Method for producing potassium alum

A production method, the technology of potassium alum, applied in the direction of chemical instruments and methods, aluminum sulfur compounds, aluminum sulfate, etc., can solve the problems of polluting groundwater, occupying a large site, and high water content, achieving low energy consumption, reducing waste residue discharge, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

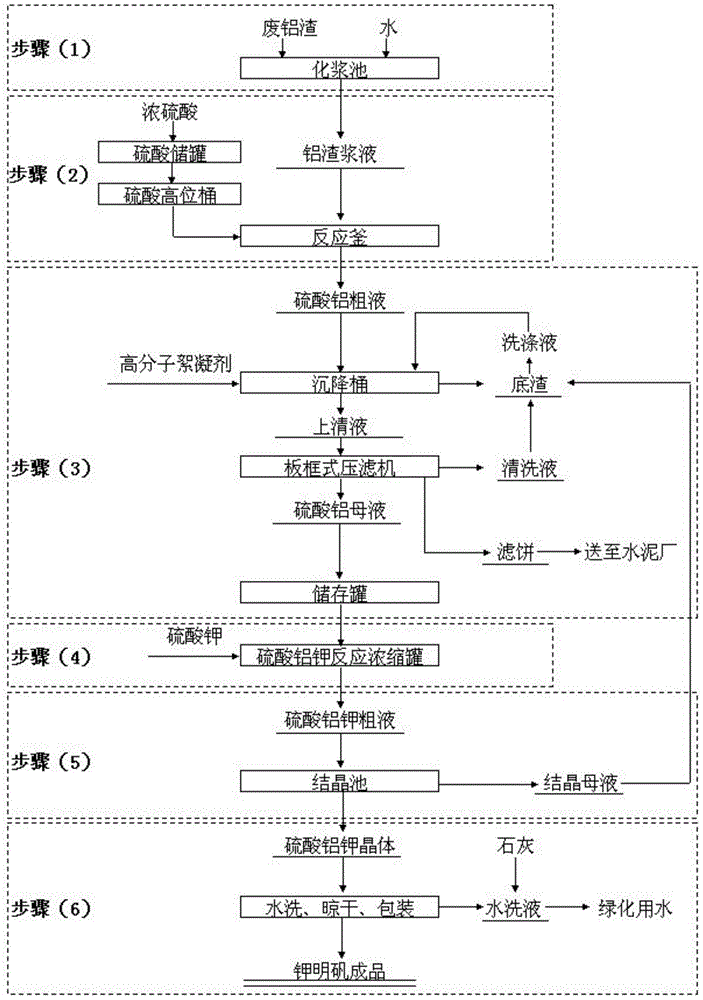

[0037] A kind of production method of potassium alum, comprises following processing steps:

[0038] (1) Pulping process: Take the waste aluminum slag raw material, crush it into 80 mesh particle size, put it in the slurry tank, add water while stirring, and make the aluminum slag slurry of 30-40 Baume degrees;

[0039] (2) Aluminum sulfate crude liquid preparation process: first pump the aluminum slag slurry prepared in step (1) into the reactor, and then add concentrated sulfuric acid with a mass fraction of 98% that has been pumped into the high level barrel into the reactor , the weight of aluminum slag slurry and concentrated sulfuric acid is 1:1, close the reaction kettle, start the stirrer to stir, the stirring speed is 25 rpm, the time is 5 minutes, when the pressure in the reaction kettle is 0.3 ~ 0.4MPa, stop Stir and stand for 2 hours to obtain crude aluminum sulfate liquid; when the pressure in the reactor is 0.1MPa, discharge the crude aluminum sulfate liquid to t...

Embodiment 2

[0048] A kind of production method of potassium alum, comprises following processing steps:

[0049] (1) Pulping process: take waste aluminum slag raw material, crush it into 100 mesh particle size, put it in the slurry tank, add water while stirring, and make aluminum slag slurry with 30-40 Baume degrees;

[0050] (2) Aluminum sulfate crude liquid preparation process: first pump the aluminum slag slurry prepared in step (1) into the reactor, and then add concentrated sulfuric acid with a mass fraction of 98% that has been pumped into the high level tank into the reactor , the weight of aluminum slag slurry and concentrated sulfuric acid is 1:1, close the reaction kettle, start the stirrer to stir, the stirring speed is 20 rpm, the time is 35 minutes, when the pressure in the reaction kettle is 0.3 ~ 0.4MPa, stop Stir and stand for 2 hours to obtain crude aluminum sulfate liquid; when the pressure in the reactor is 0.1MPa, discharge the crude aluminum sulfate liquid to the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com