Method for producing potassium sulphate and aluminium chloride by utilizing potassium alum

A technology of potassium sulfate and potassium alum, which is applied in the preparation of aluminum chloride, aluminum halide, sulfate/bisulfate, etc., can solve the problems of high production cost, high energy consumption of evaporation and concentration, and high energy consumption of high-temperature roasting, and achieves Easy solid-liquid separation, easy industrial implementation, and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

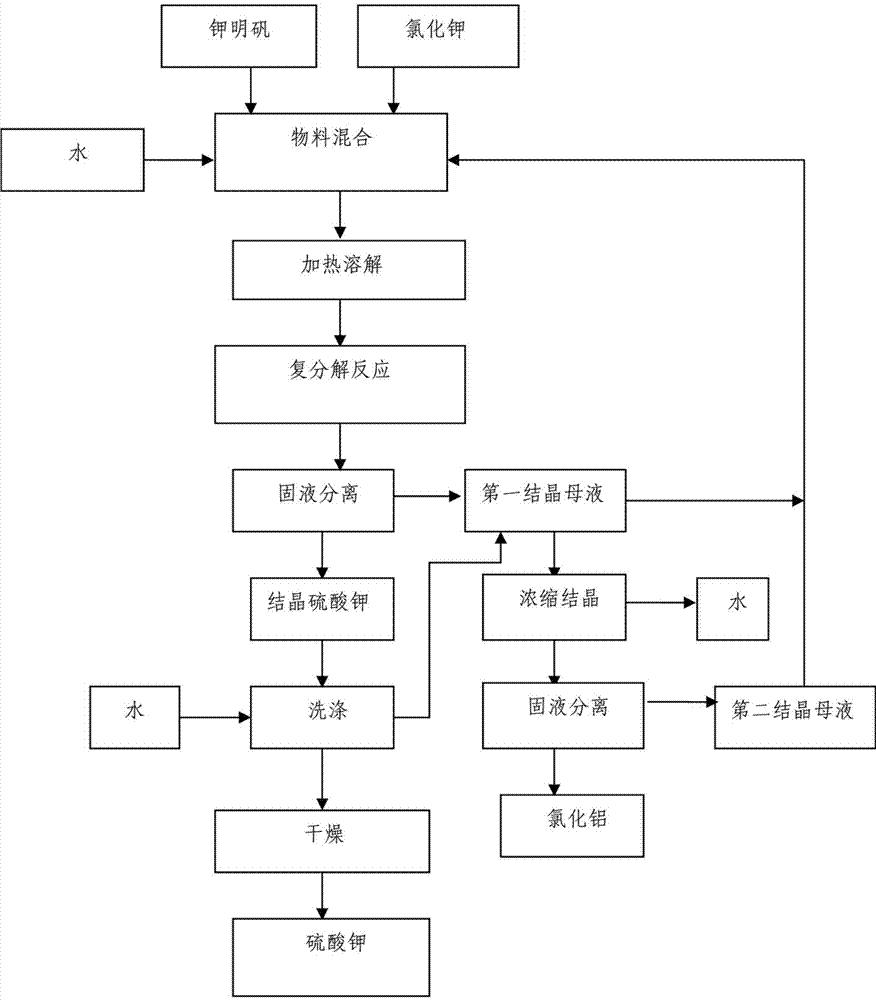

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, method 1 is adopted, that is, the first crystallization mother liquor obtained in the first stage of preparing potassium sulfate directly enters the stage of preparing aluminum chloride.

[0019] Materials for use: 100 grams of potassium alum, 50 grams of potassium chloride and an appropriate amount of water (containing potassium alum crystal water, the same below) as a solvent, the amount of water can be completely dissolved and selected with the material, and the water in this embodiment is 250 grams. 100 grams of the above-mentioned potassium alum and 50 grams of potassium chloride are the theoretical amount, and the actual consumption is 100-110% of the theoretical amount. Its preparation method includes the following stages:

[0020] (1), potassium alum / potassium chloride metathesis reaction crystallization method to prepare potassium sulfate stage:

[0021] 100 grams of Potassium Alum and 50 grams of Potassium Chloride are placed in 250 grams ...

Embodiment 2

[0025] In this embodiment, method 2 is adopted, that is, the stage of producing potassium sulfate is repeated several times.

[0026] (1), potassium alum / potassium chloride metathesis reaction crystallization method to prepare potassium sulfate stage:

[0027] Materials for use: 100 grams of potassium alum, 50 grams of potassium chloride and an appropriate amount of water (containing alum crystal water, the same below) as a solvent, the amount of water can be completely dissolved and selected with the material, and the water in this embodiment is 250 grams. 100 grams of the above-mentioned potassium alum and 50 grams of potassium chloride are the theoretical amount, and the actual consumption is 100-110% of the theoretical amount. Its preparation method includes the following stages:

[0028] Put 100 grams of Potassium Alum and 50 grams of Potassium Chloride in 250 grams of water, heat and dissolve for the first time, stir thoroughly, and after the material is completely diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com