. Increasing the current and frequency can effectively reduce the rust removal time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com