Oxyradical wet flue gas desulfurization and denitrification method

A wet flue gas desulfurization and free radical technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of difficult calcium sulfate waste treatment, pressure on market sales, and no valuable products. , to achieve the effect of low cost, convenient layout and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

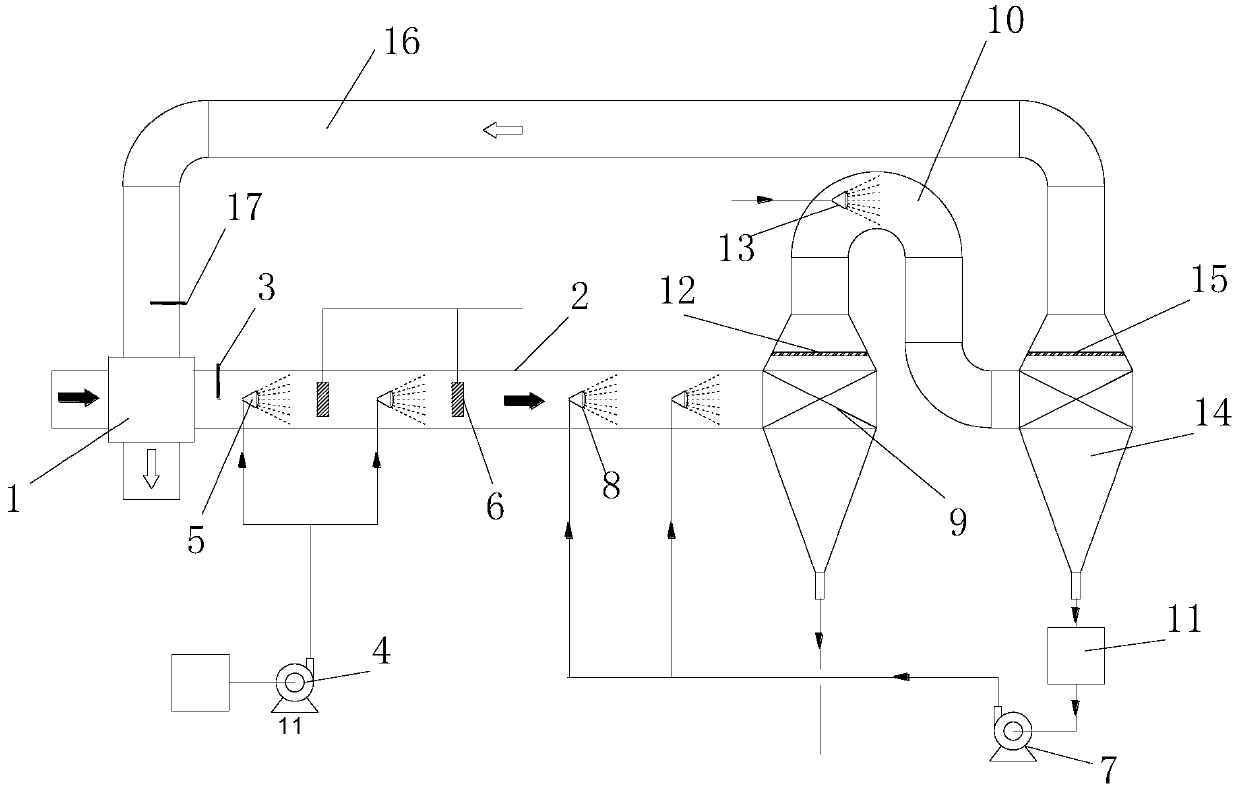

[0025] Such as figure 1 Shown:

[0026] A kind of oxidative free radical wet flue gas desulfurization and denitrification method proposed by the present invention comprises the following steps:

[0027] S1. Pass the dedusting flue gas into the air-gas heat exchanger 1 to cool down to 110°C, with a total air volume of 5000Nm 3 / h, the dedusted flue gas after cooling is passed into the first pipeline 2, and the SO in the dedusted flue gas is removed by the online detector 3 in the first pipeline 2 2 The content is 4500mg / Nm 3 , NO X The content is 1200mg / Nm 3 ;

[0028] S2. Pass 74.5kg / h of 10wt% hydrogen peroxide through the first delivery pump 4 and four first atomizing nozzles 5 into the first pipeline 2 to mix with the dust-removing flue gas, and use it in the ultraviolet light produced by four high-pressure mercury lamps 6 Under light irradiation, flue gas A is produced, and flue gas A contains a large amount of O 3 , O, OH and other active free radicals as well as N...

Embodiment 2

[0034] Such as figure 1 Shown:

[0035] A kind of oxidative free radical wet flue gas desulfurization and denitrification method proposed by the present invention comprises the following steps:

[0036] S1. Pass the dedusting flue gas into the air-gas heat exchanger 1 to cool down to 100°C, and the total air volume is 10000Nm 3 / h, the dedusted flue gas after cooling is passed into the first pipeline 2, and the SO in the dedusted flue gas is removed by the online detector 3 in the first pipeline 2 2 The content is 3500mg / Nm 3 , NO X The content is 1000mg / Nm 3 ;

[0037]S2. Pass 167kg / h of 7.5wt% hydrogen peroxide through the first delivery pump 4 and 6 first atomizing nozzles 5 into the first pipeline 2 to mix with the dedusting flue gas, and use it in the ultraviolet light generated by 6 high-pressure mercury lamps 6 Under light irradiation, flue gas A is produced, and flue gas A contains a large amount of O 3 , O, OH and other active free radicals as well as NO, N 2 ...

Embodiment 3

[0043] like figure 1 Shown:

[0044] A kind of oxidative free radical wet flue gas desulfurization and denitrification method proposed by the present invention comprises the following steps:

[0045] S1. Pass the dedusting flue gas into the air-gas heat exchanger 1 to cool down to 90°C, with a total air volume of 15000Nm 3 / h, the dedusted flue gas after cooling is passed into the first pipeline 2, and the SO in the dedusted flue gas is removed by the online detector 3 in the first pipeline 2 2 The content is 3000mg / Nm 3 , NO X The content is 800mg / Nm 3 ;

[0046] S2. Pass 100kg / h of 15wt% hydrogen peroxide through the first delivery pump 4 and five first atomizing nozzles 5 into the first pipeline 2 to mix with the dedusting flue gas, and use the ultraviolet light generated by five high-pressure mercury lamps 6 Under irradiation, flue gas A is produced, and flue gas A contains a large amount of O 3 , O, OH and other active free radicals as well as NO, N 2 o 3 , N 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com