A flue gas purification equipment and purification method for desulfurization and denitrification of industrial naphthalene waste gas

A technology for flue gas purification and waste gas desulfurization, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of equipment shelving, unusable, affecting treatment efficiency, etc., to improve desulfurization and denitration treatment, and maintain high efficiency. , Improve the effect of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The flue gas purification method of industrial naphthalene waste gas desulfurization and denitrification based on the above-mentioned flue gas purification device comprises the following steps:

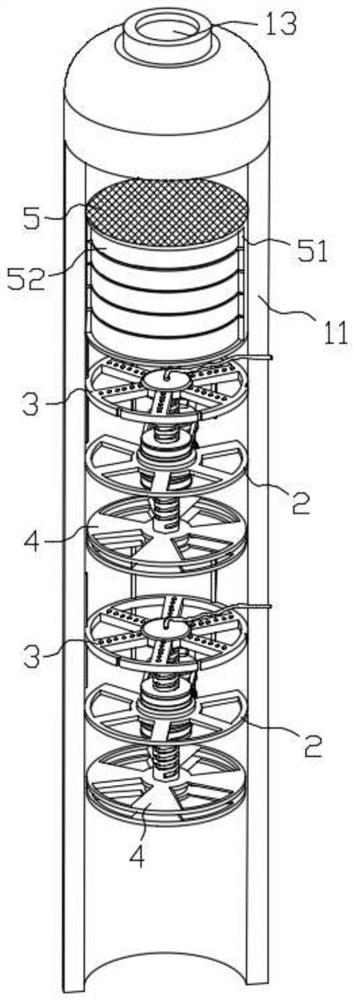

[0064] S1: Spread the acrylic fiber to the filler drawer 52, and evenly cover the acrylic fiber with activated carbon, porous ceramics, and iron oxide mixed powder, repeat the above-mentioned laying of 6 layers of desulfurization filler composed of acrylic fiber + mixed powder; Filler balls with a particle size of 1-2 mm obtained by mixing and granulation constitute denitrification fillers and fill them into the filler drawer 52, fill the ammonia water into the reaction solution chamber 14, and fill the desiccant into the exhaust chamber 15;

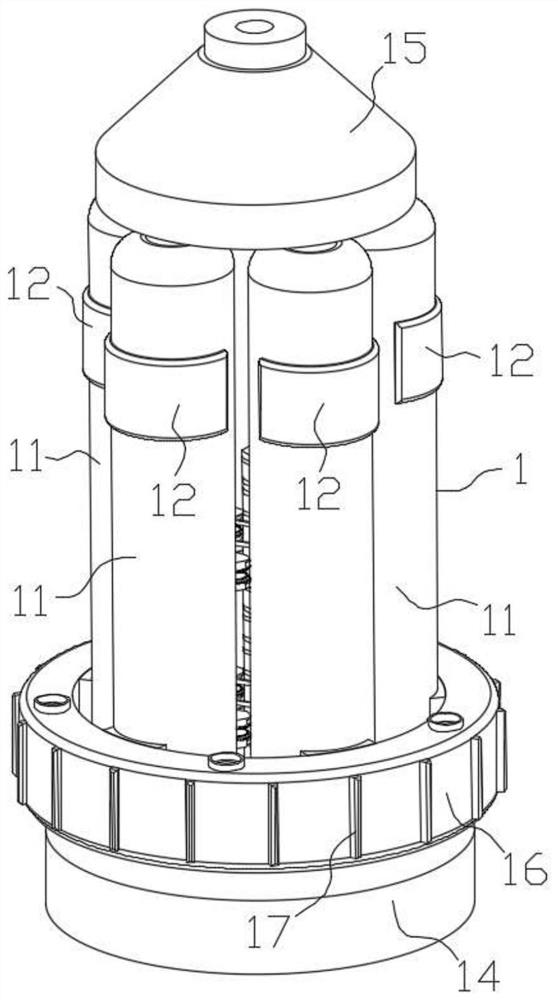

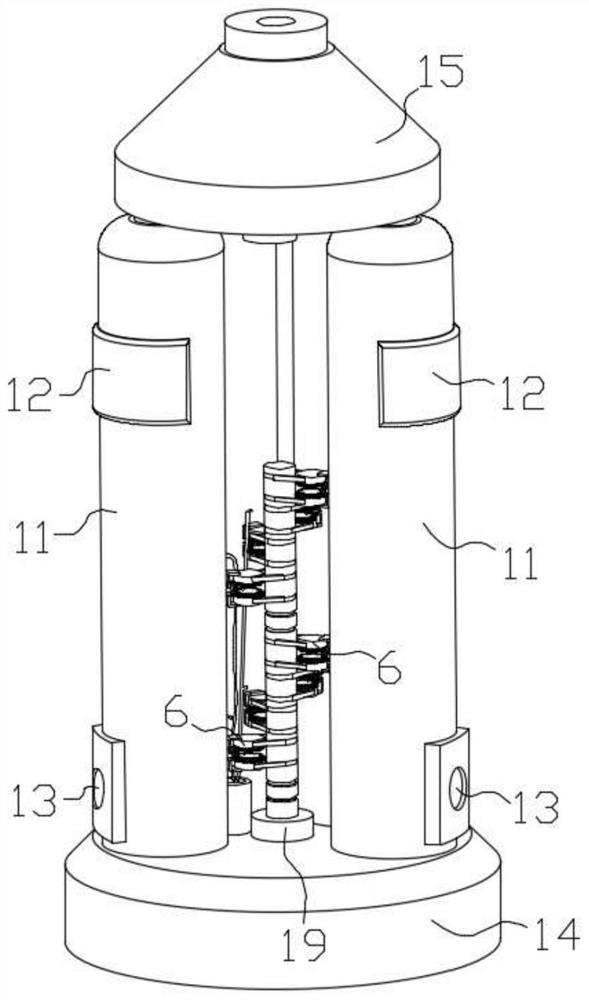

[0065] S2: Pass the industrial naphthalene waste gas into the dust removal ring bin 16 of the flue gas purification equipment, perform preliminary dust removal treatment on the industrial naphthalene waste gas through the dust removal filt...

Embodiment 2

[0071] This embodiment is basically the same as Embodiment 1, except that the combination of denitrification and desulfurization fillers is different, specifically:

[0072] The denitration filler includes, in parts by mass: 8 parts of magnesium chloride, 1 part of heteropolyacid, 1 part of glass fiber, 3 parts of expanded vermiculite powder, and 0.5 part of binder. The desulfurization filler includes, in parts by mass: 10 parts of activated carbon, 3 parts of porous ceramics, 8 parts of iron oxide, and 10 parts of acrylic fiber.

Embodiment 3

[0074] This embodiment is basically the same as Embodiment 1, except that the combination of denitrification and desulfurization fillers is different, specifically:

[0075] The denitration filler includes, in parts by mass: 15 parts of magnesium chloride, 2 parts of heteropoly acid, 2 parts of glass fiber, 7 parts of expanded vermiculite powder, and 1.5 parts of binder. The desulfurization filler includes, in parts by mass: 15 parts of activated carbon, 5 parts of porous ceramics, 10 parts of iron oxide, and 20 parts of acrylic fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com