Steel rust removal fluid and preparation method thereof

A rust removal liquid and steel technology, which is applied in the field of metal surface treatment, can solve problems such as difficult chemical methods, achieve the effect of short rust removal time and improve use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

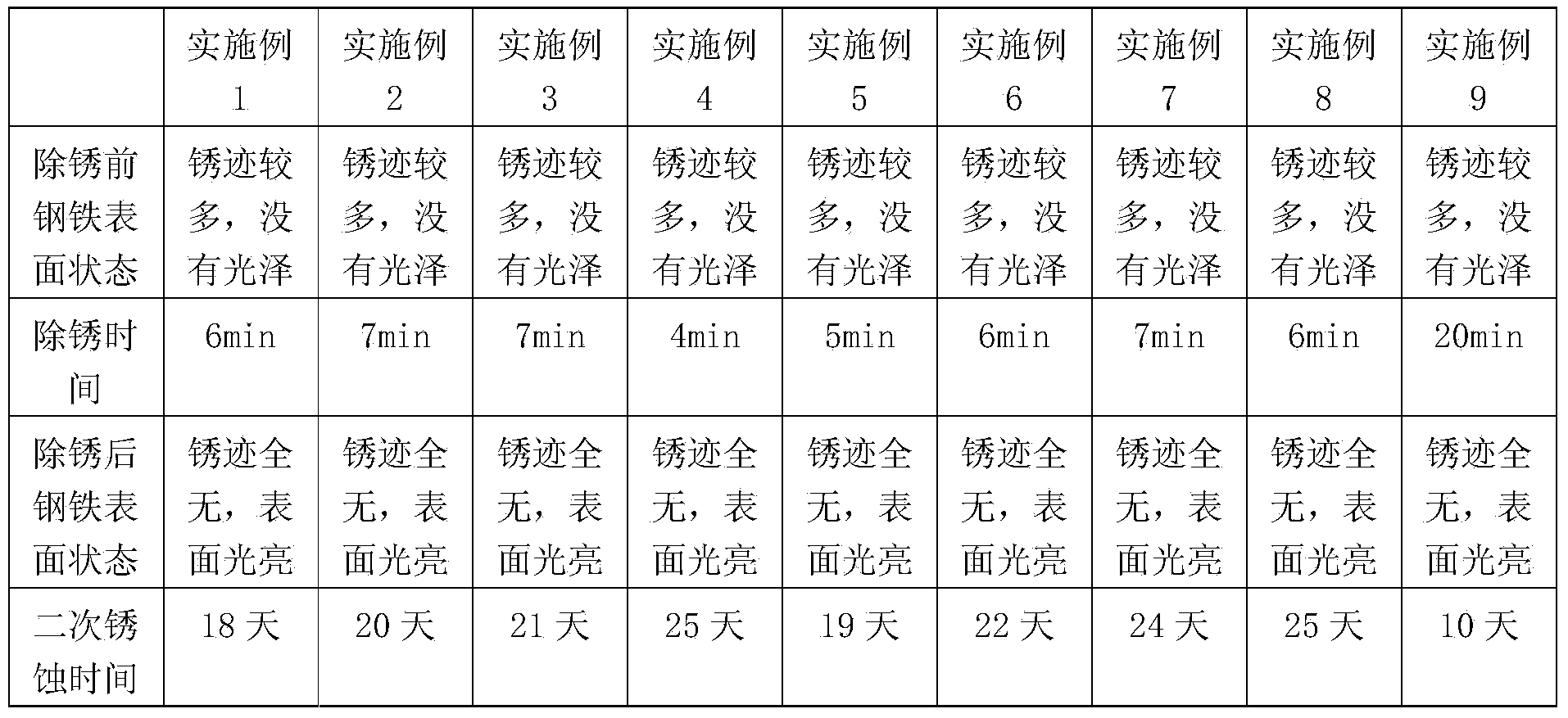

Examples

Embodiment 1

[0012] A kind of iron and steel descaling liquid, comprising by weight: 0.8 parts of oxalic acid, 1 part of tartaric acid, 0.3 parts of sodium lauryl sulfate, 2 parts of phosphoric acid solution, 30 parts of hydrochloric acid solution, 0.2 part of fatty alcohol polyoxyethylene ether, six 0.1 part of methylenetetramine, 1 part of triethanolamine, 0.2 part of alkylphenol polyoxyethylene ether, 0.3 part of polyvinyl alcohol, 0.5 part of paraffin, 0.1 part of ammonium chloride, 0.2 part of Tween-800, 0.5 part of urotropine parts, 30 parts of water.

[0013] The mass concentration of phosphoric acid in the phosphoric acid solution is 85%.

[0014] The mass concentration of hydrochloric acid in the hydrochloric acid solution is 33%.

[0015] First weigh the components by weight, then add the phosphoric acid solution and the hydrochloric acid solution into the water, then add the remaining components, and stir while adding, until the components are completely dissolved.

[0016] Wh...

Embodiment 2

[0018] A kind of iron and steel descaling liquid, comprises by weight: 1.3 parts of oxalic acid, 2 parts of tartaric acid, 0.5 part of sodium lauryl sulfate, 3 parts of phosphoric acid solution, 34 parts of hydrochloric acid solution, 0.3 part of fatty alcohol polyoxyethylene ether, six 0.2 parts of methylenetetramine, 2 parts of triethanolamine, 0.3 parts of alkylphenol polyoxyethylene ether, 0.5 parts of polyvinyl alcohol, 0.9 parts of paraffin, 0.7 parts of ammonium chloride, 0.8 parts of Tween-800, 0.7 parts of urotropine part, 40 parts of water.

[0019] The mass concentration of phosphoric acid in the phosphoric acid solution is 85%.

[0020] The mass concentration of hydrochloric acid in the hydrochloric acid solution is 33%.

[0021] First weigh the components by weight, then add the phosphoric acid solution and the hydrochloric acid solution into the water, then add the remaining components, and stir while adding, until the components are completely dissolved.

[00...

Embodiment 3

[0024] A kind of iron and steel descaling liquid, comprises by weight: 1.5 parts of oxalic acid, 4 parts of tartaric acid, 0.9 part of sodium lauryl sulfate, 7 parts of phosphoric acid solution, 38 parts of hydrochloric acid solution, 0.5 part of fatty alcohol polyoxyethylene ether, six 0.6 parts of methylenetetramine, 3 parts of triethanolamine, 0.6 parts of alkylphenol polyoxyethylene ether, 0.5 parts of polyvinyl alcohol, 1.5 parts of paraffin, 0.9 parts of ammonium chloride, 1.8 parts of Tween-80, 1.1 parts of urotropine parts, 35 parts of water.

[0025] The mass concentration of phosphoric acid in the phosphoric acid solution is 85%.

[0026] The mass concentration of hydrochloric acid in the hydrochloric acid solution is 33%.

[0027] First weigh the components by weight, then add the phosphoric acid solution and the hydrochloric acid solution into the water, then add the remaining components, and stir while adding, until the components are completely dissolved.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com