Preparation method of special-infiltration functional fabric surface with self-cleaning and oil-water separation functions

A technology for oil-water separation and functional fabrics, applied in plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of poor stability, complex operation process of super-hydrophobic self-cleaning surface, uncontrollable film morphology, etc., and achieve chemical resistance. Good properties, durable superhydrophobicity, good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

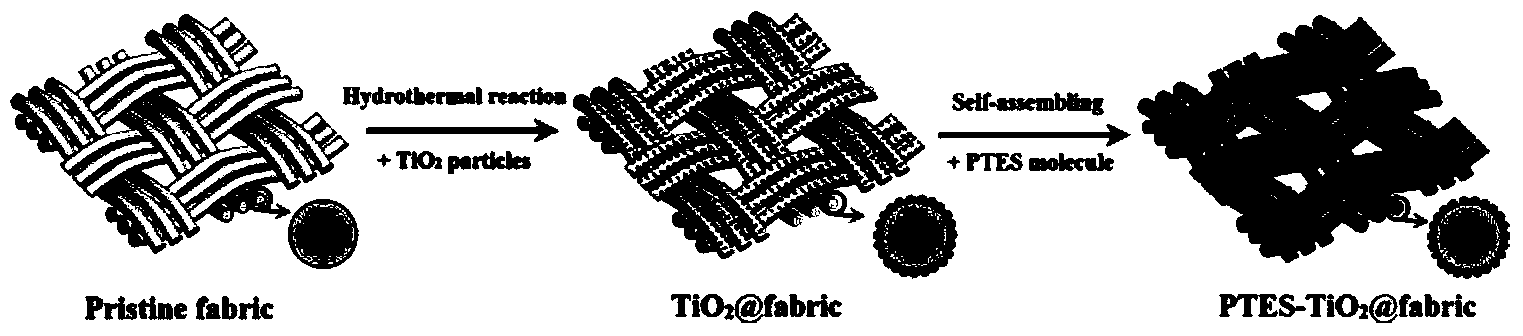

[0030] The invention provides a method for preparing the surface of a special wettable functional fabric with self-cleaning and oil-water separation functions, comprising the following steps:

[0031] A method for preparing the surface of a special wettable functional fabric with self-cleaning and oil-water separation functions, the method comprises the following steps:

[0032] (1) Dissolve potassium titanium oxalate in deionized water, and slowly add H 2 o 2 Solution, adjust the pH value of the above solution with HCl to obtain a prepared solution, move the prepared solution to a blue cap reagent bottle, add a clean cotton cloth to the blue cap reagent bottle, and prepare it by a one-step water bath method With nano TiO 2 Cotton cloth on the surface; and

[0033] (2) the described nano-TiO 2 The cotton cloth on the surface is soaked in the fluorosilane solution, and after reacting for a certain period of time, it is taken out and dried, and the cotton cloth on the surfac...

Embodiment 1

[0048] In this embodiment, the surface of a special wettable functional fabric with self-cleaning and oil-water separation functions is prepared according to the following steps:

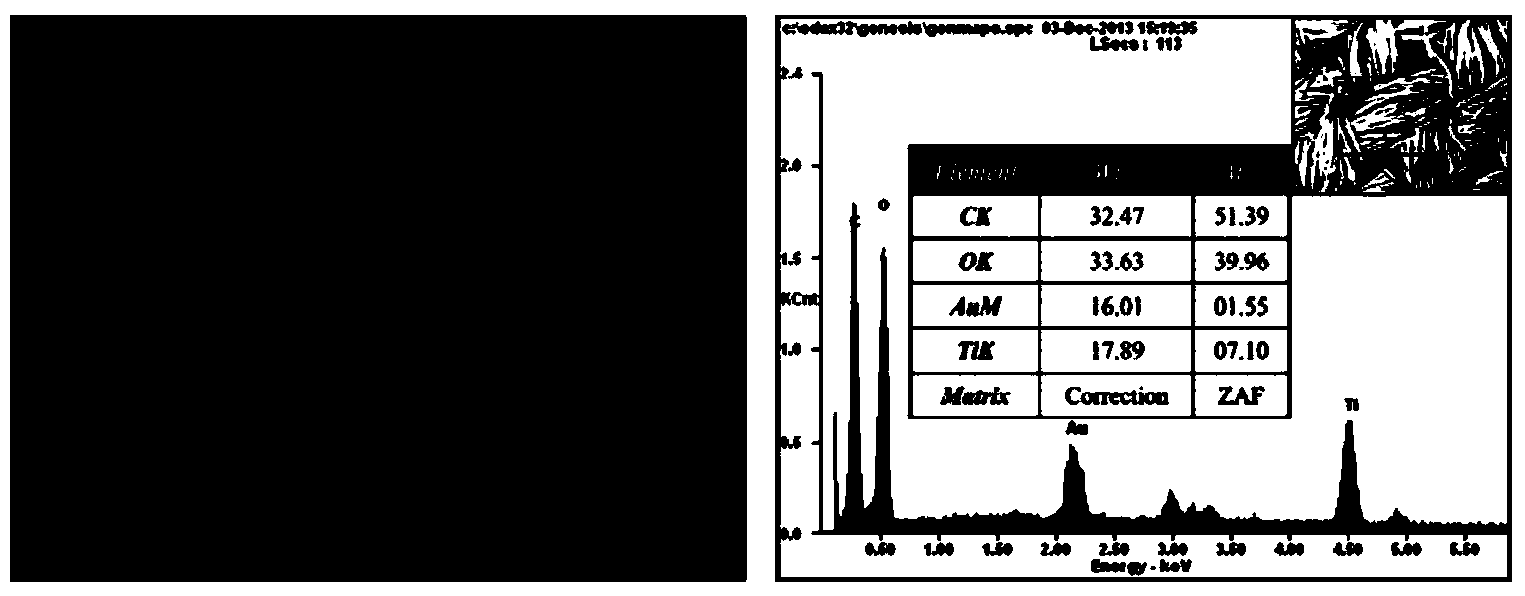

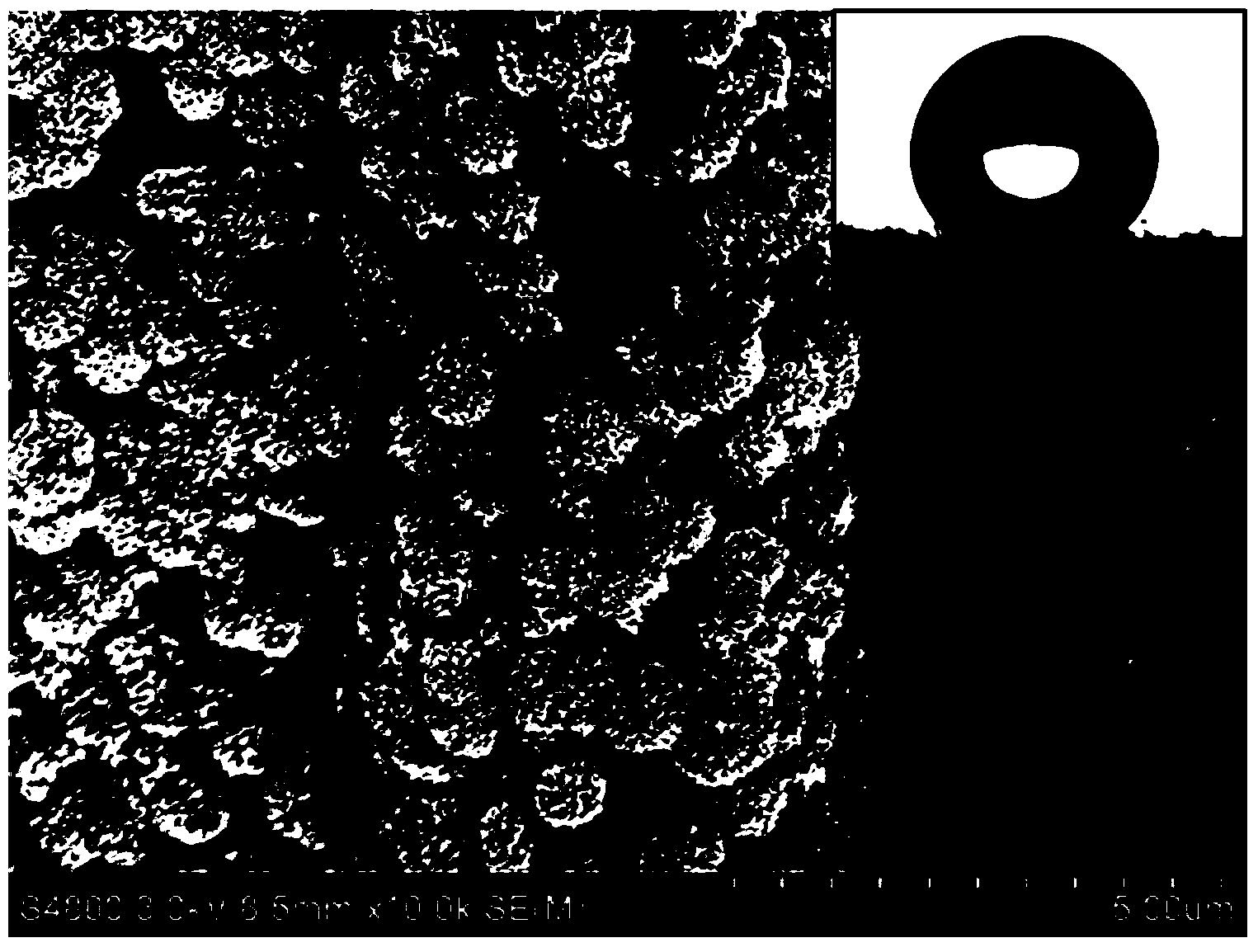

[0049] Step 1, one-step water bath method to prepare nano-TiO 2 surface

[0050] Cut 5 pieces of cotton cloth according to the size of 3×3cm, put them in a beaker, and pass through deionized water and absolute ethanol for 5 minutes. Weigh 0.25mmol titanium potassium oxalate with an electronic balance, dissolve it in 30ml deionized water, and slowly add 1ml of 30% H 2 o 2 , and then adjust the pH value of the above solution with HCl, the adjusted pH=1.5. Transfer the above prepared solution to a 100ml blue cap bottle, add clean cotton cloth, put it in an 80°C water bath for 0.5 hour reaction, after the reaction, thoroughly clean the excess reactant on the surface of the cotton fabric with deionized water.

[0051] Step 2. Preparation and modification of fluorosilane solution

[0052] Add 48ml of...

Embodiment 2

[0055] In this embodiment, the surface of a special wettable functional fabric with self-cleaning and oil-water separation functions is prepared according to the following steps:

[0056] Step 1, one-step water bath method to prepare nano-TiO 2 surface

[0057] Cut 5 pieces of cotton cloth according to the size of 3×3cm, put them in a beaker, and pass through deionized water and absolute ethanol for 5 minutes. Weigh 0.75mmol titanium potassium oxalate with an electronic balance, dissolve it in 30ml deionized water, and slowly add 1ml of 30% H 2 o 2 , and then adjust the pH value of the above solution with HCl, the adjusted pH=1.6. Transfer the above-mentioned prepared solution to a 100ml blue cap bottle, add clean cotton cloth, put it in a water bath at 80°C for 20 hours of reaction, and thoroughly wash off the excess reactant on the surface of the cotton fabric with deionized water after the reaction is completed.

[0058] Step 2. Preparation and modification of fluorosil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com