Inorganic-organic composite flocculating agent and preparation method thereof

A composite flocculant and flocculant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of positive charge density decrease, and achieve the effects of fast settling speed, low energy consumption and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

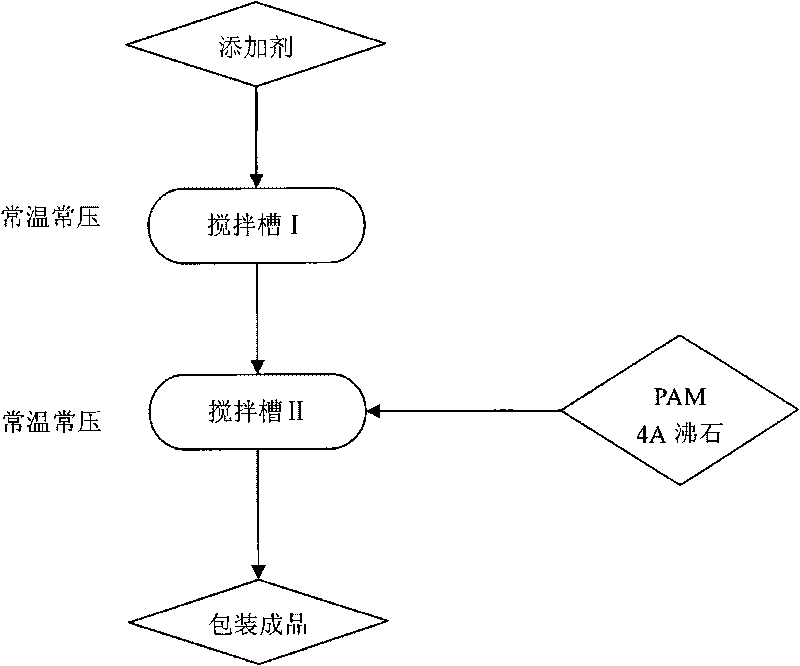

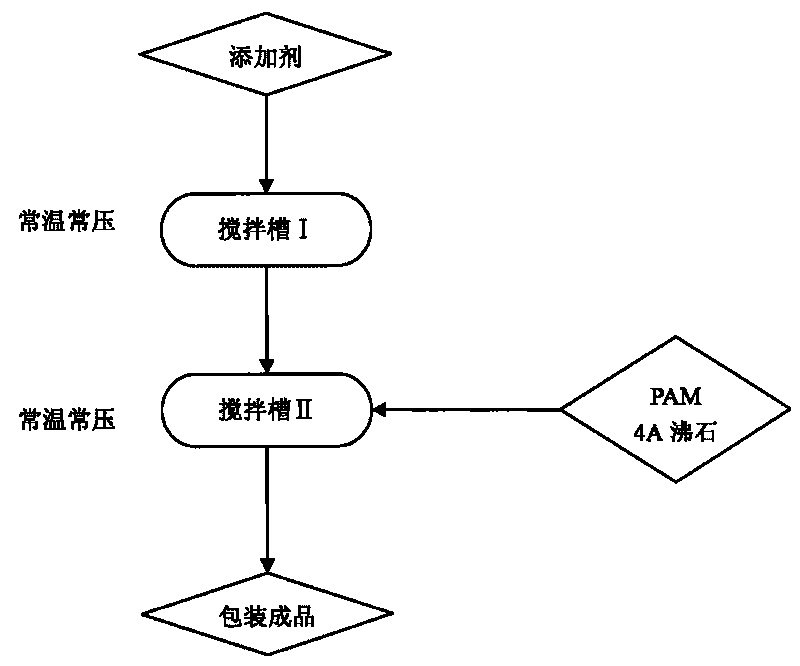

Image

Examples

Embodiment 1

[0031] Add additives according to the proportioning (ammonium sulfate 35%, sodium sulfate 40%, sodium silicate 15%, potassium alum 10%) and add stirring tank I, under normal temperature and pressure, stir 15~25 minutes with the speed of 25 revs / min. Add polyacrylamide and 4A zeolite to the stirring tank II, and then add the stirred additive. The weight ratio of polyacrylamide, 4A zeolite and additive is 90%: 5%: 5%. Stir at the highest speed for 15-25 minutes and discharge. The prepared inorganic-organic composite flocculant is applied to a sewage treatment plant, and the moisture content of the incoming sludge is 98.2%. Add 40ppm of the inorganic-organic composite flocculant according to the present invention, and pass through the belt sludge dehydrator after mixing evenly. After processing, the moisture content of the mud was 84%.

Embodiment 2

[0033] Add additives according to the proportion (50% ammonium sulfate, 30% sodium sulfate, 10% sodium silicate, 10% potassium alum) into the stirring tank I, and stir for 15 to 25 minutes at a speed of 25 rpm under normal temperature and pressure. Add polyacrylamide and 4A zeolite to the stirring tank II, and then add the stirred additive. The weight ratio of polyacrylamide, 4A zeolite and additive is 90%: 5%: 5%. Stir at the highest speed for 15-25 minutes and discharge. The prepared inorganic-organic composite flocculant is applied to a certain pig farm sewage treatment, the dosage is 0.3mg / L, the decolorization rate is 76.5%, the COD (chemical oxygen demand) removal rate is 82%, and the SS (suspended solid) The removal rate is over 95%.

Embodiment 3

[0035] Add additives according to the proportion (40% ammonium sulfate, 45% sodium sulfate, 10% sodium silicate, 5% potassium alum) into the stirring tank I, and stir for 15 to 25 minutes at a speed of 25 rpm under normal temperature and pressure. Add polyacrylamide and 4A zeolite to the stirring tank II, and then add the stirred additive. The weight ratio of polyacrylamide, 4A zeolite and additive is 90%: 5%: 5%. Stir at the highest speed for 15-25 minutes and discharge. The prepared inorganic-organic composite flocculant and aluminum sulfate compound (inorganic-organic composite flocculant 0.5mg / L, aluminum sulfate 100mg / L) is used for enhanced flocculation of influent water in a sewage treatment plant, which can make COD Cr 83.4% reduction, BOD5 reduction 75.8%, TP (total phosphorus) reduction 86.2%, SS reduction 97.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com