Method for polishing gallium nitride crystals

A gallium nitride wafer, gallium nitride technology, applied in surface polishing machine tools, grinding/polishing equipment, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor polishing of gallium nitride crystals, and improve chemical reactions speed, improve polishing efficiency, and solve the effect of difficult polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to illustrate the present invention, but not to limit the present invention.

[0030] The method for polishing a gallium nitride crystal of this embodiment includes the following steps:

[0031] Step A: Glue the gallium nitride wafer on the quartz plate with high temperature wax.

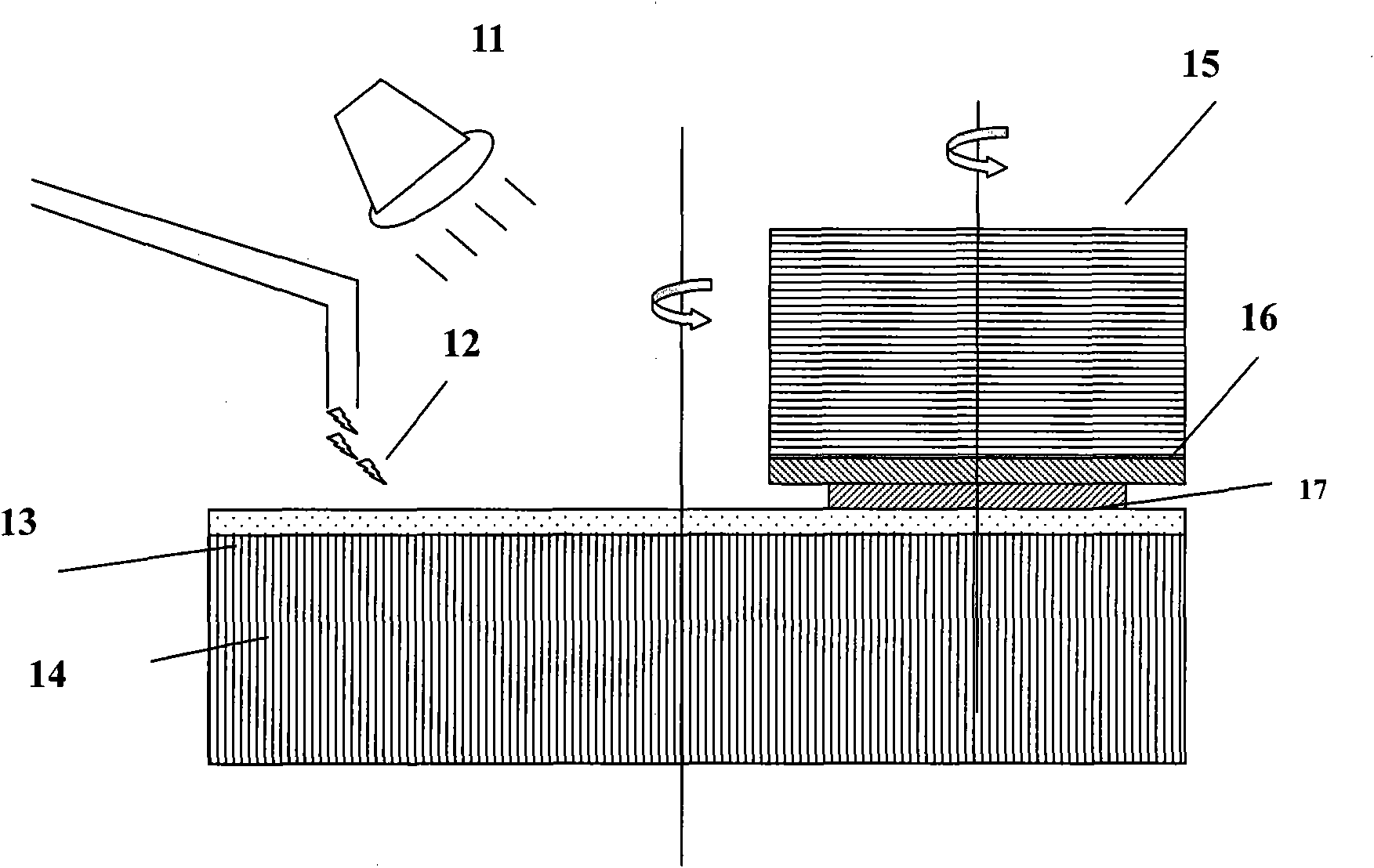

[0032] Step B: Use a grinder to grind the gallium nitride wafer pasted on the quartz plate.

[0033] Step C: heating the polishing solution by heating in a water bath, irradiating the polished wafer with ultraviolet light, and performing chemical mechanical polishing on the ground gallium nitride wafer with a polishing machine.

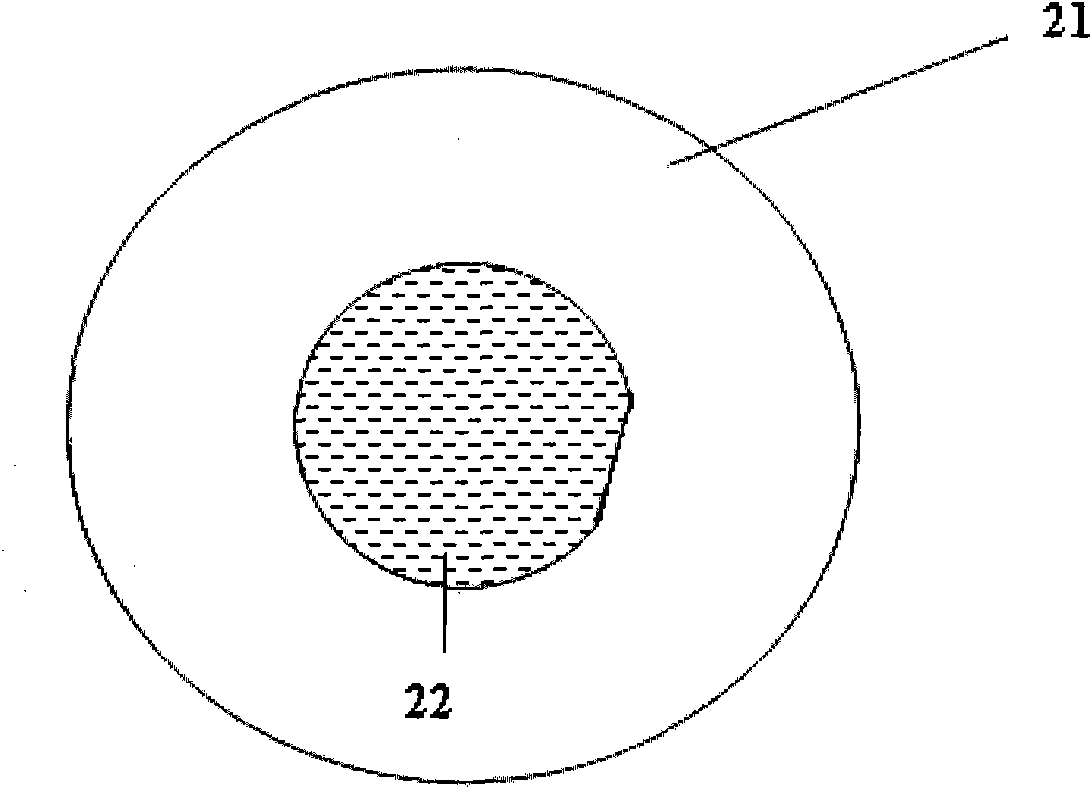

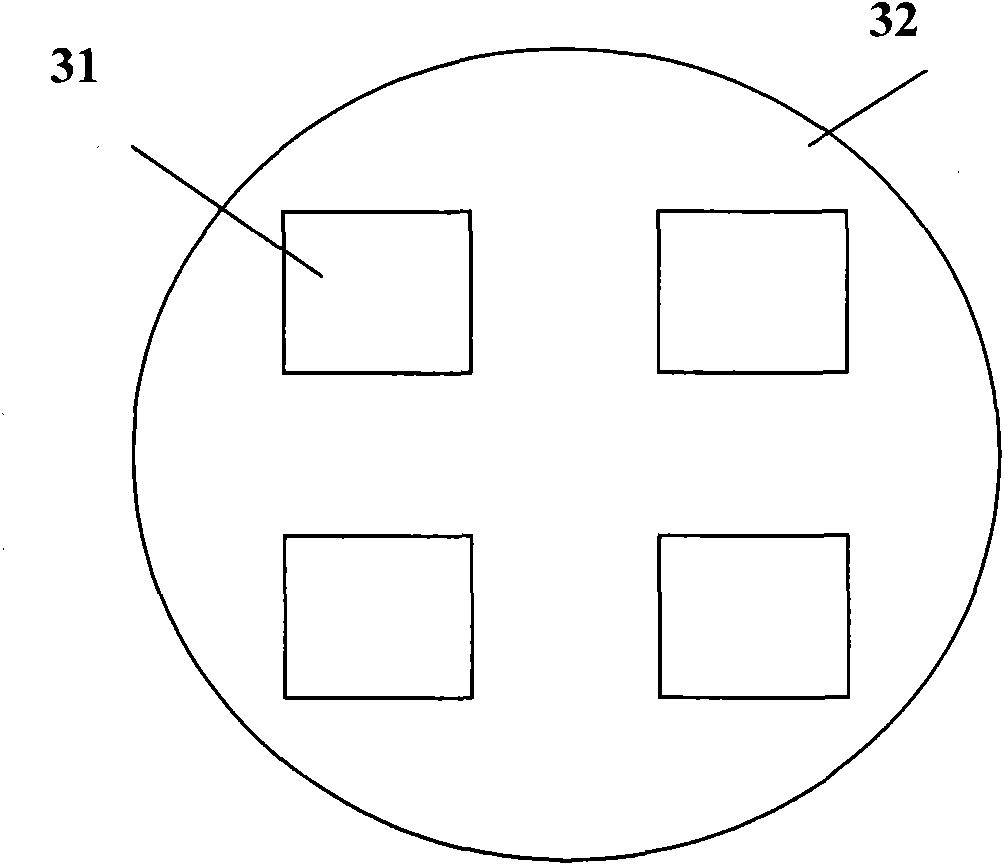

[0034] The sticking method described in step A includes large piece sticking and small piece sticking. like figure 2 As shown, a large GaN wafer 22 (≥2 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com