Sulfur-nitrogen-doped porous biochar, preparation method and application

A biochar, sulfur and nitrogen technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve problems such as not being developed and utilized, and achieve good selection and adsorption capacity, high heavy metal ion selective adsorption capacity , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The specific preparation process includes mixing calcium sulfate, potassium oxalate and defatted soybean dregs at a mass ratio of 1:1:1, and the calcination conditions are as follows: heating up to 800°C at a heating rate of 5°C / min under argon gas, heating time 1h, and naturally cooled to room temperature, the obtained product was washed three times with dilute hydrochloric acid, and dried overnight at 60°C to obtain the final product.

[0035] More specifically, the obtained sulfur-nitrogen-doped biochar was added to the heavy metal solution at 0.5 g / L, and the adsorbent was evenly dispersed in the aqueous solution by stirring, and the adsorption was carried out for 120 minutes until the adsorption equilibrium was reached, and the adsorption was separated by centrifugation. The material is separated from the solution, and the separated material is subjected to in-situ reduction treatment of surface heavy metals with 1M sodium borohydride to obtain a biochar-metal nanop...

Embodiment 1

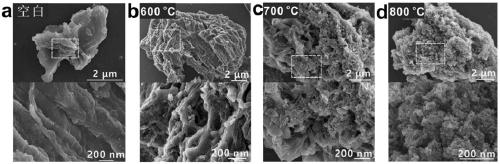

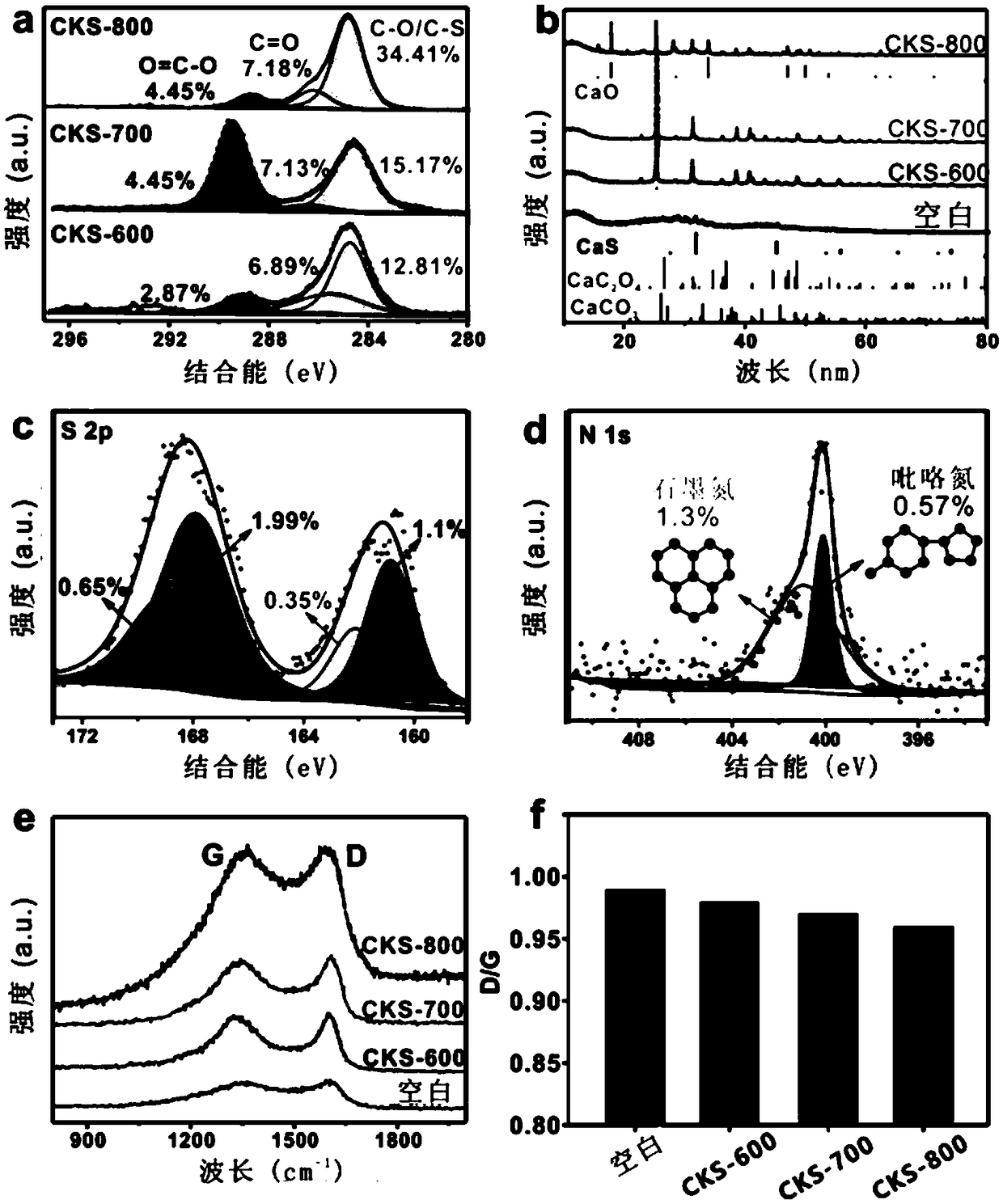

[0040] Example 1: Optimization of preparation conditions for sulfur and nitrogen doped porous biochar

[0041] The preparation process of porous biochar doped with sulfur and nitrogen is mainly to uniformly mix calcium sulfate, potassium oxalate and defatted soybean dregs and perform high-temperature calcination. The defatted soybean dregs used in this experiment contain 85% moisture, 3.0% protein, and 0.5% fat. Carbohydrates (cellulose, polysaccharides, etc.) 8.0%.

[0042] The specific calcination conditions are as follows: under argon gas, the temperature is raised to 800°C at a heating rate of 5°C / min, the heating time is 1h, and it is naturally cooled to room temperature. The obtained product is washed with dilute hydrochloric acid three times, and dried overnight at 60°C to obtain the final product.

[0043] The preparation condition optimization of the preparation method of sulfur and nitrogen doped porous biochar comprises the following steps:

[0044] 1) Auxiliary ad...

Embodiment 2

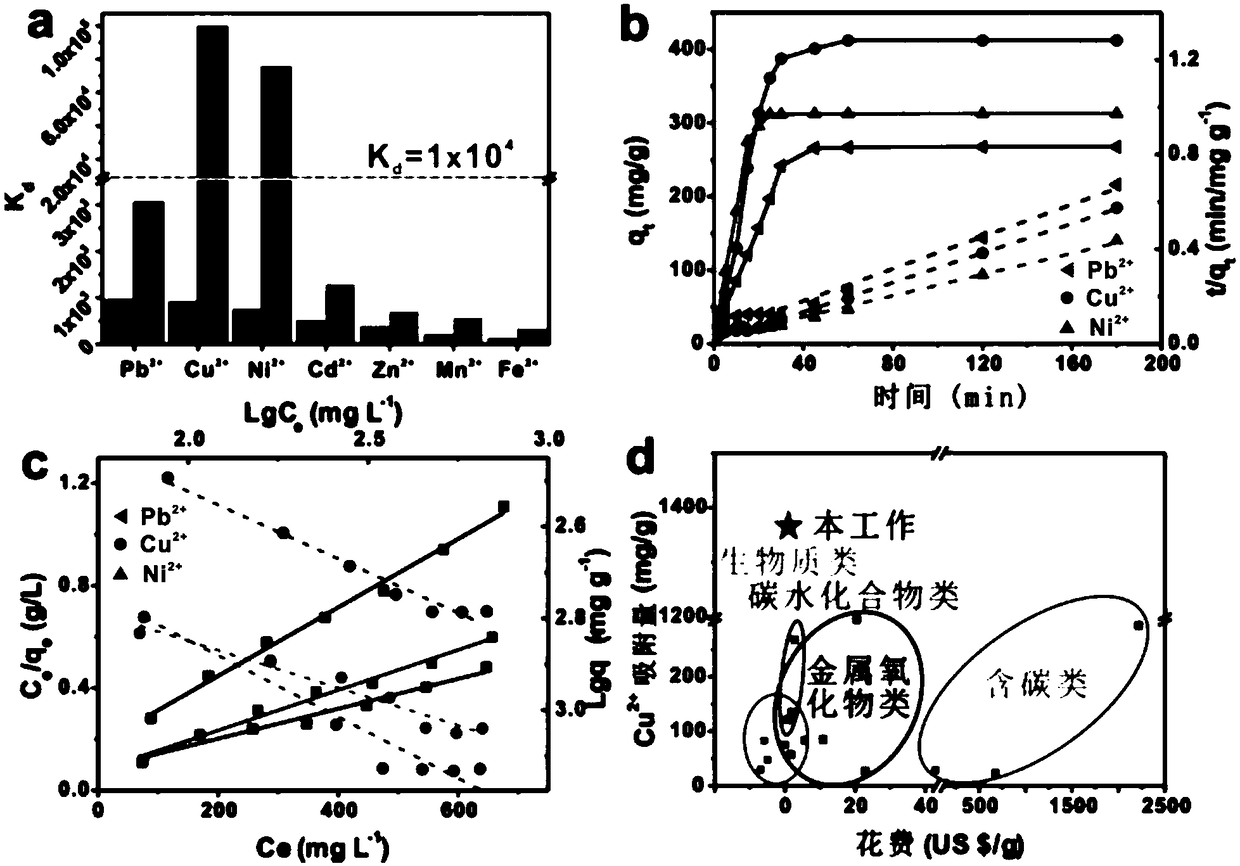

[0049] Example 2: Adsorption capacity of sulfur and nitrogen doped porous biochar for different heavy metals

[0050] 1) Competitive adsorption capacity of sulfur and nitrogen doped porous biochar in mixed heavy metal ion solution

[0051] The biochar adsorbent was added to a mixture of heavy metal ions at an amount of 0.5 mg / L to test its competitive adsorption capacity. The mixture included seven heavy metal ions lead, copper, nickel, chromium, zinc, manganese, iron and Concentrations were 10ppm, adsorption reaction 10h. After the reaction is completed, the material and the reaction solution are separated by centrifugation, and the supernatant solution is measured by flame atomic absorption, and the distribution coefficient of the biochar material for each ion is calculated using the formula to judge its selective adsorption capacity. The result is as image 3 The a in the figure shows that the partition coefficients of the biochar adsorption material for the heavy metals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com