Method for preparing TiO2 hollow micro-sphere material

A technology of microspheres and reaction solutions, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as unsuitable for industrial production, complicated process of template preparation and removal, and achieve operational The effect of simple operation and simple preparation process

Inactive Publication Date: 2009-06-03

EAST CHINA NORMAL UNIV

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Existing TiO 2 Most of the preparation methods of hollow microsphere materials use organic substances as templates, and the process of preparing and removing templates is also quite complicated, which is not suitable for industrial production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] In the first step, the amount of hydrochloric acid added is 1ml.

Embodiment 2

[0029] In the first step, the addition amount of hydrochloric acid is 1.5ml.

Embodiment 3

[0031] In the first step, the addition amount of hydrochloric acid is 2ml.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

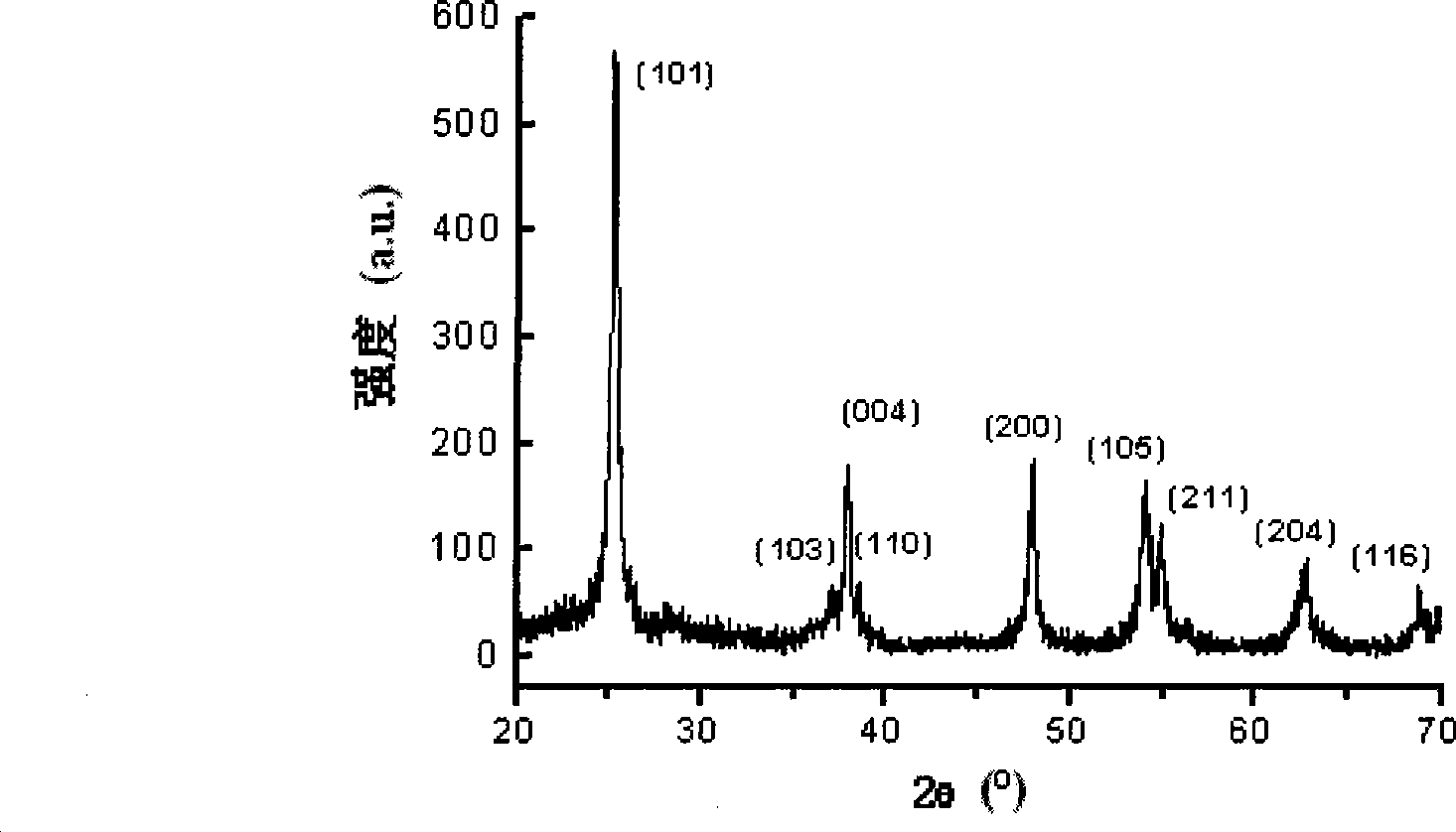

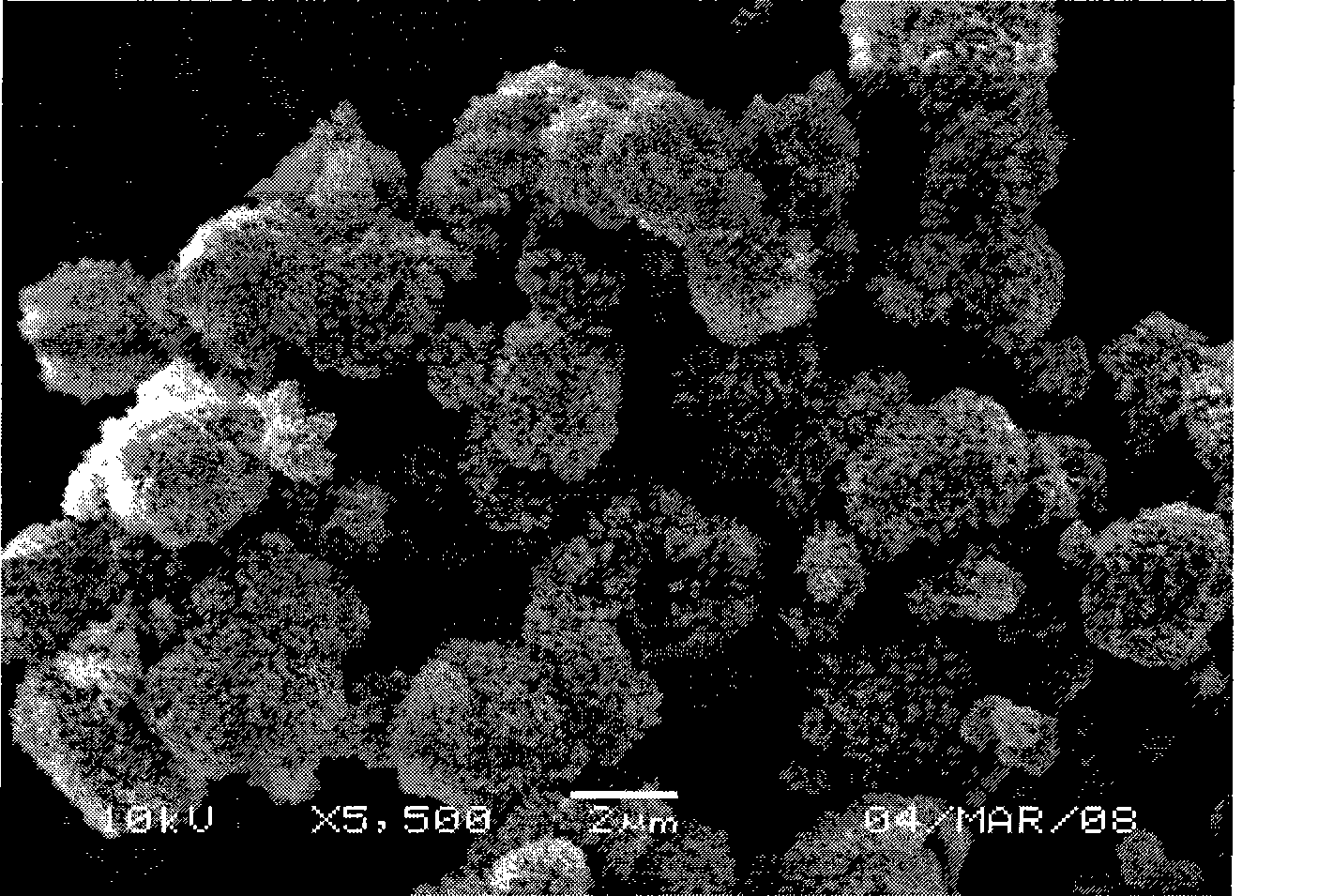

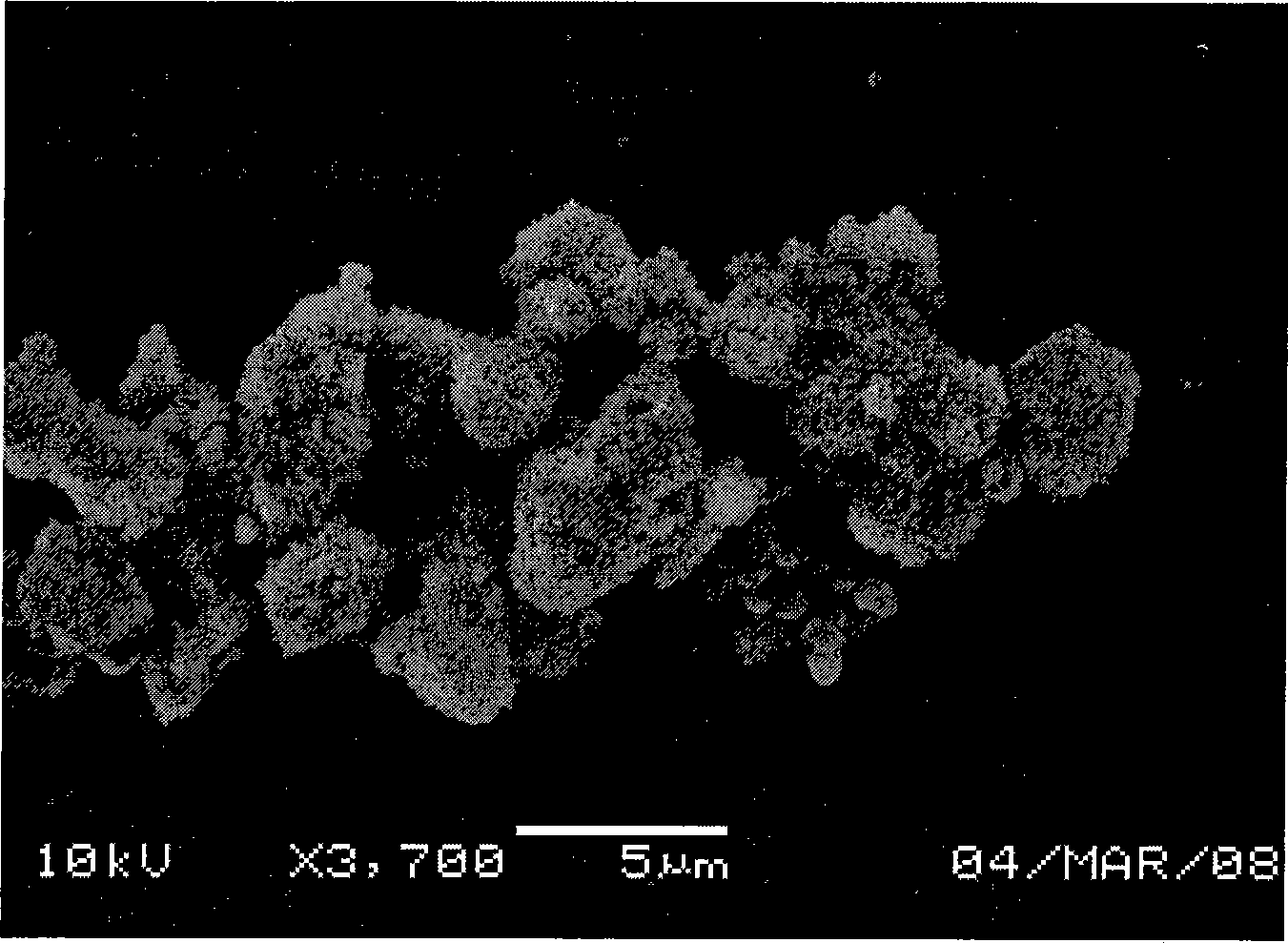

The invention discloses a method for preparing TiO2 hollow micro-sphere material which belongs to the technical field of preparing semiconductor photocatalysis material. In the method, titanium potassium oxalate, oxyful and concentrated hydrochloric acid are used as materials, and a hydrothermal synthesis method and the oxygen released in the reaction process are used as a template to prepare the TiO2 hollow micro-sphere material. The method has the advantages of simple operation, low reaction temperature and short reaction time; besides, the method takes the oxygen generated during the reaction process as the template, and does not need to include the techniques of specially preparing the template or removing the template in the preparing process; the whole preparing process is quite simple. The specific area of the prepared material is high; and the material is applied on the aspects of sterilization and gas storage in environment protection especially.

Description

technical field [0001] The present invention relates to a kind of TiO 2 The preparation method of hollow microsphere material, specifically relates to a kind of TiO with gas as template 2 The invention discloses a method for preparing hollow microsphere materials, which belongs to the technical field of semiconductor photocatalytic materials. Background technique [0002] TiO 2 It is an important multifunctional inorganic material, and it has broad application prospects in the fields of gas sensors, pollutant degradation, solar hydrogen production, and solar cells. In the past two decades, people have successfully prepared TiO by various methods (hydrothermal synthesis, vapor deposition, template, electroplating, etc.) 2 materials such as nanospheres, nanorods, nanotubes, and nanorings, while TiO 2 The preparation of hollow microsphere materials is a big challenge. [0003] At present, hollow sphere nanoparticles (Hollow spheres) have represented a group of materials, w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J21/06B01J35/08

Inventor 许玉娥郁可尚德建吴晋徐建文

Owner EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com