Screwdriver for screwing rusty screws

A screwdriver and screw technology, applied in the hardware field, can solve the problems of waste, easy corrosion of screws, pungent smell of rust remover, etc., to reduce the spread of odor, improve work efficiency, and save rust removal time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

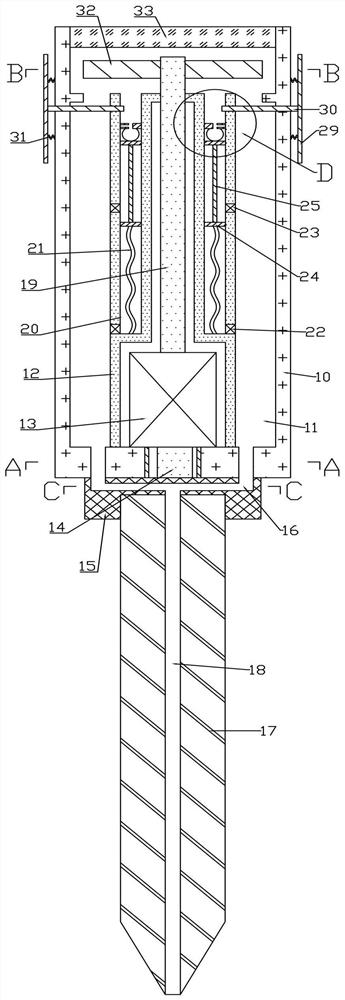

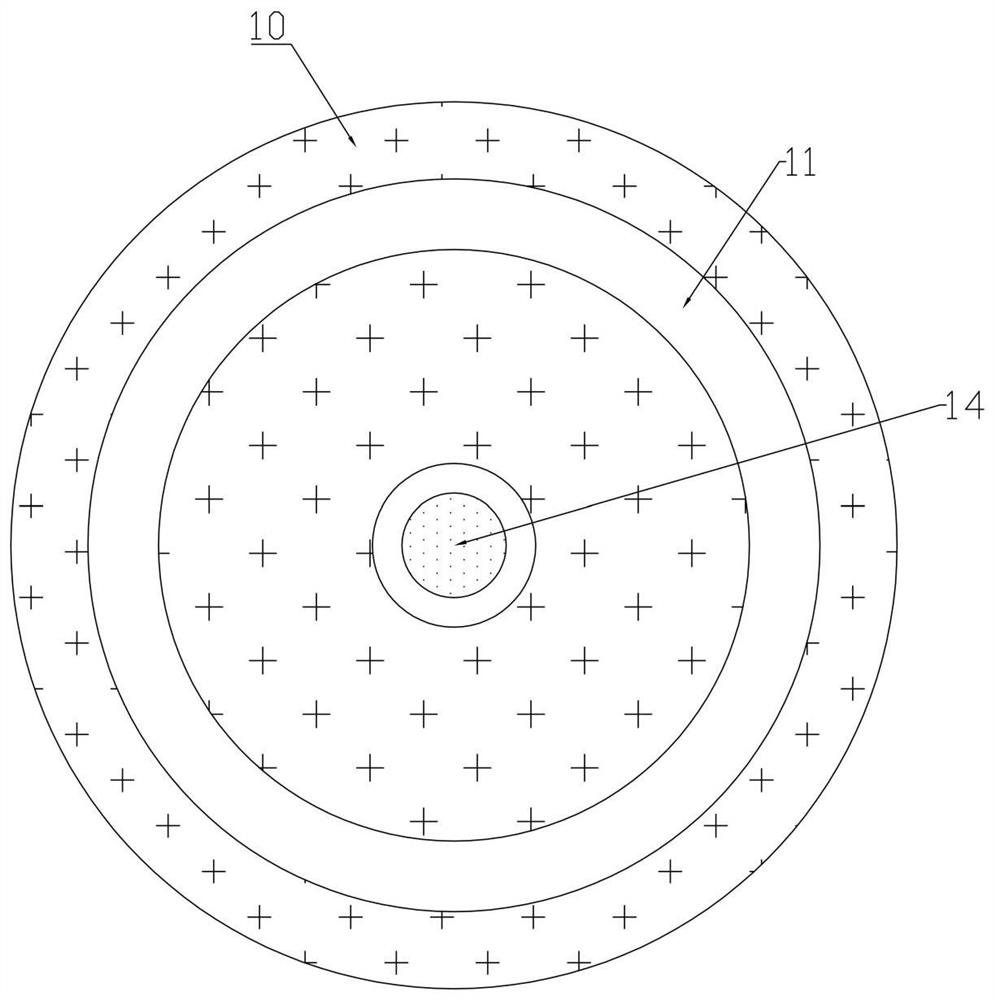

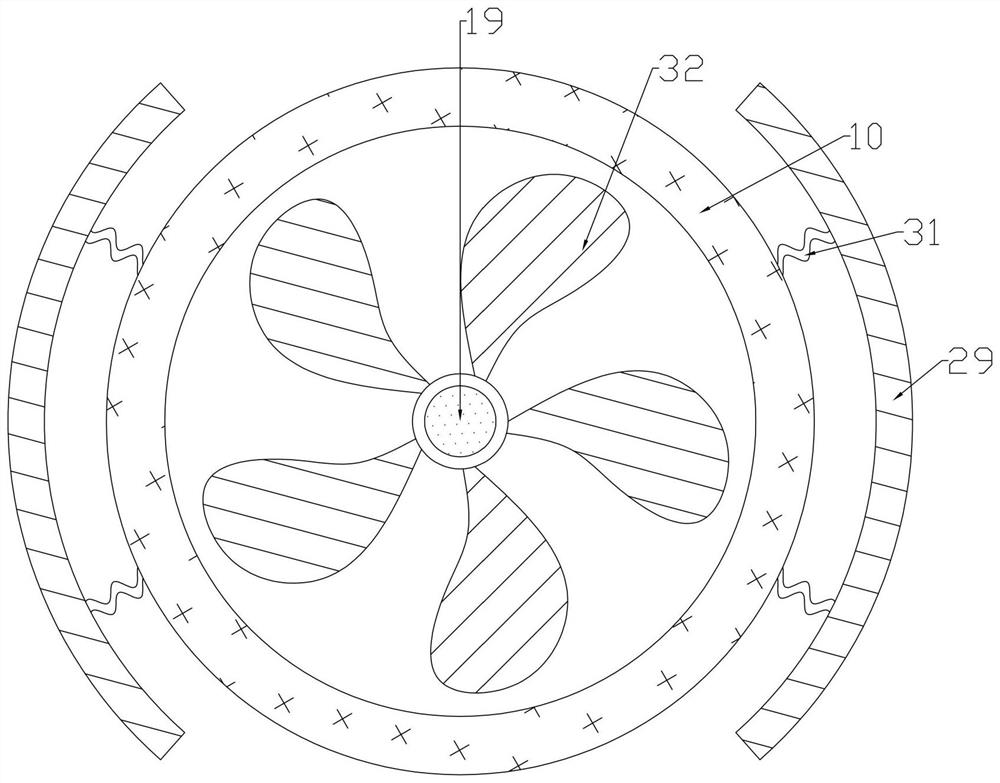

[0025] Such as figure 1 , figure 2 As shown, a screwdriver for turning rusty screws includes a housing 10 with an upper end opening, a working space 11 is defined in the housing 10, a power mechanism is installed in the housing 10, and the left and right ends of the power mechanism are respectively arranged There is a discharge mechanism, the two discharge mechanisms are symmetrically distributed about the center line of the power mechanism, and the left and right sides of the housing 10 are also distributed with limit mechanisms that control the start and stop of the discharge mechanism. The positioning mechanism is distributed symmetrically about the center line of the housing 10. The lower end surface of the housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com