Solid waste incineration flue gas desulfurization and denitrification process

A technology for desulfurization, denitrification and incineration of flue gas, applied in gas treatment, other chemical processes, separation methods, etc., can solve the problems of poor flue gas purification effect, poor adsorption performance, and waste reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

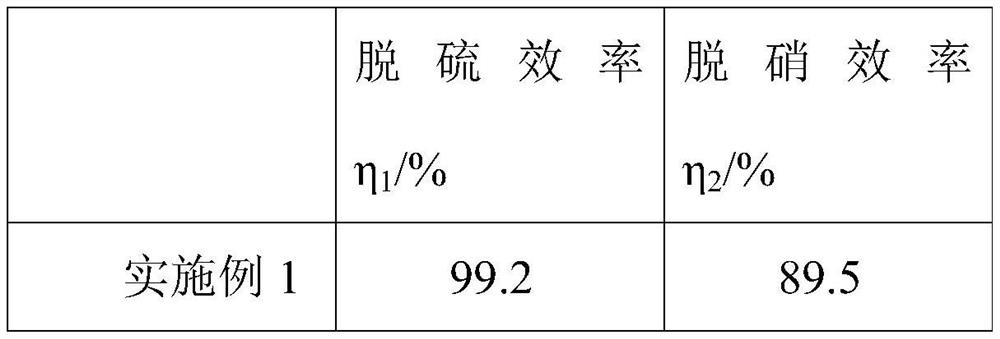

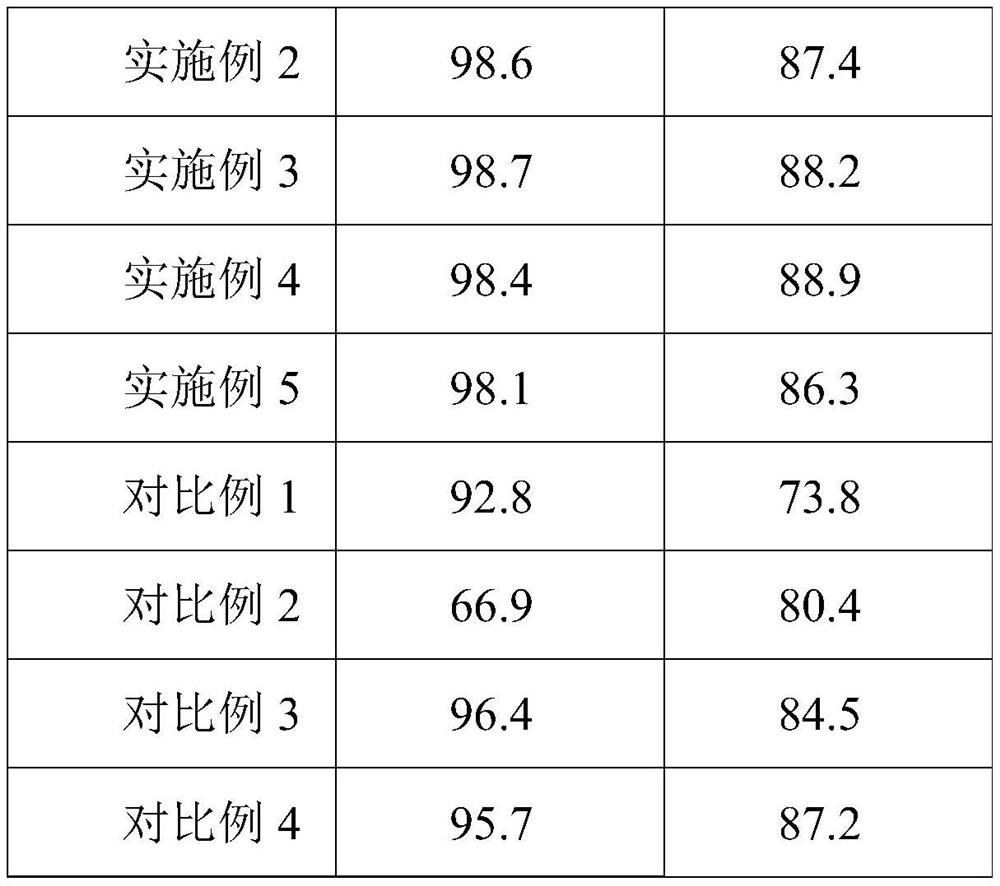

Examples

Embodiment 1

[0032] Solid waste incineration flue gas demonide denitration process:

[0033] S1: After cooling the high temperature flue gas produced by the solid waste incineration, then spray treatment with 5 wt% sodium hydroxide solution, and control the flue gas temperature after spray treatment treatment is 150 ° C;

[0034] S2: The adsorbent is filled with an adsorbent in the desulfurization denitration apparatus, and the adsorbent is preacted in the adsorbent at 120 ° C, and the treatment time is 10 min;

[0035] S3: Top the treated flue gas into the desulfurized denitration apparatus, controlling the flue gas flow rate of 400 ml / min, and the flue gas after the adsorbent treatment is removed after removal of the fog;

[0036] Among them, the adsorbent is a three-layer nuclear shell structure, including outer layers, intermediate layers, and nucleus;

[0037] Outer layer by MnO 2 NA 2 CO 3 Γ-al 2 O 3 composition;

[0038] The intermediate layer is SAPO-34 molecular sieve layer;

[0039...

Embodiment 2

[0043] Solid waste incineration flue gas demonide denitration process:

[0044] S1: After cooling the high temperature flue gas produced by solid waste incineration, then spray treatment with 5 wt% sodium hydroxide solution, and control the flue gas temperature after spray treatment treatment is 160 ° C;

[0045] S2: The adsorbent is filled with an adsorbent in the desulfurization denitration apparatus, and the adsorbent is preacted in the adsorbent at 120 ° C, and the treatment time is 10 min;

[0046] S3: Top the treated flue gas into the desulfurized denitration apparatus, controlling the flue gas flow rate of 400 ml / min, and the flue gas after the adsorbent treatment is removed after removal of the fog;

[0047] Among them, the adsorbent is a three-layer nuclear shell structure, including outer layers, intermediate layers, and nucleus;

[0048] Outer layer by MnO 2 NA 2 CO 3 Γ-al 2 O 3 composition;

[0049] The intermediate layer is SAPO-34 molecular sieve layer;

[0050] The ...

Embodiment 3

[0054] Solid waste incineration flue gas demonide denitration process:

[0055] S1: After cooling the high temperature flue gas produced by solid waste incineration, then spray treatment with 5 wt% sodium hydroxide solution, and control the flue gas temperature after spray treatment is 120 ° C;

[0056] S2: The adsorbent is filled with an adsorbent in the desulfurization denitration apparatus, and the adsorbent is poured at 120 ° C, and the treatment time is 5 min;

[0057] S3: Top the treated flue gas into the desulfurized denitration apparatus, controlling the flue gas flow rate of 400 ml / min, and the flue gas after the adsorbent treatment is removed after removal of the fog;

[0058] Among them, the adsorbent is a three-layer nuclear shell structure, including outer layers, intermediate layers, and nucleus;

[0059] Outer layer by MnO 2 NA 2 CO 3 Γ-al 2 O 3 composition;

[0060] The intermediate layer is SAPO-34 molecular sieve layer;

[0061] The nucleus is made from the nuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com