Method and device for simultaneous desulfurization and denitrification of flue gas

A technology for desulfurization, denitrification and flue gas is applied in the field of flue gas purification, which can solve the problems of large investment, high operating cost and high ozone consumption, and achieve the effects of low operating cost, energy saving and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

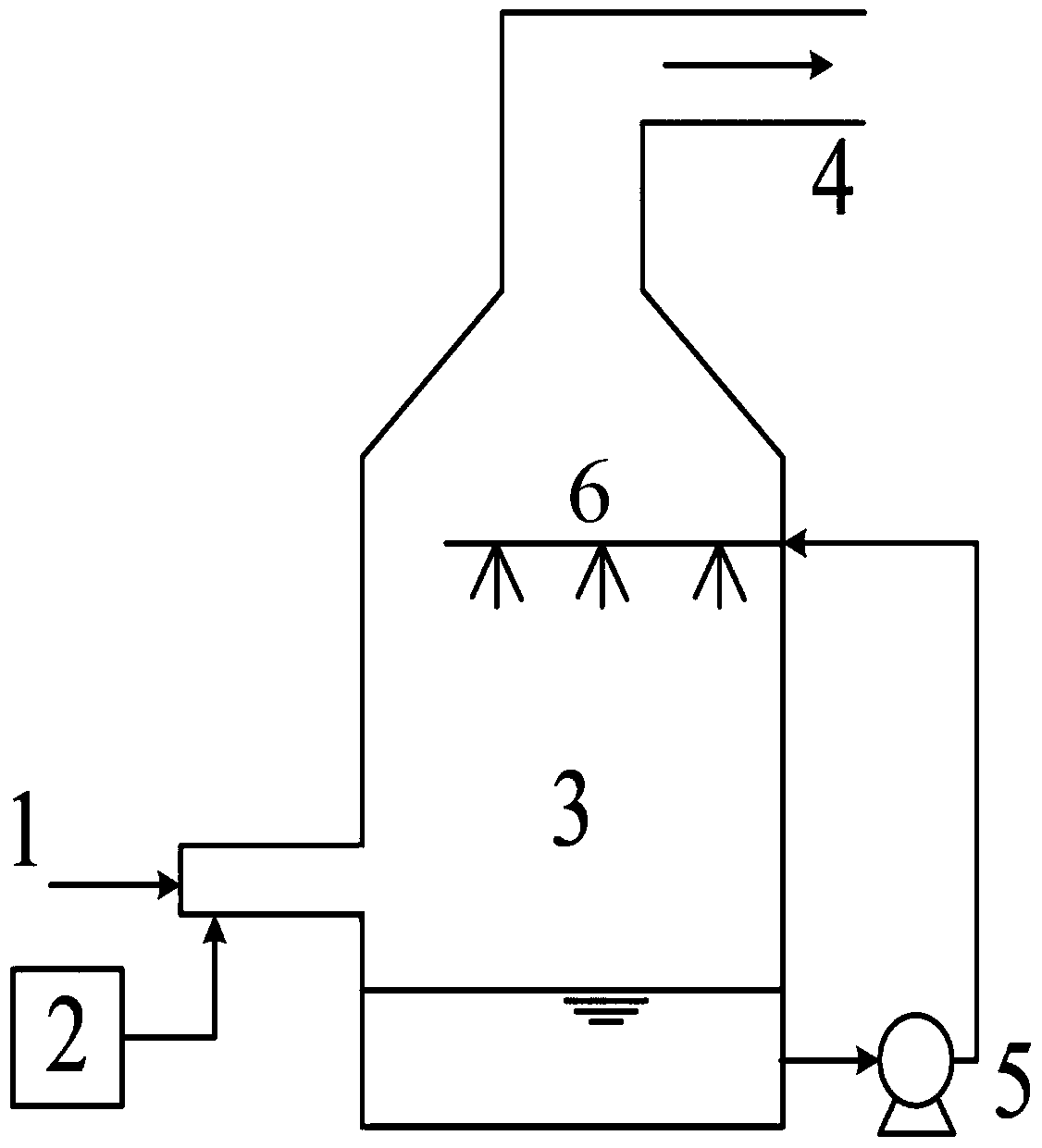

[0067] The flue gas is firstly dedusted in the dust collector, and the main composition of the dedusted flue gas is SO 2 The concentration is 1500ppm, the NO concentration is 600ppm, the oxygen content in the flue gas is 6.0% (volume), and the temperature is 150°C.

[0068] at 5000Nm 3 Pass the dust-removed flue gas into the intake flue 1 at a speed of 5.1kg / h, pass the ozone prepared in the ozone generator 2 into the intake flue 1 at a speed of 5.1kg / h, mix the two at 150°C, and react (Pre-oxidation) to obtain a mixed gas, wherein the amount of ozone added is equivalent to 0.8 times the molar amount of NO.

[0069] The mixed gas enters the desulfurization and denitrification tower 3 from the outlet of the intake flue 1 (a spray tower is used in this implementation), runs from the bottom of the desulfurization and denitrification tower 3 upwards, and the absorption liquid flows from the upper part of the desulfurization and denitrification tower 3 at a flow rate of 50t / h. Th...

Embodiment 2

[0073] The flue gas is firstly dedusted in the dust collector, and the main composition of the dedusted flue gas is SO 2 The concentration is 1000ppm, the NO concentration is 400ppm, the oxygen content in the flue gas is 7.4%, and the temperature is 120°C.

[0074] at 10000Nm 3 Pass the flue gas after dedusting into the intake flue 1 at a speed of 5.1kg / h, pass the ozone prepared in the ozone generator 2 into the intake flue 1 at a speed of 5.1kg / h, mix the two at 120°C, and react (Pre-oxidation) to obtain a mixed gas, wherein the amount of ozone added is equivalent to 0.6 times the molar amount of NO.

[0075] The mixed gas enters the desulfurization and denitrification tower 3 from the outlet of the intake flue 1 (in this implementation, a plate corrugated structured packing tower is used), and runs from the bottom of the desulfurization and denitrification tower 3 from bottom to top, and the absorption liquid flows from the desulfurization and denitrification tower at a fl...

Embodiment 3

[0079] The flue gas is firstly dedusted in the dust collector, and the main composition of the dedusted flue gas is SO 2 The concentration is 2000ppm, the NO concentration is 300ppm, the oxygen content in the flue gas is 6.5%, and the temperature is 110°C.

[0080] at 7000Nm 3 Pass the flue gas after dedusting into the intake flue 1 at a speed of 2.3kg / h, pass the ozone prepared in the ozone generator 2 into the intake flue 1 at a speed of 2.3kg / h, mix the two at 110°C, and react (Pre-oxidation) to obtain a mixed gas, wherein the amount of ozone added is equivalent to 0.5 times the molar amount of NO.

[0081] The mixed gas enters the desulfurization and denitrification tower 3 from the outlet of the intake flue 1 (a spray tower is used in this implementation), runs from the bottom of the desulfurization and denitrification tower 3 from bottom to top, and the absorption liquid flows from the upper part of the desulfurization and denitrification tower 3 at a flow rate of 140t / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com