Preparation method of metal rust removing liquid

A rust removal liquid and metal technology, which is applied in the field of metal surface treatment, can solve the problems of high labor intensity, low efficiency, troublesome cleaning, etc., and achieve the effect of short rust removal time, convenient use and thorough rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

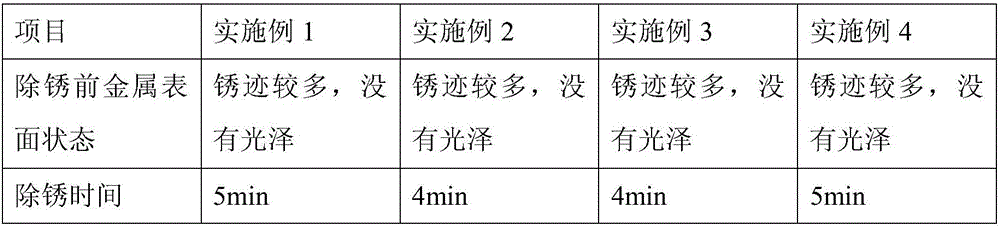

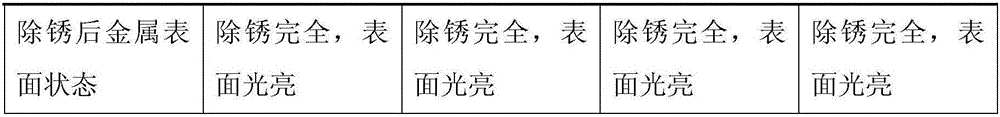

Examples

Embodiment 1

[0017] A preparation method of metal derusting liquid, the steps are as follows:

[0018] Step 1, in parts by weight, take 2 parts of sodium metasilicate, 1 part of polyethylene glycol 800, 0.2 part of polyvinyl alcohol, 0.2 part of sodium citrate, 0.3 part of lecithin and 20 parts of water, heat and mix evenly, heat The temperature is 30°C, the stirring speed is 120 rpm, and the stirring time is 20 minutes to obtain mixture 1;

[0019] Step 2, in parts by weight, take 1 part of triethanolamine, 0.3 part of ammonium molybdate, 0.5 part of triethanolamine oleate, 0.1 part of urea, 0.3 part of sodium carboxymethylcellulose, and 10 parts of water, mix well, and the stirring speed It was 100 rev / min, and the stirring time was 30 minutes to obtain mixture 2;

[0020] Step 3, in parts by weight, take 0.3 parts of hydroxyethylidene diphosphonic acid, add it to mixture 1, heat it to 50°C under the condition of nitrogen protection, and then add it to the mixture under stirring at a st...

Embodiment 2

[0021] A preparation method of metal derusting liquid, the steps are as follows:

[0022] Step 1, in parts by weight, take 3 parts of sodium metasilicate, 1 part of polyethylene glycol 800, 0.3 parts of polyvinyl alcohol, 0.4 parts of sodium citrate, 0.5 parts of lecithin and 22 parts of water, heat and mix evenly, heat The temperature was 34°C, the stirring speed was 125 rpm, and the stirring time was 23 minutes to obtain mixture 1;

[0023] Step 2, in parts by weight, take 2 parts of triethanolamine, 0.5 part of ammonium molybdate, 0.6 part of triethanolamine oleate, 0.2 part of urea, 0.4 part of sodium carboxymethylcellulose, and 12 parts of water, mix well, and the stirring speed It was 105 rpm, and the stirring time was 33 minutes to obtain mixture 2;

[0024] Step 3, in parts by weight, take 0.5 parts of hydroxyethylidene diphosphonic acid, add it to mixture 1, heat it to 55°C under the protection of argon, and then add it under stirring at a stirring speed of 73 rpm M...

Embodiment 3

[0025] A preparation method of metal derusting liquid, the steps are as follows:

[0026] Step 1, in parts by weight, take 4 parts of sodium metasilicate, 2 parts of polyethylene glycol 800, 0.4 part of polyvinyl alcohol, 0.6 part of sodium citrate, 0.7 part of lecithin and 24 parts of water, heat and mix evenly, heat The temperature was 38°C, the stirring speed was 140 rpm, and the stirring time was 26 minutes to obtain mixture 1;

[0027] Step 2, in parts by weight, take 2 parts of triethanolamine, 0.7 part of ammonium molybdate, 0.6 part of triethanolamine oleate, 0.2 part of urea, 0.5 part of sodium carboxymethylcellulose, and 13 parts of water, mix well, and the stirring speed It was 110 rpm, and the stirring time was 36 minutes to obtain mixture 2;

[0028] Step 3, in parts by weight, take 0.8 parts of hydroxyethylidene diphosphonic acid, add it to mixture 1, heat it to 55°C under the condition of nitrogen protection, and then add it to the mixture at a stirring speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com