Rust remover and preparation method and application thereof

A technology of rust remover and antacid, which is applied in the coating process of metal materials, etc., can solve the problems of resource and energy waste, economic loss, etc., and achieve mild conditions of rust remover, enhanced safety, and fast rust removal time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned rust remover, which comprises: mixing organic acid and / or organic acid salt, phosphoric acid, antacid, molybdate and water, and mixing them at room temperature or appropriate After heating, the mixture is stirred for 0.5 to 4 hours, and then a chelating agent, a cosolvent, and a surfactant are added in sequence to mix and stir to obtain a rust remover.

[0037] In some more specific embodiments, the preparation method of the rust remover comprises: first, adding organic acid and its salt, antacid, molybdate and phosphoric acid to pure water at room temperature, stirring for 0.5-2 h, After fully dissolving, add chelating agent, stir for 0.5-1h, add cosolvent, stir for 0.5-1h, finally add surfactant, stir rapidly for 1-2h to obtain rust remover.

[0038] Another aspect of the embodiments of the present invention also provides the use of the aforementioned rus...

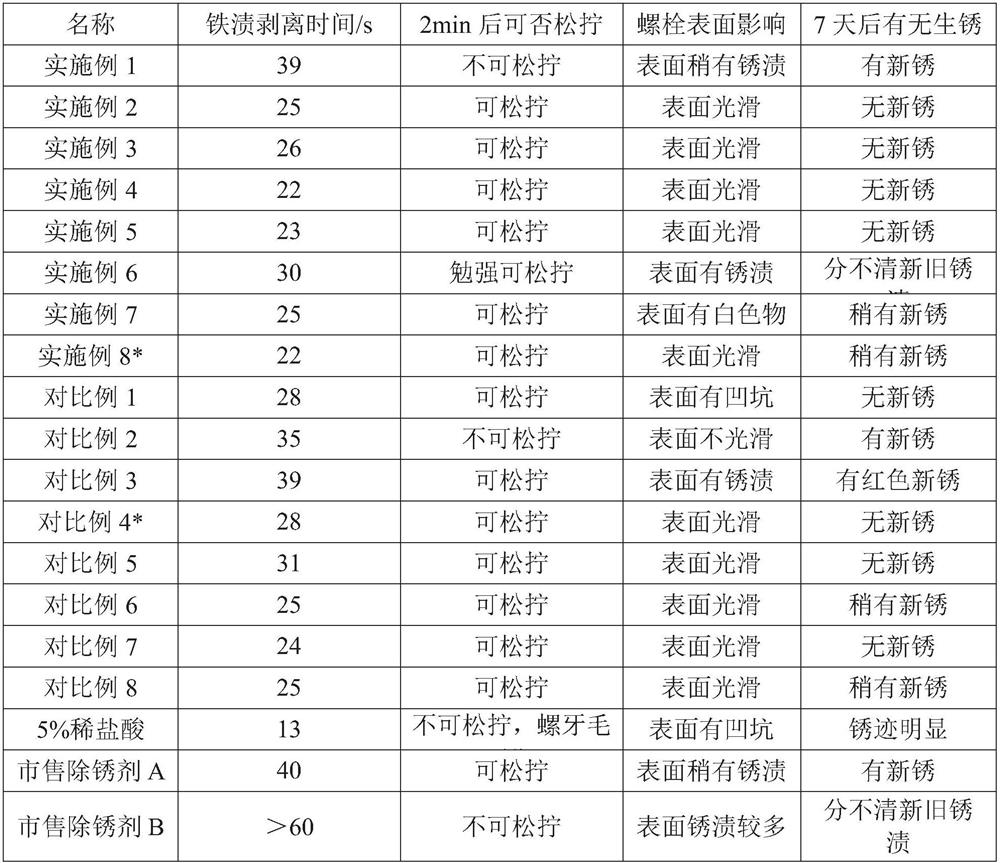

Embodiment 1

[0042] In this embodiment, the rust remover includes the following components calculated in parts by weight: 200 parts of citric acid, 10 parts of phosphoric acid, 3 parts of sodium polyacrylate, 0.8 parts of potassium bromide, 1.5 parts of sodium molybdate, methyl perfluorobutyl acetate 4.5 parts of esters, 100 parts of polyvinylpyrrolidone, and the others are deionized water, totaling 1000 parts; wherein the preparation method of the rust remover is as follows:

[0043] (1) according to the parts by weight, first add deionized water in the reactor, start stirring, control the rotating speed not too fast, the rotating speed is 50-80rpm, add citric acid, phosphoric acid, potassium bromide, sodium molybdate successively, be warming up to 50°C to dissolve the solid completely;

[0044] (2) Cool down to 40°C, adjust the rotation speed to 100rpm, add sodium polyacrylate, stir for 40min, then add polyvinylpyrrolidone, stir for 1h;

[0045](3) The rotating speed is adjusted to 120r...

Embodiment 2

[0047] In this embodiment, the rust remover includes the following components calculated in parts by weight: 150 parts of citric acid, 130 parts of sodium citrate, 10 parts of phosphoric acid, 3 parts of ammonium polyacrylate, 1 part of potassium bromide, 1.5 parts of sodium molybdate, 3.5 parts of methyl perfluorohexyl acetate, 100 parts of N-methylpyrrolidone, and the others are deionized water, totaling 1000 parts; wherein the preparation method of the rust remover is as follows:

[0048] (1) according to the parts by weight, first add deionized water in the reactor, start stirring, control the rotating speed not too fast, the rotating speed is 50-80rpm, add citric acid, sodium citrate, phosphoric acid, potassium bromide, molybdic acid successively Sodium, heat up to 50°C to dissolve the solid completely;

[0049] (2) Cool down to 40°C, adjust the rotation speed to 100rpm, add ammonium polyacrylate, stir for 40min, then add N-methylpyrrolidone, stir for 1h;

[0050] (3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com