Novel steel bar rust removal device

A steel bar, a new type of technology, used in grinding/polishing safety devices, grinding machines, metal processing equipment, etc., can solve the problems of slow construction progress, low rust removal efficiency, and large workload, so as to reduce physical expenditure and save removal. The effect of rust time and rust removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

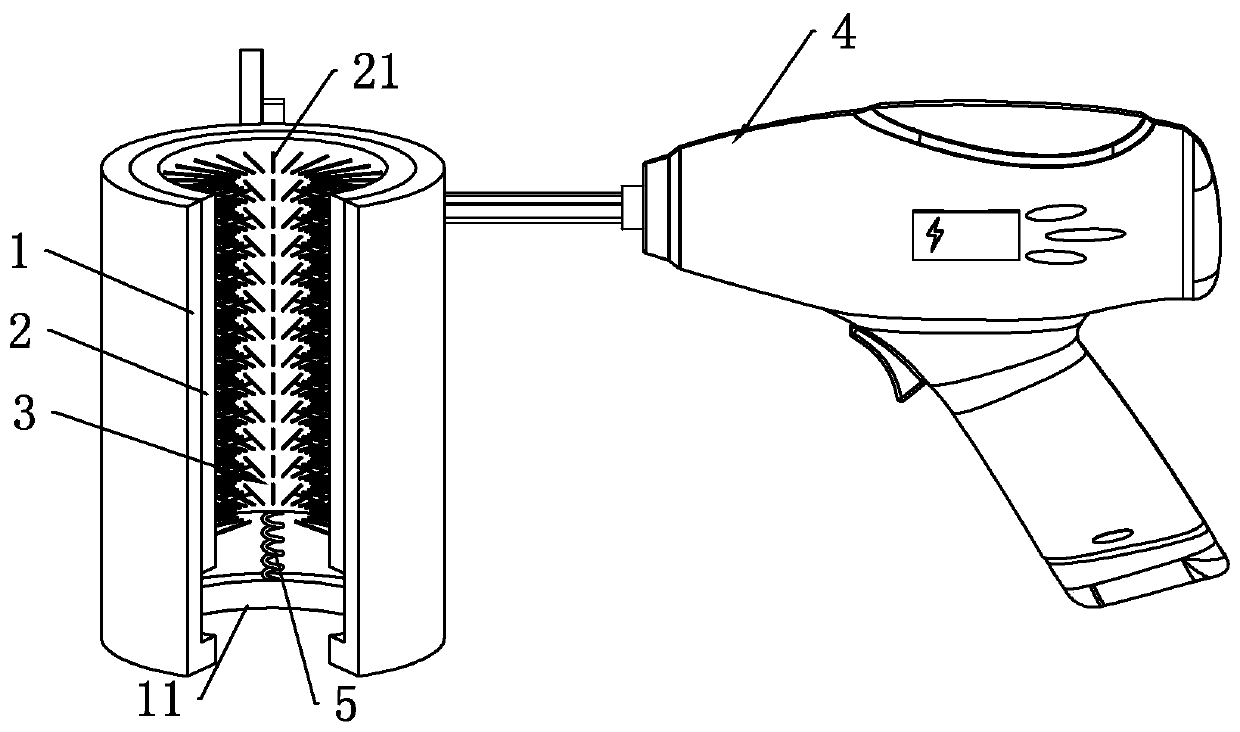

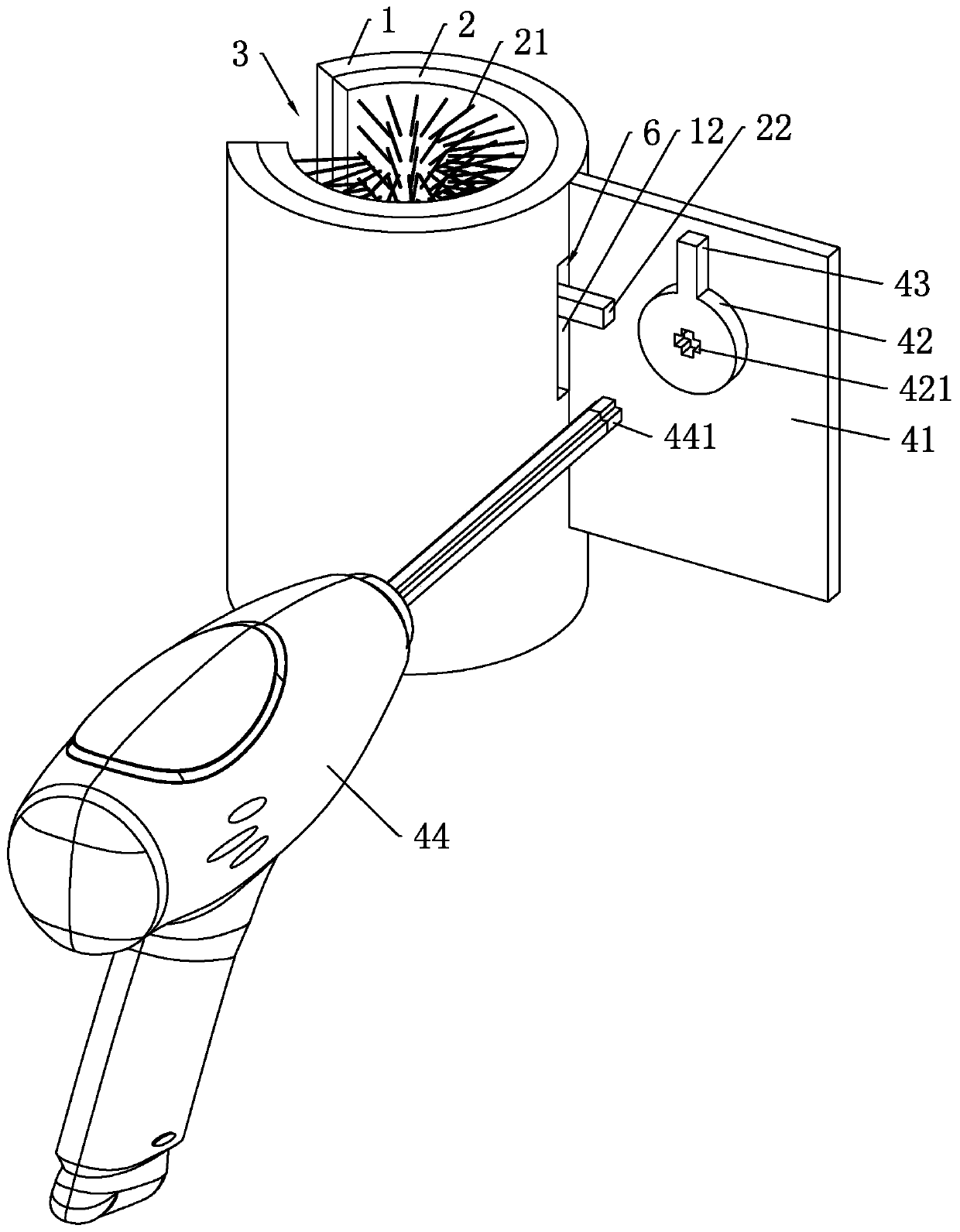

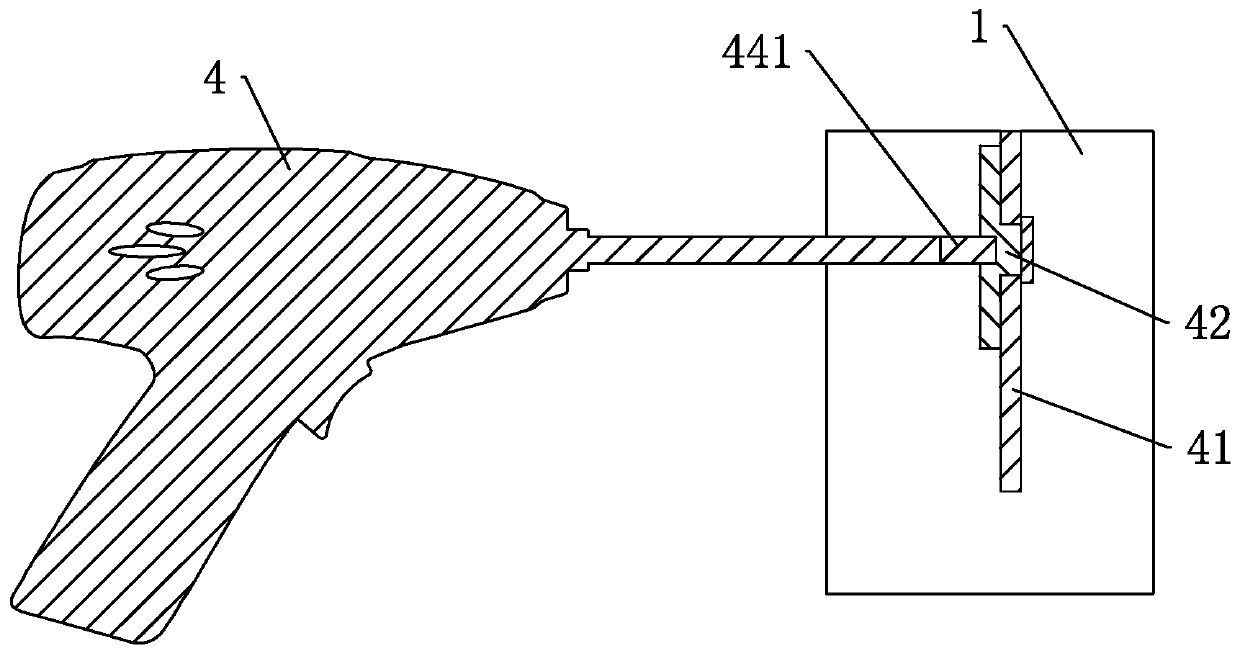

[0030] refer to figure 1 , is a new type of rust removal device for steel bars disclosed by the present invention, comprising a first casing 1 and a second casing 2, the first casing 1 is sleeved on the outside of the second casing 2, and the first casing 1 Longer than the second casing 2, the inner wall of the second casing 2 is evenly equipped with wire brushes 21, and the outer wall of the first casing 1 is fixedly equipped with a driving device 4. When in use, the rusty steel bar is extended into the second casing 2, drive the second casing 2 to slide up and down along the axial direction in the first casing 1 through the driving device 4, so that the wire brush 21 in the second casing 2 can clean the surface of the steel bar Repeated grinding to remove rust on the surface of the steel bar.

[0031] refer to figure 1 Specifically, the first casing 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com