Method for removing rust stains on porous quartz ceramic wave-transmitting material

A technology of wave-transmitting material and porous quartz, applied in the field of functional materials, can solve the problems of no device for removing rust stains on components of wave-transmitting material, inability to meet the needs of harmless rust removal, and complex composition, so as to shorten the rust removal time, Simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

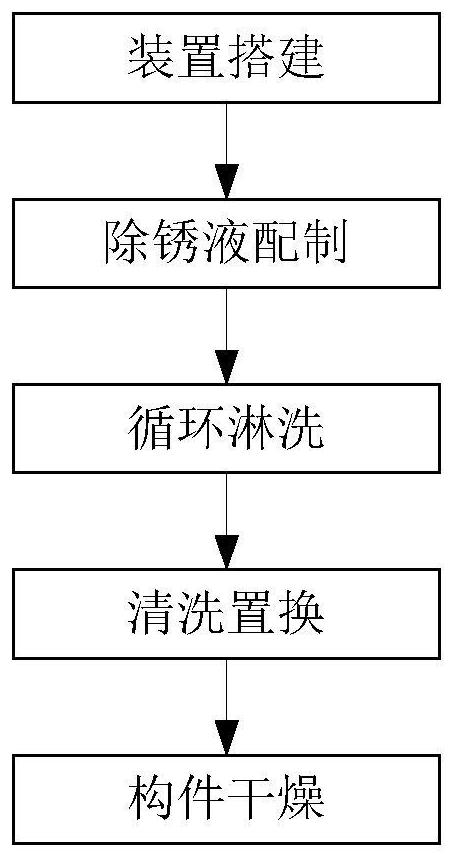

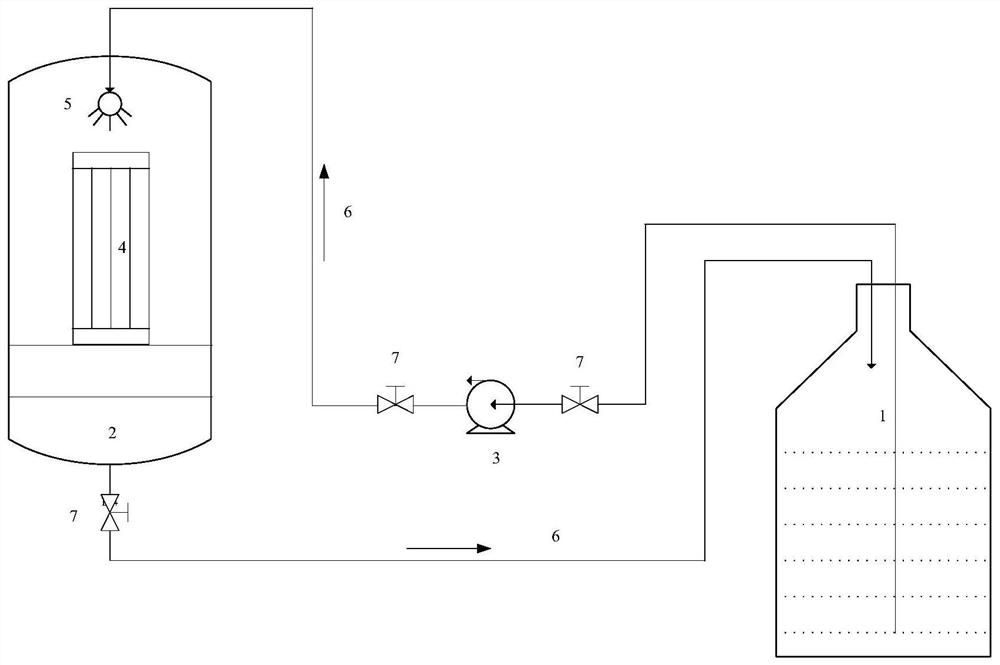

[0029] refer to figure 1 and figure 2 , weigh 2 parts of hydrochloric acid, 4 parts of oxalic acid, and 40 parts of deionized water, stir and mix evenly, and put them into the liquid storage tank for later use; Spray the pipeline and each ball valve, and start the circulation pump to spray and clean the rust removal liquid of the ceramic components. Stop the machine after spraying for 36 hours, observe with the naked eye that the rust stains on the ceramic components dissolve and disappear, take out the ceramic components, and clean the spray tank and delivery pipeline with clean deionized water, and then put the ceramic components into the clean spray tank again And placed directly below the nozzle. Then, connect the cleaning pipeline to the liquid storage tank containing clean deionized water smoothly, and start the circulation pump to implement deionized water to rinse and replace the adsorbed acid in the components. During the replacement process, clean water was repla...

Embodiment 2

[0031] Weigh 4 parts of hydrochloric acid, 2 parts of oxalic acid, and 60 parts of deionized water, stir and mix evenly, and put them into the liquid storage tank for later use; put the rusty ceramic material components into the spray tank, directly under the nozzle, Connect the spray pipeline and each ball valve, and start the circulation pump to spray and clean the ceramic components with derusting liquid. Stop the machine after 48 hours of spraying, observe with the naked eye that the rust stains on the ceramic components dissolve and disappear, take out the ceramic components, and clean the spray tank and delivery pipeline with clean deionized water, and then put the ceramic components into the clean spray tank again And placed directly below the nozzle. Then, connect the cleaning pipeline to the liquid storage tank containing clean deionized water smoothly, and start the circulation pump to implement deionized water to rinse and replace the adsorbed acid in the components...

Embodiment 3

[0033] Weigh 6 parts of hydrochloric acid, 4 parts of oxalic acid, and 50 parts of deionized water, stir and mix evenly, and put them into the liquid storage tank for later use; put the rusty ceramic material components into the spray tank, directly under the nozzle, Connect the spray pipeline and each ball valve, and start the circulation pump to spray and clean the ceramic components with derusting liquid. Stop the machine after spraying for 30 hours, observe with the naked eye that the rust stains on the ceramic components dissolve and disappear, take out the ceramic components, and clean the spray tank and delivery pipeline with clean deionized water, then put the ceramic components into the clean spray tank again And placed directly below the nozzle. Then, connect the cleaning pipeline to the liquid storage tank containing clean deionized water smoothly, and start the circulation pump to implement deionized water to rinse and replace the adsorbed acid in the components. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com