Bearing derusting device

A bearing and pulley technology, used in grinding drive devices, grinding workpiece supports, grinding machines, etc., can solve problems such as low rust efficiency, and achieve the effects of thorough rust removal, low failure rate and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

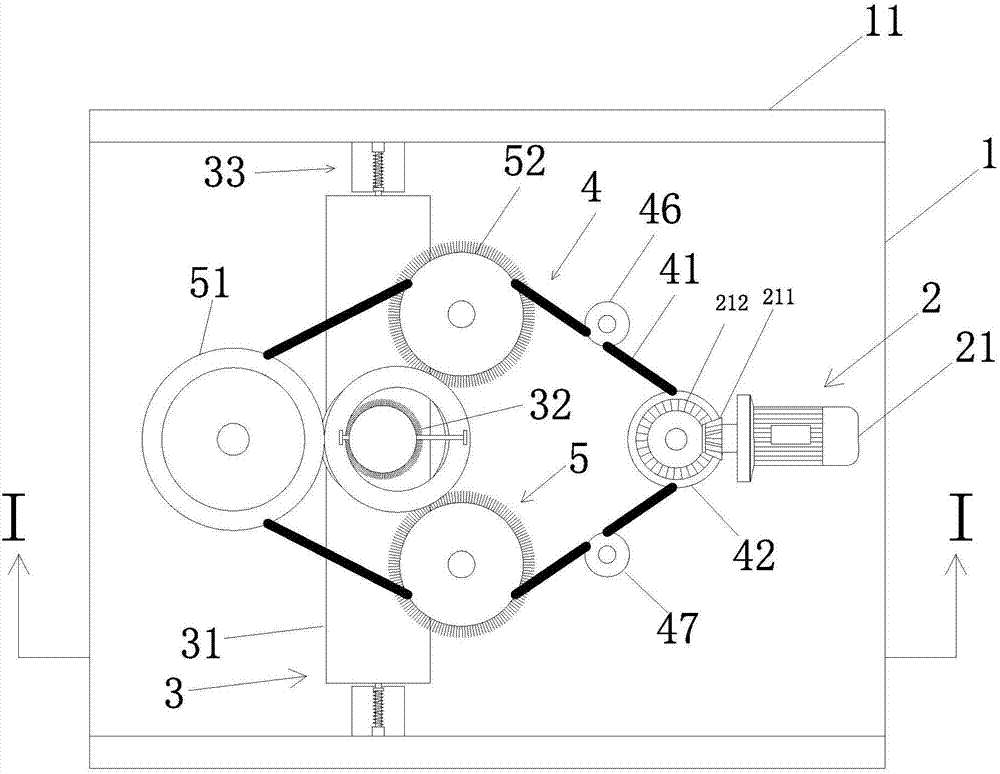

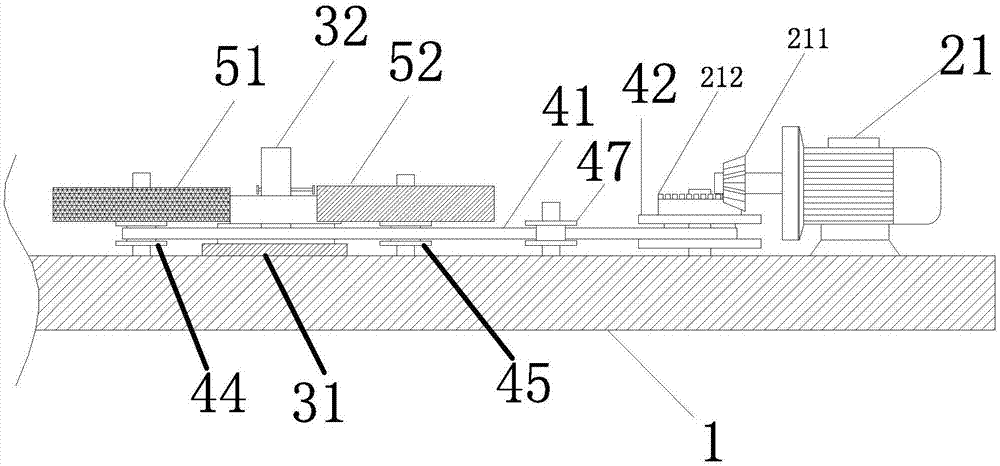

[0030] Such as figure 1 as well as figure 2 As shown, a bearing derusting device includes a base 1, and a drive assembly 2 is installed on the base 1, and the drive assembly 2 includes a drive motor 21 fixed on the base 1 by several screws;

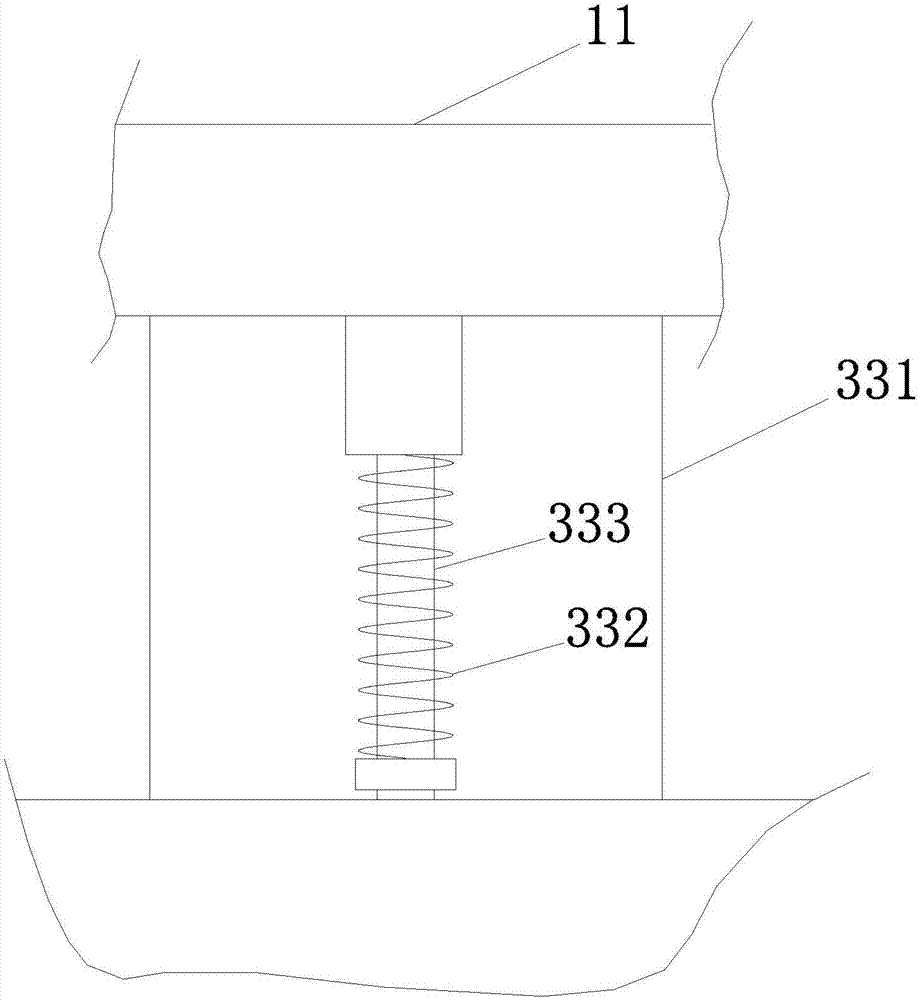

[0031] Support assembly 3, which includes a support plate 31, a support column 32 and two moving parts 33, the support plate 31 can be slidably installed on the base 1, and the support column 32 is vertically fixed on the support plate 31 , a heightening plate is also fixed on the support plate 31, and the support column 32 is used to pass through the bearing, so that the bearing can be placed on the heightening plate to be in the same plane as the driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com