Flue gas desulfurization and denitration device

A desulfurization, denitrification, and flue gas technology, which is applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve problems such as the inability to meet the economics of flue gas treatment, and achieve low investment and construction costs, simple installation structure, and efficient desulfurization and denitrification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

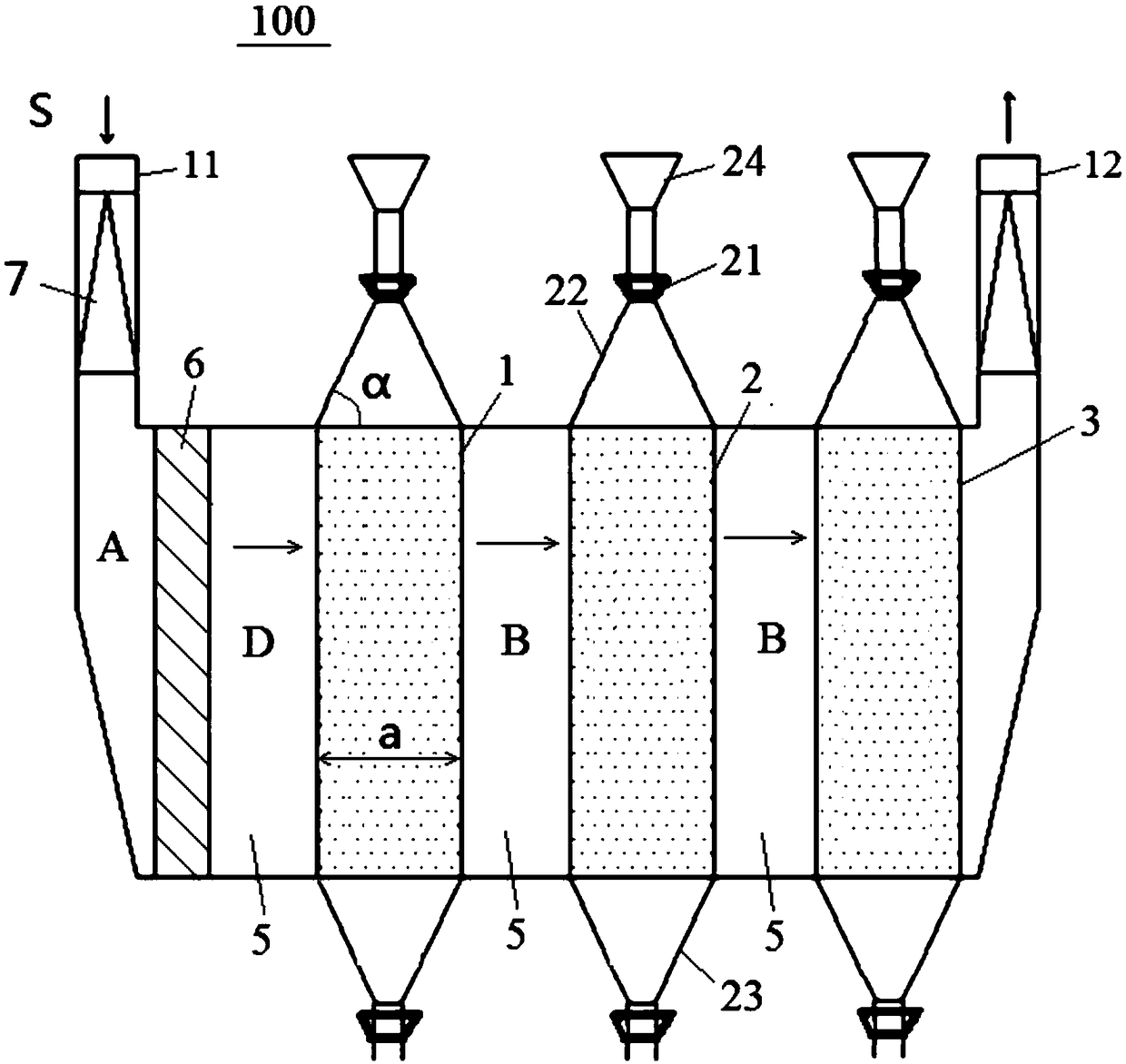

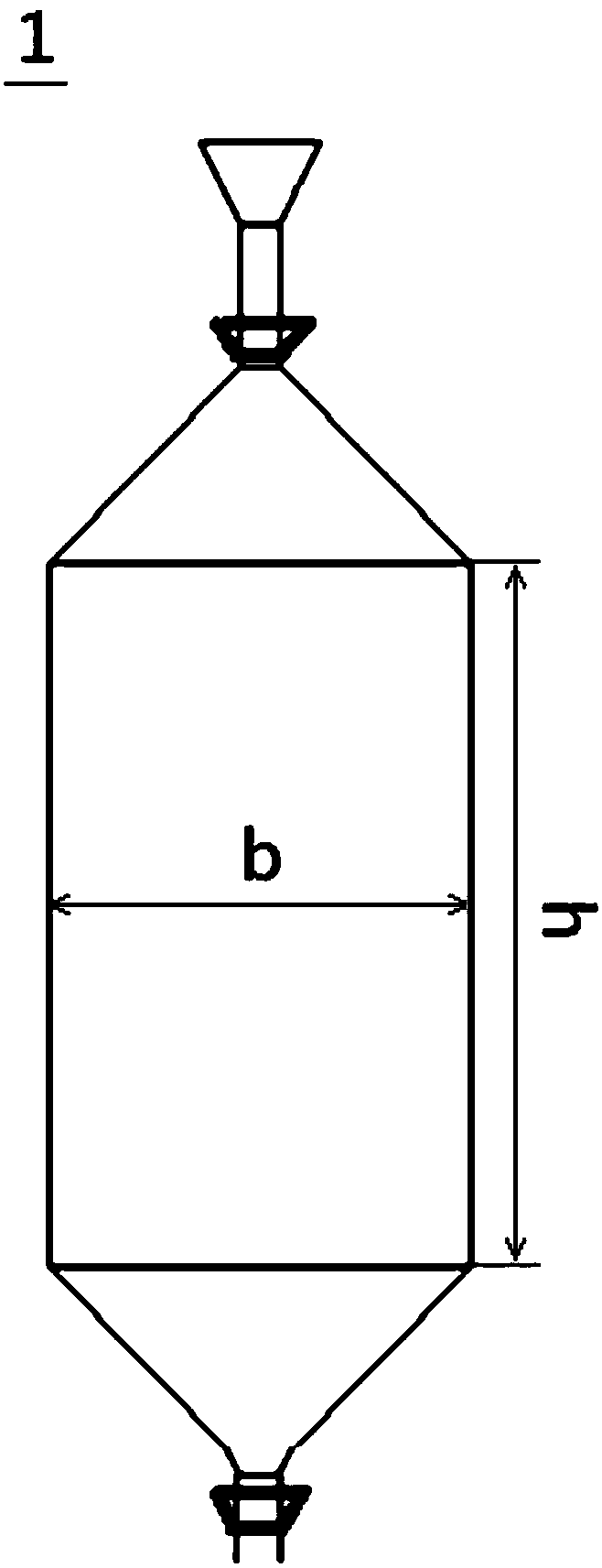

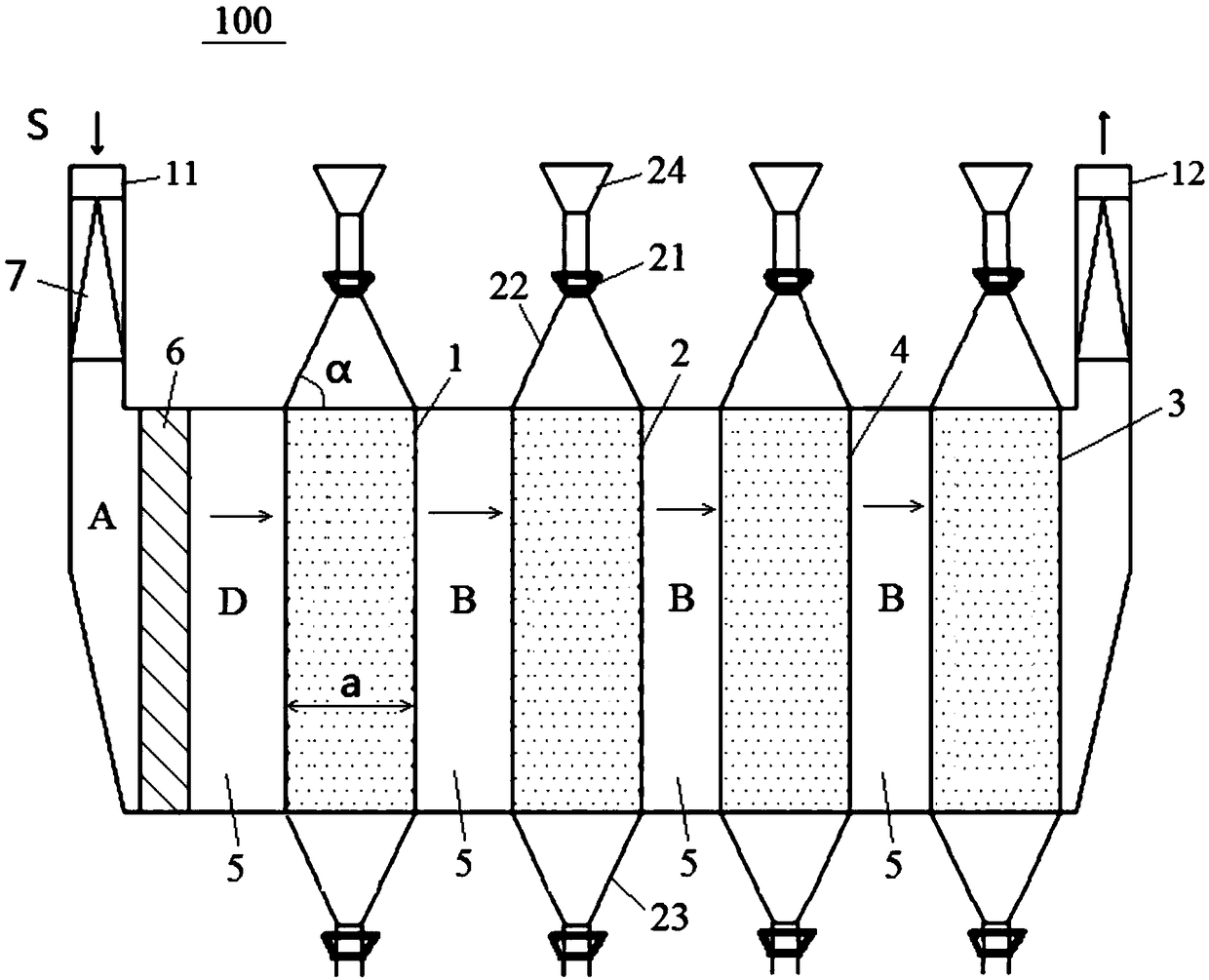

[0019] figure 1 A schematic structural diagram of a flue gas desulfurization and denitrification device 100 according to the present invention is shown. in such as figure 1 In the shown embodiment, the flue gas desulfurization and denitrification device 100 at least includes: in the initial state, a first reaction bed 1 filled with desulfurization materials and a second reaction bed 1 filled with denitrification materials are arranged at intervals along the flue gas flow channel in an initial state. Reaction bed 2 and unoccupied third reaction bed 3. Wherein, when the desulfurization material in the first reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com