Flue gas two-stage segmented desulfurization and denitrification system and method

A technology for desulfurization, denitrification, and flue gas, which is applied in the field of air pollution control, and can solve problems such as poor quality, inability to support the technical conditions of the denitrification process, and corporate burdens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

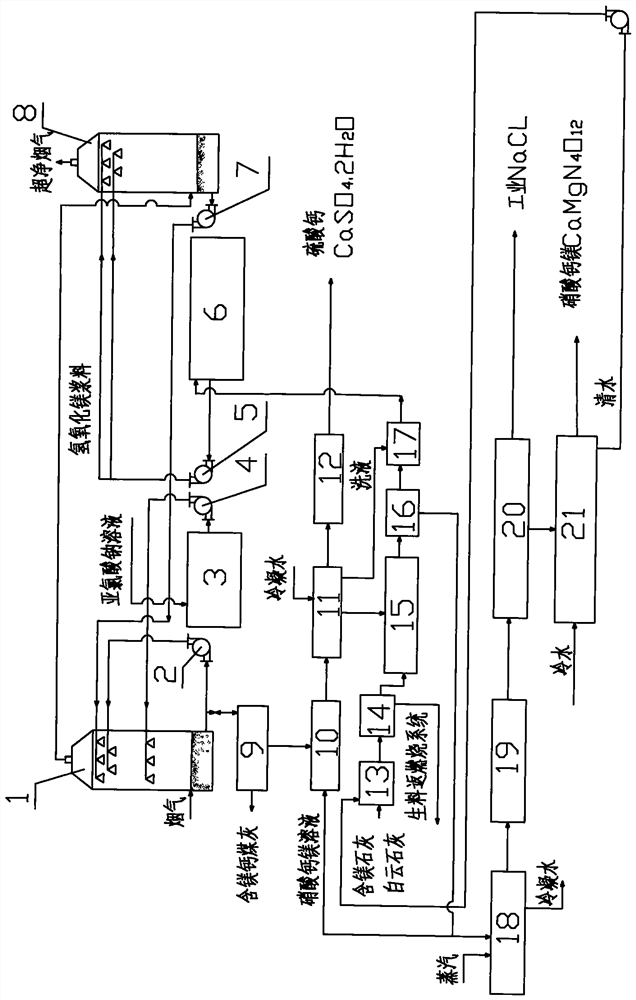

[0100] Embodiment 1: by figure 1 It can be seen that the present invention provides a system for two-stage and segmental desulfurization and denitrification of flue gas, including equipment and operating units that are sequentially matched and connected through pipes, pipe fittings and other components according to the chemical reaction process, and is characterized in that:

[0101] P1: first-level desulfurization and denitrification tower 1, first-level circulating desulfurization and denitrification pump 2, oxidation solution storage tank 3, oxidation solution supply pump 4, second-level desulfurization and denitrification pump 5, magnesium hydroxide slurry storage tank 6, and second-level desulfurization A desulfurization and denitrification sub-system composed of a denitrification transfer pump 7 and a secondary desulfurization and denitrification tower 8;

[0102] P2: Calcium sulfate CaSO4 composed of purification and impurity removal unit 9, NS separation unit 10, filtr...

Embodiment 2

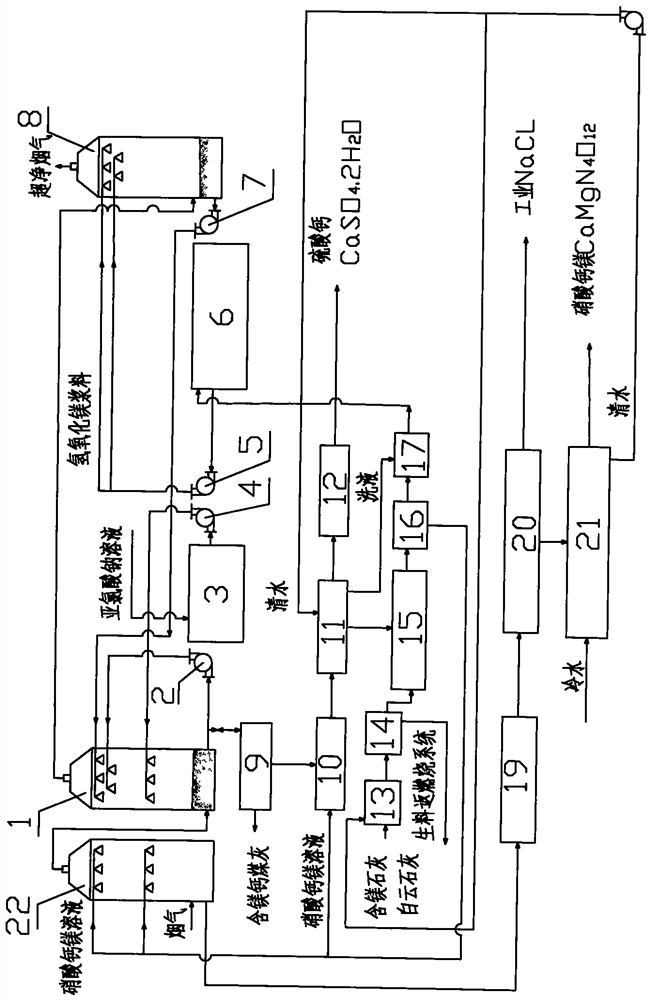

[0126] Embodiment 2: by figure 2 It can be seen that the present invention provides a system for two-stage and segmental desulfurization and denitrification of flue gas, including equipment and operating units that are sequentially matched and connected through pipes, pipe fittings and other components according to the chemical reaction process, and is characterized in that:

[0127] P1: Flue gas waste heat evaporation tower 23, primary desulfurization and denitrification tower 1, primary circulation desulfurization and denitrification pump 2, oxidation liquid storage tank 3, oxidation liquid supply pump 4, secondary desulfurization and denitrification pump 5, magnesium hydroxide slurry A desulfurization and denitrification sub-system composed of a storage tank 6, a secondary desulfurization and denitrification transfer pump 7, and a secondary desulfurization and denitrification tower 8;

[0128] P2: Calcium sulfate CaSO4 composed of purification and impurity removal unit 9, ...

Embodiment 3

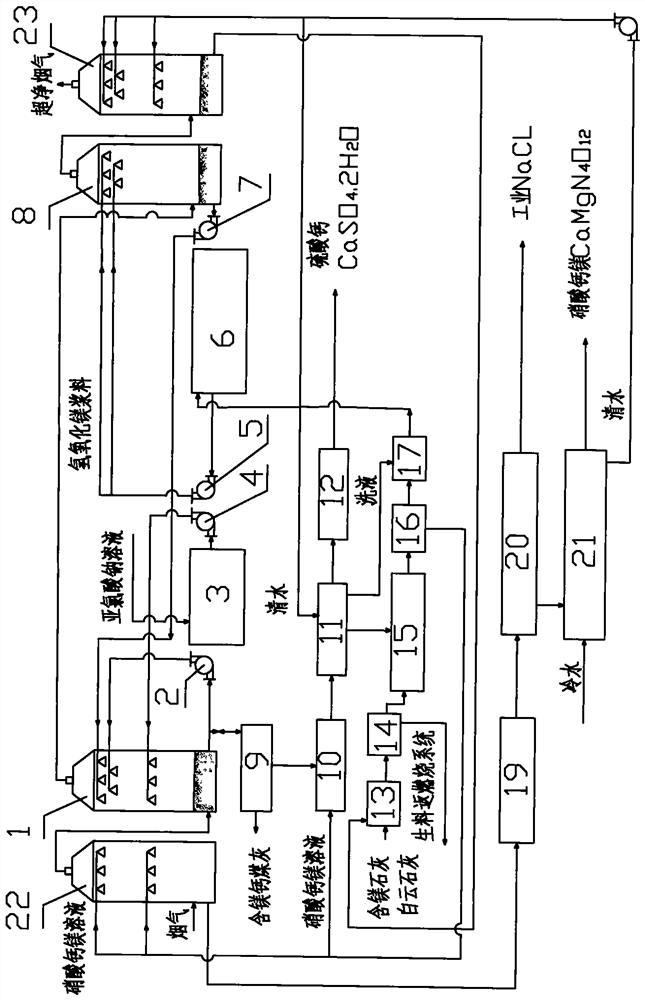

[0152] Example 3: Reference image 3 , the present invention provides a method for flue gas two-stage segmental desulfurization and denitrification, including sequentially matching operations according to the chemical reaction process, characterized in that:

[0153] Step 1: Purification of desulfurization and denitrification liquid

[0154] The first-stage desulfurization and denitrification completed liquid of the first-stage desulfurization and denitrification tower 1 enters the purification and impurity removal unit 9 through the outlet of the first-stage desulfurization and denitrification liquid, and the suspended insoluble magnesium-calcium-containing fly ash (coal ash) is filtered to obtain relatively pure MgSO-containing 4 , Mg(NO 3 ) 2 Mix semen with NaCl as the main component of soluble salt;

[0155] Step 2: NS separation

[0156] The semen obtained in step 1 is poured into the NS separation reactor, and an appropriate amount is added to the filter unit 16. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com